Table of Contents

Advertisement

Quick Links

Assembly, Use and Care

Thank You!

You have purchased the highest quality professional broadcast spreader available on the market today. The

Model 2000 is the accumulation of proven performance and will provide you with years of trouble-free service. In

the event you should have any questions or comments, please call our professional support staff.

1-800-225-2639

Our toll-free number is

Before You Begin ...

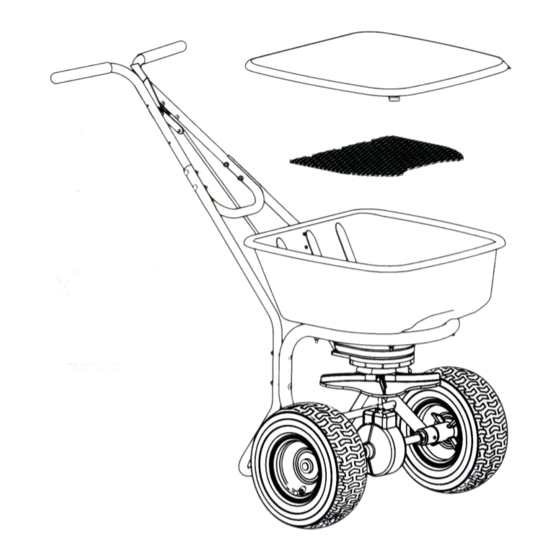

To assemble your new

spreader, we highly

recommend that you read

all the instructions thoroughly,

familiarize yourself

with the assembly and

components, and verify that all

parts are included in the

package.

You Will Need ...

The following tools:

1/2" and 7/16" open-end wrenches

—

(or adjustable wrench

Pliers

—

—Phillips head screwdriver

Grease gun

—

)

Model 2000

(U.S. Only)

Professional Rotary Spreader

Advertisement

Table of Contents

Summary of Contents for The Andersons 2000

-

Page 1: Before You Begin

You have purchased the highest quality professional broadcast spreader available on the market today. The Model 2000 is the accumulation of proven performance and will provide you with years of trouble-free service. In the event you should have any questions or comments, please call our professional support staff. - Page 2 Assembly Turn the spreader upside-down. Place the Insert the bent end of the main shutoff wheels on the axle with the longer portion of the connecting rod through the hole in the lever and hubs facing inward. Secure the drive wheel secure with a 3/32”...

- Page 3 Assembly continued Grease Fittings Using a grease gun, lubricate the grease fittings on the axle bearing housings and gear carrier. Do not overfill. Apply a small amount of grease to the gear teeth. Install the two gearbox cover halves and secure with the three retainer clips. Insert the screen inside the hopper and secure it with the factory installed clips.

- Page 4 Operation HOW TO USE Check product bag for rate setting (letter), cone setting (number), and swath width. The rate setting is achieved by Rate Control loosening the rate control knob and sliding the rate control plate Plate until the pointer aligns with the desired letter. The cone setting is used to control spread pattern left to right and is adjusted by rotating the index tab on the orange helical cone to the desired Helical Cone...

- Page 5 Calibration Instructions Calibration depth Calibration Key Pointer Setting “E” Rate Control Plate Your professional spreader has been factory calibrated. For best results, occasionally check calibration and adjust if necessary. Pull the main shutoff lever to the closed position. Slide the rate control plate to the right until it comes in contact with the protruding end of the rate control rod.

- Page 6 Parts Diagram–Model 2000 Optional Deflector Kit (used for side spread pattern shut off) (includes 2,3,7, 8, 9, 10,11,& 12) (includes 4,5, 6, &13) (includes 16,17,18, &19) (includes 30 & 31...

- Page 7 Ordering Parts See diagram for assistance in identifying specific parts. For parts orders, call 1-800-294-0671. (Note: Sales of parts for the Andersons spreaders are handled by EarthWay.) IMPORTANT: When ordering replacement parts, always provide the following information: 1) Part number (DO NOT use key numbers when ordering parts. ALWAYS use part numbers.)

- Page 8 This warranty does not extend to any Product or parts thereof that have been allowed to corrode, subjected to misuse, neglect, accident, or modification by anyone other than The Andersons or that have been affixed to any nonstandard accessory attachment or that have been used, stored, installed, maintained operated in violation of The Andersons instructions or standard industry practice.

Need help?

Do you have a question about the 2000 and is the answer not in the manual?

Questions and answers

How do your Letter compare to number on bags!