Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

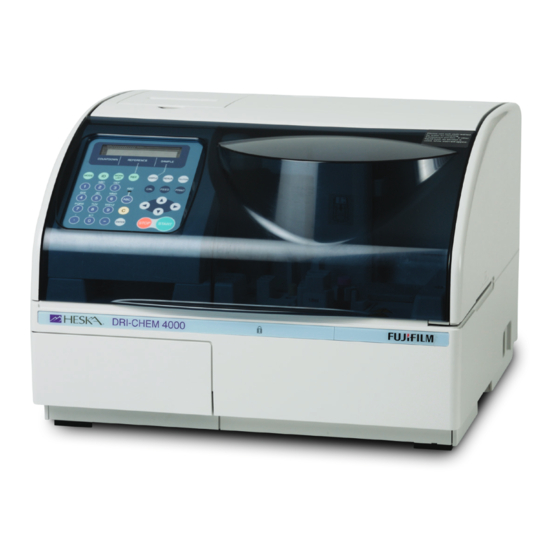

Summary of Contents for Heska DRI-CHEM 4000

- Page 1 DRI-CHEM 4000 Veterinary Chemistry Analyzer Product Manual...

- Page 2 • System Performance Data • Maintenance and Control Log Operator Requirements The following operator requirements must be fulfilled before operating the DRI-CHEM 4000 Veterinary Chemistry Analyzer. • Basic skills in a laboratory environment. • Basic skills in diagnostic chemistry. •...

-

Page 3: Table Of Contents

DRI-CHEM 4000 Table of Contents Veterinary Chemistry Analyzer PREFACE SECTION 1: SAFE USAGE AND HANDLING PRECAUTIONS Section Overview ......................1 Definition of Specific Safety Precautions . - Page 4 Inspecting and Replacing the Sampler O-ring ..............37 4.6.1 Inspecting the Sampler O-ring .

- Page 5 6.2.10 Mode 29 Printing Out Slide Lot Number <Normal> ............75 6.2.11 Mode 30 Work List Display Item Setting <Admin.>...

-

Page 6: Section Overview

DRI-CHEM 4000 Section 1: Safe Usage and Handling Precautions Veterinary Chemistry Analyzer Section Overview This section contains safety precautions which must be followed for the safe operation of the DRI-CHEM Analyzer. Before using this equipment, please read this chapter carefully and follow the precautions so that you can operate it correctly. -

Page 7: Biohazards And Disposal

CAUTION Intended use of this equipment is to quantitate the concentration or the activity of the components in blood by using the DRI-CHEM Analyzer Slides. Do not use the equipment for other purposes. Please read the Instructions for Use for the slides. This equipment is only to be operated by personnel appropriately trained for the intended use and operation. -

Page 8: Electromagnetic Capabilities (Emc)

Electromagnetic Compatibility (EMC) This equipment conforms to the following EMC requirements: EN61326:1997 + A1:1998 + A2:2001 + A3:2003 (Class A) FCC Part 15 Subpart B: 2006, Class A ICES-003 Issue No. 4, Class A This is a Class A product. In a domestic environment, this product may cause radio interference in which case the user may be required to take adequate measures. -

Page 9: Dri-Chem Analyzer Slides (Sd)

1. Install the equipment in the following environmental conditions: Location: Indoor Use Below 6000 cd/m (lux) Illumination: (Below 3000 cd/m (lux) when using the sample barcode reader) Altitude: Up to 2000m (6,500 ft) Transient overvoltage category: Pollution degree: Operating temperature: 59°F to 89°F (15°C to 32°C) Operating humidity: 30% to 80% RH (no dew condensation) -

Page 10: Calibration Card System

List of DRI-CHEM Analyzer Slides Classification Test Name Alkaline Phosphatase Amylase Creatine Phosphokinase Gamma Glutamyltransferase Enzymes GOT/AST Aspartate Aminotransferase GPT/ALT Alanine Aminotransferase Lactate Dehydrogenase Lipase Albumin Blood Urea Nitrogen Calcium Creatinine Biochemical Tests Glucose Inorganic Phosphorus General Chemistry Magnesium Ammonia TBIL Total Bilirubin TCHO... -

Page 11: Dri-Chem Analyzer Auto Tips, Sample Tubes And Dri-Chem Analyzer Mixing Cups

1.10 DRI-CHEM Analyzer Auto Tips, Sample Tubes, and DRI-CHEM Analyzer Mixing Cups (Henceforth, DRI-CHEM Analyzer Auto Tip is shortened into "tip, " Sample Tubes into "Sample tubes, " and DRI-CHEM Analyzer Mixing Cups into "mixing cup" in this manual). The sampler of the DRI-CHEM Analyzer performs pipetting automatically. However, it is necessary to load the Auto Tip, Sample Tubes (Heparin or Non-Heparinized Tube), and Mixing Cups designed for use with the DRI-CHEM Analyzer. -

