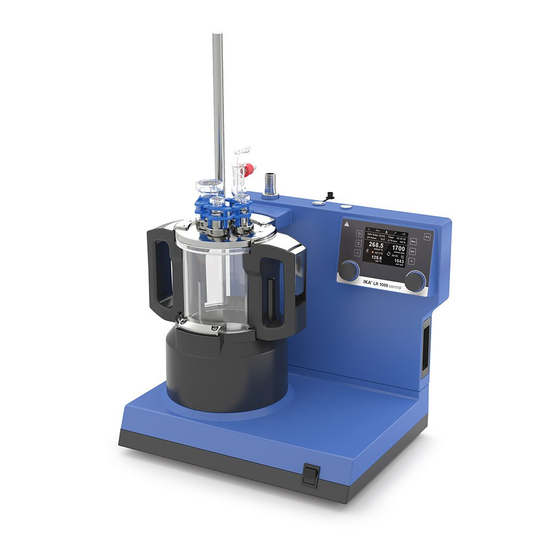

IKA LR 1000 basic Operating Instructions Manual

Compact reactor system

Hide thumbs

Also See for LR 1000 basic:

- Operating instructions manual (164 pages) ,

- Operating instructions manual (83 pages)

Summary of Contents for IKA LR 1000 basic

- Page 1 20000005830 LR 1000 basic/control_012015 LR 1000 basic ® LR 1000 control ® Operating instructions...

-

Page 2: Table Of Contents

Source language: German Contents Page EC Declaration of Conformity Explication of warning symbols Safety instructions Correct use Unpacking System configuration Setting up Safety temperature limit Operator panel and display Commissioning Interface and output Maintenance and cleaning Error codes Warranty Accessories Materials in contact with medium Technical data EC Declaration of Conformity... -

Page 3: Safety Instructions

• The equipment is designed for operation at vacuum set- or comprehensive monitoring equipment. Furthermore, tings up to 25 mbar. users must make sure that the unit switch of the IKA • Certain applications and materials may be hazardous. You ®... -

Page 4: Correct Use

25 °C lower than the fire point of the media used. Correct use • Use: This equipment is suitable for use in all areas except: The IKA LR 1000 system is a compact reactor system. - Residential areas ® It has been designed to simulate and optimize chemical... -

Page 5: Unpacking

- Mains cable - Tool kit (see Fig. 1) - Operating Instructions - Warranty card. Fig. 1 System configuration LR 1000 basic/control laboratory reactor comprises: ® • LR 1000 basic/control base: Fig. 3 Fig. 2 Mains switch Adjustable safety circuit... - Page 6 • Reactor vessel (LR 1000.1): Glass vessel (Borosilicate glass 3.3) Handle Cover latch Vessel locker Anchor stirrer NS 29/32 (1x) NS 14/23 (3x) Safety clips NS 29/32 (1x) Stopper NS 29/32 (1x) Safety clips NS 14/23 (3x) Stopper NS 14/23 (2x) Vacuum cock NS 14/23 (1x) Fig.

-

Page 7: Setting Up

Screw the support rod onto the LR 1000 basic/control base: base with the double open end wrench included with the Ensure the LR 1000 basic/control is set up on an even, device until the end stop is reached. stable, clean and non-slip working table. -

Page 8: Safety Temperature Limit

Connect external cooler: The reactor can connect an external cooler (e.g. IKA ® RC 2 basic or RC 2 control) via the connections (13, 14, see Fig. 3) at the back of the device. The cooling con- nections IN and OUT is labelled accordingly at the back of the device. -

Page 9: Operator Panel And Display

Operator panel and display • LR 1000 basic: Fig. 11 Item Designation Function Rotating/pressing knob: Start/stop the stirring function Change the settings of stirring speed Rotating/pressing knob: Start/stop the heating function Change the settings of the temperature Counter/Timer (C/T) button: Switch between “Counter“ and “Timer“ function Timer (+): Increase the “Timer“... - Page 10 • LR 1000 control: Fig. 12 Item Designation Function Rotating/pressing knob: Start/stop the stirring function Change the settings of stirring speed in working screen Navigation, selecting and changing the settings in the menu Rotating/pressing knob: Start/stop the heating function Change the settings of the temperature in working screen Key button: Lock/unlock knobs and keys “Menu”...

