Table of Contents

Advertisement

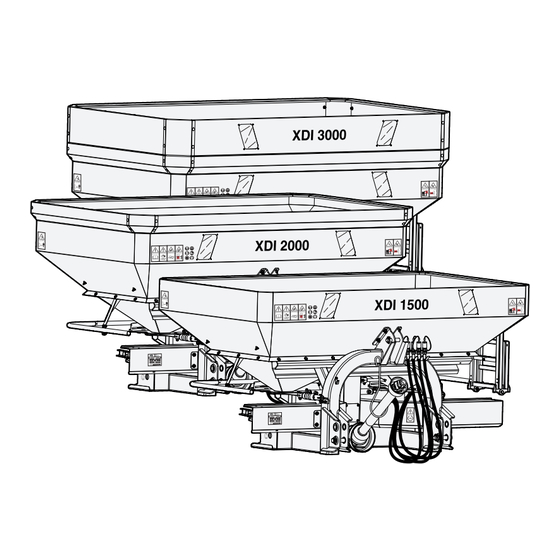

XDI

1500/2000/3000

USER AND MAINTENANCE MANUAL

IMPORTANT! Carefully read this manual before

using the machine.

AGREX S.p.A.

Via Balla, 55/57 - Loc. Taggì di Sotto - 35010 Villafranca Padovana (PD)

Tel. +39 049 50 00 000 - Fax. +39 049 90 75 524

e-mail: info@agrex.com - web site: www.agrex.com

Translation of the original instructions

P/N MNenXDI152030CE - 11.2014

English

Advertisement

Table of Contents

Summary of Contents for AGREX XDI 1500

- Page 1 AGREX S.p.A. Via Balla, 55/57 - Loc. Taggì di Sotto - 35010 Villafranca Padovana (PD) Tel. +39 049 50 00 000 - Fax. +39 049 90 75 524 e-mail: info@agrex.com - web site: www.agrex.com English Translation of the original instructions...

- Page 2 Reproduction prohibited. All rights reserved. No part of this manual may be reproduced in any form, by photocopy, microfilm or any other means, without the written permission of Agrex S.p.A. All enquiries should be addressed to Agrex S.p.A. P/N MNenXDI152030CE Rev.

- Page 3 Users of the machine should carefully read the entire manual before starting any type of work, complete compulsory training in accordance with current occupational health and safety requirements, as provided by authorised training centres, and contact our dealers in case of doubt or to request further explanations or information.

- Page 4 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 The machine must be used, maintained and stored in accordance with the operating conditions described in this manual. Other operating conditions not described in this manual, or described incompletely (i.e. not fully clear due to the user’s level of knowledge or poor familiarity with the language used), must never be adopted, as these represent “improper use”...

-

Page 5: Table Of Contents

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 SUMMARY SECTION 1 - IDENTIFICATION DATA ............................1-1 1.1. MANUFACTURER’S IDENTIFICATION DATA ......................1-3 1.2. MODEL IDENTIFICATION DATA ..........................1-3 1.3. MACHINE RATING PLATE ............................1-4 1.4. DECLARATION OF CONFORMITY ...........................1-5 SECTION 2 - GENERAL PRECAUTIONS ............................2-1 2.1. - Page 6 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.2.1. DRIVE SHAFT CONNECTION ...........................5-7 5.2.2.2. SHORTENING THE DRIVE SHAFT TO THE CORRECT LENGTH ...................5-8 5.2.2.3. DISCONNECTING THE DRIVE SHAFT ........................5-10 5.2.3. HYDRAULIC CONNECTIONS ..........................5-11 5.2.3.1. CONNECTING AND DISCONNECTING THE HYDRAULIC HOSES ................5-12 5.2.4.

- Page 7 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 SECTION 7 - MAINTENANCE AND PRESERVATION ........................7-1 7.1. RECOMMENDED MAINTENANCE STRATEGY AND AUTHORISED OPERATORS ............7-4 7.1.1. CLEANING AND WASHING ............................7-4 7.1.2. VISUAL INSPECTION OF MAINTENANCE CONDITIONS AND RELIABILITY ..............7-6 7.2. MAINTENANCE..............................7-8 7.2.1. ROUTINE MAINTENANCE ............................7-8 7.2.1.1.

-

Page 8: P/N Mnenxdi152030Ce Rev. 00/11.2014 © Agrex S.p.a

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 P/N MNenXDI152030CE Rev. 00/11.2014 © Agrex S.p.A. - Page 9 SECTION IDENTIFICATION DATA...

-

Page 10: P/N Mnenxdi152030Ce Rev. 00/11.2014 © Agrex S.p.a

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 P/N MNenXDI152030CE Rev. 00/11.2014 © Agrex S.p.A. -

Page 11: Section 1 - Identification Data

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 IDENTIFICATION DATA 1.1. MANUFACTURER’S IDENTIFICATION DATA MANUFACTURER AGREX S.p.A. ADDRESS Office and Production Facilities: Via Balla, 55/57 - Loc. Taggì di Sotto 35010 Villafranca Padovana (PD) Tel. +39 049 50 00 000 - Fax +39 049 90 75 524 e-mail: info@agrex.com - website: www.agrex.com... -

Page 12: Machine Rating Plate

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 1.3. MACHINE RATING PLATE The machine is fitted with a rating plate showing the serial or registration number that identifies the machine. The rating plate is applied on the front of the machine and comprises a series of fields, as shown in the figure. -

Page 13: Declaration Of Conformity

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 1.4. DECLARATION OF CONFORMITY The “EC Declaration of Conformity” is a document issued by the manufacturer for machines sold in Europe. The original document, enclosed with the technical documents, must be kept with care throughout the machine’s working life. - Page 14 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 P/N MNenXDI152030CE Rev. 00/11.2014 © Agrex S.p.A.

