Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Braemar RPA Series

- Page 1 January 2014...

- Page 2 RPA INDUSTRIAL AIR CONDITIONERS IMPORTANT As with any product that has moving parts or is subject to wear and tear, it is VERY IMPORTANT that you maintain the cooler and have it regularly serviced. It is a condition of warranty cover for your cooler that you comply with all of the maintenance and service requirements set out in the Owner’s Manual.

-

Page 4: Table Of Contents

RPA INDUSTRIAL AIR CONDITIONERS TABLE OF CONTENTS ITEM PAGE Employer and Employee Responsibilities. General Specifications. Introduction. Location of Air Conditioner. Mounting the Air Conditioner Product Specifications. Flexible Connection. Flexible Connection Kit Instructions Water Supply and Drain Fittings. Electrical Connection. Wiring Diagram - Single Phase Wiring Diagram - Three Phase Variable Pitch Pulley and Belt Tension. -

Page 5: Employer And Employee Responsibilities

EMPLOYER AND EMPLOYEE RESPONSIBILITIES The installation and maintenance of evaporative air conditioning units, particularly at height, has the potential to create Occupational Health and Safety issues for those involved. Installers are advised to ensure they are familiar with relevant State and Federal legislation, such as Acts, Regulations, approved Codes of Practice and Australian Standards, which offer practical guidance on these health and safety issues. -

Page 6: General Specifications

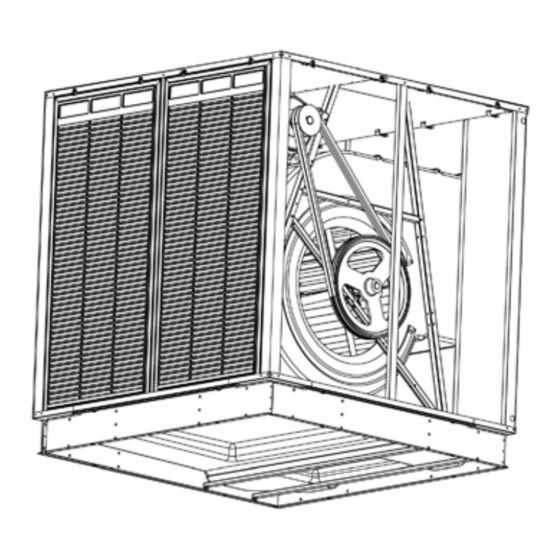

RPA INDUSTRIAL AIR CONDITIONERS Cabinet. The cabinet is constructed from marine grade aluminium, incorporating channel section corner pillars, mounted on a heavy gauge base frame for structural stability. Many components have been powder coated for extra corrosion protection. Cabinet fasteners are Stainless steel and Aluminium. -

Page 7: Introduction

Subject to normal handling during storage, transit, installation and operation, they will provide years of economical air conditioning with the minimum of service and maintenance. All Braemar air conditioners are designed for a range of installations and are readily adaptable to the following applications. -

Page 8: Product Specifications

RPA INDUSTRIAL AIR CONDITIONERS Product Specification. Services Layout RPA400 - RPA600 Services Layout RPA700 - RPA900 M 10 M 10 M 10 M 10 500 Only Drain DRAIN DRAIN RPA700/900 400/500 600 Only CONTROL MOTOR BLOWER ASSEMBLY CONTROL MOTOR BLOWER ASSEMBLY PLAN VIEW PLAN VIEW Mounting Detail RPA400 - RPA900... - Page 9 RPA INDUSTRIAL AIR CONDITIONERS Product Specifications cont. Mounting Detail RPA1000 - RPA1800 Services Detail RPA1000 - RPA1800 2030 TYP 1937 1917 Distance between mount holes centres 1625 1025 DRAIN VALVE WATER LOCATION INLET FLOAT VALVE 1275 200 ±10 ISOLATION Up to 4 pumps located behind SWITCH motor platform Lifting Eyes (Optional Extra)

-

Page 10: Flexible Connection

RPA INDUSTRIAL AIR CONDITIONERS Flexible Connections. RPA1000 to 1800 DOWN DISCHARGE Mounting Frame SIDE DISCHARGE Ductwork Flexible Connector. TOP DISCHARGE... -

Page 11: Flexible Connection Kit Instructions

RPA INDUSTRIAL AIR CONDITIONERS RPA1000 to RPA1800 Series Flexible Connection..Fitting Instructions. FLEXIBLE CONNECTOR KIT - 096582 CONTENTS DESCRIPTION STOCK CODE 1. Flexible Connector 609645 2. Channel 609423 3. Rivet - 5/32" Alum FAS204 4. Instruction Sheet 621920 Flexible Connector Channel FITTING INSTRUCTIONS The flexible connector on the RPA1000 to 1500 has not been fitted at the factory. - Page 12 RPA INDUSTRIAL AIR CONDITIONERS RPA1000 to RPA1800 Series Fitting Instructions cont. SIDE DISCHARGE C hannels A to D C hannels E to H DOWN DISCHARGE Note: On down discharge units, secure flexible connector to each of the edges (4) where the tank and outlet meet as highlighted by the shaded section below.

