Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Mahindra Gyrovator SLX Series

- Page 1 MAHINDRA GYROVATOR SLX Series Owner Manual...

- Page 3 Gyrovator . This booklet also contains the warranty policy for Mahindra Gyrovator SLX and its acknowledgment forms. The purchaser of this Mahindra Gyrovator SLX shall read and understand all the terms and conditions mentioned under warranty and sign the warranty acknowledgment forms.The purchaser of Mahindra Gyrovator SLX is also entitled for two free services...

-

Page 5: Table Of Contents

INDEX IDENTIFICATION ..........................06 Technical Data ............................. 06 Warning Signals ........................... 10 Danger Signals ............................. 10 Indicator Signals ........................... 10 Warranty ..............................10 When the Warranty Becomes Void ....................... 10 SAFETY AND ACCIDENT PREVENTING PROVISIONS ..............12 USE INSTRUCTIONS .......................... 16 Transport .............................. -

Page 6: Identification

1.0 IDENTIFICATION 1.1 TECHNICAL DATA Each individual machine has an identification plate (A Fig. 1) indicating the following details: 1) The Manufacturer's address. 2) Machine type. 3) Mass / Standard weight. 4) Serial number. 5) Machine model. 6) Year of manufacture. You are advised to note down your data on the form below, along with the date of purchase (7) and the dealer's name (8). - Page 7 200 78.9 217 85.4 41-44 55-60 SLX-175 177 69.6 194 76.3 36-41 50-55 33-36 45-50 SLX-150 153 60.4 170 66.9 NOTE : Above weights are exclusive of propeller shaft weight. All weight approx to ± 5 kg. Rotor MAHINDRA GYROVATOR SLX Fig. 2...

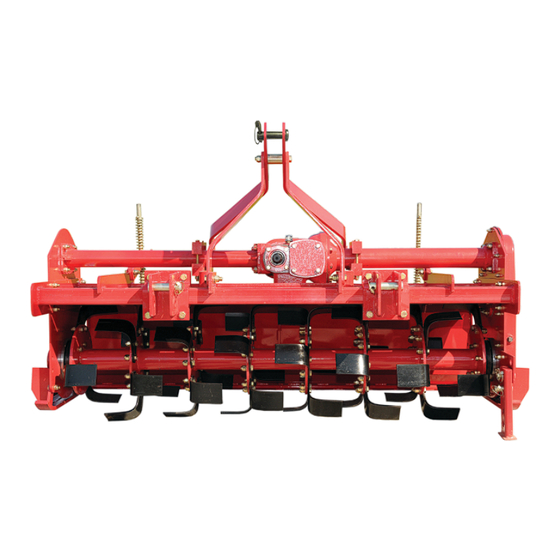

- Page 8 1.0 IDENTIFICATION 1.1 TECHNICAL DATA Fig. 3 1) Pin Top Link 10) Stand 2) Mast Bracket Front 11) Pic Shaft (Power Input Connection) 3) Lifting stirrup. 12) Adjuster Rod 4) Main Gearbox. 5) Side Cover Assembly I = Front side 6) Skid Shoe Adjuster Plate II = Back side / Rear side 7) Skid Shoe Adjuster...

- Page 9 1.0 IDENTIFICATION 1.1 TECHNICAL DATA...

-

Page 10: Warning Signals

1.0 IDENTIFICATION WARNING SIGNALS 1) Before operating machine, carefully read the instruction book. 2) Before any operation of maintenance a/o adjustment, stop, brake the tractor on level ground, lower the machine to the ground and read the instruction book. 3) Loud noise. Wear adequate hearing protection, e.g. headphones. DANGER SIGNALS 4) Danger. - Page 11 1.0 IDENTIFICATION When, following repairs made by the customer without authorization from the Manufacturer or owing to installation of spurious spare parts, the machine is subjected to variations and the damage can be ascribed to these variations. When the user has failed to comply with the instructions in this handbook.