- Page 15 SECTION GENERAL PRECAUTIONS...

- Page 16 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 P/N MNenXDI152030CE Rev. 00/11.2014 © Agrex S.p.A.

-

Page 17: Section 2 - General Precautions

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 GENERAL PRECAUTIONS This section provides detailed information on all the rules to be respected when using the machine. These rules do not however exempt users of the machine from having to comply with local traffic regulations (only products approved for driving on public roads) and local requirements in force on occupational health and safety. -

Page 18: Definition Of Operator Qualifications

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 2.2. DEFINITION OF OPERATOR QUALIFICATIONS In order to more precisely describe the skills and responsibilities of users and maintenance personnel, the following definitions are used: SYMBOL JOB TITLE General labourer: operator without specific skills, only able to carry out simple tasks under the supervision of qualified technicians. -

Page 19: Obligations

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 2.3. OBLIGATIONS 2.3.1. PURCHASER’S OBLIGATIONS The purchaser is solely responsible for the machine and shall ensure that it is operated and serviced only by operators with the right aptitude for the task and in good mental and physical condition. -

Page 20: General Safety And Accident-Prevention Rules

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 2.4. GENERAL SAFETY AND ACCIDENT-PREVENTION RULES The manufacturer declines all liability for failure to observe the rules on safety and accident prevention. Operators should read the following general safety and accident prevention rules. - Page 21 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Speed. The machine must be driven at speed that is suitable for the conditions of the terrain (flat and solid ground), with the load always visible. Avoid sudden acceleration and braking, and tight cornering at high speed. The machine or the tractor may roll over, and movement of the load - consisting of the machine and any materials to be spread - must not be underestimated.

- Page 22 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Towed loads. People and towed loads cannot be transported on the machine. Only transport the products to be spread in loose form. The heap of the product to be spread must never exceed the line of the high sides.

- Page 23 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Electrical system maintenance. Maintenance is reserved for specialist maintenance technicians, including the control and tractor hitching devices. Noise produced by the machine. During operation, the machine generates noise that is generally covered by the noise of the tractor’s engine. PPE, such as earmuffs, must be used to avoid damage caused by noise, in accordance with the information provided in the tractor’s...

- Page 24 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Operator training. Operators must have the right aptitude for the task, and before using the machine or performing maintenance, must be suitably trained, qualified and authorised through activities provided by authorised training centres, in accordance with the requirements in force on occupational health and safety and the use of dangerous equipment.

-

Page 25: Warranty

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 2.5. WARRANTY 2.5.1. WARRANTY CONDITIONS The manufacturer or its representative guarantees that the parts making up the product are new and have been designed and developed to meet the product technical specifications. The warranty period is: 12 months (twelve months) if the purchaser is an enterprise ( “B to B”, i.e. -

Page 26: Specialist Technical Service

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 2.6. SPECIALIST TECHNICAL SERVICE WARNING! No repairs, work or modifications of any type that are not specified in this manual may be performed on the machine. Service requests must be sent directly to the manufacture’s authorised technical service centre, which will send out specialist personnel and provide all information and explanations required. - Page 27 SECTION SAFETY AND PREVENTION...

- Page 28 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 P/N MNenXDI152030CE Rev. 00/11.2014 © Agrex S.p.A.

-

Page 29: Section 3 - Safety And Prevention

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 SAFETY AND PREVENTION The purpose of this section is to provide more detailed information on the rules to be observed when using the machine and that are described in section 02. These rules do not however exempt users of the machine from having to comply with local traffic regulations (only products approved for driving on public roads) and local requirements in force on occupational health and safety. -

Page 30: Personal Protective Equipment

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 3.2. PERSONAL PROTECTIVE EQUIPMENT Operators must use suitable clothing and personal protective equipment (PPE). SYMBOL DESCRIPTION Use protective gloves. Use safety shoes. Use protective overalls. Use protective glasses. Use protective face masks. WARNING! Operators must wear suitable high-visibility clothing. -

Page 31: Airborne Noise Level

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 3.3. AIRBORNE NOISE LEVEL The noise level (airborne noise) measured with the machine operating at a distance of one metre is: VALUE MEASURED NOTE LpA < 85 dB(A) This noise level is most likely covered by the noise of the tractor’s engine. -

Page 32: Residual Risks

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 3.5. RESIDUAL RISKS The manufacturer has provided a series of safety devices; these are described in this paragraph. Operators must use personal protective equipment suitable for the risk they are exposed to. The most widely used PPE are:... -

Page 33: Environment And Pollution

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 3.6. ENVIRONMENT AND POLLUTION CAUTION! Observe the laws in force in the country where the machine is operated relating to the use and disposal of products used for cleaning and maintenance on the machine, as well as the recommendations of the manufacturer of such products. -

Page 34: How To Avoid Injuries And Accidents

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 3.7. HOW TO AVOID INJURIES AND ACCIDENTS CAUTION! To avoid injuries and for correct use of the machine, carefully read this manual and pay attention to the warnings shown on the labels affixed to the machine. -

Page 35: Checks During Use

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 3.7.3. CHECKS DURING USE After having engaged the PTO, check the operating speed. Never exceed 540 rpm. Never spread ferrous materials, stones, rocks, glass and similar material, as these may cause serious or very serious damage to things or people. -

Page 36: Description And Position Of The Stickers

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 3.8.1. DESCRIPTION AND POSITION OF THE STICKERS The stickers are shown with reference numbers (1,2,3….12) that identify their position on the machine. The position shown in this manual must be complied with when restoring or replacing the stickers. - Page 37 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 cod. PTG1059 Caution! Moving spreader elements. Never enter the hopper when the machine is operating. cod. PTG1010 Caution! Keep away from the machine: danger of product being ejected. cod. PTG1021 Caution! Danger of falling, do not climb onto or ride on the machine.

