Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Santint A4b

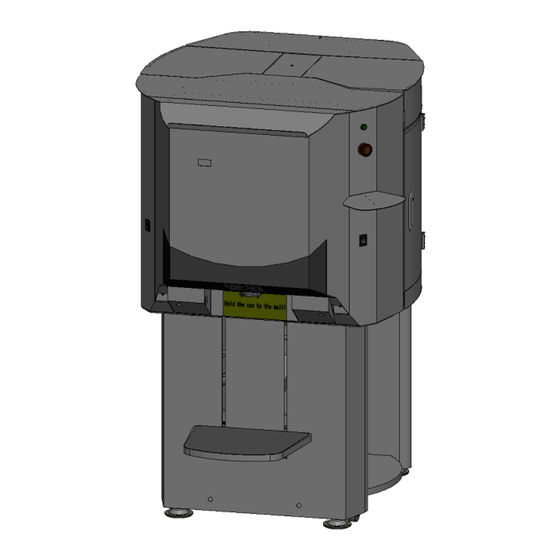

- Page 1 A4b Automatic Dispenser User Manual ISO 9001: 2008 Certified...

-

Page 2: Table Of Contents

Contents 1. Using Requirement…………………………………………………………………1 2. Specifications…………………………………………………………………………1 3. Safety Instructions……………………………………………………………………2 4. Machine Composition…………………………………………………………………3 5. Installation………………………………………………………………………………5 5.1 Machine…………………...…………………………………………………………………………5 5.2 Computer……………………………………………………………………………………………6 5.3 Software………………….…………………………………………………………………………7 6. Machine Adjustment…………………………………………………………………7 6.1 Software……………………………………………………………………………………………7 6.2 Machine……………………………………………………………………………………………10 6.3 Add Colorants……………………………………………………………………………………10 6.4 Purge………………………………………………………………………………………………11 6.5 Calibration……………………..……………………………………………………………………11 7. Operation………………………………………………………………………………12 7.1 Load Base Paint Can……………………..…………………………………………………………12 7.2 Change Water for Cleaning Box…………….……………………………………………………13 8. -

Page 3: Using Requirement

13) Do not operate the machine in case the machine shell is removed. 14) Computer composition: CPU PIII CD-ROM Driver 15 Inches Monitor, screen resolution is 1024X768 pixels or higher A4b Automatic Dispenser V1.0... -

Page 4: Specifications

7). If it is not used for a long time, the canisters should be cleaned and plugged off. 8). During first use, please discharge the fixing seats of the machine( as fig. 3.1, left one and right one) and keep the fixing seats for next transportation. Fixing Seat 色浆桶部件 A4b Automatic Dispenser V1.0... -

Page 5: Machine Composition

13). Take out the mouse seat and the two M5X12 inner hexagon screw. Put the Ф5 flat washer and spring washer on it. Then fix the mouse seat onto the machine. Mouse Seat Inner Hexagon Screw M5X12(with Ф5 flat washer and spring washer) 4. Machine Composition A4b Automatic Dispenser V1.0... - Page 6 Canisters Turntable Cleaning Parts Lifting Parts 色浆桶部件 色浆桶部件 Base Paint Can Tray Punch Assembly Turntable Drive Assembly 色浆桶部件 色浆桶部件 A4b Automatic Dispenser V1.0...

-

Page 7: Installation

Do not operate any appliance with a damaged cord or plug, or after the appliance malfunctions or is dropped or damaged in any manner. Contact the nearest authorized service facility for examination, repair, or electrical or mechanical adjustment. Do not lengthen the power line. A4b Automatic Dispenser V1.0... -

Page 8: Computer

Connect the power supply wire, data wire with the monitor, and connect the monitor with the A4b Automatic Dispenser V1.0... -

Page 9: Software

2. Open (double-click the icon) Color Expert 2.0 program; 3. Machine begins to initialize, and pop up the interface shown in 6.1.1. If there is abnormal sound coming from the machine, press emergency button and start troubleshooting. A4b Automatic Dispenser V1.0... -

Page 10: Machine

The left side of the machine is default side for adding the colorant. Open maintenance, choose the colorant code, click “add colorant” to add corresponding colorant (6.3.1), please ensure the colorant names in the software match the colorant of the canisters. Fig. 6.3.1 A4b Automatic Dispenser V1.0... -

Page 11: Purge

Stir for 30 minutes after adding colorants, to remove bubbles. When no continuous dispensing of colorants, please re-empty air or check if nozzle is blocked. In 4 hours, the machine can be calibrated again. A4b Automatic Dispenser V1.0... -

Page 12: Operation

Press down the lifting switch after finishing the dispensing. Release the lifting switch when the base can and the tray are lowered to a proper height. Repeat the foregoing procedures for other cans to continue the dispensing. A4b Automatic Dispenser V1.0... -

Page 13: Change Water For Cleaning Box

Clean box and add water. (Water level should be lower than wheel axis) Put the cleaning box back. Make sure it is in bottom position. Push down lock handle. Wheel Box Hanlde Lock Handle A4b Automatic Dispenser V1.0... -

Page 14: Maintenance

Change Outer Canister. Loose the fixing screws of the fixing plate. See 9.1. Remove the fixing plate. Loose the fixing screws of the canister. Rotate the canister clockwise to remove it from the turntable. Change Middle Canister. A4b Automatic Dispenser V1.0... - Page 15 Hold the rack and the caniste, pull them to take them out. Be careful not to outpour the colorants inside the canister. Change pipe cover Turn the handle away from the nozzle. Remove the old cover and install the new one. See 9.2. Fixing Pipe Plate Cover A4b Automatic Dispenser V1.0...

- Page 16 10. Circuit Board A4b Automatic Dispenser V1.0...

-

Page 17: Troubleshooting

Release emergency button LCD show “Emergency 2. Emergency button is broken or Change emergency button or connect Button Pressed” the wire is disconnected wire LCD show “Door Open” The door is not closed well Close the door A4b Automatic Dispenser V1.0... - Page 18 Vale motor driver is broken Change motor driving board Left valve sensor too far away Close sensor Left valve sensor is broken Change sensor Contact the supplier for other issue(s). Get the model and serial number of the machine prepared. A4b Automatic Dispenser V1.0...

- Page 19 ZHENGZHOU SANHUA TECHNOLOGY & INDUSTRY CO., LTD. ADD: Feilong Road, Xingyang City, Henan 450121 P.R. China TEL:(86) 371-67857168 After-Service:(86) 371-67857219 FAX:(86) 371-67857166 WEB:http://www.santint.com E-mail:info@santint.com A4b Automatic Dispenser V1.0...

Need help?

Do you have a question about the A4b and is the answer not in the manual?

Questions and answers