Page 12: Warning Labels

1.13 Warning Labels Warning labels and safety labels on the DRI-CHEM Analyzer are: • High temperature caution label • Lamp caution label • Biohazard label • Chemicals caution label • Power switch • Name plate 200VA 200VA... -

Page 13: Component Names

DRI-CHEM 4000 Section 2: Component Names and Functions Veterinary Chemistry Analyzer Component Names CF card slot CF Card Slot Display... - Page 14 CAUTION Do not connect the RS–232C connector to a sample barcode reader other than specified for the DRI-CHEM Analyzer. Do not connect the RS–232C or USB connector to a computer or PC which has not been approved by IEC/UL60950–1. (Refer to Section 6.2.20) Do not connect an external printer to the RS–232C or USB connectors.

-

Page 16: Names And Functions Of Keyboard Controls

Names and Functions of Keyboard Controls DISPLAY Displays the status of the "analyzer" and the operating procedures. COUNTDOWN Displays estimated time (sec.) to complete current measurements on the analyzer. REFERENCE Displays a selected reference interval (e.g., DOG). SAMPLE Displays a selected sample type. Cover lock LED The LED lights when the sampler cover is locked during sample processing. - Page 17 MODE KEY The MODE key is used to enter Mode functions. ID KEY The ID key is used to input sample numbers or sample IDs. WORK LIST KEY WORK LIST The WORK LIST key is provided for requesting patient ID and test request information (work list) from an external PC.

- Page 18 The SAMPLE key will be used for selecting sample types. The sample type changes each time the key is pressed. The order of change is P/S (plasma/serum), U (urine) and W (whole blood). The U + W functions are not used with Heska's current slide set. RERUN KEY RERUN The RERUN key is used for rerunning tests with the previous sample.

- Page 19 STOP KEY STOP The STOP key is used for stopping a sampling process. The sampler stops after discarding tips. To restart the sampling process, load new tips into the sample rack and press the START key. This key is also used for stopping alarms and terminating a mode process.

-

Page 20: Section Overview

DRI-CHEM 4000 Section 3: Operations Veterinary Chemistry Analyzer Section Overview Following is an overview of the operations and processes used to obtain test results. Detailed operation procedures begin with Section 3.2. Principles of Operations Slide loading: The analyzer can compensate for the differences between the slide production lots by reading the Calibration card included with each box of slides. -

Page 21: Detailed Operations

Detailed Operations Preparation: List of daily checks before use. 1. Empty disposal box. 2. Check air filter in disposal box. 3. Remove any used consumables such as mixing cup, reference fluid and sample. 4. Check printer paper for red line appearing along the sides indicating the need to replace. IMPORTANT If the disposal box is completely filled, slide transfer and tip eject errors may occur. - Page 22 List of daily checks after use: 1. Empty disposal box. 2. Remove any used consumables such as mixing cup, reference fluid and sample. 3. Clean any spills on and around the spotting part and sample rack. Turning the power off: 1.

- Page 23 Clean the spotting area and around the sample rack. If necessary, use swabs moistened with ethyl alcohol for cleaning. Close the sampler cover. Sample racks: Two pre-assembled sample racks are supplied with the instrument. The proper sample rack must be placed in the instrument depending on the sample tube selected.

- Page 24 2. Sample Rack for 1.5 ml Sample Tubes Using samples with sample tubes Four types of Sample Tubes are available: 1. 0.5 ml Heparin Tubes (green cap) 2. 1.5 ml Heparin Tubes (green cap) 3. 0.5 ml Non-Heparinized Tubes (red cap) 4.

-

Page 25: Operations

Obtaining serum samples Collect whole blood samples not processed with anticoagulant into standard glass clinical plain tubes. Allow sample to clot at room temperature for at least 20 minutes (40 minutes for horses). Centrifuge the sample using a standard clinical centrifuge according to standard practices. - Page 26 12. Close the sampler cover. NOTE: Measurements cannot start with the sampler cover open. 13. Press START to start tests. IMPORTANT The disposal box must remain closed during testing. Otherwise, the test results may affected. NOTE: When the message on the display returns to [Ready] and the cover lock LED turns off, the sampler cover can be opened and the next sample and tests can be prepared.

- Page 27 MPORTANT If the reference fluid is set in the sample setting position, erroneous test results will be obtained. Be sure to set in the reference fluid position. NOTE: A dead volume of 50 µL of reference fluid will remain in the bottom of the tube and cannot be aspirated.

- Page 28 Tests that require dilution There are 2 ways to perform tests that require dilution. The first is using the DILUTION button to set a dilution factor which is described in this section. The second is using Mode 45 to preset a dilution factor for any test type such that any time that test is used the dilution occurs automatically.

