Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Logosol LM410

- Page 1 USER MANUAL Ref. no. 0458-395-2345 LOGOSOL LM410 LOG HOUSE MOULDER...

- Page 2 Logosol has been manufacturing equipment since 1989. In that time we have supplied approximately 50,000 machines to satisfied customers the world over.

-

Page 3: Table Of Contents

LM410 LOG HOUSE MOULDER TABLE OF CONTENTS Safety instructions Description of the machine Technical data List of components Assembly: wheel suspension & anti-tip guards Assembly: control panel Installing moulding knives Installing planing knives Installing the log moulder on the rails... -

Page 4: Safety Instructions

SAFETY INSTRUCTIONS • Read carefully through the entire user manual Key to symbols before starting to operate the machine. Failure For your own safety, read through the entire to observe these safety instructions may result in user manual carefully and do not start fatal injuries. - Page 5 LM410 LOG HOUSE MOULDER Safety distances Respect the safety distances. The safety distance is 5 m for the operator and 15 m for persons other than the operator. The illustration below shows the machine from above. The operator is to remain within the area marked with a dashed line (- - - -) when the machine is...

-

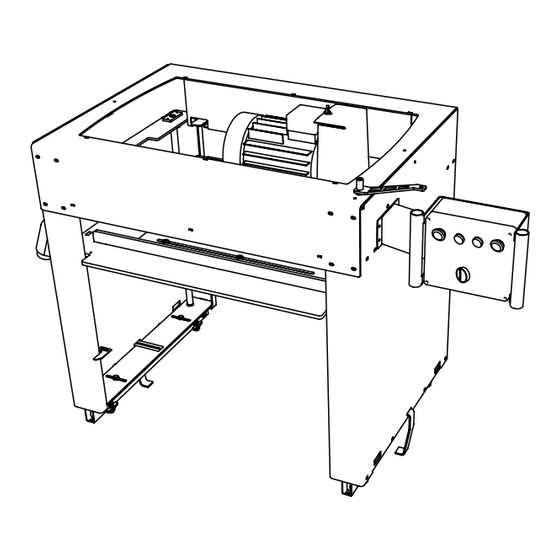

Page 6: Description Of The Machine

MACHINE DESCRIPTION The LM410 is a log moulder that is designed to be pushed manually on rails. The wheels, which are guided by two or three sides of the rails, are suspended by separate wheel suspensions, which can individually be adjusted laterally. -

Page 7: Technical Data

TECHNICAL DATA The LM410 fits directly on band sawmills with a rail frame width from 825 to 960 mm. It can be installed on both narrow, flat and angled rail types. The flexible wheel suspension can be guided from the inner or the outer side, or from both sides of the rails. -

Page 8: List Of Components

COMPONENTS LIST OF COMPONENTS A Pos. Description Quantity Ref. no. Electrical box 9999-000-9999 Hoisting ring 9999-000-9999 Anti-tip guards LM 9999-000-9999 Industrial inlet 9999-000-9999 Crank 9999-000-9999 Horizontal chassis 9999-000-9999 Vertical chassis L 9999-000-9999 Vertical chassis R 9999-000-9999 Wheel suspension (E) 9999-000-9999 Trapezoidal threaded bar 9999-000-9999 Chain tensioner... - Page 9 LM410 LOG HOUSE MOULDER Item Qt Pa ISO E Logoso 0611-1 1-063-208 Handtag 1-063-29 fästvinkel 1-063-102 Fräshuvud...

- Page 10 COMPONENTS LIST OF COMPONENTS B Description Quantity Ref. no. Cutter head chassis 9999-000-9999 Bearing block 9999-000-9999 Cutter head 9999-000-9999 Ball bearing 30x62 9999-000-9999 Side plate, belt side 9999-000-9999 Electric motor B14 9999-000-9999 Chip deflector 9999-000-9999 Bottom plate, cutter head 9999-000-9999 Side plate L 9999-000-9999 Belt pulley 49 mm...

- Page 11 LM410 LOG HOUSE MOULDER 1-048-21 1-048-21 EH-6A-5V5 1-061-01 EH-6A-5V5 1-063-10 1-061-01 1-063-10 1-063-07 1-063-12 1-063-07 1-063-12 1-063-06 1-063-11 1-063-06 1-063-08 1-063-11 1-063-08 1-063-05 7502-001-0 1-063-05 7502-001-0 1-063-04 Item Qt Part Numb 1-063-04 IronCAD Item Qt Part Numb 2D-ritning. 3D-detalj tillgänglig...

- Page 12 Senast sparad: IronCAD Generella 1-063-104_Bord.icd 2008-11-11 11:02 2D-ritning. toleranser enligt: 3D-detalj tillgänglig. Skapad datum: Skala: Ritad av: Kontrollerad av: Godkänd av: ISO 2768-1 2008-11-10 medium ISO E Blad nr: Rev. Logosol AB Bord 0611-182 85 Dok nr: Ingår i "TF410" 1-063-104...