-

Page 13: Water Supply And Drain Fittings

RPA INDUSTRIAL AIR CONDITIONERS Water Supply and Drain Fittings. Mains Water connection is made to the float valve fitted in the reservoir. The mains water supply to and inside the unit should be made with the appropriate copper pipe and fittings. -

Page 14: Wiring Diagram - Single Phase

1. THE INCOMING MAINS POWER MUST BE TAKEN DIRECTLY TO THE COOLER. 2. 5 WIRES ARE REQUIRED BETWEEN THE COOLER AND THE WALL SWITCH. 3. FOR DRAIN KIT 077444 WIRING INSTRUCTIONS SEE MANUAL SUPPLIED IN KIT OR VISIT OUR WEB SITE www.braemar.com.au ALL FIELD WIRING IS SHOWN AS FUSE... -

Page 15: Wiring Diagram - Three Phase

RPA INDUSTRIAL AIR CONDITIONERS Wiring Diagram - Two Speed Three Phase. 3 PHASE MAINS IN L3 N WIRING DIAGRAM ISOLATING ISOLATING SWITCH SWITCH RPB600-1000 RPB1200-1800 TO EARTH RPA450-900 RPA1000-1800 WALL SWITCH POINT 1 NEUTRAL Neon2 Neon1 TERMINAL BLACK (Neutral) POINT 6 DRAIN KIT COMPONENTS Electronics Drain... -

Page 16: Variable Pitch Pulley And Belt Tension

RPA INDUSTRIAL AIR CONDITIONERS Variable Pitch Pulley and Belt Tension. Models RPA400 - 900 are fitted with a variable pitch pulley so that the full potential of the motor can be utilised. The pulley is set at the factory to approximate the full motor load with the unit at free delivery. -

Page 17: Bleed Control

RPA INDUSTRIAL AIR CONDITIONERS Variable Pitch Pulley and Belt Tension (cont.) Motor / Pulley arrangement for models RPA700 TO RPA1500 PULLEY 1.6mm/100mm SPAN @ 2.0kg BELT DEFLECTION FORCE If turning pulley counter clockwise to reduce blower speed, be sure that the V section is not opened far enough to allow the belt to ride on the threaded part of pulley, as this will cause damage to the belt. -

Page 18: Effective Cooling Requirements

RPA INDUSTRIAL AIR CONDITIONERS Effective Cooling Requirements. To provide efficient cooling or ventilation your air conditioner must be operated with sufficient exhaust openings in the form of doors, windows, or other vents. One square metre of open area is the minimum requirement for every 3000 m /hr (830 l/s) of air delivery. -

Page 19: Operating The Air Conditioner

- Select either High or Low fan speed. - Turn on the fan by switching the Fan switch to ON. Service Information. Should you consider that your Braemar air conditioner requires service, you should contact your local Braemar Dealer/Service Agent. For Service please phone 1300 650 644 quote the unit Model number and Serial number as shown below. -

Page 20: Service & Maintenance

Service & Maintenance REGULAR MAINTENANCE IS ESSENTIAL FOR MAXIMUM EFFICIENCY To ensure that your Braemar Evaporative Air conditioner remains in first class working condition for many years, it should be thoroughly serviced four (4) times a year. Service schedules should include a service at the end of the summer season and prior to the commencement of the next summer season. -

Page 21: Pre Season Maintenance

Replacing the Filter Pads. If, during your scheduled maintenance you determine that the filter pads need replacing, you will be able to purchase replacements from you local Braemar Dealer/Service Agent. Replacing the pads is as follows. • Turn air conditioner off at the isolating switch. -

Page 22: Trouble Shooting

RPA INDUSTRIAL AIR CONDITIONERS Trouble Shooting. PROBABLE CAUSE SUGGESTED REMEDY Insufficient air discharge Make sure adequate openings are openings. provided to exhaust the incoming cool air. Inadequate exhaust for area being Open windows, doors etc. cooled, causing high humidity and discomfort. - Page 23 RPA INDUSTRIAL AIR CONDITIONERS Trouble Shooting. PROBABLE CAUSE SUGGESTED REMEDY Low supply voltage. Consult with local Electrical Authority. Incorrect settings on current Reset overloads to correct setting. overloads. Motor Overheats & Trips Overload. Wrong motor size. Fit correct size motor. Fan speed too high.

- Page 24 RPA INDUSTRIAL AIR CONDITIONERS Trouble Shooting. PROBABLE CAUSE SUGGESTED REMEDY Fan rubbing on housing. Reposition fan. Fan out of balance due to dirt, Clean fan, adjust blades if bent blade etc. possible: Replace fan. Air conditioner delivering more air Adjust any baffles or balance air to than required.

-

Page 25: Maintenance Schedule

To owner/user: please note that as explained in your Warranty Card, installation is not covered by the warranty (for example, ductwork, roof penetrations, and electrical and water connections to the Braemar Evaporative Air Conditioner). However, we still require that you have these things checked, because they can affect the performance (and/or safety) of the product. - Page 26 Seeley International Pty Ltd does not assume any liability for errors and/or omissions. Braemar is a registered trademark of Braemar Industries Pty Ltd. Seeley International Pty Ltd ACN 23 054 687 035...

Need help?

Do you have a question about the RPA Series and is the answer not in the manual?

Questions and answers