Table of Contents

Advertisement

Quick Links

PREVIOUS REFERENCE NO. IM-P134-07

1340050/7

IM-S19-04-EN-ISS1

CMGT

DCV1, DCV3 and DCV3LT

Disc Check Valves

Installation and Maintenance Instructions

1. Safety information

2. General product information

3. Installation

4. Commissioning

5. Operation

6. Maintenance

7. Spare parts

© Copyright 2018

IM-S19-04-EN-ISS1 CMGT

1

Printed in France

Advertisement

Table of Contents

Summary of Contents for Spirax Sarco DCV1

- Page 1 PREVIOUS REFERENCE NO. IM-P134-07 1340050/7 IM-S19-04-EN-ISS1 CMGT DCV1, DCV3 and DCV3LT Disc Check Valves Installation and Maintenance Instructions 1. Safety information 2. General product information 3. Installation 4. Commissioning 5. Operation 6. Maintenance 7. Spare parts © Copyright 2018 IM-S19-04-EN-ISS1 CMGT...

-

Page 2: Safety Information

Determine the correct installation situation and direction of fluid flow. iv) Spirax Sarco products are not intended to withstand external stresses that may be induced by any system to which they are fitted. It is the responsibility of the installer to consider these stresses and take adequate precautions to minimise them. -

Page 3: Protective Clothing

1.9 Tools and consumables Before starting work ensure that you have suitable tools and/or consumables available. Use only genuine Spirax Sarco replacement parts. 1.10 Protective clothing Consider whether you and/or others in the vicinity require any protective clothing to protect against the hazards of, for example, chemicals, high/low temperature, radiation, noise, falling objects, and dangers to eyes and face. -

Page 4: Residual Hazards

Customers and stockists are reminded that under EC Health, Safety and Environment Law, when returning products to Spirax Sarco they must provide information on any hazards and the precautions to be taken due to contamination residues or mechanical damage which may present a health, safety or environmental risk. -

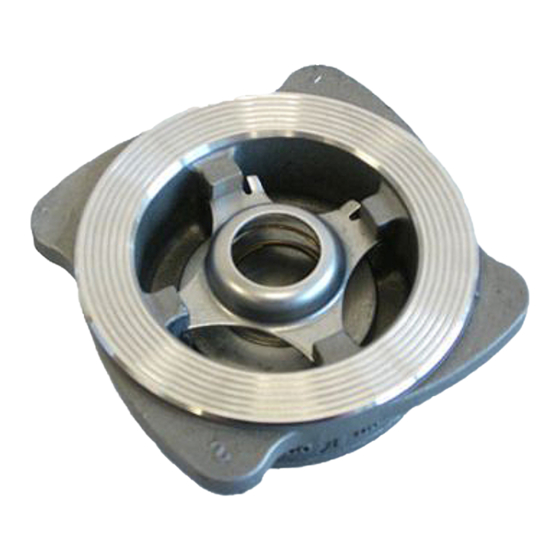

Page 5: General Product Information

2.1 General description The DCV1, DCV3 and DCV3LT disc check valves are of the wafer pattern designed to be sandwiched between flanges. They are suitable for use on a wide range of fluids for applications in process lines, hot water systems, steam and condensate systems etc. -

Page 6: Seating Options

2.4 Materials Part Material DCV1 Bronze Body DCV3 Austenitic stainless steel DCV3LT Austenitic stainless steel Disc Austenitic stainless steel Spring retainer Austenitic stainless steel Standard spring Austenitic stainless steel Heavy duty spring Austenitic stainless steel High temperature spring Nickel alloy 2.5 Seating options... - Page 7 -40 °C to +120 °C (-40 °F to 248 °F) Designed for a maximum cold hydraulic test pressure of 24 bar g (348 psi g) Note: Special testing to allow lower temperature operation can be provided at extra cost. Consult Spirax Sarco. IM-S19-04-EN-ISS1 CMGT...

- Page 8 2.7 Pressure/temperature limits - DCV3 and DCV3LT Pressure psi g Steam saturation curve Pressure bar g Only the DCV3LT can be used down to -60 °C The product must not be used in this region. Use either a DCV3 with high temperature spring or DCV3/DCV3LT without spring for use in this area. A-B-F DCV3 without spring and with high temperature spring.

- Page 9 Minimum operating temperature DCV3 -10 °C (14 °F) Note: For lower operating temperatures DCV3LT -60 °C consult Spirax Sarco Viton seat -25 °C to +205 °C (-13 °F to 401 °F) Temperature limits EPDM seat -40 °C to +120 °C (-40 °F to 248 °F)

-

Page 10: Installation

The DCV1, DCV3 and DCV3LT can be installed in any plane with the exception of DCV's supplied without an internal spring. These must be fitted in a vertical flow line with the flow from bottom-to- top i.e. -

Page 11: Operation

4. Commissioning After installation or maintenance ensure that the system is fully functional. Carry out tests on any alarms or protective devices. 5. Operation Disc check valves are opened by the pressure of the fluid and closed by the spring as soon as the flow ceases and before the reverse flow occurs. -

Page 12: Maintenance

7. Spare parts There are no spare parts available for this product. How to order a new product Example: 1 off Spirax Sarco DN25, DCV3 Austenitic stainless steel disc check valve for fitting between DN25, PN40 flanges. IM-S19-04-EN-ISS1 CMGT...

Need help?

Do you have a question about the DCV1 and is the answer not in the manual?

Questions and answers