- Page 38 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 cod. PTG1016 Attachment point. Indicates the point of attachment for lifting the machine. cod. PTG1022 Grease points. Grease the mechanisms in accordance with the procedures and intervals shown in the manual. 3-12 P/N MNenXDI152030CE Rev.

- Page 39 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 3-13 P/N MNenXDI152030CE Rev. 00/11.2014 © Agrex S.p.A.

- Page 40 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 3-14 P/N MNenXDI152030CE Rev. 00/11.2014 © Agrex S.p.A.

- Page 41 SECTION GENERAL DESCRIPTION...

- Page 42 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

-

Page 43: Section 4 - General Description

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 GENERAL DESCRIPTION This section describes the machine with the objective of helping operators understand the general operating principle and get to know the main parts and components. 4.1. OPERATION The XDI fertilizer spreaders are intended for use by professio- nal operators and subcontractors, due to their high performance in spreading product over extensive areas of land. - Page 44 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 The basic hopper has a capacity of 1,500 litres, which can be in- creased to 3,000 litres by simply fitting the high sides, at any time. Inside the hopper, near the openings, are two special ultra-slow rotating mixers, which optimise product feed to the discs and pre- vent the fertilizer from being pulverised.

-

Page 45: Intended Use

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 4.2. INTENDED USE The machine is designed for professional use and operators must have proven aptitude and be able to read and understand the information described in this manual. Operators should in addition use the machine in accordance with safety standards in force and the operating conditions and characteristics of the machine. -

Page 46: Improper Use

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 4.3. IMPROPER USE WARNING! Never use the machine before carefully reading this manual. WARNING! Never spread materials that are not specified in this manual: this represents a risk to the safety of the people who use the machine or who are in the immediate vicinity. -

Page 47: Technical Specifications

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 4.4. TECHNICAL SPECIFICATIONS MODEL XDI 1500 XDI 2000 XDI 3000 1.500 l 2.000 l 3.000 l Capacity 396 US gallons 528 US gallons 792 US gallons 3.000 kg 3.000 kg 3.000 kg Maximum admissible load 6.613 lb... -

Page 48: Main Components

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 4.5. MAIN COMPONENTS The machine is made up of the following components: POS. COMPONENT Chassis/three-point hitch (category 1/2) Feed hopper Hopper high sides Power take-off (PTO) for activating the spreader discs Drive shaft... - Page 49 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 3.000 liters 2.000 liters 1.500 liters Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

-

Page 50: Control Devices

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 4.6. CONTROL DEVICES The machine is made up of the following components: POS. DEVICE NOTES Hydraulic control for opening and closing the fertilizer outlets Positioned at the front of the machine (Optional). (hydraulic hoses). - Page 51 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 4-11 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

-

Page 52: Protection Devices

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 4.7. PROTECTION DEVICES Fixed guards are installed on the machine that prevent direct contact with moving or dangerous parts of the machine. These protection devices can only be removed using special tools. When the machine is operating, all the devices must be correctly fitted. - Page 53 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 4-13 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

-

Page 54: Optional Devices

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 4.8. OPTIONAL DEVICES cod. KITR2000V02 Extension from 1.500 to 2.000 liters (from XDI 1500 to XDI 2000) Painted version. § "5.2.1. ASSEMBLING THE HOPPER SIDES AND EXTENSIONS" on page 5-4 cod. KITR3000V02 Extension from 2.000 to 3.000 liters (from XDI 2000 to XDI 3000) Painted version. - Page 55 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 cod. 30810002 Road safety kit. § "5.2.7. ROAD SAFETY KIT (Optional)" on page 5-23 cod. KITBORDXDIV02 Edge limiter device. § "5.2.8. MOVEABLE LIMITER FOR BOUNDARY SPREADING (Optional)" on page 5-24 cod. KITTUBXDIV02 Fertilizer unloading pipe.

- Page 56 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 cod. KITP240VHW LONG LIFE VANES kit with anti-wear treatment (VHW) 12-24 meters Vanes 38 cm § "5.2.10. LONG LIFE BLADE KIT WITH VHW WEAR PROTECTION TREATMENT (Optional)" on page 5-27 33,5 cm cod. KITP320VHW...

- Page 57 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 cod. PTG1001 Tarpaulin cover with full opening. § "5.2.12. TARPAULIN COVER (Optional)" on page 5-28 cod. PTG1001 Computer for data management mod. PFI Is composed of: - Computer - Electric actuators - Actuator electronic card...

- Page 58 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 4-18 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 59 SECTION HANDLING AND INSTALLATION...

- Page 60 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

-

Page 61: Section 5 - Handling And Installation

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 HANDLING AND INSTALLATION This section describes the correct procedures for handling and installing the machine, operations that may cause serious or very serious injuries, for example due to collision and crushing by overturned loads or using unsuitable hoisting equipment. -

Page 62: Assembling Components And Accessories

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2. ASSEMBLING COMPONENTS AND ACCESSORIES WARNING! The fertilizer spreader and the accessories are typically partly installed in the factory. To complete assembly, follow the instructions provided in this manual. In some cases, when requested by the customer, the machine is delivered fully assembled. - Page 63 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Fit the longer extensions to the hopper and secure them in place, without fully tightening the bolts. The heads of the bolts must be on the outside of the hopper, while the washer and the nut should be tightened from the inside.