- Page 29 NOTE: [---] on the display indicates no dilution unless one is preset using Mode 45. NOTE: Press STOP to cancel a dilution setting. 11. Close the sampler cover. 12. Press START to start the tests that require dilution. DILUTION 13. After the tests are completed, dispose of the used mixing cup and remove the remaining sample.

-

Page 30: Inputting Sample Id

NOTE: When performing tests that require dilution, put a tip into hole "b" and place a mixing cup on the sample rack and diluent into the left hole of the mixing cup. NOTE: When performing an ISE test, put tips into holes "c" and "d" and place a tube with reference fluid into the RE position. - Page 31 NOTE: A blank space can be input using . NOTE: Special characters (Ä, ü, ê, etc.) cannot be input. Input procedures 1. Press ID to enter the sample number input mode. Next, press ENTER to enter the sample ID input mode. 2.

- Page 32 Sample barcode reader By using the optional sample barcode reader, the sample ID can be easily input if barcodes are used for samples at the facility. Prior to using the sample barcode reader it is necessary to set the communicating configuration by using Mode 46. (Refer to Section 6.2.20).

- Page 33 DRI-CHEM 4000 Section 4: Periodic Maintenance Veterinary Chemistry Analyzer In order to keep the analyzer performance at its best, periodic user maintenance and specific Heska service maintenance must be followed. IMPORTANT If the periodic maintenance in this manual is not followed, the analyzer’s performance and specifications may degrade, and adverse effects on test results may occur.

-

Page 34: Cleaning The Air Filter

Cleaning the Air Filter The air filter may become dirty in some environmental conditions. Check and clean at least once a month. IMPORTANT If the air filter is not cleaned, the analyzer temperature will not be regulated properly with adverse effects on test results. - Page 35 6. Clean the pressure plates. Pressure plate Wipe off the 7 pressure plates on the backside of the incubator with a soft cloth or swabs lightly moistened with ethyl or isopropyl alcohol. Allow the pressure plates to dry by placing the incubator on a counter with the (pressure plate surface) facing up.

- Page 36 10. Clean reference plate C. Turn over reference plate C and clean the black plate and the white plate with a dry cotton swab. Black plate White plate IMPORTANT Do not touch the surface of the black plate and the white plate with bare hands.

- Page 37 14. Reset incubator cover A and plug in the incubator cable. Pass the cable of incubator B through the hole in the center of incubator cover A. Align on the incubator cover with the LOCK mark on the analyzer. Plug the connector of the incubator cable to the analyzer and lock it by turning it clockwise.

-

Page 38: Cleaning The Slide Reader And The Spotting Part

Cleaning the Slide Reader and the Spotting Part When the slide reader is dirty, frequent reading errors may occur. When the spotting part is dirty, slide transfer errors may occur. Perform cleaning procedures to avoid these errors. CAUTION Turn off the analyzer when cleaning the slide reader or the spotting part. IMPORTANT If the analyzer is used without cleaning the slide reader and the spotting part, test results may be adversely affected. -

Page 39: Replacing The Recording Paper

A red line appearing along the sides of the recording paper means that the printer is nearly out of paper. Replace the recording paper roll with a new one. NOTE: Use specified recording paper from Heska. Replacement procedures 1. Open the printer cover. -

Page 40: Replacing And Cleaning The Light Source Lamp

9. Lock the lever. (10)Pass paper through opening and close cover Make sure that the paper will advance straight and then lower the lever to lock the paper. 10. Pass paper through the cutter opening on the printer cover and close the cover. 11. - Page 41 4. Clean the lens using a dry cotton swab. NOTE: If cleaning with ethyl or isopropyl alcohol, always wipe off the lens using a dry cotton swab to dry it well. Lens 5. Replace the lamp. Unscrew thumbscrew B to remove the lamp. Place new lamp in place and tighten thumbscrew B.

-

Page 42: Inspecting And Replacing The Sampler O-Ring

Inspecting and Replacing the Sampler O-ring The sampler nozzle O-rings wear with use. Periodic inspection (once a month) and replacement (once a year) are necessary. IMPORTANT If the analyzer is used without inspecting and replacing the sampler O-ring, spotting volume may be inaccurate and test results may be adversely affected. -

Page 43: Replacing The Sampler O-Ring

3. Leak check for the dilution tip. a. Select [Dil tip] and press ENTER. b. Put the sampler leak check tool into hole "b" on the sample rack. START c. Close the sampler cover and press START. The leak check starts, and the result will be printed out. d. -

Page 44: Replacing The Fuse

Model No.: 314010 CAUTION Be sure to use the above model of fuse (packed as an accessory). NOTE: If the fuse immediately burns out after the power switch is turned on, contact Heska's Technical Support Services for assistance, 1-800-GO HESKA. -