-

Page 12: Safety And Accident Preventing Provisions

2.0 SAFETY AND ACCIDENT PREVENTING PROVISIONS Pay great attention to the danger signal where indicated in this handbook. There are three types of danger signal: DANGER: This signal warns when serious injuries, death or long-term health risks would be caused by failure to correctly carry out the described operations. - Page 13 2.0 SAFETY AND ACCIDENT PREVENTING PROVISIONS 4) Disconnect the hydraulic pipes from the tractor taps when the machine is serviced. 5) Before proceeding with any work under the machine, make sure that the driveline has been detached from the PTO and secure the machine itself with supports to make sure that it is unable to accidentally drop. 6) It is absolutely forbidden for persons without a driving license, inexpert persons or those in precarious health conditions to drive the tractor with the machine mounted.

- Page 14 2.0 SAFETY AND ACCIDENT PREVENTING PROVISIONS 24) Before leaving the tractor, lower the implement coupled to the lift unit, stop the engine, engage the hand brake and remove the ignition key from the control panel. 25) It is absolutely forbidden to stand between the tractor and the machine (Fig. 5) when the engine is running and the propeller shaft is engaged without having first engaged the hand brake.

- Page 15 2.0 SAFETY AND ACCIDENT PREVENTING PROVISIONS 44) Lengthy use of the machine can, as secondary effect, overheat the overdrive and parts of the hydraulic circuit. Never touch these parts immediately after use as they are very hot and can cause burns. 45) Never carry out maintenance or cleaning work unless the pto has been disengaged, the engine switched off, the hand brake engaged.

-

Page 16: Use Instructions

3.0 USE INSTRUCTIONS TRANSPORT If it becomes necessary to transport the machine for a long distance, it can be loaded onto a railway wagon or a truck. For this purpose, consult «Technical Features» for weight and specific dimensions. The latter are very useful to check the possibility of driving along all types of roads. -

Page 17: Machines Supplied Partly Broken Down

3.0 USE INSTRUCTIONS MACHINES SUPPLIED PARTLY BROKEN-DOWN Owing to their size, the machines may be supplied with detached parts, always fixed in the same pack. Normally, the parts that are detached and subsequently assembled by the customer are the 3rd point mounting which, depending on the type, weighs. - Page 18 3.0 USE INSTRUCTIONS Fig. 7 IMPORTANT The plates (1 Fig. 7) must always and only be mounted as shown in Fig. 7 with the holes towards the front of the square tubular. The Manufacturer declines any liability for damage to the machine or the tractor if this essential installation requirement is not observed.

-

Page 19: Check The Lifting Capacity And Stability Of The Tractor To Which The Machine Is Hitched

3.0 USE INSTRUCTIONS 6) Besides supporting the Levelling bonnet and acting as a shock absorber for it during road transport, the spring ram (Fig. 10) prevents the steerage hoe from overturning when parking. The effect of the levelling bonnet on the soil can be increased or decreased depending on the position, established by the split pin, Nut and bolts (Fig. -

Page 20: Propeller Shaft

3.0 USE INSTRUCTIONS Overhang from rear axle of the machine (cm). S1 = Distance of rear axle from parallel hitch (cm). S2 = Distance between bar hitch hole and center of gravity of machine (cm) (Fig. 11). PROPELLER SHAFT Propeller shaft adaption The Propeller shaft, supplied with the machine, is of standard length. - Page 21 3.0 USE INSTRUCTIONS Shorten the sliding tubes by the same extent (Fig. 14 and 15), deburr and trim, then grease the inside of the outer tube. Make sure that the upper hitch bar is as parallel as possible to the lower bars of the hitch. If this is not sufficient, correct the way the top link of the hitch couples to the tractor or machine, as necessary, or at least considerably attenuate, the jolts to which the driveline shaft is subjected during the lifting phase.

- Page 22 3.0 USE INSTRUCTIONS CAUTION This inspection must be performed at the beginning of each new working season. Driveline with safety limiter and shear bolt The limiter, inserted in the cardan joint, is equipped with a safety bolt that is set for an average force. Whenever unduly resistant obstacles cause the bolt to shear, it must be replaced by a new bolt, of the same size and material and grade.