-

Page 11: Commissioning

Commissioning Check whether the voltage specified on the type plate If these conditions are met, the device is ready for operating (LR 1000 basic/control base) matches the mains voltage after plugging in the mains plug. available. If these procedures are not followed, safe operation cannot be guaranteed and/or the equipment may be damaged. - Page 12 Counter and timer function: Timer function: The Time (+) button (D, see Fig. 11) or Time (-) button (D, Counter function: see Fig. 11) is used to adjust the heating time. If the timer When the heating function is started, the counter will start value is more than 1 hour, the display switch to hour/minute automatically.

- Page 13 USB: Key: This symbol means the device is communicating via a USB cable. This symbol means that the function of the keys and the rotary knobs for controlling the device are disabled. The symbol no longer appears if the functions are enabled Heating: once again by pressing the key button a second time.

- Page 14 Menu structure: Factory settings Stirring Torque trend measurement ……………………………………………………… Intermittent mode Run/Stop …………………………………..- Interval Run Time…..…………... 01:00 [mm:ss] Stop Time………………. 00:10 [mm:ss] Speed limit ………………………………………………………………………... 150 rpm Control method Accurate ………………………………………… activated Heating Fast ……………………………………………… - Limits Medium limit …………………………………… 120 Limit information Medium limit ……………...

- Page 15 Menu (Details): Limits: In “External (ext)“ option, the user is allowed to set the max- Stirring: imum and minimum temperature for external temperature Torque trend measurement: control. Confirm and store the setting by pressing on “OK“. The torque trend measurement is used to deduce the Temperature sensor: change in viscosity of the reaction medium.

- Page 16 Note: a pH calibration can only be carried out with an in- Password: serted temperature sensor. In the menu, the user can protect the device settings using a password. The user is requested to input the password in Reset pH probe: order to access the working screen (factory setting: 000).

-

Page 17: Interface And Output

RS 232 interface items of laboratory control equipment, rev. 1.1). Configuration The NAMUR commands and the additional specific IKA ® - The functions of the interface connections between the mmands serve only as low level commands for communication machine and the automation system are chosen from the between the machine and the PC. - Page 18 Commands: NAMUR Commands Function IN_NAME Input description name IN_PV_X Reading the real value X=1;2;3;4; IN_SOFTWARE Input software ID number date, version IN_SP_X Reading the set rated value X=1;2;3;4;6; IN_TYPE Input laboratory unit ID OUT_NAME Output description name. (Max. 10 characters, default: LR 1000) OUT_SP_12@n Setting the WD safety temperature with the echo of the set value OUT_SP_42@n...

- Page 19 “Watchdog”– Mode 2 If an interruption in data transmission occurs which is longer than the preset watchdog time, the speed setpoint value will be set to the WD safety speed setpoint and the temperature setpoint will be set to the WD safety temperature setpoint. The PC 2 warning message will be displayed.

-

Page 20: Maintenance And Cleaning

Maintenance and cleaning Cleaning: Disassemble the anchor stirrer: After removing the glass tube from the vessel base, the an- For cleaning disconnect the main plug! chor stirrer together with the reactor vessel bottom of the socket can be taken apart from the vessel base (see Fig. 23). Disassemble the reactor vessel: Remove the reactor vessel from the LR basic/control base. - Page 21 - item number and designation of the spare part see - Electrical devices may not be placed in the cleaning agent www.ika.com, spare parts diagram and spare parts list. for the purpose of cleaning. - Do not allow moisture to get into the equipment when Repair: cleaning.

-

Page 22: Error Codes

Er 60 motor control is activated in Mode B and C Only for LR 1000 basic! If the actions described fails to resolve the fault or another error code is displayed then take one of the following steps: - Contact the service department - Send the instrument for repair, including a short description of the fault. -

Page 23: Warranty

LR 1000.64 pH Electrode labworldsoft ® Only for LR 1000 control! See more accessories on www.ika.com. Materials in contact with medium Reactor cover AISI 316 L / AISI 316 TI / PTFE / Borosilicate glass 3.3 Bottom AISI 316 L / AISI 316 TI Reactor vessel Borosilicate glass 3.3... -

Page 24: Technical Data

Technical data LR 1000 basic LR 1000 control Nominal voltage 100 – 120 Frequency 50 / 60 Input power 1200 Viscosity max. mPas 100000 Usable volume 300 – 1000 Useful volume with dispersing 500 – 1000 Attainable vacuum mbar Stirring speed range 10 –... - Page 25 - Werke GmbH & Co.KG ® Janke & Kunkel-Str. 10 D-79219 Staufen Tel. +49 7633 831-0 Fax +49 7633 831-98 sales@ika.de www.ika.com...

Need help?

Do you have a question about the LR 1000 basic and is the answer not in the manual?

Questions and answers