Page 45: Section 5: Troubleshooting

DRI-CHEM 4000 Section 5: Troubleshooting Veterinary Chemistry Analyzer Section Overview When performing troubleshooting, always follow biohazard procedures (e.g., wearing gloves, lab coat, and safety goggles). If any part of the body comes in contact with contaminated parts, immediately rinse the contaminated body part thoroughly under running water and then use ethyl alcohol as a disinfectant. - Page 46 Error Code Error Description Reference Section E1000-E1002 Sampler vertical operation error 5.2.4 E1100-E1103 Sampler rotational operation error 5.2.4 E1200-E1204 Syringe operation error 5.2.4 E1500-E1504 Temperature control error 5.2.7 E1510-E1514 Temperature control error 5.2.7 E1521 Room temperature error 5.2.7 E30xx Circuit board malfunction 5.2.8 E40xx QC card read error...

-

Page 47: Printout Indication Table

5.1.2 Printout indication table Printout Message Description Reference Section Testing value exceeds the upper limit of the preset reference interval. Testing value falls below the lower limit of the preset reference interval. > Testing value exceeds the upper limit of the measurement range. <... -

Page 48: Troubleshooting

Check that the power cable is properly connected and the fuse is not burned out. Then try turning on the analyzer again. If the analyzer still does not start up, please contact Heska's Technical Support Services for assistance at 800.464.3752. NOTE: Refer to Section 4.7 for replacing the fuse. -

Page 49: Slide Reading Errors

Check that the analyzer is not exposed to excessive external light. c. Check that the dot-print part of the slide is not stained or obscured. If the error still occurs, contact Heska's Technical Support Services for assistance. 5.2.4 Sampler Errors 1. - Page 50 6. W120 A tip remains on the nozzle. Remove the tip from the sampler nozzle by hand and empty the disposal box. 7. E0120, W060 E0120 => No sample surface found. W060 => Sample was found, but the volume is insufficient. Perform the following troubleshooting.

- Page 51 10. E0143 Diluent surface has been found, but the volume is insufficient. Check the diluent volume. Replace the mixing cup, pour diluent, and set tips, and then rerun the tests from the beginning. 11. E0129 No reference fluid surface has been found. Check the reference fluid volume.

- Page 52 IMPORTANT DRI-CHEM Analyzer Auto Tips cannot be reused. If the error still occurs after troubleshooting, contact Heska's Technical Support Services for assistance. 16. E0110, E0111, E0112, E0113, E0124, E0125 Clogging error has been detected during sampling. Fibrin may be present in sample.

- Page 53 TUBE with reference fluid is set properly. Replace the mixing cup and set consumables (tips and diluent, etc.), and rerun the tests from the beginning. NOTE: If the error still occurs, the pipetting system may be clogged. Contact Heska's Technical Support Services for assistance.

- Page 54 Make sure that no foreign matter (tip or slide) is present around the sampler movement area. Remove foreign matter if present. c. Turn the power switch on. d. If the error still occurs, contact Heska's Technical Support Services for assistance.

-

Page 55: Photometer Errors

See (Refer to Section 4.2) After cleaning, turn the power switch on. If the error still occurs, replace the light source lamp. Refer to Section 4.5. If the error still occurs, contact Heska's Technical Support Services for assistance. CAUTION The light source lamp gets very hot. Before replacing the lamp, turn the power off and wait at least 5 minutes. The... - Page 56 The circuit board has malfunctioned (abnormal reference white plate reading). Turn the power switch off and on. If the error still occurs, contact Heska's Technical Support Services for assistance. 4. E0900 - E0903 Interference motor drive error has occurred. Turn the power switch off and on. If the error still occurs,...

-

Page 57: Transfer Errors

Turn the power switch off, and perform the following: • Empty the disposal box. • Incubator cleaning (Refer to Section 4.2). • Spotting part cleaning (Refer to Section 4.3). If the error still occurs, contact Heska's Technical Support Services for assistance. -

Page 58: Temperature Control Errors

"E1510" may occur. In this case, turn the power switch off to cool down the incubator (about 10 minutes), and then turn the power switch on. If the error still occurs, please contact Heska's Technical Support Services for assistance. -

Page 59: Circuit Board Malfunction

NOTE: To properly plug in the incubator cable, the connector must be turned clockwise to lock it into the receptacle. Refer to Section 4.2. If the error still occurs, contact Heska's Technical Support Services for assistance. E1514 When starting the measurements, the incubator temperature is not ready. - Page 60 E30xx, E5000 - E5035, E5201 - E5204, E5500, E9999, EFFxx The circuit board has malfunctioned. If the error still occurs after turning the power off and on, contact Heska's Technical Support Services for assistance. NOTE: “ x ” means given value (letter).

