Table of Contents

Advertisement

OPERATOR'S

MANUAL

Baron / 2400 / RD Series

16HP Hydro Tractors

Mfg. No.

Description

1694315

Baron, 16HP Hydro (CE)

1694329

Baron, 16HP Hydro (CE)

1694346

2416H, 16HP Hydro (CE)

17HP Hydro Tractors

Mfg. No.

Description

1694482

Baron, 17HP Hydro (CE)

1694485

2417H, 17HP Hydro (CE)

1694505

RD1740, 17HP Hydro (CE)

18HP Hydro Tractors

Mfg. No.

Description

1694328

Baron, 18HP Hydro (CE)

1694347

2418H, 18HP Hydro (CE)

1694375

Rapid 2003, 18HP Hydro (CE)

1694384

RD1840, 18HP Hydro (CE)

20HP Hydro Tractors

Mfg. No.

Description

1694481

Baron, 20HP Hydro (CE)

1694483

2420H, 20HP Hydro (CE)

1694484

RD2040, 20HP Hydro (CE)

40" Mower Decks

Mfg. No.

Description

1694331

40" Mower Deck (CE)

1694338

40" Mower Deck (CE)

1694385

40" Mower Deck (CE)

TP 100-3765-06-BR-SMN

1724585-06

Rev 9/2003

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Simplicity RT Series

- Page 1 OPERATOR’S MANUAL Baron / 2400 / RD Series 16HP Hydro Tractors Mfg. No. Description 1694315 Baron, 16HP Hydro (CE) 1694329 Baron, 16HP Hydro (CE) 1694346 2416H, 16HP Hydro (CE) 17HP Hydro Tractors Mfg. No. Description 1694482 Baron, 17HP Hydro (CE) 1694485 2417H, 17HP Hydro (CE) 1694505...

-

Page 2: Table Of Contents

Safety Rules & Information...2 Identification Numbers...5 Safety Decals ...6 Safety Icons ...7 Safety Interlock System ...7 Features & Controls ...8 Control Functions ...8 Operating the Tractor ...10 General Operating Safety ...10 Adding Fuel ...10 Starting the Engine ...10 Stopping the Tractor & Engine ...11 Driving the Tractor ...11 Mowing...11 Pushing the Tractor by Hand ...11... -

Page 3: General Operation

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment. This mowing deck is capable of amputating hands and feet and throwing objects. The triangle in text signifies important cautions or warnings which must be followed. -

Page 4: Safety Rules And Information

SLOPE OPERATION Slopes are a major factor related to loss-of-control and tip- over accidents, which can result in severe injury or death. Operation on all slopes requires extra caution. If you can- not back up the slope or if you feel uneasy on it, do not operate on it. -

Page 5: Service And Maintenance

Safety Rules & Information SERVICE AND MAINTENANCE Safe Handling of Gasoline 1. Extinguish all cigarettes, cigars, pipes, and other sources of ignition. 2. Use only approved gasoline containers. 3. Never remove the gas cap or add fuel with the engine running. -

Page 6: Identification Numbers

J. Sound Pressure at Operator’s Position in Decibels ** K. Vibration at the Steering Wheel * L. Vibration at the Seat * This unit complies with European Harmonized Lawn Mower Standard EN 836, European Machinery Directive 98/37/EC, and European EMC Directive 89/336/EC... -

Page 7: Safety Decals

Safety Decals SAFETY DECALS This unit has been designed and manufactured to pro- vide you with the safety and reliability you would expect from an industry leader in outdoor power equipment manufacturing. Although reading this manual and the safety instructions it contains will provide you with the necessary basic knowledge to operate this equipment safely and effec- tively, we have placed several safety labels on the unit to... -

Page 8: Safety Icons

SAFETY ICONS Warning: Read Operator’s Manual. Read and understand the Operator’s Manual before using this machine. Warning: Remove Key Before Servicing. Remove the key and consult techni- cal literature before performing repairs or maintenance. Danger: Dismemberment. This machine can amputate limbs. Keep bystanders and children away when engine is running. -

