Table of Contents

Advertisement

Quick Links

MASCHIO GASPARDO S.p.A.

PRIMAVERA

IT

USO E MANUTENZIONE

EN

USE AND MAINTENANCE

DE

GEBRAUCH UND WARTUNG

FR

EMPLOI ET ENTRETIEN

ES

EMPLEO Y MANTENIMIENTO

Cod. G19503101

2011-04

*)

*) Valido per Paesi UE

*) Valid for EU member countries

*) Valable dans les Pays UE

*) Gilt für EU-Mitgliedsländer

*) Válido para Países UE

Advertisement

Table of Contents

Summary of Contents for Gaspardo Primavera

- Page 1 MASCHIO GASPARDO S.p.A. PRIMAVERA USO E MANUTENZIONE USE AND MAINTENANCE GEBRAUCH UND WARTUNG EMPLOI ET ENTRETIEN EMPLEO Y MANTENIMIENTO *) Valido per Paesi UE *) Valid for EU member countries *) Valable dans les Pays UE *) Gilt für EU-Mitgliedsländer Cod.

-

Page 2: Table Of Contents

ITALIANO ENGLISH DEUTSCH INDICE INDEX INHALT Premessa ..........5 Introduction ........39 Vorwort ..........73 Garanzia ..........5 Guarantee ..........39 Garantie ..........73 1.1.1 Scadenza garanzia .......5 1.1.1 Expiry of guarantee ......39 1.1.1 Verfall des Garantieanspruchs ...73 Descrizione della seminatrice ....5 Description of the seeder ....39 Beschreibung der Sämaschine ..73 Dati tecnici ..........6 Technical data ........40... -

Page 3: Accessori

ENGLISH 1.0 INTRODUCTION 1.2 DESCRIPTION OF THE SEEDER This farming implement, can only be operated by a farming tractor equipped with lift unit and universal three-point hitch. This booklet describes the regulations for use, maintenance for The seeder is suitable for stand-alone use on tilled soil. seeding machine. - Page 4 ENGLISH USE AND MAINTENANCE 1.3 TECHNICAL DATA U.M. PRIMAVERA Working width 4,00 4,50 5,00 6,00 Transport width 3,00 Max. row number [nr.] (40) Row distance [cm] 12,5 12,5 12,5 12,5 (15) Seed hopper capacity 1500 Seed hopper extension PTO (r.p.m.) [r.p.m.]...

- Page 5 ENGLISH USE AND MAINTENANCE 1.4 IDENTIFICATION Each individual machine has an identifi cation plate (Fig. 1) indica- ting the following details: 1) Mark and address of the Manufacturer; 2) Type and model of machine; 3) Unloaded mass, in Kilograms; 4) Mass full load, in Kilograms; 5) Registration of the machine;...

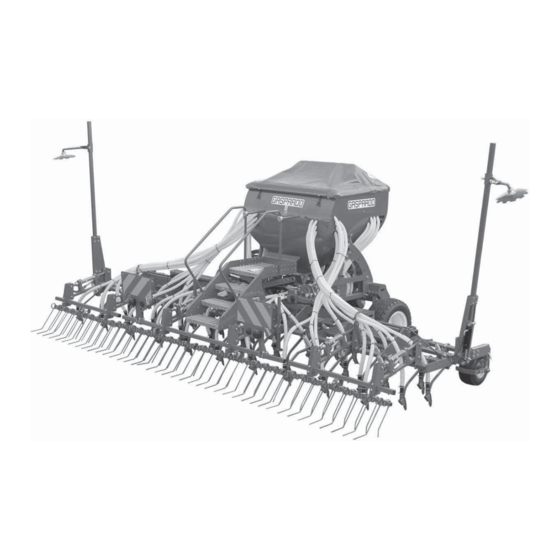

- Page 6 ENGLISH USE AND MAINTENANCE 1.6 ASSEMBLY DRAWING (Fig. 3) 1) Seed hopper; 2) Fan; 3) Seed distributor; 4) Gearbox; 5) Drive wheel; 6) a) Spike furrow opener; b) Double disc coulter; 7) Footboard; 8) Tranks remover; 9) Hydraulic row marker; 10) Seed covering harrow;...

- Page 7 ENGLISH USE AND MAINTENANCE 1.7 DANGER AND INDICATOR SIGNALS 7) Danger of injury to the hands. Keep away from the mowing parts. The signs described are reproduced on the machine (Fig. 4). keep 8) Danger of envelopment. Do not remove the guards while the them clean and replace them if they should come off or become machine is running (parts in movement).

- Page 8 ENGLISH USE AND MAINTENANCE General norms 2.0 SAFETY REGULATIONS AND ACCIDENT 1) Pay close attention to the danger signs in this manual and on PREVENTION the seeder. 2) The labels with the instructions attached to the machine give Pay attention to danger signs, where shown, in this booklet. abbreviated advice for avoiding accidents.

- Page 9 ENGLISH USE AND MAINTENANCE Tractor hitch 9) When the dimensions of carried or partially-carried equipment 1) Hook the equipment to a suitable, suffi ciently-powered tractor conceal the tractor’s signalling and lighting devices, these must by means of the appropriate device (lifter), in conformity with also be installed on the equipment itself, in conformity with applicable standards.