-

Page 61: Calibration Card Read Error

The analyzer could not read calibration card information. Read the calibration card again. Refer to Section 3.2. If the error still occurs, contact Heska's Technical Support Services for assistance. 2. E4000 - E4009 The analyzer could not read calibration card information. -

Page 62: Slide Loading Errors

A self-test error has been detected before starting ISE tests. Turn the power switch off and on, and then rerun the tests. If the error still occurs, please contact Heska's Technical Support Services for assistance. NOTE: Without turning the power off and on, the "W141"... - Page 63 O-ring. Refer to Section 4.6. • Spotted fluids in the spotting holes on the slide are almost equal in volume. If the fluids are not spotted into the spotting holes normally, please contact Heska's Technical Support Services for assistance.

-

Page 64: Errors Related To Data Communication Or Sample Barcode Reader

• Make sure that the communication settings (Mode 46) have been set correctly. NOTE: If the error still occurs, contact Heska's Technical Support Services for assistance. NOTE: "x" means given value. 2. W200 The sample barcode reader has not been connected to the analyzer. - Page 65 Be sure to close the sampler cover when starting the next test. 8. W026 The analyzer has failed to lock the sampler cover. Please contact Heska's Technical Support Services for assistance. Closing the sampler cover allows testing to continue. 9. W027 The analyzer has failed to unlock the sampler cover.

- Page 66 10. W500, W501 A fan is faulty. Contact Heska's Technical Support Services for assistance. 11. When "&" marks appear on test results: IMPORTANT Measured values with a "&" mark may NOT be accurate. a. In case of Ca-P tests, the sample has not been spotted.

-

Page 67: Section 6: Mode Settings And Functions

DRI-CHEM 4000 Section 6: Mode Settings and Functions Veterinary Chemistry Analyzer Mode Function List and Mode Selection Mode functions are used for changing functions, inputting or printing parameters, or cleaning the analyzer. 6.1.1 Mode List Visual checking There are two kinds of modes: one is the administrator mode, which can only be operated by administrators; another is the normal mode, which can be operated by normal operators. -

Page 68: How To Select Each Mode

6.1.2 How to Select Each Mode 1. To enter a mode operation: There are 2 ways to select a mode: • Select a Mode by scrolling: a) • Input a Mode No. directly: b) a. Selecting a Mode by scrolling: When the display shows [Warming Up] or [Ready], press MODE to display the mode number input dialog. - Page 69 b. Inputting a Mode No. directly: When the display shows [Warming Up] or [Ready], press MODE to display the mode number input dialog. Input a Mode No. from the keyboard and press ENTER to display the first dialog of the mode. NOTE: indicates a key, and indicates input order.

-

Page 70: Mode Functions

Mode Functions 6.2.1 Mode 0 changing Mode type <Normal> 1. Enter into Mode 0. 2. Select [Administrator mode]. Select [Administrator mode] by using the scroll keys, then press ENTER. NOTE: Although the service mode will be displayed on the menu, the mode is not available. ENTER 3. -

Page 71: Mode 19 Turning On The Control Mode (A, B Canceled)

Dilution factors (Mode 45 settings) ==> Resets to no dilution On the printout for each measurement, the indication "C" appears after the sample No. NOTE: This mode should NOT be set for use with HESKA Chemistry Control. NOTE: Turning off the power cancels this mode. -

Page 72: Mode 20 Setting Date And Time

6.2.3 Mode 20 Setting Date and Time <Normal> This mode is used to set the date and time. 1. Enter into Mode 20. 2. Input date. a. Input the year from the keyboard and press ENTER. NOTE: Input the last 2 digits of the year. b. -

Page 73: Mode 23 Displaying And Resetting The Lamp's Cumulative Illumination Time

6.2.4 Mode 23 Displaying and resetting the lamp’s cumulative illumination time <Normal> This mode is used to display and reset the cumulative illumination time of the lamp currently installed in the analyzer. The illumination time will be counted up to 9,999 hours if not reset. When replacing the light source lamp, reset the cumulative illumination time using this mode. -

Page 74: Mode 24 Unit Conversion [Unit (A)/Unit (B) Switch]

6.2.5 Mode 24 Unit Conversion [Unit (A) / Unit (B) Switch] <Admin.> This mode is used to switch the test units printed or transmitted to a computer. The Unit (A) and Unit (B) for each test code are listed on the table on the following page. 1. - Page 75 Classification Test Name Test Code Unit (A) Unit (B) Conversion Coefficient µkat/L 0.0167 vAMY µkat/L 0.0167 µkat/L 0.0167 µkat/L 0.0167 Enzymes AST/GOT µkat/L 0.0167 ALT/GPT µkat/L 0.0167 µkat/L 0.0167 vLIP µkat/L 0.0167 g/dL mg/dL mmol/L 0.357 mg/dL mmol/L 0.25 mg/dL µmol/L 88.4 Biochemical...

