Table of Contents

Advertisement

Quick Links

N

MODEL

DRIVE SYSTEM TYPE

MOWER ORIENTATION

LARGE FRAME MODEL

N - Model Designation

Z - Zero Turning - Hydro Drive 30.0 - Engine Power

M - Mid Mount Mower

Thank you for buying a SNAPPER Product! Before operating your machine, read this manual carefully and pay

particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 - 4. Remember that all power equip-

ment can be dangerous if used improperly. Also keep in mind that SAFETY requires careful use in accordance

with the operating instructions and common sense!

NOTE: Specifications are correct at time of printing and are subject to change without notice.

* Actual sustained engine power will likely be lower due to operating limitations and environmental factors.

COPYRIGHT © 2006

SNAPPER - A DIVISION OF SIMPLICITY MFG., INC.

ALL RIGHTS RESERVED

Safety Instructions & Operator's Manual for

Safety Instructions & Operator's Manual for

MODEL NUMBER EXPLANATION

Z

M

X - Large Frame

32.0 - Engine Power

MID-MOUNT Z-RIDER

ZERO TURNING

X

32

73

61 - 61" Mower Width

73 - 73" Mower Width

4 - Series Designation

MANUAL No. 7100718 (Rev. 1, 7/20/2006)

LARGE FRAME

HYDRO DRIVE

SERIES 4

MODELS

NZMX30614KH

NZMX32734BV

4

BV

SERIES DESIGNATION

MOWER DECK SIZE

ENGINE POWER *

B - Briggs Engine

KH - Kohler Engine

V - Over Head Valve

TP 100-5176-R1-HZ-N

ENGINE TYPE

Advertisement

Table of Contents

Summary of Contents for Snapper NZMX30614KH, NZMX32734BV

- Page 1 M - Mid Mount Mower 32.0 - Engine Power Thank you for buying a SNAPPER Product! Before operating your machine, read this manual carefully and pay particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 - 4. Remember that all power equip- ment can be dangerous if used improperly.

-

Page 2: Important Safety Instructions

If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). -

Page 3: Safe Handling Of Gasoline

7. Evaluate the terrain to determine what accessories and attachments are needed to properly and safely perform the job. Only use accessories and attach- ments approved by SNAPPER. 8. Keep people and pets out of mowing area. Immediately, STOP blades, STOP engine, and STOP machine if anyone enters the area. - Page 4 14. Carefully release pressure from components with stored energy. 15. Have machine serviced by an authorized SNAPPER dealer at least once a year and have the dealer install any new safety devices. Never allow untrained personnel to service machine.

-

Page 5: Table Of Contents

IMPORTANT SAFETY INSTRUCTIONS ....2-4 TABLE OF CONTENTS ......5 STATEMENT OF USAGE . -

Page 6: Section 1 - Familiarization

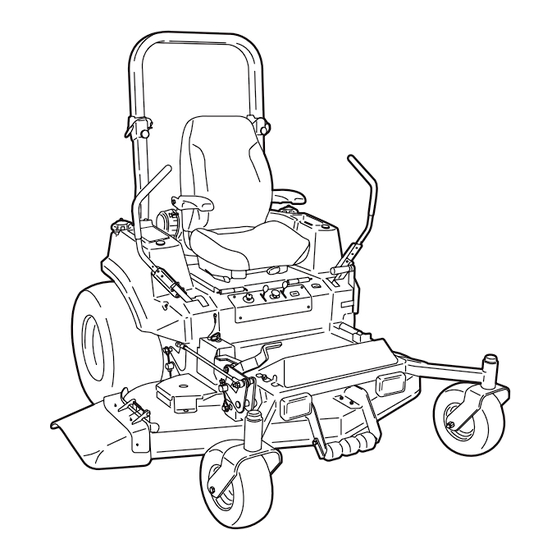

FIGURE 1.1 1.2 NOMENCLATURE The nomenclature information above, Figure 1.1, shows the essential parts of the SNAPPER MID MOUNT Z-RIDER. It is recommended that all operators of this equipment become thoroughly familiar with the controls, components, and operation of this machine before operating. Specific details involving the engine are found in the separate engine owner’s manual. -

Page 7: Section 2 - Safety Messages And Symbols

Section 2 - SAFETY MESSAGES AND SYMBOLS DANGER ! ROTATING PARTS KEEP AWAY FROM MOVING PARTS MOTION CONTROL LEVER OPERATION PARKING BRAKE LEVER OPERATION WEAR HEARING PROTECTION WARNING ! AVOID SERIOUS INJURY OR DEATH STARTING, OPERATION & STOPPING OF MACHINE... - Page 8 Section 2 - SAFETY MESSAGES AND SYMBOLS CONTROL PANEL IDENTIFICATION DANGER! ROTATING BLADES KEEP CHILDREN AND OTHERS OUT OF MOWING AREA FUEL TANK SELECT START STOP FUEL GAUGE (2) IGNITION SWITCH...

