Table of Contents

Advertisement

Quick Links

Side Draw Discharge

Wide-Corr® Centurion® Grain Bin

Installation and Storage Instructions

Original Instructions

Read this manual before using product. Failure to

follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

Part Number: 198201 R17

Revised: November 2018

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Westeel Wide-Corr Centurion Side Draw Discharge

- Page 1 Side Draw Discharge Wide-Corr® Centurion® Grain Bin Installation and Storage Instructions Original Instructions Read this manual before using product. Failure to Part Number: 198201 R17 follow instructions and safety precautions can Revised: November 2018 result in serious injury, death, or property damage.

- Page 2 New in this Manual The following changes have been made in this revision of the manual: Description Section Updated Safety Decal Locations 2.6. Safety Decal Locations and Details on page 7 Updated the roof charts. Section 3.1.1 – Roof Design Capacities for Non- Structural Roofs on page Section 3.1.2 –...

-

Page 3: Table Of Contents

5.6. Side Draw Reinforcing Sheet Installation (60’ — 108’ Bins)..........30 5.7. Remaining Capacity after Side Draw Discharge (Bushels) ............. 32 5.8. Number of Extra Wind Rings Needed for Side Draw............. 33 6. Limited Warranty: Westeel Grain Bin Products .................. 34 198201 R17... -

Page 4: Introduction

SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 1. Introduction This manual describes how to assemble a Westeel Side Draw Discharge. Before assembling the side draw discharge, please read this manual. Familiarize yourself with the process and the necessary precautions for efficient and safe assembly. -

Page 5: Safety

2. SAFETY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 2. Safety 2.1. Safety Alert Symbol and Signal Words This safety alert symbol indicates important safety messages in this manual. When you see this symbol, be alert to the possibility of injury or death, carefully read the message that follows, and inform others. -

Page 6: Safety Decals

2. SAFETY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN Safety Glasses • Wear safety glasses at all times to protect eyes from debris. Coveralls • Wear coveralls to protect skin. Hard Hat • Wear a hard hat to help protect your head. Steel-Toe Boots •... -

Page 7: Safety Decal Locations And Details

2. SAFETY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 2.6. Safety Decal Locations and Details Replicas of the safety decals that are attached to the side draw discharge and their messages are shown in the figure(s) that follow. Safe operation and use of the side draw discharge requires that you familiarize yourself with the various safety decals and the areas or particular functions that the decals apply to, as well as the safety precautions that must be taken to avoid serious injury, death, or damage. - Page 8 2. SAFETY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN WARNING WARNING SAFETY INSTRUCTIONS ENTRAPMENT HAZARD • Read operator’s manual and all safety decals Never enter the bin when loading or before assembling, using, or servicing bin. unloading grain. • Close/latch all access doors when not in use. If you must enter the bin: •...

- Page 9 2. SAFETY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN NOTICE WARNING When equipped with aeration system, to prevent roof and/or bin damage: • Consult dealer to install adequate roof venting. • Ensure all roof vents are open and unobstructed. •...

-

Page 10: Before You Begin

3. BEFORE YOU BEGIN SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 3. Before You Begin 3.1. Bin Design and Capacity Standard Westeel Grain Bins are designed for: 1. Non-corrosive free-flowing materials up to 55 lbs/ft (880 kg/m ) average compacted bulk density. -

Page 11: Roof Design Capacities For Non-Structural Roofs

3. BEFORE YOU BEGIN SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 3.1.1 Roof Design Capacities for Non-Structural Roofs Table 2. Maximum Roof Snow Load at STANDARD Peak Load Plus Upgrade 1 Plus Upgrade 2 Std Peak Load Standard Roof Bin Series lbs (kN) 2.15... -

Page 12: Roof Design Capacities For Structural Roofs

3. BEFORE YOU BEGIN SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 3.1.2 Roof Design Capacities for Structural Roofs Table 4. Maximum Roof Snow Load at STANDARD Peak Loads Std Peak Load Standard Roof Bin Series lbs (kN) 1.87 1.87 1.87 1.87 1.82... -

Page 13: Foundation Design And Loads

43,500 lbs. per sq. in. (300 MPa) re-bar. The foundation designs included in this manual are suggestions only, and will vary according to local soil conditions. Westeel will not assume any liability for results arising from their use. -

Page 14: Cutting Openings In Wide-Corr® Grain Bins

5. Openings shall be sealed all the way around for all weather conditions. 6. Instructions shall be followed closely to avoid damage to bin structure. 7. Except cutting openings described below, any other modification to Westeel bins shall be approved by a professional engineer. -