-

Page 76: Mode 25 Data Retransmission To Host Computer

6.2.6 Mode 25 Data Retransmission to Host Computer <Normal> This mode is used to retransmit test results to a host computer via the RS232C or USB connector. Prior to using this mode, it is necessary to set the communication destination and the protocol using Mode 46. 1. -

Page 77: Mode 26 Reprinting Test Results

6.2.7 Mode 26 Reprinting Test Results <Normal> This mode is used to output test results stored in the analyzer memory to the printer or the display in sequence beginning with the most recent data. A maximum of 100 samples are stored in memory and can be reprinted (displayed). 1. -

Page 78: Mode 27 Sample No. And Sample Id Settings

6.2.8 Mode 27 Sample No. and Sample ID Settings <Admin> This mode is used to change the settings for sample No. and sample ID. 1. Enter into Mode 27. 2. Select sample No. and/or sample ID printed along with test results. -

Page 79: Mode 28 Switching Display Method For Values Outside Of The Determination Range

6.2.9 Mode 28 Switching Display Method for Values outside of the Determination Range <Admin> This mode is used to switch the display method for results outside of the determination range for all tests. 1. Enter into Mode 28. 2. Select a display format. a. -

Page 80: Mode 29 Printing Out Slide Lot Number

6.2.10 Mode 29 Printing out Slide Lot Numbers <Normal> This mode is used to print out slide lot numbers recorded in the analyzer memory. 1. Enter into Mode 29. 2. Select a print format. Select [Each test] or [All tests] using and press ENTER. ENTER ENTER 3. -

Page 81: Mode 30 Work List Display Item Setting

6. To print out lot numbers for all tests at once: By selecting [All tests] followed by ENTER in the dialog of (2), all lot number information in the analyzer memory will be printed out. After the printout is complete, the analyzer quits the mode operation. -

Page 82: Mode 35 Editing Sample No. And Sample Id

6.2.12 Mode 35 Editing Sample No. and Sample ID <Admin.> This mode is used to edit sample No. and sample IDs memorized in the analyzer memory. The edited data can be sent to a host computer. 1. Enter into Mode 35. 2. - Page 83 5. Put new alphanumerical characters for the sample ID. Select a sample ID you want to edit. Input a new sample ID from the keyboard and press ENTER. 6. The edited result (the new sample ID) will be printed out. Check the result before editing [Old=xxxx] and after editing [New=xxxx] to make sure it is correct.

-

Page 84: Mode 36 Correlation Coefficients (A, B) Settings And Printout

6.2.13 Mode 36 Correlation Coefficients (a, b) Settings and Printout <Admin> This mode is used to input, reset or print out correlation coefficients (a, b) for each test and sample type (W, P/S, U). For further details, refer to the Description of the Correlation Function at the end of this section. IMPORTANT Incorrect inputs for (a, b) will cause incorrect test results. - Page 85 4. To input coefficients for each test: Select [Input for Each Test] from the menu and press ENTER. a. Select a sample type and input a test code. The default setting for the sample type is [P/S]. Input a test code and press ENTER.

- Page 86 d. After completing the inputs of (a, b), the old values, the input values, and the new values are printed out. IMPORTANT Incorrect inputs for (a, b) will cause incorrect test results. Make sure that the printed new values for (a, b) are correct. NOTE: If values for (a, b) have already been input, old values will not be canceled as follows.

- Page 87 c. Select [End] to terminate the mode. To reset coefficients for other tests, select [Next] followed by ENTER. ENTER ENTER 6. To reset coefficients for all tests: Select a menu using the keys and press ENTER. a. When selecting [Yes] (reset): The analyzer prints out that all coefficients have been reset and quits the mode operation.

- Page 88 1. It is possible to set separate a and b values for each sample type. 2. The correlation function is independent of other compensation functions. 3. If values for (a, b) have already been input, old values will not be canceled as follows. If the old values are represented as (a1, b1), and the new values as (a2, b2), the resulting values for (a, b) will be determined according to the following formulas: a = a1 x a2...

-

Page 89: Mode 37 Lot Compensation Coefficients (C, D, E) Settings And Printout

6.2.14 Mode 37 Lot Compensation Coefficients (c, d, e) Settings and Printout <Admin.> This mode is used to input, reset or print out the values (c, d, e) printed on the calibration cards included with slides. This mode is needed if it is not possible to read in the data directly from a calibration card due to loss or damage. IMPORTANT Incorrect inputs for (c, d, e) will cause incorrect test results. - Page 90 4. To input coefficients for each test: Select [Input for Each Test] from the menu and press ENTER. a. Select a sample type and input a test code. The default setting for the sample type is [P/S]. SAMPLE Input a test code and press ENTER. ENTER b.