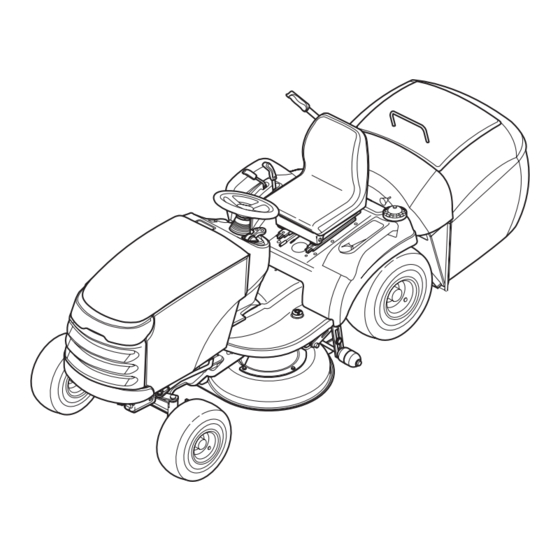

Page 9: Features & Controls

Features & Controls Figure 1. Tractor and Mower Controls NOTE: Steering wheel removed for clarity Please take a moment and familiarize yourself with the name, location, and function of these controls so that you will better understand the safety and operating instructions pro- vided in this manual. - Page 10 PTO Switch The PTO (Power Take-Off) switch engages and disen- gages attachments that use the PTO. To engage the PTO, pull UP on the switch. Push DOWN to disengage. Note that the operator must be seated firmly in the trac- tor seat for the PTO to function.

-

Page 11: Operating The Tractor

Features & Controls Catcher Open/Close Lever The catcher open/close lever opens the catcher so that it may be emptied and closes it for mowing. To empty the catcher, depress the catcher dump lock pedal and pull forward on the handle. To close, push the lever back- ward until the catcher closes and locks. -

Page 12: Stopping The Tractor & Engine

STOPPING THE TRACTOR & ENGINE 1. Return the ground speed control(s) to neutral. 2. Disengage the PTO and wait for all moving parts to stop. 3. Place the throttle control in the position specified in the engine owner’s manual provided in the operator's packet shipped with your tractor. -

Page 13: Parking Brake Functions

Operating the Tractor Figure 3. Engaging the Parking Brake A. Ground Speed Pedals B. Brake Pedal C. Parking Brake Knob PARKING BRAKE FUNCTION Applying the Parking Brake - See Figure 3. To lock the parking brake, release the ground speed pedals (A), fully depress the brake pedal (B), pull UP on the parking brake knob (C), and then release brake pedal. -

Page 14: Attaching A Trailer

5. Reinstall the mower deck. 6. Install the back plate (A, Figure 7) and secure with clevis pins and hair pin clips (B). ATTACHING A TRAILER NOTE: Remove the hopper to attach a trailer. The maximum horizontal drawbar force allowed is 444 Newton. -

Page 15: Mower Deck Removal & Installation

Operating the Tractor Figure 9. Raising & Lowering Mower A. Attachment Lift C. Hopper Lever B. Cutting Height Control WARNING Engage parking brake, disengage PTO, stop engine and remove key before attempting to install or remove the mower. MOWER DECK REMOVAL & INSTALLATION Removing the Mower Deck 1. -

Page 16: Installing The Mower Deck

Installing the Mower Deck 1. Park tractor, shut off PTO and engine, remove the key and apply parking brake. Turn the wheels fully to the left. 2. Place mower height adjuster (B, Figure 9) in the low- est cutting position. Place the mower lift lever (A) in the lowest position. -

Page 17: Regular Maintenance

Regular Maintenance MAINTENANCE SCHEDULE & PROCEDURES The following schedule should be followed for normal care of your tractor and mower. Use the hour meter to deter- mine your operating time. SAFETY ITEMS Check Safety Interlock System Check Tractor Brakes Check Mower Blade Stopping Time TRACTOR MAINTENANCE ITEMS Check Tractor/Mower for loose hardware Check / Clean Cooling Fins... -

Page 18: Check Tire Pressures

CHECK TIRE PRESSURES Service Interval: Every 25 Hours Tire Pressure should be checked periodically, and main- tained at the levels shown in the chart. Note that these pressures may differ slightly from the “Max Inflation” stamped on the side-wall of the tires. The pressures shown provide proper traction, improve cut quality, and extend tire life. -

Page 19: Lubrication

Regular Maintenance LUBRICATION Service Interval: Every 25 Hours Lubricate the unit at the locations shown in Figures 17- 20 as well as the lubrication points listed. Generally, all moving metal parts should be oiled where contact is made with other parts. Keep oil and grease off belts and pulleys. -

Page 20: Lubricate Rear Axle Shafts

LUBRICATE REAR AXLE SHAFTS Service Interval: Yearly We recommend removing the rear wheel hubs and lubri- cating the axle shafts yearly. This prevents the wheel hubs from seizing onto the axle shaft and makes future service easier. 1. Turn off the ignition, turn off the PTO, engage the parking brake, and block the front tires. -