-

Page 64: Drive Shaft

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.2. DRIVE SHAFT CAUTION! Before proceeding with this operation, the fertilizer spreader must be uncoupled from the tractor and parked on solid, level ground, so as to ensure maximum stability. For all operations, use the PPE (Personal Protective Equipmen) described below:... -

Page 65: Drive Shaft Connection

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 CAUTION! The drive shaft must work at the minimum possible angle. This will not only extend working life of the drive shaft, but also the fertilizer spreader transmission components. IMPORTANT! Replace any missing or damaged parts of the drive shaft with original spare parts supplied by the drive shaft manufacturer. -

Page 66: Shortening The Drive Shaft To The Correct Length

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.2.2. SHORTENING THE DRIVE SHAFT TO THE CORRECT LENGTH If the drive shaft is too long, this may collide with and cause damage to the PTO (on the machine or tractor) when the machine, connected to the three-point hitch, is lifted. - Page 67 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Cut the protective plastic cover. Shorten the tube to the same length as the plastic cover. Shorten the other half of the drive shaft to the same length. Carefully remove any burrs from the tubes and grease both parts.

-

Page 68: Disconnecting The Drive Shaft

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.2.3. DISCONNECTING THE DRIVE SHAFT DANGER! Danger of crushing and collision due to insufficient space when disconnecting the drive shaft! Disconnect the machine before disconnecting the drive shaft from the tractor. This will create enough space to guarantee safe disconnection of the drive shaft. -

Page 69: Hydraulic Connections

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.3. HYDRAULIC CONNECTIONS All hydraulic hoses have coloured markings so as to associate the corresponding hydraulic function with the outlet tube from a hydraulic diverter valve on the tractor. HYDRAULIC DIVERTER VALVE FUNCTION... -

Page 70: Connecting And Disconnecting The Hydraulic Hoses

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.3.1. CONNECTING AND DISCONNECTING THE HYDRAULIC HOSES For all operations, use the PPE (Personal Protective Equipmen) described below: Protective gloves Safety shoes Work overalls Protective glasses DANGER! Danger of malfunctions in the event of incorrect connection of the hydraulic hoses! Make sure that the hydraulic hoses are connected correctly. - Page 71 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 CHECKS At least once a year have the hydraulic hoses checked by an expert to make sure that these are in safe working condition. In the event of damage or ageing, replace the hydraulic hoses: only use original hydraulic hoses.

-

Page 72: Spreader Discs

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.4. SPREADER DISCS CAUTION! This operation must only be performed by specialist maintenance technicians! To avoid accidents and situations of danger, all the operations must only be carried out by one maintenance technician alone. - Page 73 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 STEP OPERATION IMAGE ASSEMBLING THE DISC Clean and grease the drive shaft (B). Insert the centre hole of the disc (A) on the drive shaft. Push the disc downwards and turn it until it is locked by the pin (C) on the drive shaft.

-

Page 74: Distributor Blades

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.4.1. DISTRIBUTOR BLADES CAUTION! This operation must only be performed by specialist maintenance technicians! To avoid accidents and situations of danger, all the operations must only be carried out by one maintenance technician alone. - Page 75 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 STEP OPERATION On the spreader disc, fit the pair of blades that is suitable for the desired spread width. 12 - 24 metres 24 - 36 metres 36 cm 38 cm 33,5 cm 30,5 cm Depending on the specific weight of the fertilizer being spread, to ensure uniform spreading, both to the right and...

- Page 76 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 ADJUSTING THE POSITION OF THE BLADE ON THE SPREADER DISC STEP OPERATION IMAGE Pull the blade upwards. Move the blade to the new position and insert it in the notch on the disc.

- Page 77 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 REPLACING THE BLADES STEP OPERATION IMAGE Use a spanner to loosen the bolts that fasten the blade to the spreader disc. Use a 13 mm spanner. Remove the bolts and the blade being replaced.

-

Page 78: Wheels For Transport And Parking (Optional)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.5. WHEELS FOR TRANSPORT AND PARKING (OPTIONAL) Removable device to be fitted on the bottom of the machine’s chassis for easy movement in the parking area. CAUTION! Before proceeding with this operation, the fertilizer spreader must be lifted from the tractor. - Page 79 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5-21 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

-

Page 80: Tail Light Bar Kit (Optional)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.6. TAIL LIGHT BAR KIT (Optional) POS. DEVICE Rear parking lights Brake lights Indicators 7-pin 12V plug (ISO 1724) Plug in to the connector on the tractor. WARNING! Before moving the machine, always make sure that the lights are working correctly (switching them on/off) and that all the reflective devices are intact. -

Page 81: Road Safety Kit (Optional)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.7. ROAD SAFETY KIT (Optional) POS. DEVICE Reflective warning panels Reflective warning strips white/red Reflex reflectors orange WARNING! Before moving the machine, always make sure that the lights are working correctly (switching them on/off) and that all the reflective devices are intact. -

Page 82: Moveable Limiter For Boundary Spreading (Optional)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.8. MOVEABLE LIMITER FOR BOUNDARY SPREADING (Optional) A limiter for boundary spreading is needed for spreading fertilizer along the edges of the field. This essentially comprises a moveable guard that limits the trajectory of the product to the edges of the field. -

Page 83: Hopper Discharge Hose (Optional)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.9. HOPPER DISCHARGE HOSE (Optional) This is a removable device to be fitted to the bottom of the machine’s chassis, near the hopper outlets, in order to completely empty the product remaining on the bottom of the hopper. - Page 84 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 STEP OPERATION IMAGE Fit the support to the deviator that controls discharge to the right or left. Position the hose as shown. Tighten the handwheel so as to fasten the hose to the chassis.

