Table of Contents

Advertisement

Quick Links

Full Floor Aeration System (with

Welded Supports)

14' & 19' STANDARD CORR BINS

FULL FLOOR AERATION SYSTEM

14' & 19' Standard Corr Grain Bins

(WITH WELDED SUPPORTS)

Installation and Storage Instructions

INSTALLATION & STORAGE INSTRUCTIONS

Original Instructions

READ INSTRUCTIONS CAREFULLY AND COMPLETELY

BEFORE BEGINNING AERATION FLOOR ASSEMBLY

Read this manual before using product. Failure to

follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

EFFECTIVE DATE: June, 2015

Part Number: 198930

Revision 2

Part Number: 198930 R4

Revised: Nov. 2018

Advertisement

Table of Contents

Summary of Contents for Westeel Full Floor Aeration System

- Page 1 Full Floor Aeration System (with Part Number: 198930 Revision 2 Welded Supports) 14' & 19' STANDARD CORR BINS FULL FLOOR AERATION SYSTEM 14’ & 19’ Standard Corr Grain Bins (WITH WELDED SUPPORTS) Installation and Storage Instructions INSTALLATION & STORAGE INSTRUCTIONS...

- Page 2 New in this Manual The following changes have been made in this revision of the manual: Description Section Updated Safety Decal Locations 2.6. Safety Decal Locations and Details on page 7...

-

Page 3: Table Of Contents

FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS CONTENTS 1. Introduction ............................4 2. Safety............................... 5 2.1. Safety Alert Symbol and Signal Words..................5 2.2. General Product Safety ......................5 2.3. Personal Protective Equipment....................5 2.4. -

Page 4: Introduction

CORR GRAIN BINS 1. Introduction This manual describes how to assemble a Westeel Full Floor Aeration System (with Welded Supports). Before assembling the full floor aeration system, please read this manual. Familiarize yourself with the process and the necessary precautions for efficient and safe assembly. -

Page 5: Safety

2.2. General Product Safety YOU are responsible for the SAFE use and maintenance of your full floor aeration system. YOU must ensure that you and anyone else who is going to work around the full floor aeration system understands all procedures and related SAFETY information contained in this manual. -

Page 6: Safety Decals

2. SAFETY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS Safety Glasses • Wear safety glasses at all times to protect eyes from debris. Coveralls • Wear coveralls to protect skin. Hard Hat •... -

Page 7: Safety Decal Locations And Details

2.6. Safety Decal Locations and Details Replicas of the safety decals that are attached to the full floor aeration system and their messages are shown in the figure(s) that follow. Safe operation and use of the full floor aeration system requires that you familiarize yourself with the various safety decals and the areas or particular functions that the decals apply to, as well as the safety precautions that must be taken to avoid serious injury, death, or damage. - Page 8 2. SAFETY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS WARNING WARNING SAFETY INSTRUCTIONS ENTRAPMENT HAZARD • Read operator’s manual and all safety decals Never enter the bin when loading or before assembling, using, or servicing bin.

- Page 9 2. SAFETY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS NOTICE WARNING When equipped with aeration system, to prevent roof and/or bin damage: • Consult dealer to install adequate roof venting. • Ensure all roof vents are open and unobstructed.

-

Page 10: Before You Begin

43,500 lbs. per sq. in. (300 MPa) re-bar. The foundation designs included in this manual are suggestions only, and will vary according to local soil conditions. Westeel will not assume any liability for results arising from their use. -

Page 11: Methods Of Installation

5. Comply with all assembly instructions provided in the appropriate assembly manual to make sure your whole full floor aeration system is constructed safely. Important: Do not deviate from the wall sheet and upright layouts provided. -

Page 12: Product Storage

3. BEFORE YOU BEGIN FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS 9. If installing an existing bin on a hopper, make sure the bin is designed for a hopper application, and that the foundation is capable of withstanding the substantial point loads that the hopper legs apply. -

Page 13: Grain Bin Use

• Never enter a loaded grain bin for any reason. Grain can be a killer. 3.8. Important Notes • Westeel does not provide a foundation design for this product, and is not liable for any damages or injuries related to inadequately designed or constructed foundations. Customers must contract professional services for all foundation design and construction work. - Page 14 3. BEFORE YOU BEGIN FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS • Contact local power officials for minimum power line clearance. • See Section 3.5. – Critical Assembly Requirements on page 11 for mandatory siting and assembly requirements.

-

Page 15: Preparation

4. PREPARATION FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS 4. Preparation 4.1. Check Shipment Unload the parts at the assembly site and compare the packing slip to the shipment. Ensure that all items have arrived and that none are damaged. -

Page 16: Assembly

Always use the proper tools, rated lifting equipment, and lifting points for the job. • Carry out assembly in a large open area with a level surface. • Always have two or more people assembling the full floor aeration system. • Make sure you have sufficient lighting for the work area. -