- Page 91 g. Input the expiration date. Input year from the keyboard and press ENTER. NOTE: Input the last 2 digits for inputting the year. ENTER Input month from the keyboard and press ENTER. ENTER h. The new input data will be printed out. The new input coefficients for (c, d, e) and the expiration date will be printed out.

- Page 92 5. To reset coefficients for each test: Select [Reset for Each Test] from the menu and press ENTER. SAMPLE a. Select a sample type and input a test code. The default setting for the sample type is [P/S]. ENTER Input a test code and press ENTER. b.

-

Page 93: Mode 39 Reference Interval Settings And Printout

6.2.15 Mode 39 Reference Interval Settings and Printout <Admin.> This mode is used to input reference intervals for each reference interval name, for each sample type (W, P/S, U), and for each unit [Unit (A), Unit (B)] respectively. The reference intervals for DOG, CAT, HORSE and CONTROL have been set at the factory. - Page 94 c. Input a lower limit value. After the input, press ENTER. d. Input a upper limit value. After the input, press ENTER. e. The new data will be printed out. To input reference intervals for other tests, select [Next] followed by ENTER. Select [End} to terminate the mode.

-

Page 95: Mode 40 Setting Spotting Count

5. To print out reference intervals along with results: Select a menu using and press ENTER. After the selection has printed out, the analyzer quits the mode operation. 6.2.16 Mode 40 Setting Spotting Count <Admin.> The number of tests per one sample in automatic sampling can be changed within the range of 1 to 20. -

Page 96: Mode 42 Leak Check

6.2.17 Mode 42 Leak Check <Admin.> This mode is used to test sampler leakage. Prior to using the mode, prepare a sampler leak check tool (packed as an accessory). 1. Enter into Mode 42. MODE ENTER 2. Select sample tip [Sample Tip] or dilution tip [Dil Tip]. Select a menu using ... - Page 97 4. To check the dilution nozzle: Put a leak check tool into hole b on the sample rack. Close the sampler cover and press START. After the leak check is completed, the analyzer will print out the result and return to the tip selection dialog. START Replace the sampler O-ring (refer to Section 4.6.2), if an error occurs.

-

Page 98: Mode 44 Lamp Off Selection

6.2.18 Mode 44 Lamp off Selection <Admin.> This mode is used to select whether to turn off the light source lamp after the analyzer has not been used for 20 minutes in the "Ready" state. The default selection is to turn off the lamp after 20 minutes. NOTE: The average life of the lamp is about 1000 hours if the lamp is continuously on. -

Page 99: Mode 45 Dilution Factor Settings

6.2.19 Mode 45 Dilution Factor Settings <Admin.> This mode is used to set dilution factors for each test and for each sample type (P/S, U). When performing tests without setting a dilution factor using the DILUTION key, the analyzer performs tests according to the preset dilution factors in this mode. - Page 100 4. To input dilution factors: Select [Input] from the previous menu and press ENTER. ENTER SAMPLE a. Select a sample type and input a test code. The default setting for the sample type is [P/S]. ENTER Input a test code and press ENTER.

-

Page 101: Mode 46 Selecting Communication Destinations

5. To reset dilution factors: Select [Reset] from the previous menu in (3) and press ENTER. a. When selecting [Yes] (reset): The analyzer prints out that all dilution factors have been reset and quits the mode operation. ENTER ENTER b. When selecting [No] (not to reset): The analyzer quits the mode. - Page 102 1. Enter into Mode 46. MODE ENTER 2. Select a menu. Menu Setting for host computer: See 3. Communication parameter settings for COM1A and B: See 4. Setting for barcode reader: See 5. NOTE: Pressing can change the menu on the LCD. ENTER 3.

- Page 103 4. Communication parameter settings for COM1A and B: a. Select a baud rate. Select a baud rate ([19200], [9600] or [1200]) using and press ENTER. ENTER b. Set vertical parity. Select a menu ([None], [Odd], or [Even]) using and press ENTER.

