Advertisement

Quick Links

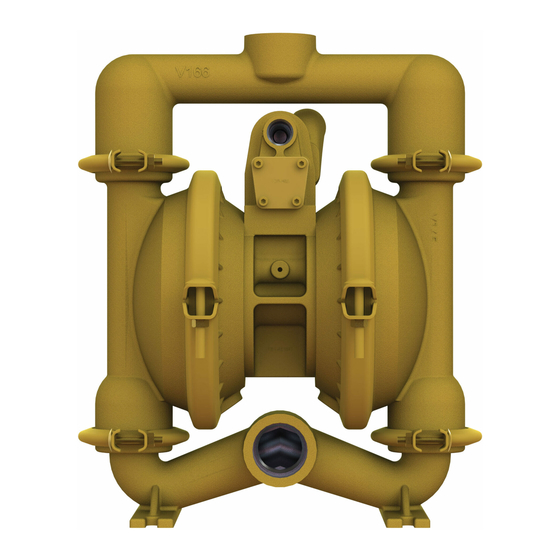

E4

1 1/2" Elima-Matic Clamped Metallic

with Metallic Center Section

E4 Metallic Pumps

• Aluminum

• Cast Iron

• Stainless Steel

-

See E4AAxxxx0

REV

REVISION

VERSA-MATIC

®

• Warren Rupp, Inc. • A Unit of IDEX Corporation

800 North Main Street, Mansfield, OH 44902 USA • Phone: (419) 526-7296 • www.versamatic.com

© Copyright 2013 Warren Rupp, Inc. All rights reserved

Advertisement

Summary of Contents for Versa-Matic E4

- Page 1 1 1/2" Elima-Matic Clamped Metallic with Metallic Center Section E4 Metallic Pumps • Aluminum • Cast Iron • Stainless Steel See E4AAxxxx0 REVISION VERSA-MATIC ® • Warren Rupp, Inc. • A Unit of IDEX Corporation 800 North Main Street, Mansfield, OH 44902 USA • Phone: (419) 526-7296 • www.versamatic.com...

-

Page 2: Safety Information

Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty. - Page 3 Table of Contents SECTION 1: PumP SPECIfICaTIONS ....1 • Nomenclature • Performance • Materials • Dimensional Drawings SECTION 2: INSTallaTION & OPEraTION ..5 • Principle of Pump Operation • Typical Installation Guide • Troubleshooting SECTION 3: ExPlOdEd VIEw ......8 • Composite Drawings • Parts List • Materials Code SECTION 4: warraNTy & CErTIfICaTES ..12 • Warranty • EC Declaration of Conformity - Machinery versamatic e4mdlAsmC-rev1213...

- Page 4 F Flap Valve 9 Geolast 9 Geolast HD Horizontal Discharge A Acetal A Aluminum w/ PTFE O-Rings 3A 3-A Certified S Stainless Steel S Stainless Steel w/ PTFE O-Rings UL UL Listed Y FDA Santoprene C Carbon Steel w/ PTFE O-Rings OB Oil Bottle H Alloy C w/ PTFE O-Rings T PTFE Encapsulated Silicone O-Rings Y FDA Santoprene *More than one option may be specified for a particular pump model. versamatic • Model E4 Metallic Clamped e4mdlAsmC-rev1213...

- Page 5 Yamada Corporation. ARO ® is a registered trade name of Ingersoll-Rand Company. Wilden ® is a registered trade name of Wilden Pump and Engineering Company, a Dover Resources Company. Model E4 Metallic Clamped • versamatic e4mdlAsmC-rev1213...

- Page 6 Performance E4 1 1/4" Clamped Pump ELASTOMERIC AND TPE FITTED Flow Rate Displacement Per Stroke, 0.25 Gal. (0.95 L) Adjustable to ..0-71 gpm (268 lpm) Port Size AIR CONSUMPTION IN SCFM AIR PRESSURE IN PSI Suction ....1 1/2" NPT Discharge.

- Page 7 E4 Metallic Clamped - Aluminum Dimensions in inches (metric dimensions in brackets) The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed. 13.66 [346.96] 14.36 [364.74] 1 1/4" NPT / BSP TAPERED 11.50 DISCHARGE PORT [292.10]...

- Page 8 E4 Metallic Clamped - Base Mounted Aluminum Dimensions in inches (metric dimensions in brackets) The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed. 14.28 [362.71] 13.66 [346.96] 1 1/4" NPT / BSP TAPERED DISCHARGE PORT 11.50...

- Page 9 E4 Metallic Clamped - Cast Iron Dimensions in inches (metric dimensions in brackets) The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed. 13.66 [346.96] 11.50 [292.10] 14.36 [364.74] 1 1/4" NPT / BSP TAPERED 2.51...

- Page 10 E4 Metallic Clamped - Stainless Steel Dimensions in inches (metric dimensions in brackets) The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed. 13.61 [345.69] 11.50 14.40 [292.10] [365.76] 1 1/4" NPT / BSP TAPERED DISCHARGE PORT 1/2"...