Page 15: Guidelines For Side Draw Use

2. Design and build foundations with the necessary strength for the loads they must support, and for local soil conditions. Westeel foundation guidelines are based on specific stated conditions and may not be applicable to local conditions. 3. Your foundation must provide uniform and level support to the structure being supported. Surface imperfections causing gapping must be remedied. -

Page 16: Product Storage

3. BEFORE YOU BEGIN SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 9. If installing an existing bin on a hopper, make sure the bin is designed for a hopper application, and that the foundation is capable of withstanding the substantial point loads that the hopper legs apply. If uprights are present, make sure that they are supported. -

Page 17: Grain Bin Use

• Never enter a loaded grain bin for any reason. Grain can be a killer. 3.10. Important Notes • Westeel does not provide a foundation design for this product, and is not liable for any damages or injuries related to inadequately designed or constructed foundations. Customers must contract professional services for all foundation design and construction work. - Page 18 (800 kg/m ) average compacted density in Westeel bins. • Tighten all bolts to the recommended torque settings. • Do not locate grain bins close to high buildings, which might cause snow to fall onto or build up on the roof of the grain bin.

-

Page 19: Preparation

4. PREPARATION SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 4. Preparation 4.1. Check Shipment Unload the parts at the assembly site and compare the packing slip to the shipment. Ensure that all items have arrived and that none are damaged. Report damaged parts or shortages immediately to the delivering carrier, followed by a confirming letter requesting inspection by the carrier, if required. -

Page 20: Assembly

5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 5. Assembly Before continuing, ensure you have completely read and understood this manual’s Safety section, in addition to the safety information in the section(s) below. 5.1. Assembly Safety • Do not take chances with safety. The components can be large, heavy, and hard to handle. Always use the proper tools, rated lifting equipment, and lifting points for the job. -

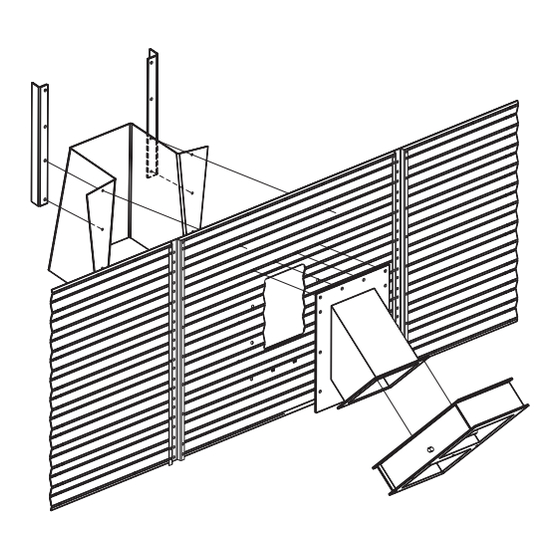

Page 21: Side Draw Baffle Location Details

5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 5.2. Side Draw Baffle Location Details SIDEDRAW BAFFLE LOCATION DETAILS See the following setup pages for location details SEE FOLLOWING SETUP PAGES FOR LOCATION DETAILS Figure 3. Side Draw baffle orientation HORIZONTAL WALL SEAM FOR STIFFENED BINS... -

Page 22: Baffle Location - 7 To 10 Tiers

5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 5.2.1 Baffle Location — 7 to 10 Tiers BAFFLE LOCATION - 7 to 14 TIERS Use the following baffle layouts to ensure that the discharge opening is centered to the wall sheet. Adhere to the following baffle layouts to ensure that the discharge opening is centered to wall sheet. -

Page 23: Baffle Location - 11 To 14 Tiers

5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN SECOND BOTTOM TIER DISCHARGE 5.2.2 Baffle Location — 11 to 14 Tiers Use the following baffle layouts to ensure that the discharge opening is centered to the wall sheet. # of BAFFLES # of BAFFLES # of BAFFLES # of BAFFLES... -

Page 24: Baffle Location - 15 To 18 Tiers

5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 5.2.3 Baffle Location — 15 to 18 Tiers BAFFLE LOCATION - 15 to 22 TIERS Use the following baffle layouts to ensure that the discharge opening is centered to the wall sheet. Adhere to the following baffle layouts to ensure that the discharge opening is centered to wall sheet. -