-

Page 9: Section 2 –Safety Messages And Symbols

Section 2 - SAFETY MESSAGES AND SYMBOLS CAUTION! SPRING LOADED MECHANISM ROLL BAR PROTECTIVE STRUCTURE DECALS WARNING Cutting Hazard Fans rotate while engine is running. Keep away while engine is running. ATTENCION Peligro de corte Los ventiladores giran mientras el motor esta funcionando. -

Page 10: Section 3 - Operating Instructions

Section 3 - OPERATING INSTRUCTIONS Section 3 - OPERATING INSTRUCTIONS 3.1 PRE-START CHECK LIST Make the following checks and perform the service required before each start-up. 3.1.1. Check tires and add or release air as needed to bring pressure to 12 psi in drive tires. Pressure in front caster wheels should be 25 psi. -

Page 11: Starting & Stopping Engine, Blades & Parking Brake

Section 3 - OPERATING INSTRUCTIONS Section 3 - OPERATING INSTRUCTIONS ROLL RELEASE: To roll the machine without the engine running, pressure within the hydraulic pumps must be released. There is a hydraulic pressure relief valve on the upper side of each pump that is used to release the pressure. -

Page 12: Stopping Engine

7 seconds, the electric clutch should be checked. Adjustment or replace- ment of electric clutch may be necessary. Return the machine to an authorized Snapper dealer for replacement. DO NOT CONTINUE to operate mower if blades fail to stop in 7 seconds. -

Page 13: Cutting Height Adjustment

Section 3 - OPERATING INSTRUCTIONS 3.3 CUTTING HEIGHT ADJUSTMENT 1. Depress deck lift pedal fully to lock deck in trans- port position. See Figure 3.9. 2. Insert stop pin to desired cutting height. See Figure 3.10. 3. Depress deck lift pedal while flipping back transport lever, and slowly release pedal to lower deck. -

Page 14: Stopping Machine

NEUTRAL LOCK ing interlock system checks during the operating season. POSITION Contact your authorized Snapper dealer if you have ques- tions. DO NOT operate machine if any safety interlock or safety device is not in place and functioning properly. DO NOT attempt to defeat, modify or remove any safety device. -

Page 15: Section 4 - Maintenance

Section 3 - OPERATING INSTRUCTIONS Section 4 - MAINTENANCE 4.1 INTRODUCTION To retain the quality of the SNAPPER mower, use gen- uine SNAPPER replacement parts only. Contact a local SNAPPER dealer for parts and service assis- tance. For the correct part or information for a particu- lar SNAPPER mower, always mention the model and serial number. -

Page 16: Check Mower Drive Belt

Section 3 - OPERATING INSTRUCTIONS Section 4 - MAINTENANCE 4.2.3. CHECK MOWER DRIVE BELT 1. Lower deck to lowest setting. 2. Remove footrest. See Figure 4.3. 3. Removal of footrest will allow access to deck belt. 4. Check the belt tension. springs provide proper tension and require no adjust- ments. -

Page 17: Front Wheel Bearings Lubrication

Section 3 - OPERATING INSTRUCTIONS Section 4 - MAINTENANCE 4.3.3. RIDING MOWER - LUBRICATION 1. Front Wheel Bearings Lubricate with Kendall NLGI No. 2 lithium grease or equivalent, from a grease gun. See Figure 4.5. FIGURE 4.5 2. Hydro Pumps Check the level of the fluid in both of the fluid reser- voirs. -

Page 18: Fuel Filter Replacement

Section 3 - OPERATING INSTRUCTIONS Section 4 - MAINTENANCE WARNING Allow engine to cool for at least ten minutes before performing service or maintenance. DO NOT smoke near fuel components when performing service or maintenance. DO NOT perform service and mainte- nance near an open flame. -

Page 19: Deck Removal

After the first change, the recommended interval is every 500 hours. Replace both with approved filters only (Snapper P/N 1719168). Install following instruc- tions provided with the filter. Add SAE 20W50 oil to bring the level in the reservoirs to 1-½" below top of filler neck. -

Page 20: Section 5 - Adjustments & Repair

Section 3 - OPERATING INSTRUCTIONS Section 5 - ADJUSTMENTS & REPAIR WARNING Exercise EXTREME CAUTION when making this adjustment, due to close proximity of moving parts. 5.1 NEUTRAL POSITION ADJUSTMENTS The motion control levers control the movement and stopping of the machine. Move the control levers to the center or neutral position to stop machine. -

Page 21: Mower Deck Adjustment (Levelness)

Section 3 - OPERATING INSTRUCTIONS Section 5 - ADJUSTMENTS & REPAIR 5.1 NEUTRAL POSITION ADJUSTMENTS (Continued From Previous Page) 12. With motion control levers remaining in the neutral lock position, See Figure 3.7, hold connecting rod up to the activation assembly and check length of rod. Tie rod end bolt must align with the activation assembly. -

Page 22: Parking Brake Adjustment

The parking brake can be adjusted by rotating hex nut clockwise to increase brake tension. If this adjustment does not result in proper braking action contact your authorized SNAPPER dealer for corrective action. See Figure 5.8. 1. Disengage parking brake. Measure the relaxed length of the brake spring. -