-

Page 85: Long Life Blade Kit With Vhw Wear Protection Treatment (Optional)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.10. LONG LIFE BLADE KIT WITH VHW WEAR PROTECTION TREATMENT (Optional) Kit of wear-resistant distributor blades for spreading more corrosive products (granulated fertilizers, sand, etc.). Set of vanes 12-24 meters Set of vanes 28-32 meters Set of vanes 136 meters 5.2.11. -

Page 86: Tarpaulin Cover (Optional)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.12. TARPAULIN COVER (Optional) Sliding hopper tarpaulin to protect the product being spread in the event of rain. When loading the hopper, the tarpaulin is tipped back using a manual opening system. 1 8 0 °... -

Page 87: Management Computer Kit, Model Pfi (Optional)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.2.13. MANAGEMENT COMPUTER KIT, model PFI (Optional) Is composed of: - Computer - Electric actuators - Actuator electronic card - Electrical wiring - Speed wheel sensor The flow-rate (kg/ha) and spread width are set on the... -

Page 88: Verifying Suitability Of The Tractor

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.3. VERIFYING SUITABILITY OF THE TRACTOR DANGER! Danger of breakage during operation, tractor stability, steering and braking capacity may be insufficient in the event of non-compliant use. Verify that the tractor is suitable before attaching or hooking the machine to the tractor. - Page 89 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 F,min [kg] Empty weight of the tractor (*). [kg] Load on the tractor’s front axle when empty (*). [kg] Load on the tractor’s rear axle when empty (*). [kg] Weight of the fertilizer spreader plus the load (**).

-

Page 90: Connecting To The Tractor

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.4. CONNECTING TO THE TRACTOR CAUTION! The machine can be connected to any type of vehicle or tractor with suitable power and compat- ible with the characteristics of the fertilizer spreader. Also see: §... - Page 91 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Before proceeding with the operations for hitching the machine to the tractor, proceed as follows: STEP OPERATION Keep people away from the danger zone between tractor and machine before moving the tractor towards the machine.

- Page 92 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Proceed as follows to correctly hitch the machine to the tractor: STEP OPERATION Connect the drive shaft fitted on the fertilizer spreader to the tractor’s PTO. § “5.2.2. DRIVE SHAFT” on page 5-6 Connect the hydraulic hoses.

- Page 93 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 STEP OPERATION The three-point coupling system on the machine’s chassis must be configured according to the requirements and size category of the tractor. Cat. 1 Cat. 2 Coupling system for category 1 and 2 tractors CAUTION Make sure that all of the protection devices are correctly installed.

- Page 94 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Engage the parking brake and make sure the tractor cannot start or move accidentally. Check that the power take-off is disengaged. Turn off the tractor engine and remove the ignition key. The machine must work perfectly parallel to the ground: check the angle of the machine from the horizontal, as indicated by the spirit level, and if necessary adjust the length of the third-point attachment so that the angle is “0”.

-

Page 95: Disconnecting From The Tractor

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.5. DISCONNECTING FROM THE TRACTOR CAUTION! Park the machine and leave enough space to reverse up to the machine again for connection. WARNING Danger of the machine rolling. Park the fertilizer spreader only with the hopper empty and on horizontal, compact ground. - Page 96 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 STEP OPERATION Disconnect the bottom lift bars on the tractor from the bottom hitch points on the fertilizer spreader. Disconnect the attachment to the third point. Move the tractor forwards around 30 cm so as to create enough space to facilitate disconnection of the drive shaft and the power supply lines.

-

Page 97: Adjustments

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6. ADJUSTMENTS CAUTION! The adjustments described here must only be performed by suitably trained and authorised personnel, when the machine is cold, so as to avoid the risk of burns, fire and explosions. The tractor must be off and the keys removed from the ignition. -

Page 98: Adjusting Spreading Height

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.1. ADJUSTING SPREADING HEIGHT DANGER! Danger of collision and crushing due to the machine falling accidentally after removing the con- nection to the third point. Keep people and animals away from the danger zone behind and underneath the machine. - Page 99 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 STEP OPERATION IMAGE Adjust the length of the third point so that in the working position the fertilizer spreader is horizontal (a=b). Set the height of the spreader disc from the ground as shown in the spreading tables.

-

Page 100: Adjusting Delivery Of The Product To Be Spread (Metering Device)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.2. ADJUSTING DELIVERY OF THE PRODUCT TO BE SPREAD (METERING DEVICE) DANGER! Danger of lacerations or entrapment due to accidental contact with the machine’s mechanisms during the operations. Keep people and animals away from the danger zone behind and underneath the machine. -

Page 101: Adjusting Spread Quantity For Machines Without On-Board Computer

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.2.1. ADJUSTING SPREAD QUANTITY FOR MACHINES WITHOUT ON-BOARD COMPUTER Proceed as follows: STEP OPERATION IMAGE Release the adjustment ring by unscrewing the handwheel (V). Turn the adjustment ring (G) clockwise or anticlockwise to increase or decrease the opening of the metering device (D). -

Page 102: Adjusting Spread Quantity For Machines With On-Board Computer (Optional)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.2.2. ADJUSTING SPREAD QUANTITY FOR MACHINES WITH ON-BOARD COMPUTER (Optional) Also see: § “5.2.13. MANAGEMENT COMPUTER KIT, model PFI (Optional)” on page 5-29 Proceed as follows: STEP OPERATION IMAGE Remove the manual controllers. - Page 103 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 STEP OPERATION IMAGE Connect the wheel speed sensor cable. MFit the wheel speed sensor on the tractor (see the figure alongside). The support is not supplied, as this depends on the model of tractor.