- Page 11 SUBMERGED ILLUSTRATION Primed Fluid MUFFLER 1" DIAMETER AIR LIQUID EXHAUST PIPING LEVEL SUCTION LINE Pump can be submerged if the pump materials of construction are compatible with the liquid being pumped. The air exhaust must be piped above the liquid level. When the pumped product MUFFLER source is at a higher level than the pump (flooded suction condition), pipe the exhaust higher than the product source to prevent siphoning spills. 1" DIAMETER AIR EXHAUST PIPING LIQUID LEVEL SUCTION LINE Model E4 Metallic Clamped • versamatic e4mdlAsmC-rev1213...

-

Page 12: Available Accessories

Installation And Start-Up Locate the pump as close to the product being pumped as possible. Keep the suction line length and number of fittings to a minimum. Do not reduce the suction line diameter. Air Supply Connect the pump air inlet to an air supply with sufficient capacity and pressure to achieve desired performance. A pressure regulating valve should be installed to insure air supply pressure does not exceed recommended limits. Air Valve Lubrication The air distribution system is designed to operate WITHOUT lubrication. This is the standard mode of operation. If lubrication is desired, install an air line lubricator set to deliver one drop of SAE 10 non-detergent oil for every 20 SCFM (9.4 liters/sec.) of air the pump consumes. Consult the Performance Curve to determine air consumption. Air Line Moisture Water in the compressed air supply may cause icing or freezing of the exhaust air, causing the pump to cycle erratically or stop operating. Water in the air supply can be reduced by using a point-of-use air dryer. Air Inlet And Priming To start the pump, slightly open the air shut-off valve. After the pump primes, the air valve can be opened to increase air flow as desired. If opening the valve increases cycling rate, but does not increase the rate of flow, cavitation has occurred. The valve should be closed slightly to obtain the most efficient air flow to pump flow ratio. versamatic • Model E4 Metallic Clamped e4mdlAsmC-rev1213... -

Page 13: Troubleshooting Guide

Check Operating Manual to check for correct part and installation. Ensure outer plates have not been installed incorrectly or worn. worn to a sharp edge. Unbalanced Cycling Excessive suction lift. For lifts exceeding 20’ of liquid, filling the chambers with liquid will prime the pump in most cases. Undersized suction line. Meet or exceed pump connections. Pumped fluid in air exhaust muffler. Disassemble pump chambers. Inspect for diaphragm rupture or loose diaphragm plate assembly. Suction side air leakage or air in product. Visually inspect all suction-side gaskets and pipe connections. Check valve obstructed. Disassemble the wet end of the pump and manually dislodge obstruction in the check valve pocket. Check valve and/or seat is worn or needs adjusting. Inspect check valves and seats for wear and proper setting. Replace if necessary. Entrained air or vapor lock in chamber(s). Purge chambers through tapped chamber vent plugs. For additional troubleshooting tips contact After Sales Support at service.warrenrupp@idexcorp.com or 419-524-8388 Model E4 Metallic Clamped • versamatic e4mdlAsmC-rev1213... - Page 14 FUSION SEE NOTE 4 SEE NOTE 4 DIAPHRAGM PILOT ASY DETAIL SEE NOTE 4 METALLIC SEAT METALLIC SEAT OPTION OPTION METALLIC SEAT METALLIC SEAT SEE PILOT METALLIC SEAT OPTION OPTION ASY DETAIL OPTION versamatic • Model E4 Metallic Clamped e4mdlAsmC-rev1213...

- Page 15 PTFE See item # 24 V171TF N/A (use metallic seat) Santoprene V163TPEXL V171TPEXL V170TPEXL Hytrel V163TPEFG V171TPEFG V170TPEFG Geolast V163G V171G V170G Aluminum V170A (See Note 3) Carbon Steel V170CS (See Note 3) Stainless Steel V171SS SV170 (See Note 3) Alloy C HV170 (See Note 3) Notes: 1.) The outer diaphragm plate material is to match the water chamber material (Cast Iron pumps are to use Stainless outer diaphragm plate) 2.) The inner diaphragm plate material is to match the air chamber material 3.) This metallic seat material is to match the water chamber material. In addition to this seat, (4) o-rings are needed. (Ref Note 4) 4.) (4) V170T o-rings are only used with metallic fitted seats. 5.) V=Aluminum, SV=Stainless Steel, WV=Cast Iron, H =Hastelloy, TC=PTFE Coated, NP=Nickel Plated Model E4 Metallic Clamped • versamatic e4mdlAsmC-rev1213...

- Page 16 Versa-Matic warrants to the original end-use purchaser that no product sold by Versa-Matic that bears a Versa-Matic brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Versa-Matic’s factory.

Need help?

Do you have a question about the E4 and is the answer not in the manual?

Questions and answers