- Page 13 LM410 LOG HOUSE MOULDER COMPONENTS LIST OF COMPONENTS E (Wheel suspension) Pos. Description Quantity Ref. no. Bogie 9999-000-9999 Wheel 10mm 9999-000-9999 Ball bearing 8x22x7 9999-000-9999 Bolt M8x25 9999-000-9999 Ball bearing 6201 9999-000-9999 Spacer 9999-000-9999 Bolt M8x40 9999-000-9999 Washer M8 9999-000-9999...

-

Page 14: Assembly: Wheel Suspension

ASSEMBLY: WHEEL SUSPENSION & ANTI-TIP GAURDS Place four wooden blocks (approx. 20x20x20 cm) under the machine table. Lift the log house moulder by lowering the table against the blocks until you can reach and adjust the wheel suspension on the underside of the machine. -

Page 15: Assembly: Control Panel

LM410 LOG HOUSE MOULDER ASSEMBLY: CONTROL PANEL The control panel is not installed when the machine is shipped, but lies on the machine table inside the machine. Fit the control panel to one of the shortsides of the machine. In the box of components, which also lies... -

Page 16: Installing Moulding Knives

INSTALLING MOULDING KNIVES on the machine, or on the workpiece that is to be Before opening the hatch of the log house machined. moulder, ensure that the power is disconnected and that the cutter head is not rotating. Use protective Make sure that all bolts are securely tightened. -

Page 17: Installing Planing Knives

LM410 LOG HOUSE MOULDER INSTALLING PLANING KNIVES To get the planing knives at the correct height, the Before opening the hatch of the log house adjusting block (ref. no. 7500-000-1020) should moulder, ensure that the power is disconnected and be used. The knives should just touch the block that the cutter head is not rotating. -

Page 18: Installing The Log Moulder On The Rails

Ensure that the machine cannot accidantally tip off the rails. Consult Logosol if the anti-tip guards do not fit on your sawmill model. Make sure that all wheels and wheel bearings in the wheel suspension are correctly fitted on the rails and that all bolts are firmly tightened. -

Page 19: Operation

LM410 LOG HOUSE MOULDER OPERATION Starting the log house moulder: Make sure that the hatch over the cutter head is completely closed. Perform the safety check under Before starting the machine in the Safety Instructions. Set the main switch to ”ON”. Take hold... -

Page 20: Belt Tension/Belt Replacement

BELT TENSION/BELT REPLACEMENT If the belt jumps off the pulley or if it breaks, the cutter and the motor can continue to rotate several minutes. It can be difficult to see whether the motor and the belt are rotating. Ensure that the power is disconnected before opening any protective covers or carrying out any servicing on the machine. - Page 21 LM410 LOG HOUSE MOULDER Loosen the four fixing bolts on the front of the motor. The bolts only have to be loosened enough to allow for adjusting the belt tension. Adjust the belt tension by using the wing nut. The belt should be tightened until you by hand can rotate it 90 degrees.

-

Page 22: Moulding Log House Timber

MOULDING LOG HOUSE TIMBER Below follows a description of how to mould 150 mm (approx. 6’’) wide log house timber on the sawmill B751. The method is the same for other widths and other profiles, even though the dimensions differ. Installing additional log supports 400 mm Three log supports should be used to ensure the... - Page 23 LM410 LOG HOUSE MOULDER 410 mm 150 mm Install the moulding knives in the 75 mm cutter head The cutter is 410 mm wide. On one half of the cutter head you install the knives that only round the cant. On the other half you install the knives for rounding the edges and making the groove in the cant.

-

Page 24: Chip Management

Chip Extractor be an air outlet in your chip container (e.g. a fine- Logosol has a wide range of suitable chip extractors. meshed net, or a filter if you collect the wood debris Consult our customer service to get the right indoors). -

Page 25: Maintenance

Risk of serious injury if maintenance is neglected. debris and dust stick to them. The LM410 is easy to maintain since most of the - Check the safety switch on the hatch: machine structure is protected against rust. All Disconnect the power and make sure that the safety cutter bearings and the motor are maintenance free. -

Page 26: Troubleshooting

TROUBLESHOOTING Problem Possible Cause Remedy The motor cannot be started. 1. The hatch is not entirely 1. Tighten the locking bolt on closed. the hatch. You can hear a soft 2. The hold-to-run buttons are click when the safety switch is not pressed down. - Page 27 LM410 LOG HOUSE MOULDER Problem Possible Cause Remedy The motor becomes overheated. 1. Wood debris has accumulated 1. Clean. If the motor is kept on the motor and around its clean it will be cooled more cooling fan. efficiently. 2. Dull knives.

-

Page 28: Electrical System

ELECTRICAL SYSTEM The LM410 is available in two elecric models: 230 V 3-phase 50 Hz and 400 V 3-phase 50 Hz. The power cable to the log house moulder must be at least 2.5 mm /wire (1/8’’) and be max. 25 m (82 ft) long. -

Page 29: Declaration Of Conformity

LM410 LOG HOUSE MOULDER... - Page 30 Fiskaregatan 2, 871 33 Härnösand, SWEDEN +46 611 182 85 | info@logosol.com | www.logosol.com...

Need help?

Do you have a question about the LM410 and is the answer not in the manual?

Questions and answers