-

Page 104: Setting The Flow Rate

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.2.3. SETTING THE FLOW RATE When using fertilizer with characteristics other than those indicated in the spreading tables, the flow rate must be set using the new type of fertilizer. DANGER! Danger of entrapment or crushing due to the machine connected to and lifted by the tractor accidentally falling. - Page 105 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 STEP OPERATION IMAGE Connect the machine to the tractor. Make sure that the shutters are closed. Load around 100 kg of fertilizer. Lift the fertilizer spreader using the three-point hitch on the tractor until the spreader disc is around 100 cm above the ground.

-

Page 106: How To Calculate The Quantity To Be Spread In Kg/Hectare

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 STEP OPERATION IMAGE Get on the tractor, switch on the engine and switch on the power takeoff. Use the tractor’s hydraulic control and open delivery only from the side where flow is being measured (do not open the other shutter). -

Page 107: Adjusting Working Width

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.3. ADJUSTING WORKING WIDTH Working width is determined by the shape and the length of the blades fitted on the spreader discs: different working widths correspond to different pairs of spreader discs. Also see: §... -

Page 108: Adjusting The Position Where The Product Drops Onto The Spreader Discs

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.4.1. ADJUSTING THE POSITION WHERE THE PRODUCT DROPS ONTO THE SPREADER DISCS For all operations, use the PPE (Personal Protective Equipmen) described below: Protective gloves Safety shoes Work overalls Proceed as follows: STEP... - Page 109 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 AMMONIUM NITRATE 33,5% N Speed (km/h) Border Blade position Opening Drop kg/min (Dose) Point position kg/ha With reference to the SPREADING TABLES, set the graduated index (IG) to the specified opening position. 5-51 Cod.

-

Page 110: Adjusting The Distributor Blades

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.4.2. ADJUSTING THE DISTRIBUTOR BLADES For all operations, use the PPE (Personal Protective Equipmen) described below: Protective gloves Safety shoes Work overalls Proceed as follows: STEP OPERATION IMAGE Depending on the specific weight of the fertilizer... - Page 111 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 STEP OPERATION IMAGE Switch off the tractor’s engine and remove the keys from the ignition. Block the vehicle comprising the tractor and the machine to avoid accidental movement when working on the machine.

-

Page 112: Adjustable Spreading

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.5. ADJUSTABLE SPREADING The hopper shutter OPENING/CLOSING controls (L) (R) are used to deliver fertilizer to the right and left spreader discs independently. This allows three possible types of spreading: (L) + (R) both open = Spreading over 180°... -

Page 113: Adjusting The Moveable Limiter For Boundary Spreading (Optional)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.6. ADJUSTING THE MOVEABLE LIMITER FOR BOUNDARY SPREADING (optional) DANGER! Mechanical danger due to raising/lowering the moveable limiter, with the risks of crushing, cuts, amputation, entrainment, entrapment and impact. Keep a safe distance away from the machine. -

Page 114: Adjustment Of The Spreader With A New Fertiliser Type

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.7. ADJUSTMENT OF THE SPREADER WITH A NEW FERTILISER TYPE 5.6.7.1. FERTILIZER THAT CAN BE SPREADER This centrifugal action fertilizer spreader can be used to spread fertilizer with the following characteristics (as defined in EN 13739-2... -

Page 115: New Fertilizer

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.7.2. NEW FERTILIZER To spread a type of fertiliser different from the ones listed in the spreading charts, it is necessary to do some spreading tests in order to find the adjusting parameters of the new fertiliser type. -

Page 116: Spreading Test

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.7.3. SPREADING TEST 1. Place the five collecting containers along the working distance (see the picture). 2. Make 3 passes with the spreader, adjusting the machine as instructed in the manual. Bear in mind that the height indicated must be taken from the upper edge of the trays. -

Page 117: Estimation Of The Results And Adjustments

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5.6.7.4. ESTIMATION OF THE RESULTS AND ADJUSTMENTS The graphs below show the typical patterns that can be achieved during spreading tests. In the graphs featured, the amount of fertilizer contained in the collection trays is given as a percentage. To interpret the graphs correctly, you should bear in mind that the reference value, which is 100%, is given by the amount of fertilizer collected in the individual containers when the fertilizer spreader is adjusted to pro-duce even, uniform distribution (Optimal spreading). - Page 118 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Type A diagram: Too much fertiliser on the sides. Working Widht (m) Adjustment: Draw back the vanes on the discs to the highest positions (for example if the vane is set on position n.

- Page 119 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Type C diagram: Too much fertilizer just at ends of working width. Working Widht (m) Adjustment: Move just the long blades to higher settings (for instance, if the long blade is on set-ting 1, move it to 2 or 3).

- Page 120 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Type E diagram: Slightly too much fertilizer just at centre of the swath. Working Widht (m) Adjustment: To eliminate excessive fertilizer at the centre of the swath, you have to close the short blade gap, i.e.

- Page 121 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Type G diagram: Optimum adjustment. So it is possible to spread the fertiliser on the field. Working Widht (m) 5-63 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 122 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 5-64 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 123 SECTION USING THE MACHINE...