-

Page 23: Work Depth

3.0 USE INSTRUCTIONS WORK DEPTH Machine work depth is regulated on the basis of the different possible configurations by the position of the following devices: Side Adjuster Skids. Draft and Position Lever on Tractor. DANGER Turn the adjustment handle only when the tractor is at a standstill and with the power take-off disconnected. -

Page 24: Gearshift

3.0 USE INSTRUCTIONS Remember to mount the new hoe blade in exactly the same position as the old one (Fig. 20). If several hoe blades must be replaced, it is advisable to remove and assemble one hoe blade at a time in order to prevent positioning errors. - Page 25 3.0 USE INSTRUCTIONS WARNING To carry out this operation: 1) Make sure that the gearbox is cool enough to work in safety without scorching the hands. Wear adequate gloves if necessary. 2) Unscrew its bolts and remove the rear cover of the gearbox. CAUTION Watch out: oil will come out.

-

Page 26: In Work

3.0 USE INSTRUCTIONS 3.11 IN WORK Start work with the pto at running rate, gradually lowering the machine into the soil. Never excessively press down on the accelerator pedal when the pto is engaged. This could be very harmful for both the machine and the tractor itself. When choosing how much to break up the soil which is to be rotary hoed the following points must be considered: the type of soil (mixed, sandy, clay etc.);... -

Page 27: Parking

3.0 USE INSTRUCTIONS Fig. 23 Fig. 24 During transport, or whenever the implement must be raised, it is advisable to adjust the lift unit of the tractor so that the implement itself is not raised more than about 35 cm from the ground (Fig. 25). Fig. -

Page 28: Troubleshooting Hints For The Tractor Operator

3.0 USE INSTRUCTIONS Fig. 27 Fig. 26 (Fig. 27) prevents the steerage hoe from overturning when parking. 3) Hold the propeller shaft with a suitable support. 4) The rod (Fig. 27) should be positioned as shown in the figure when parking the machine. 3.14 TROUBLESHOOTING HINTS FOR THE TRACTOR OPERATOR/DRIVER The following are some useful suggestions for problems which might arise during work. - Page 29 3.0 USE INSTRUCTIONS Other problems The machine does not hoe to the same depth over the whole width e.g. if it hoes too deeply on the right side shorten the right arm of the lift bars and regulate the position of the right-hand skid. Working a hill/slope Where possible always try to «work up»...

-

Page 30: Maintenance

4.0 MAINTENANCE The various routine servicing operations required are listed below along with a Maintenance table (which should be complied with) that briefly illustrates the operations, points and inspection frequencies. Lower running costs and longer machine life depend on constant and methodical compliance with these operations. -

Page 31: Storage

4.0 MAINTENANCE Add oil through the fill plug if necessary (1 Fig. 28). It should flow from the level plug. Side transmission gears: check the level of the oil in the side casing of the transmission unit, unscrewing the level plug (5 Fig. 28) and checking that oil flows out. Add oil through the fill plug if necessary (3 Fig. - Page 32 4.0 MAINTENANCE...

- Page 33 4.0 MAINTENANCE...

-

Page 36: Manufacturer's Warranty

Company’s Authorized dealer will repair or replace any part thereof found, in its opinion, to be defective in materials or workmanship. The warranty shall be for a period of 15 months from the date of manufacturing and 12 months from the date of purchase of New Mahindra Gyrovator SLX by the original purchaser (“retail purchaser”.) This warranty is limited to the delivery to the retail purchaser, free at the Authorized Dealer’s workshop or... -

Page 37: Spare Parts

This warranty also does not cover the cost of packaging to and fro freight and transportation charges etc. on the defective Mahindra Gyrovator SLX or other parts of the Mahindra Gyrovator SLX sent to Mahindra Dealers locations Claims arising from this warranty will be considered only if they are notified in writing to the concerned Authorized Dealer or to the Company promptly after the defect has been ascertained. - Page 39 Acknowldegement The blank spaces have been filled in and are correct, and I acknowledge that I have read and I accept this warranty and limitation of liability. Purchaser ______________________________ Dealer ____________________ Code ____________ Address _______________________________ Address ____________________________________ ______________________________________ ____________________________________________ City ______ State _________ Pin __________ City __________ State __________ Pin ___________ Model/ Type _______ Serial no.