Page 23: Traction Belt Tension & Replacement

Section 3 - OPERATING INSTRUCTIONS Section 5 - ADJUSTMENTS & REPAIR WARNING DO NOT attempt any maintenance, adjustments or service with engine running. STOP engine. STOP blades. Set brake. Remove key. Remove spark plug wires and secure away from spark plugs. Engine and components are HOT. -

Page 24: Tracking Adjustment

Section 5 - ADJUSTMENTS & REPAIR Section 3 - OPERATING INSTRUCTIONS 5.6 TRACKING ADJUSTMENT If the machine does not track straight when the Motion Control Levers are in the maximum forward speed position, perform the following adjustment. Rear tire pressure must be set to 12 PSI before making this adjustment. -

Page 25: Engine Adjustments & Repair

Section 5 - ADJUSTMENTS & REPAIR Section 3 - OPERATING INSTRUCTIONS 5.8 ENGINE ADJUSTMENTS & REPAIR Refer to the engine owner's manual for engine adjust- ments and/or repairs. 5.9 MOWER BLADE REPLACEMENT 5.9.1. BLADE WEAR LIMITS 1. Inspect blade frequently for signs of excessive wear or damage. -

Page 26: Battery Removal

Section 5 - ADJUSTMENTS & REPAIR Section 3 - OPERATING INSTRUCTIONS WARNING Shield the positive terminal with terminal cover locat- ed on battery harness. This prevents metal from touching the positive terminal, which could cause sparks. Cables must be connected to battery terminals in the proper position. -

Page 27: Battery Testing

Section 5 - ADJUSTMENTS & REPAIR Section 3 - OPERATING INSTRUCTIONS 5.10.4. BATTERY TESTING 1. Remove battery. Refer to Section "BATTERY REMOVAL". 2. Using a voltmeter, check the battery's state of charge by comparing the voltmeter reading with the chart below. (Remember to hook the positive (red) lead of the voltmeter to the battery's positive terminal, and the negative lead to the negative terminal.) Battery Condition Chart... -

Page 28: Hydraulic System, Purging

Section 3 - OPERATING INSTRUCTIONS Section 5 - ADJUSTMENTS & REPAIR 5.11 HYDRAULIC SYSTEM, PURGING After replacing or repairing hydraulic system compo- nents, one or both of the wheel drives may not pull properly. This is likely to be caused by air entrapped in the system. -

Page 29: Troubleshooting

1. Service battery. 2. Replace fuse. 3. Clean and check connections for good contact. 4. Contact authorized SNAPPER dealer. 1. Move blade engagement switch to "OFF". 2. Set park brake and Operator in Operator Seat. 3. Place Motion Controls in Neutral Lock Position. - Page 30 5. Replace traction drive belts. 1. Move blade switch to the "ON" position. 2. Replace clutch belt. 3. Replace mower belt. 4. Contact authorized SNAPPER dealer. 1. Bring to proper pressure. 2. Adjust cutting height. 3. Move throttle control to "FAST" position.

-

Page 31: Service Schedule

SERVICE SCHEDULE Section 3 - OPERATING INSTRUCTIONS ITEM SERVICE PERFORMED Engine Oil Check Oil Level Initial Oil Change Periodic Oil Change Air Cleaner Clean or Replace Spark Plug Replace Fuel Filter Replace Engine Cooling Clean Shroud & Fins System Battery Charge Battery Testing Battery Tires... -

Page 32: Year Limited Warranty

For ninety (90) days from purchase date for the original purchaser's rental use, SNAPPER, through any authorized SNAPPER dealer will replace, free of charge (except for taxes where applicable), any part or parts found upon exami- nation by the factory at McDonough, Georgia, to be defective in material or workmanship or both All transportation costs incurred by the purchaser in submitting material to an authorized SNAPPER dealer for replace- ment under this warranty must be paid by the purchaser. -

Page 33: Primary Maintenance

PRIMARY MAINTENANCE... - Page 34 PRIMARY MAINTENANCE...

- Page 35 PRIMARY MAINTENANCE...

-

Page 36: Primary Maintenance

PRIMARY MAINTENANCE... -

Page 37: Product Registration Form

Date of Purchase_______________________________________________________ Retailer ______________________________________________________________ Retailer's Phone Number _______________________________________________ It is very important that you register your purchase with Snapper to ensure war- ranty coverage. Please mail your product registration card to: Snapper at P.O. Box 1379, McDonough, Georgia 30253. - Page 38 NOTES...

- Page 39 NOTES...

- Page 40 HYDRO DRIVE SERIES 4 Snapper products are built using engines that meet or exceed all applicable emissions requirements on the date manufactured. The labels on those engines contain very important emissions information and critical safety warnings. Read, Understand, and Follow all warnings and instructions in this manual, the engine manual, and on the machine, engine and attachments.

Need help?

Do you have a question about the NZMX30614KH, NZMX32734BV and is the answer not in the manual?

Questions and answers