- Page 124 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

-

Page 125: Section 6 - Using The Machine

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 USING THE MACHINE This section describes how to correctly use the machine and therefore defines the range of normal and expected operating conditions. Operators must read this section very carefully; nonetheless, reading this section alone is not sufficient, and consequently operators... -

Page 126: Filling The Hopper

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 6.3. FILLING THE HOPPER CAUTION! The hopper must only be filled after having hitched the fertiliser spreader to the tractor, with the engine off and with the parking brake engaged, so as to avoid sudden movements and prevent the machine from rolling over. - Page 127 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 DANGER! Danger of the machine rolling. Do not park the machine with the hopper full or partly loaded. For best results and safe operation, the following warnings must be observed at all times:...

-

Page 128: Spreading

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 6.4. SPREADING CAUTION! The machine must only be operated by personnel who understand its specific features and are aware of the main safety procedures. Before starting work, users must familiarise themselves with the machine’s controls. -

Page 129: Spreading Around Edges, On Boundaries And On Boundaries With Watercourses

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 6.4.1. SPREADING AROUND EDGES, ON BOUNDARIES AND ON BOUNDARIES WITH WATERCOURSES The distance from boundaries or edges generally corresponds to half of the working width. The area adjacent to the edge of the field is agricultural land: consequently, a small quantity of product falling over the edges of the field can be... -

Page 130: Step-By-Step Summary (Working Procedures)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 6.4.2. STEP-BY-STEP SUMMARY (WORKING PROCEDURES) STEP OPERATION REFERENCE The machine is coupled to the tractor with all § “5.4. CONNECTING TO THE TRACTOR” on page the hydraulic hoses and power cables correctly 5-32 connected. - Page 131 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 STEP OPERATION REFERENCE Move the tractor forwards and operate the hydraulic OPEN/CLOSE controls to open (and close) the shutter on the metering device. § “6.5. OPERATOR’S DRIVING TECHNIQUE (DRIVING ON THE FIELD)” on page 6-10...

-

Page 132: Operator's Driving Technique (Driving On The Field)

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 6.5. OPERATOR’S DRIVING TECHNIQUE (DRIVING ON THE FIELD) The quality of spreading depends greatly on the operator’s driving technique. During spreading, adopt evenly-distanced spreading passages in order to maintain constant distance from all previous spreading passages. - Page 133 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 6-11 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

-

Page 134: Emptying The Hopper

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 6.6. EMPTYING THE HOPPER § “5.2.9. HOPPER DISCHARGE HOSE (Optional)” on page 5-25 DANGER! Rolling. Never approach the machine if, accidentally, it is not safely parked and stabilised, even if the machine is correctly attached to the tractor. -

Page 135: Rules For Driving On Roads

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 6.7. RULES FOR DRIVING ON ROADS DANGER! Driving on private and public roads. For road transport the fertilizer spreader must be connected to the tractor as described in this manual. Incorrect hitching may affect the vehicle’s stability when braking. Moreover, observe the traffic rules in force in the country in question. - Page 136 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Before moving the machine, check that the required transport equipment is correctly fitted on the machine, for example lights, warning devices and protective equipment. Before moving the machine, visually check that the pins on the top and bottom connecting bars are fitted with the stop plug to prevent accidental release.

-

Page 137: Malfunction, Cause And Remedy

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 6.8. MALFUNCTION, CAUSE AND REMEDY MALFUNCTION CAUSE REMEDY Close the disc feed shutters further. § “5.6.2.1. ADJUSTING SPREAD QUANTITY FOR MACHINES WITHOUT ON-BOARD Fertilizer build-up on the spreader COMPUTER” on page 5-43 discs due to excessive metering for the set disc rotation speed. - Page 138 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 MALFUNCTION CAUSE REMEDY Decrease power take-off speed Power take-off speed is too high. to the value specified in the SPREADING TABLES Move the drop point lever (DP) towards settings (a, b, c...) on the...

-

Page 139: Parking

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 6.9. PARKING If the machine is not used for a long period of time, the mechanical parts need to be checked. Carefully check all the parts most subject to wear. Worn or damaged parts must be replaced immediately, ordering the spare parts from your dealer or the manufacturer. - Page 140 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Attach the PARKING LEGS (optional): § “5.2.5. WHEELS FOR TRANSPORT AND PARKING (Optional)” on page 5-20 Rest the machine on the ground. Disconnect the bottom lift bars on the tractor from the bottom hitch points on the fertilizer spreader.

- Page 141 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Disconnect the lights. Disconnect any optional devices (if featured). § “4.8. OPTIONAL DEVICES” on page 4-14 6-19 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

-

Page 142: Putting The Machine Back In Service

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 6.10. PUTTING THE MACHINE BACK IN SERVICE CAUTION! Before putting the machine back in service, check the overall condition of the machine: this will depend on the condition the machine was left in the last time it was used. -

Page 143: Section 7 - Maintenance And Preservation

SECTION MAINTENANCE AND PRESERVATION... - Page 144 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 145 SPARE PARTS CATALOGUE , enclosed with the machine’s technical documents. Replacement spare parts must be ordered from AGREX S.p.A. If the customer does not use original spare parts or parts authorised by the manufacturer, the latter declines all liability for operation of the machine and the safety of operators.

-

Page 146: Recommended Maintenance Strategy And Authorised Operators

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 7.1. RECOMMENDED MAINTENANCE STRATEGY AND AUTHORISED OPERATORS MECHANICAL/ MAINTENANCE LEVEL 1 LEVEL 2 ELECTROMECHANICAL STRATEGY MACHINE OPERATOR MACHINE OPERATOR MAINTENANCE TECHNICIAN Preventive maintenance 1. Cleaning and washing 2. General inspection 3. Maintenance in accordance with “lubrication plan”... - Page 147 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Frequency Daily or after each use (no longer than 3 days), before parking. Operator User Safety measures Specific training in accordance with requirements in force on occupational health and safety and the use of dangerous equipment;...