Page 21: Servicing The Mower Blades

Regular Maintenance 4x4 Wood Block Figure 22. Removing the Blade SERVICING THE MOWER BLADES WARNING For your personal safety, do not handle the sharp mower blades with bare hands. Careless or improper handling of blades may result in serious injury. Service Interval: Every 100 Hours or As Required NOTE: Replace blades and bolts in sets. -

Page 22: Set Mower Belt Tension

SET MOWER BELT TENSION WARNING For your personal safety, do not handle the sharp mower blades with bare hands. Careless or improper handling of blades may result in serious injury. Service Interval: Yearly 1. Turn the PTO to the off position, engage the parking brake, turn the engine off, and remove the key. -

Page 23: Troubleshooting, Adjustments, & Service

Troubleshooting, Adjustments, & Service TROUBLESHOOTING While normal care and regular maintenance will extend the life of your equipment, prolonged or constant use may eventually require that service be performed to allow it to continue operating properly. The troubleshooting guide below lists the most common problems, their causes and remedies. -

Page 24: Troubleshooting The Mower

Tractor Troubleshooting Continued Tractor drive belt slips. Brake will not hold. Tractor steers hard or handles poorly. TROUBLESHOOTING THE MOWER PROBLEM Mower will not raise. Mower cut is uneven. Mower cut is rough looking. Engine stalls easily with mower engaged. Excessive mower vibration. -

Page 25: Seat Adjustment

Troubleshooting, Adjustment, & Service SEAT ADJUSTMENT Pitch Adjustment The pitch of the seat can be adjusted to one of three positions. To adjust, remove the carriage bolts, spacers, washers, and nuts (B, Figure 26) from the hinge and reinstall them in the desired holes. Seat Slide Adjustment The seat can also be adjusted forward and back. -

Page 26: Steering Gear Adjustment

STEERING GEAR ADJUSTMENT If there is excessive slack in the steering system, the steering gear backlash can be removed. 1. See Figure 28. Locate the steering gear assembly on the underside of the tractor. Loosen the two nuts and adjust the bracket so the gear teeth are closely meshed. -

Page 27: Catcher-Full Alarm Adjustment

Troubleshooting, Adjustment, & Service CATCHER-FULL ALARM ADJUSTMENT To adjust the “catcher full” alarm, slide the sensor plate (A, Figure 30) forward or backward on the sensor rod. If the chute is plugging, slide the plate backwards to increase sensitivity. If the alarm is going on before the hopper is full, slide the plate forwards to decrease sensi- tivity. -

Page 28: Pto Clutch Adjustment

PTO CLUTCH ADJUSTMENT WARNING To avoid serious injury, perform adjustments only with engine stopped, key removed and tractor on level ground. Check the PTO clutch adjustment after the initial 25 hour break-in period and then after every 250 hours of opera- tion. -

Page 29: Transmission Purging

Troubleshooting, Adjustment, & Service TRANSMISSION PURGING Purge the transmission if the unit is excessively noisy or lacks drive in forward or reverse. 1. Elevate the rear end of the tractor using a chain hoist or floor jack. Support the rear of the unit using jack- stands. -

Page 30: Mower Adjustments

MOWER ADJUSTMENTS WARNING Before checking mower, shut off PTO and engine, remove the key, and allow all moving parts to stop. Cutting Height Adjustment The cutting height adjustment lever (A, Figure 35) con- trols the mower cutting height. Push the button to release the lever. -

Page 31: Pto Belt Replacement

Troubleshooting, Adjustment, & Service PTO BELT REPLACEMENT 1. With the mower deck installed, park the tractor on a smooth, level surface such as a concrete floor. Disengage the PTO, engage the parking brake, shut the engine off, and remove the key. 2. -

Page 32: Specifications

NOTE: Specifications are correct at time of printing and are subject to change without notice. * Actual sustained equipment horsepower will likely be lower due to operating limitations and environmental factors. ENGINE: 16 HP* Briggs & Stratton Make Briggs & Stratton Model Intek 31F777 Horsepower... -

Page 33: Parts & Accessories

Parts & Accessories REPLACEMENT PARTS Replacement parts are available from your authorized dealer. Always use genuine Simplicity Service Parts. MAINTENANCE ITEMS Many convenient and helpful service and maintenance items are available from you authorized dealer. Some of these items include: Engine Oil Tire Sealant Touch-Up Paint... - Page 34 M A N U F A C T U R I N G , I N C . 500 N Spring Street / PO Box 997 Port Washington, WI 53074-0997 www.simplicitymfg.com © Copyright 2003 Simplicity Manufacturing, Inc. All Rights Reserved. Printed in USA.

Need help?

Do you have a question about the RT Series and is the answer not in the manual?

Questions and answers