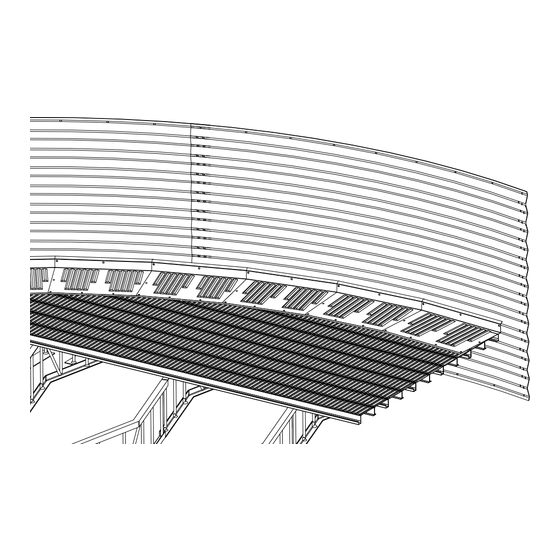

Page 17: Planning The Floor Layout

FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS 5.2. Planning the Floor Layout Westeel aeration bins are built on aeration floors consisting of floor planks on top of supports. This section describes how floor planks are laid out and supported. - Page 18 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS Planning the Locations of Fans and Auger Unload Tubes Take care to ensure that the results of an installation meet the customer’s expectations. A few basic considerations follow: 1.

- Page 19 60º apart, and the auger discharge hole sh 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS the midpoint between the fans. Figure 3. Recommended Locations for Fan and Auger Unload Tube RECOMMENDED FAN LOCATION 30°...

- Page 20 Both the floor 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD plank layouts and the floor support layouts are required to properly assemble a floor for any given bin diameter and CORR GRAIN BINS tier height.

- Page 21 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS slightly to better support the angled cut ends. However this angle cannot be too great as all three legs on the floor planks must be supported.

- Page 22 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CUT DETAIL OF FIRST AND LAST PLANK CORR GRAIN BINS NOTE ORIENTATION OF THE PLANK WITH RESPECT TO THE VISIBLE LEG, AND THE LEG HIDDEN UNDERNEATH...

- Page 23 PLANKS OF THE FINISHING SIDE OF BIN 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS Flashing: VISIBLE LEG IMPORTANT: ONLY CUT THOSE PLANKS WITH A "C" IN Flashings cover the gap between the floor planks and the bin wall. The overlap on mating flashings should be THE DESCRIPTION.

-

Page 24: Floor Assembly Procedure

Generally the floor planks run perpendicular to the unloading tube and span over the tube. For smaller bins with 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD larger support spacing's (S ≥ 24”), the required “S” spacing will accommodate the clearance required to span the CORR GRAIN BINS unload tube. - Page 25 2. There should be a support within the “O” dimension from every end of a plank…be it against 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS the wall, where the split planks come together, or where planks are cut to accommodate the unloading wells.

- Page 26 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS d. This method of positioning the supports relative to the chalk lines would remain consistent for all other a) FOR SUPPORT SPACINGS “S” ≥ 24” - Place the first row of floor supports as illustrated, on the chalk supports (i.e.

- Page 27 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS wall. For angled cut planks it would be beneficial to angle the supports to provide maximum support to the plank legs. Figure 11. For S Spacing Equal to or Greater than 24"...

- Page 28 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS Note The first few rows can be confusing as the bin wall will interfere with the establishment of a consistent support grid pattern that runs in two directions. However once the first few rows of supports are positioned a support grid of rows and columns should be established.

- Page 29 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS Figure 14. Overlapping V-Supports If "V" supports are placed end to end, do not allow plank legs to sit directly on the location where two supports meet, as shown below.

- Page 30 15) After the center of the bin is reached successive planks will get shorter but the rules remain. Continue adding 5. ASSEMBLY FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD supports along the chalk lines to provide continuous rows of support across the bin, along every support chalk CORR GRAIN BINS line.

-

Page 31: Appendix

6. APPENDIX FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS 6. Appendix 6.1. Floor Plank Layouts Figure 16. Floor Plank Layout — 14’ Floor Page 20 198930 R4... - Page 32 6. APPENDIX FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS Figure 17. Floor Plank Layout — 19’ Floor Page 21 198930 R4...

-

Page 33: Floor Support Layouts

6. APPENDIX FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS 6.2. Floor Support Layouts Figure 18. 19’ SC Support Layout — Full Plank 198930 R4... - Page 34 6. APPENDIX FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS Figure 19. 14’ SC Support Layout — Full Plank 198930 R4 Page 23...

-

Page 35: Limited Warranty: Westeel Grain Bin Products

(the "goods") subject to the following terms and limitations, (the "warranty"): Duration of Warranty This warranty will run from the date of purchase from the dealer or distributor, authorized by Westeel. The duration of the warranty is limited as follows: 5 years... - Page 36 2. improper storage of the goods both prior to and after purchase; 3. damage caused by, or in the course of, installation or assembly; 4. any use of the goods which is not an intended use as specified in Westeel's published product literature, or otherwise specified by Westeel in writing;...

- Page 37 7. LIMITED WARRANTY: FULL FLOOR AERATION SYSTEM (WITH WELDED SUPPORTS) – 14’ & 19’ STANDARD CORR GRAIN BINS WESTEEL GRAIN BIN PRODUCTS competent jurisdiction to be void or unenforceable, in whole or in part, such provision shall be deemed severable and will not affect or impair the legal validity of any other provision of the warranty.

- Page 38 450 Desautels Street P.O. Box 792 Winnipeg, Manitoba, R3C 2N5 Canada Phone: (866) 299-4312 Fax: (204) 235-0796 Website: www.westeel.com Email: info@westeel.com ©Ag Growth International Inc. 2018 Printed in Canada...

Need help?

Do you have a question about the Full Floor Aeration System and is the answer not in the manual?

Questions and answers