- Page 10 ENGLISH USE AND MAINTENANCE Safety measures concerning the hydraulics Maintenance in safety 1) At the moment of connecting the hydraulic tubes to the hydraulic During work and maintenance operations, use suitable per- system of the tractor, make sure that the hydraulic systems of sonal protection gear: the operating machine and the tractor are not under pressu- 2) For the operative hydraulic connections between tractor and...

-

Page 11: Guarantee

ENGLISH USE AND MAINTENANCE 3.0 RULES OF USE To obtain the best performance from the equipment, carefully follow what is set out below. ATTENTION The following maintenance, adjustment, and work preparation operations must be performed with the tractor off and locked fi... -

Page 12: Identifi Cation

ENGLISH USE AND MAINTENANCE 3.1.2 UNHITCHING THE PLANTING UNIT FROM THE 3.3 STABILITY OF PLANTING UNIT AND TRACTOR TRACTOR DURING TRANSPORT When a planting unit is coupled to a tractor, so becoming an integral part of it for the purposes of road travel, the stability of the planting unit-tractor complex may change and cause driving or operating PERICOLO diffi... -

Page 13: Folding Frame

ENGLISH USE AND MAINTENANCE 3.4 FOLDING FRAME 3.4.2 FLOATING FRAME A fl oating system for the furrower holding frame has been incor- porated in the planter: in specifi c ground conditions (valleys, hill 3.4.1 DESCRIPTION OF FUNCTIONING planting etc.), this system facilitates even planting of the seedbed, The machine frame is designed so that the side ends that hold the despite its irregularity. -

Page 14: Dosing

ENGLISH USE AND MAINTENANCE 3.4 DOSING fi g. 14 3.4.1 DOSER (Fig. 14) The doser the most important part for seeder operation, is located underneath the seed hopper. Motive power is transmitted to it by the drive wheel through gears (with ratios proportional to the width of the work to be carried out) and chains. - Page 15 ENGLISH USE AND MAINTENANCE Replacing the DOSING ROLLER fi g. 17 Perform this operation while the dosing chamber is empty: A) Empty hopper; B) Hopper with product: use the movable panel (P, Fig. 14) to exclude feeding from the hopper to the doser. Then empty the dosing chamber.

- Page 16 ENGLISH USE AND MAINTENANCE fi g. 23 fi g. 22 CLEANING SPRING ELEMENTS Cleaning spring elements (A, Fig. 22) are used during the distri- bution of oily seeds by means of the yellow seeding roller, mod. F25-125. The main action of these spring elements is keeping the chambers of the seeding roller clear so that seed distribution is regular and constant.

-

Page 17: Dosing Test

ENGLISH USE AND MAINTENANCE 3.5.2 DISTRIBUTION OF FINE SEEDS 3.5.3 ADJUSTMENT FLOW AIR The air capacity can and must be changed according to the spe- Distribution of quantities lower than 3 kg/ha. cifi c weight of the seeds by rotating the butterfl y valve supplied During the dosing test the number of gearbox revolutions is low (Abb. - Page 18 ENGLISH USE AND MAINTENANCE 3.5.4 DOSING TEST Adjust the doser with the unit on the ground, the motor turned TEST off and the tractor blocked in place. Before carrying out the dosing test, make sure there are no foreign bodies inside the hopper and the doser.

- Page 19 ENGLISH USE AND MAINTENANCE 3.5.5 DISTRIBUTION TABLE (FOR TYRES 13.0/55-16 AW) (Table 2) Cod. G19707240 cod. G19503101...

-

Page 20: Power Take-Off Rpm

ENGLISH USE AND MAINTENANCE 3.6 BLOWER DRIVE fi g. 33 3.6.1 POWER TAKE-OFF RPM The blower pump is enabled by the tractor power take-off. It is important that the rpm indicated are respected. If the minimum rpm is not reached the machine could lose distribution precision and where there are large quantities of seeds, the granulate pipes could get clogged. - Page 21 ENGLISH USE AND MAINTENANCE Working description The oil fl ow necessary to drive the blower, is taken from the tractor distributor, through a pressure tube to a three-way regulator. The rotational speed of the oleo-dynamic motor, and therefore that of the blower, is proportional to the fl ow pressure shown on the manometer (Table 3).