- Page 41 Acknowldegement The blank spaces have been filled in and are correct, and I acknowledge that I have read and I accept this warranty and limitation of liability. Purchaser ______________________________ Dealer ____________________ Code ____________ Address _______________________________ Address ____________________________________ ______________________________________ ____________________________________________ City ______ State _________ Pin __________ City __________ State __________ Pin ___________ Model/ Type _______ Serial no.

- Page 43 PRE DELIVERY INSPECTION (PDI) REPORT First time buyer (Write Yes/No) Job Card No. : _________________________ Dealer Code : _________________________ Model / Type : _________________________ Dealer Location : _________________________ Sr. No. : _________________________ Date Received : _________________________ PDI done by : _________________________ Date : _________________________ Gyrovator Invoice No.

- Page 44 Points to be checked during PDI 1. List if any shortages parts : _______________________________________________ v Please check that the Gyrovator is properly installed. _______________________________________________ v Operator manual cum parts catalogue along with warranty _______________________________________________ booklet is provided at the time of delivery. v All oil i.e.

- Page 45 INSTALLATION REPORT First time buyer (Write Yes/No) Job Card No. : _________________________ Dealer Code : _________________________ Model / Type : _________________________ Dealer Location : _________________________ Sr. No. : _________________________ Date Received : _________________________ Installation done by : _________________________ Date : _________________________ Gyrovator Invoice No.

- Page 47 MAHINDRA GYROVATOR SLX Series Parts Catalogue...

- Page 49 6.0 SPARE PARTS Spare parts should be ordered from your Dealer and should always include the following indications: Type and serial number of the machine. These data are punched on the data plate with which every machine is equipped (A Fig. 3). Part number of the required spare part.

- Page 50 A) GEAR BOX & SUPPORT TUBE DRIVE SIDE ASSEMBLY Cont. MAHINDRA GYROVATOR SLX...

- Page 51 GASKET HOLLOW SHAFT BEVEL END-0.5 MM 007904029C1 GASKET HOLLOW SHAFT BEVEL END -0.25MM 007904075C91 TAPPER ROLLER BEARING 130 X 75 X 27.25 007905157C1 SLX SPIRAL BEVEL GEAR-T19 MAHINDRA GYROVATOR SLX ABBREVIATION : M - METER, MS - MULTI SPEED,CM - CENTER MOUNTED,OS-OFFSET...

- Page 52 A) GEAR BOX & SUPPORT TUBE DRIVE SIDE ASSEMBLY MAHINDRA GYROVATOR SLX...

- Page 53 SLX SPIRAL BEVEL GEAR-T11 007904077C91 TAPPER ROLLER BEARING 112.7 X 57.15 X 30 P3110114A CIRCLIP 35x1.5N IS:3075 007903950C1 SPUR GEAR 17 T 007903949C1 SPUR GEAR 21 T MAHINDRA GYROVATOR SLX ABBREVIATION : M - METER, MS - MULTI SPEED,CM - CENTER MOUNTED,OS-OFFSET...

- Page 54 B) DRIVE SIDE PLATE ASSEMBLY MAHINDRA GYROVATOR SLX...

- Page 55 SPRING WASHER M12 007904089C1 BOLT M12 X 1.5 X 30 (GRADE 10.9) 007904284C1 BOLT M10 X 1.5 X 50 (GRADE 8.8) 007904035C1 GASKET-IDLER SHAFT 007904451C1 SHAFT -IDLER GEAR 007904102C1 SPRING WASHER M10 007904290C1 NUT M10 X 1.5 NYLOC MAHINDRA GYROVATOR SLX...

- Page 56 C) NON DRIVE SIDE PLATE ASSEMBLY MAHINDRA GYROVATOR SLX...

- Page 57 WASHER PLAIN M12 O.D. 24 (1.6 t) 007904104C1 SPRING WASHER M12 007904089C1 BOLT M12 X 1.5 X 30 (GRADE 10.9) 007904442C1 SPACER CUP TYPE 007904443C1 PLATE LOCK CUP SIDE 007904082C1 BOLT M8 X 1.25 X 30 (GRADE 8.8) MAHINDRA GYROVATOR SLX...

- Page 58 D) MAIN FRAME ASSEMBLY MAHINDRA GYROVATOR SLX...