Page 25: Baffle Location - 19 To 22 Tiers

5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 5.2.4 Baffle Location — 19 to 22 Tiers Use the following baffle layouts to ensure that the discharge opening is centered to the wall sheet. # of BAFFLES # of BAFFLES # of BAFFLES # of BAFFLES Figure 7. -

Page 26: Baffle Location - 23 & 24 Tiers

5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN CATION - 23 & 24 TIERS 5.2.5 Baffle Location — 23 & 24 Tiers Adhere to the following baffle layouts to ensure Use the following baffle layouts to ensure that the discharge opening is centered to the wall sheet. ms and that the discharge opening is centered to wall tening... -

Page 27: Baffle Installation Notes

1. For stiffened bins, 48' diameter and smaller, install 2 baffle angles (195476) per baffle as illustrated. 5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 2. Some bins with side discharge systems must have extra wind rings installed. Consult bin installation manual for location and quantity of wind rings. -

Page 28: Side Draw Discharge Opening Location

WEATHER TIGHT. 4. IF THE DISCHARGE OUTLET IS LOCATED WHERE TWO LAMINATED WALL SHEETS ARE USED, AN ALTERNATIVE REINFORCING METHOD WILL BE REQUIRED. CONSULT WESTEEL ENGINEERING FOR FURTHER DETAILS ON YOUR SPECIFIC APPLICATION. Page 17 198201 R17... -

Page 29: Side Draw Reinforcing Sheet Installation (15' - 54' Bins)

If the discharge outlet is located where two laminated wall sheets are used, an alternative reinforcing method will be required. Consult Westeel Engineering for further details on your specific application. 5.5. Side Draw Reinforcing Sheet Installation (15’ — 54’ Bins) For some bin models a shorter reinforcing sheet needs to be added behind the opening to reinforce this area. -

Page 30: Side Draw Reinforcing Sheet Installation (60' - 108' Bins)

195477 5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN - Remove some existing horizontal seam bolts from the wall sheet that receives the sidedraw outlet. - align and bolt the reinforcing sheet on to the wall sheet. Figure 12. Side draw opening using the retrofit sheet as a template Re-attach drill 13/32"... - Page 31 SIDE DRAW REINFORCING SHEET 5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN For some Bin models a shorter reinforcing sheet needs to be added behind the opening to reinforce this SIDE DRAW REINFORCING SHEET area. The views below describes the installation procedure and the chart explains which Bins require the Figure 13.

-

Page 32: Remaining Capacity After Side Draw Discharge (Bushels)

5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 5.7. Remaining Capacity after Side Draw Discharge (Bushels) Table 6. Remaining Capacity after Side Draw Discharge Bin Diameter Outlet In Second Tier Outlet in Fifth Tier 4,900 9,100 6,600 11,900 8,600 15,100 11,000... -

Page 33: Number Of Extra Wind Rings Needed For Side Draw

5. ASSEMBLY SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN 5.8. Number of Extra Wind Rings Needed for Side Draw Table 7. Number of extra wind rings needed for Side Draw Wind Ring kit p/n Diameter 232301 232302 232303 232304 232305 232306 232307... -

Page 34: Limited Warranty: Westeel Grain Bin Products

(the "goods") subject to the following terms and limitations, (the "warranty"): Duration of Warranty This warranty will run from the date of purchase from the dealer or distributor, authorized by Westeel. The duration of the warranty is limited as follows: 5 years... - Page 35 2. improper storage of the goods both prior to and after purchase; 3. damage caused by, or in the course of, installation or assembly; 4. any use of the goods which is not an intended use as specified in Westeel's published product literature, or otherwise specified by Westeel in writing;...

- Page 36 6. LIMITED WARRANTY: WESTEEL GRAIN BIN SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN PRODUCTS competent jurisdiction to be void or unenforceable, in whole or in part, such provision shall be deemed severable and will not affect or impair the legal validity of any other provision of the warranty.

- Page 37 6. LIMITED WARRANTY: SIDE DRAW DISCHARGE – WIDE-CORR® CENTURION® GRAIN BIN WESTEEL GRAIN BIN PRODUCTS 198201 R17...

- Page 38 450 Desautels Street P.O. Box 792 Winnipeg, Manitoba, R3C 2N5 Canada Phone: (866) 299-4312 Fax: (204) 235-0796 Website: www.westeel.com Email: info@westeel.com ©Ag Growth International Inc. 2018 Printed in Canada...

Need help?

Do you have a question about the Wide-Corr Centurion Side Draw Discharge and is the answer not in the manual?

Questions and answers