Table of Contents

Advertisement

Operation, Repair, Parts

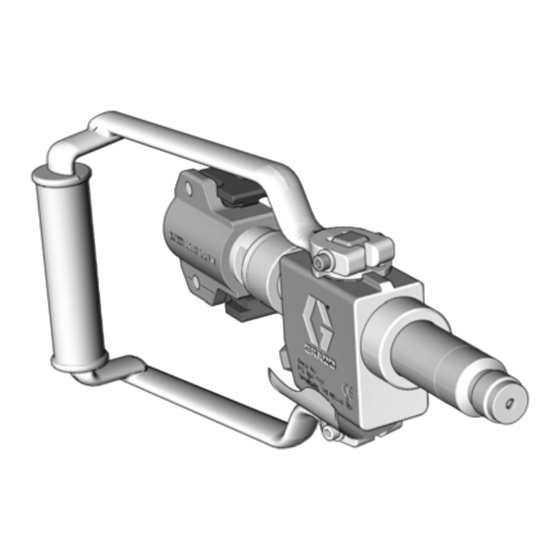

T-Max Applicator

For portable spraying of water-based materials. Can be used for application of

solvent-based materials only when solvent compatible seals are installed and solvent

compatible, conductive hoses are used. For professional use only.

Not approved for use in European explosive atmosphere locations.

Models 256383, 17Z054

1000 psi (6.9 MPa, 69 bar) Maximum Fluid Working Pressure

250 psi (1.7 MPa, 17 bar) Maximum Air Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual and in

the T-Max operation manual before using the equipment.

Save these instructions.

Related Manuals:

3A6748

T-Max Operation, Repair, Parts

312879E

EN

Advertisement

Table of Contents

Need help?

Do you have a question about the T-Max Applicator 256383 and is the answer not in the manual?

Questions and answers