Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for CLA-VAL 98-06

- Page 1 98-06/698-06...

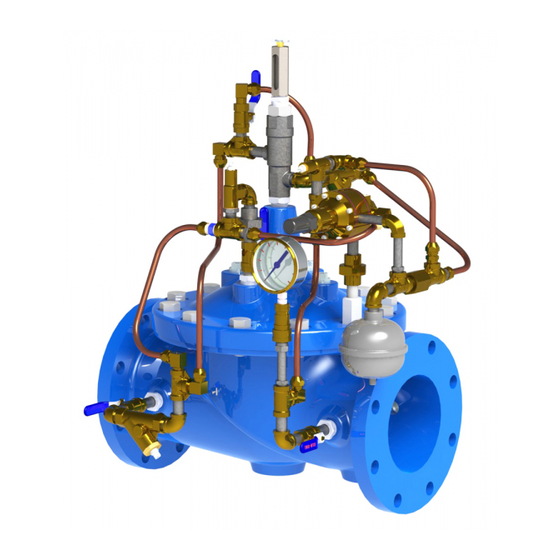

- Page 9 • Retrofits to existing valve without removal from pipeline How It Works The Cla-Val Model 98-06/698-06 Water Saving Valve is Modulating Profile a pressure reducing valve that uses two downstream set points to achieve optimum system pressure; i.e. the Downstream...

- Page 10 7. Desired Options Temperature Range 8. When Vertically Installed Water: to 180°F CLA-VAL 1701 Placentia Ave • Costa Mesa CA 92627 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com • • © Copyright Cla-Val 2015 Printed in USA Specifications subject to change without notice.

- Page 11 2. lt is recommended that gate or line block valves be installed on both ends of the 98-06 valve assembly, at a minimum of one pipe diameter apart to facilitate isolating the valve for maintenance. You will need a 3/16” X 4” slim head screwdriver to set low pressure.

- Page 12 (8) is at the desired maximum system Management Control Valve and optimize the pressure management downstream pressure condition conditions within the system. Consult factory for Cla-Val data logging 6) Close Isolation Valve (6A) products (such as the X142FPT Flow and Pressure Tracker and the...

- Page 13 The Accumulator is factory air charged to approximate- Valve Size Total Travel Per Turn ly 51 psi (3.5 bar). This pre-charge condition is satisfac- tory for most Model 98-06/698-06 applications and no 2” 100-01 .40” (10 mm) 9.9% additional field charging is required.

- Page 14 (8) X141 Speed Control (11) Accumulator CLA-VAL 1701 Placentia Ave • Costa Mesa CA 92627Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com © Copyright Cla-Val 2015 Printed in USA Specifications subject to change without notice. N-98 Series (R-09/2015)

- Page 15 (usually atmosphere) the line pressure With the use of a Cla-Val. "modulating chamber the valve closes drip-tight. (5 psi Min.) at the valve inlet opens the control," which reacts to line pressure valve.

-

Page 16: Troubleshooting

When flow is “up-and-over the seat,” it is in “normal” flow and the valve will fail in the open position. When flow is “over- 2. Cla-Val Model X101 Valve Position Indicator. This pro- the seat-and down,” it is in “reverse” flow and the valve will fail in the closed position. - Page 17 (See “Maintenance” the valve should be fully open. Section for procedure.) 6. If the valve has a Cla-Val X101 Position Indicator, observe the Tight Sealing Check (#3) indicator to see that the valve opens wide. Mark the point of max- imum opening.

- Page 18 Thread Size (UNF Internal) 1 1/4" —2 1/2" Preventative Maintenance 10—32 3"—4" 1/4—28 The Cla-Val Co. Model 100-01 Hytrol Valve requires no lubrication or 6"—14" 3/8—24 packing and a minimum of maintenance. However, a periodic inspec- 16" 1/2—20 tion schedule should be established to determine how the operating 3/4-16 conditions of the system are affecting the valve.

- Page 19 Inspection of Parts Lime Deposits After the valve has been disassembled, each part should be One of the easiest ways to remove lime deposits from the valve examined carefully for signs of wear, corrosion, or any other stem or other metal parts is to dip them in a 5-percent muriatic abnormal condition.

- Page 20 INLET OUTLET TOP VIEW GLOBE PATTERN PARTS LIST Item Description Pipe Plug Drive Screws (for nameplate) Hex Nut (8” and larger) Stud (8” and larger) Cover Bearing Cover Stem Nut Diaphragm Washer Diaphragm Spacer Washers Disc Guide Disc Retainer Disc Stem OUTLET Seat...

- Page 23 Globe Pattern Valves parts are going to be for a smaller size main valve. Cla-Val iden- Seat Size tifies main valve parts with the flange size of the standard 100...

- Page 24 20" — 24" COVER DETAIL 3" — 6" COVER DETAIL CLA-VAL P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com © Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

- Page 25 Brass No parts available. Rreplacement assembly only. 3/8 NPT P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com CLA-VAL © Copyright Cla-Val 2012 Printed in USA Specifications subject to change without notice.

- Page 28 • Material • Part Number CLA-VAL P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com © Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice. PL- X101 (R-3/2011)

- Page 29 CLA-VAL P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com © Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice. PL-CK2 (R-3/2011)

- Page 30 "O" Ring, Strainer Plug Syn. Rub. CLA-VAL P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com © PL-x44a (R-3/2011) Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

- Page 31 *Specify desired pressure range and valve location (inlet or outlet) on order. CLA-VAL P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com © Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

- Page 32 O-Ring (Size 2-113) 00753E Restrictor 208329-01C CLA-VAL P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com © Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice. PL-X58E...

- Page 33 Cla-Val Main Valve. CLA-VAL 1701 Placentia Ave • Costa Mesa CA 92627 Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com N-CV (R-06/2018) Copyright Cla-Val 2018 Printed in USA Specifications subject to change without notice.

- Page 34 Stem BAR STOCK O-Ring CONFIGURATION Housing CLA-VAL 1701 Placentia Ave • Costa Mesa CA 92627 Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com PL-CV (R-03/2011) Copyright Cla-Val 2018 Printed in USA Specifications subject to change without notice. ©...

- Page 35 INLET SIZE & inquiries concerning valve operation, it is important to CAT NO. EINTRITT STOCK properly identify Cla-Val products already in service CODE ENTREE by including all nameplate data with your inquiry. MFD. BY CLA-VAL ENTRADA Pertinent product data includes valve function, size, NEWPORT BEACH, CALIF, U.S.A.

-

Page 36: Limited Warranty

This product. Cla-Val shall not be liable for any damages or charges for warranty is expressly conditioned on the purchaser’s providing written labor or expense in making repairs or adjustments to the product. - Page 37 INSTALLATION / OPERATION / MAINTENANCE REPAIR KITS MODEL Model 100-01 Hytrol Main Valve BUNA-N MATERIAL RUBBER KIT REPAIR KIT REBUILD KIT STUD & NUT KIT STOCK NO. STOCK NO. STOCK NO. STOCK NO. 3/8” 9169801K 21176614B 21176633J 1/2” 9169802H 21176602F 21176615A 21176634H 3/4”...

- Page 38 When ordering, please give complete nameplate data of the valve and/or control being repaired. MINIMUM ORDER CHARGE APPLIES CLA-VAL 1701 Placentia Ave • Costa Mesa CA 92627 Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com © Copyright Cla-Val 2018 Printed in USA Specifications subject to change without notice.

Need help?

Do you have a question about the 98-06 and is the answer not in the manual?

Questions and answers