-

Page 104: Mode 49 Printing Out Error Logs

5. Setting for barcode reader: Select a menu using whether to use a sample barcode reader or not, and press ENTER. After the new selection is printed out, the analyzer quits the mode operation. ENTER 6.2.21 Mode 49 Printing out Error Logs <Normal> This mode is used to display error logs stored in the analyzer’s memory. -

Page 105: Mode 52 Reference Plate Level Check

6.2.22 Mode 52 Reference Plate Level Check <Normal> This mode is used to check the quality level for the reference plate of the photometer. 1. Enter into Mode 52. MODE ENTER 2. Press ENTER. ENTER 3. The reference plate level check will start. 4. -

Page 106: Mode 55 Selecting Language

6.2.23 Mode 55 Selecting Language <Admin.> This mode is used to select a language for display and printout. 1. Enter into Mode 55. MODE ENTER 2. Select a language. Select a language using and press ENTER. Menu • [Japanese] •... -

Page 107: Mode 81 Alarm Sound Settings

ENTER ENTER 3. To print out for each test: NOTE: Make sure the sample type is correct. The default setting is [P/S]. SAMPLE Input a test code and press ENTER. ENTER 4. The DI card information is printed out. 5. Select [End] to terminate the mode. NOTE: To print information for other tests, select [Next] followed by ENTER. -

Page 108: Mode 82 Display Brightness And Print Density

3. To change error volume: When entered, the currently set volume will be heard. (When the setting [Off ] is set, the beep will not be heard.) By moving the shaded part (cursor) using the volume change is heard. Select the desired volume and press ENTER. The analyzer will terminate the mode. - Page 109 3. To adjust Display Brightness: Move the shaded part (cursor) using to change brightness. Select the desired brightness and press ENTER. After printing, the analyzer quits the mode operation. ENTER 4. To adjust print density: By moving the shaded part (cursor) using a test printout is made at the changed density.

-

Page 110: Mode 83 Test Result Print Sheet Setting

6.2.27 Mode 83 Test Result Print Sheet Setting <Admin.> This mode is used to set the number of result print sheets (selectable 1, 2, or 3). 1. Enter into Mode 83. MODE ENTER 2. Select the number of print sheets, using and press ENTER. -

Page 111: Mode 86 Editing And Inputting Reference Interal Names

3. Select a menu to change by scrolling or input a number of the menu directly. By selecting an order to be changed followed by ENTER in (2), the edit dialog for the order will appear. There are 2 ways to select a reference interval name to input: a. -

Page 112: Mode 103 Displaying Temperature And Humidity

3. Input a [Ref No.] to be edited. Input a number in 2 digits. NOTE: Available input numbers: 6 to 49 4. Type a name for the reference interval. After the input, press ENTER. The left is an example for inputting "COW" into No. [14]. NOTE: A maximum of 13 alphanumerical characters can be input. -

Page 113: Section 7: Data Communication

3. Set up the analyzer’s communication protocol using Mode 46 (Section 6.2.20). NOTE: When using this function for the first time, consult the computer software manual and contact Heska's Technical Support Services for assistance at 800.464.3752. CF card The slot for a CF card on the top of the analyzer is used for upgrading the software on the DRI-CHEM Analyzer. -

Page 114: Section 8: Specifications/Consumables

DRI-CHEM 4000 Section 8: Specifications/Consumables Veterinary Chemistry Analyzer Specifications Throughput: 60 tests/hour (CM) 77 tests/hour (simultaneous CM and ISE tests) Number of incubator cells: CM 6, ISE 1 Incubation temperature: 99°F (37°C) (CM) 86°F (30°C) or environmental temperature +2°C (ISE) -

Page 115: Standard Accessories

Specifications (cont'd) Electrical requirements Voltage limit: 100–240 V~ Frequency: 50–60 Hz Supply voltage fluctuations: ± 10% Rated wattage: 200 VA Phase: Single Type of protection against electrical shock: CLASS 1 EQUIPMENT Data transfer: RS-232C interface (1 port), USB interface (1 port) 16.3 (W) x 15.2 (D) x 11.4 (H) in External dimensions: 415 (W) x 385 (D) x 290 (H) mm... -

Page 116: Consumables And Optional Accessories

Consumables and Optional Accessories To purchase consumables or optional accessories listed below, please contact Heska at 800.464.3752. 8.2.1 Consumables Accessories Package *DRI-CHEM Analyzer Auto Tips 96 tips/box Sample Tubes *Heparin Tube 1.5 (1.5 ml containing Heparin Li) 500 tubes per box Heparin Tube 0.5 (0.5 ml containing Heparin Li) -

Page 117: Slide Code Table

Slide Code Table Test Slide Code Test Slide Code Test code Sample code Test code Sample code GLU-P Mg-P BUN-P GGT-P UA-P GOT/AST-P TCHO-P GPT/ALT-P NH 3 -P CPK-P TG-P CRE-P ALP-P TP-P vAMY-P ALB-P vLIP-P TBIL-P Ca-P IP-P... -

Page 118: Section 9: Glossary

For further assistance, please call Heska’s Technical Support Services at 800.464.3752, option 3. ©2018 Heska Corporation. All Rights Reserved. DRI-CHEM is a registered trademark of FUJIFILM Corporation. HESKA is a registered trademark of Heska Corporation in the U.S. and other countries.

Need help?

Do you have a question about the DRI-CHEM 4000 and is the answer not in the manual?

Questions and answers