- Page 59 007904291C1 NUT M16 X1.5 NYLOC 007904106C1 SPRING WASHER M16 007904192C1 HOLDING BLOCK - DRIVE SIDE 007904104C1 SPRING WASHER M12 007904289C1 NUT M12 X 1.5 NYLOC MAHINDRA GYROVATOR SLX ABBREVIATION : M - METER, MS - MULTI SPEED,CM - CENTER MOUNTED,OS-OFFSET...

- Page 60 E) SIDE COVER ASSEMBLY MAHINDRA GYROVATOR SLX...

- Page 61 P3110050A RUBBERIZED CORK GASKET - SIDE COVER SLX 007903955C1 SIDE SPUR GEAR SLX - T27 007904764C1 O-RING 20X2 007904730C1 AIR BREATHER ADOPTER SMALL 007904763C1 BREATHER ASSY 007905021C1 WASHER PLAIN M8 X 3 THK P3110021A BOLT M8X1.25X40(Grade 8.8) MAHINDRA GYROVATOR SLX...

- Page 62 F) ASSEMBLY SUPPORT TUBE NON DRIVE SIDE & MAST BRACKET MAHINDRA GYROVATOR SLX...

- Page 63 BOLT M12 X 1.5 X 160 (GRADE 10.9) 007904781C1 PIN TOP LINK IMPLEMENT END P3110088A SKID SHOE WEAR PLATE SLX 007904089C1 BOLT M12 X 1.5 X 30 (GRADE 10.9) MAHINDRA GYROVATOR SLX ABBREVIATION : M - METER, MS - MULTI SPEED,CM - CENTER MOUNTED,OS-OFFSET...

- Page 64 G) LEVELLING BONNET ASSEMBLY MAHINDRA GYROVATOR SLX...

- Page 65 BOLT M8 X 1.25 X 50 (GRADE 8.8) 007904288C1 NUT M8 X 1.25 NYLOC P3110088A SKID SHOE WEAR PLATE SLX 007904089C1 BOLT M12 X 1.5 X 30 (GRADE 10.9) P3110034A CUP WASHER MAHINDRA GYROVATOR SLX ABBREVIATION : M - METER, MS - MULTI SPEED,CM - CENTER MOUNTED,OS-OFFSET...

- Page 66 H) ROTOR SHAFT ASSEMBLY 2M (Regular & Anti-Clogging) MAHINDRA GYROVATOR SLX...

- Page 67 ANTI CLOGGING ROTOR SHAFT ASSY. FOR SLX (10MM FLANGE THK.) P3110093A ROTOR SHAFT ASSY. FOR SLX 1.5M REGULAR (12MM FLANGE THK.) P3110103A ROTOR SHAFT ASSY. FOR SLX 1.5M ANTI-CLOGGING (12MM FLANGE THK.) MAHINDRA GYROVATOR SLX ABBREVIATION : M - METER,RH-RIGHT HAND SIDE,LH-LEFT HAND SIDE...

- Page 68 I) FITMENT OF ROTOR SHAFT ASSEMBLY MAHINDRA GYROVATOR SLX...

- Page 69 Illus. Description Quantity Part 007904087C1 BOLT M12 X 1.5 X 40 (GRADE 10.9) 007904104C1 SPRING WASHER M12 007904088C1 BOLT M12 X 1.5 X 50 (GRADE 10.9) MAHINDRA GYROVATOR SLX...

- Page 70 J) FITMENT OF PROPELLER SHAFT FITMENT OF PROPELLER SHAFT MAHINDRA GYROVATOR SLX...

- Page 71 007904876C1 SPRING YOKE 007904878C1 UNIVERSAL JOINT CROSS 007904877C1 SPLINED SHAFT SET - 9 SPLINED 007904879C1 GUARD COVER 007904881C1 BUSH SET - 9 TEETH 007904882C1 SHEAR YOKE 007904883C1 QUICK RELEASE PIN 007904884C1 SHEAR BOLT WITH NUT M10X65 (8.8G) MAHINDRA GYROVATOR SLX...

Need help?

Do you have a question about the Gyrovator SLX Series and is the answer not in the manual?

Questions and answers