-

Page 22: Adjusting The Seeding Depth

ENGLISH USE AND MAINTENANCE 3.7 SEEDER POSITION fi g. 36 It is important to adjust the position of the planting unit correctly on the supporting equipment when in the fi eld. DANGER Positioning the seeder on the equipment is an extremely dangerous phase. -

Page 23: Row Marker

ENGLISH USE AND MAINTENANCE 3.8 ROW MARKER Depending on the seed drill model, two different options of row marker are provided: - Mod. 400/450: hydraulically folding row marker with trace on the tractor wheel (Fig. 40); - Mod. 500/600: row marker with trace in the centre of the tractor and hydraulic folding inside the planter’s overall dimensions (Fig. -

Page 24: Transport

ENGLISH USE AND MAINTENANCE 3.8.2 ROW MARKING ARM LENGTH (mod. 400/450) 3.8.3 ROW MARKING ARM LENGTH (mod. 500/600) See Fig. 44 and observe the following rules for correct row market See Fig. 45 and observe the following rules for correct row market arm adjustment: arm adjustment: L = D (N +1) - C... - Page 25 (A-B, Fig. 47). Changing the position of the bolt (C, Fig. 47), vary the cutting angle of the spring-loaded teeth. fi g. 47 mod. mod. PRIMAVERA 500 PRIMAVERA 400 PRIMAVERA 450 PRIMAVERA 600 PRIMAVERA 500 PRIMAVERA 600 fi...

- Page 26 ENGLISH USE AND MAINTENANCE 3.10 TRANSPORT Transit and transporting on the public highways If it becomes necessary to transport the machine for a long distance, When driving on public roads, be sure to follow the highway it can be loaded onto a railway wagon or a truck. For this purpose, code of the country involved.

-

Page 27: During Work

ENGLISH USE AND MAINTENANCE 3.11 BEFORE STARTING WORK 3.13 DURING WORK Before starting the seeding operation grease all parts indicated by Bear in mind that a variation in tractor speed does not lead to a transfer nr. 16 (‘GRASE’) Fig. 4 at page 43 of this leafl et. corresponding variation in seed sown per hectare. -

Page 28: The End Of Operation

ENGLISH USE AND MAINTENANCE 3.14 THE END OF OPERATION At the end of the work processes, stop all the mechanical moving parts in safe conditions. Let the machine sit on the ground, stop the engine, remove the ignition key and engage the parking brake. EMPTYING THE HOPPER The emptying hatch opens the doser the entire width of the dosing roller so that the machine can be emptied quickly and effectively. -

Page 29: Optionals

ENGLISH USE AND MAINTENANCE 4.0 OPTIONALS 4.1 TRACTOR WHEEL TRACK ERADICATORS The wheel track eradicators should be placed on the same line as the tyres of the tractor. To adjust the depth of the wheel track era- dicators, varying the position of pin (A, Fig. 54). 4.2 FRONT PREP UNIT (mod. -

Page 30: Rear Seed Pressing Wheels

ENGLISH USE AND MAINTENANCE fi g. 57 4.4 REAR SEED PRESSING WHEELS fi g. 58 Alternatively to the rear seed covering harrow, the machine can be fi tted with a number of rear seed pressing wheels (F, Fig. 57) fea- turing built-in springs (G, Fig. -

Page 31: Maintenance

ENGLISH USE AND MAINTENANCE 5.0 MAINTENANCE HYDRAULIC SYSTEMS - Hydraulic systems must be maintained exclusively by skilled operators. Here follows a list of various maintenance operations to be carri- - The hydraulic system is under high pressure; because of ed out periodically. Lowered operating costs and a longer lasting the accident risk, when searching for leakage points special seeding machine depend, among others, on the methodical and auxiliary instruments should be used. -

Page 32: At The Biginning Of The Seeding Season

ENGLISH USE AND MAINTENANCE 5.0.1 WHEN THE MACHINE lS NEW fi g. 62 - After the fi rst hours of work check that all the bolts are still tight. - Lubricate the transmission chains. - Check the tightness of the bolts on the listers. 5.0.2 AT THE BIGINNING OF THE SEEDING SEASON - Operate the empty seeding machine, the air-fl... -

Page 33: Setting Aside

ENGLISH USE AND MAINTENANCE 5.0.9 SETTING ASIDE 6.0 DEMOLITION AND DISPOSAL At the end of the season, or if a long period of rest is for seen it is advisable: This operation is to be carried out by the customer. 1) Carefully empty all the seed from the hopper and distribution Before demolishing the machine, you are advised to carefully check assÕy. - Page 34 Notes ...

- Page 35 Notes ...

- Page 36 cod. G19503101...

-

Page 37: Dosier

- ***Norma utilizada apenas para máquinas combinadas ˜ÒÁÛÈÏÔðÔÈÂ Ù·È Ï¸ÌÔ „È· Ûð·ÒÙÈÍ›Ú ÏÁ˜·Ì›Ú ÛÂ Û Ì‰ ·Ûϸ Ï ۂ‹ÒÌÂÚ. TYPE MODEL PLACE SERIAL NUMBER DATE Cod. F07040035 (06-2010) – Uff. Tecnico MASCHIO GASPARDO S.p.A. Il Presidente Maschio Egidio... - Page 38 MASCHIO-GASPARDO CINA 404126 Волжский 315100 Chisineu-Cris (Arad) - România MASCHIO MIDDLE EAST MASCHIO-GASPARDO KOREA Волгоградская область Tel. +40 257 307030 Тел. +7 8443 515152 Fax +40 257 307040 e-mail: maschio@maschio.ro факс. +7 8443 515153 Uffi cio Tecnico MASCHIO GASPARDO S.p.A.

Need help?

Do you have a question about the Primavera and is the answer not in the manual?

Questions and answers