-

Page 148: Visual Inspection Of Maintenance Conditions And Reliability

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 7.1.2. VISUAL INSPECTION OF MAINTENANCE CONDITIONS AND RELIABILITY Before using and starting the machine, only in accordance with the operating conditions described in this manual, the user must check the maintenance conditions and reliability of the machine. Machine maintenance and reliability must be verified before the machine is put into service, meaning every day, and after any abnormal events during operation. - Page 149 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 CAUTION! Failure to carry out the visual inspection of machine maintenance and reliability correctly may cause damage to the machine, as well as harm to people, animals and things. CAUTION! The machine can only be operated after the successful conclusion of the visual inspection of machine maintenance and reliability.

-

Page 150: Maintenance

The operations listed above must be explained and performed practically on the machine during the training performed following installation of the machine. During this stage, the technical instructor AGREX S.p.A. will highlight all anomalies, maintenance and danger situations and the solutions to work in complete safety when resolving the problems. - Page 151 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 DANGER! Do not perform maintenance operations with the machine hitched to the tractor. The various maintenance operations are described below. The specified intervals relate to normal operating conditions; therefore, if the machine is used for heavy duty work these must be reduced accordingly.

-

Page 152: Grease The Transmission Assemblies

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 7.2.1.1. GREASE THE TRANSMISSION ASSEMBLIES In normal operating conditions, the primary transmission and the angular transmissions are maintenance-free. Nonetheless, periodically check that there is enough grease inside the assemblies and, if necessary, add lubricant following the instructions show below. - Page 153 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 The lubrication points (P) are on the distributor assembly. Remove the closing cap over the grease nipple. Use a 10 mm Allen key Pump the grease into the transmission assembly. Use Q8 REMBRANT EP 2 grease Keep pumping until grease comes out through the hole in the grease nipple.

- Page 154 TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 Replace the closing cap on the grease nipple and screw it on tightly. Use a 10 mm Allen key 7-12 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

-

Page 155: Grease The Transmission Chain

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 7.2.1.2. GREASE THE TRANSMISSION CHAIN CAUTION! Before proceeding with this operation, the fertilizer spreader must be uncoupled from the tractor and parked on solid, level ground, so as to ensure maximum stability. CAUTION! -

Page 156: Unscheduled Maintenance And Repairs

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 7.2.2. UNSCHEDULED MAINTENANCE AND REPAIRS CAUTION! Unscheduled maintenance operations and repairs must only be performed by qualified technicians, who are trained and authorised by the manufacturer or its authorised service centre. To avoid accidents and situations of danger, all the operations must only be carried out by one maintenance technician alone. -

Page 157: Torque Tools

TWIN DISC CENTRIFUGAL SPREADER - XDI 1500/2000/3000 7.2.3. TORQUE TOOLS BOLTS AND NUTS CLASSES (METRIC THREADS, TRIANGULAR SHAPE, HIGH PITCH) 10,9 12,9 Friction coefficient Friction coefficient Friction coefficient 0,10 0,15 0,20 0,10 0,15 0,20 0,10 0,15 0,20 Torque Torque Torque... - Page 158 APPENDIX B Sheet: Machine model: Maintenance and the cleaning Year of manufacture: of the machine Owner: Maintainer Date of Component Maintenance or cleaning operation Workshop execution 7-16 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 159 APPENDIX B Sheet: Machine model: Maintenance and the cleaning Year of manufacture: of the machine Owner: Maintainer Date of Component Maintenance or cleaning operation Workshop execution 7-17 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 160 APPENDIX B Sheet: Machine model: Maintenance and the cleaning Year of manufacture: of the machine Owner: Maintainer Date of Component Maintenance or cleaning operation Workshop execution 7-18 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 161 APPENDIX B Sheet: Machine model: Maintenance and the cleaning Year of manufacture: of the machine Owner: Maintainer Date of Component Maintenance or cleaning operation Workshop execution 7-19 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 162 APPENDIX B Sheet: Machine model: Maintenance and the cleaning Year of manufacture: of the machine Owner: Maintainer Date of Component Maintenance or cleaning operation Workshop execution 7-20 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 163 APPENDIX B Sheet: Machine model: Maintenance and the cleaning Year of manufacture: of the machine Owner: Maintainer Date of Component Maintenance or cleaning operation Workshop execution 7-21 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 164 APPENDIX B Sheet: Machine model: Maintenance and the cleaning Year of manufacture: of the machine Owner: Maintainer Date of Component Maintenance or cleaning operation Workshop execution 7-22 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 165 APPENDIX B Sheet: Machine model: Maintenance and the cleaning Year of manufacture: of the machine Owner: Maintainer Date of Component Maintenance or cleaning operation Workshop execution 7-23 Cod. MNenXDI152030CER00 Rev. 00/11.2014 © Agrex S.p.A.

- Page 166 AGREX S.p.A. Production & Sales Dept: Via Balla, 55/57 (Loc. Taggì di Sotto) 35010 Villafranca Padovana (PD) - ITALIA Tel. +39 049 50 00 000 Fax. +39 049 90 75 524 E-mail: info@agrex.com Web Site: www.agrex.com...

Need help?

Do you have a question about the XDI 1500 and is the answer not in the manual?

Questions and answers