Advertisement

Quick Links

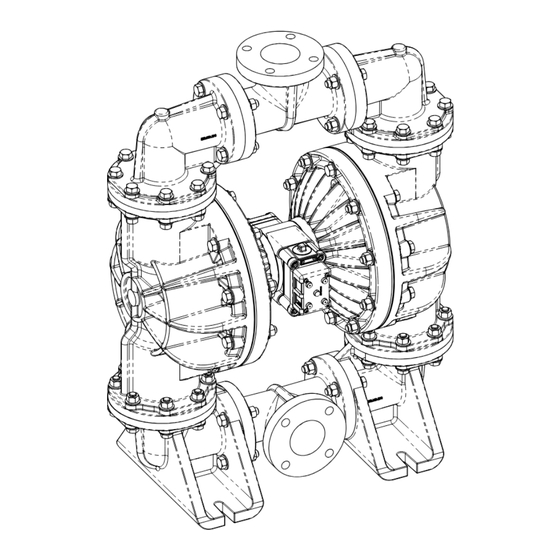

SERVICE & OPERATING MANUAL

ORIGINAL INSTRUCTIONS

3" Elima-Matic Bolted Non-Metallic

with Non-Metallic Center Section

E3 Non-Metallic Pumps

• Polypropylene

• PVDF

VERSAMATIC

®

Warren Rupp, Inc. • A Unit of IDEX Corporation

800 North Main Street, Mansfield, OH 44902 USA

Phone: (419) 526-7296 • www.versamatic.com

E3

© Copyright 2019

Warren Rupp, Inc. All rights reserved

Advertisement

Need help?

Do you have a question about the V Series and is the answer not in the manual?

Questions and answers