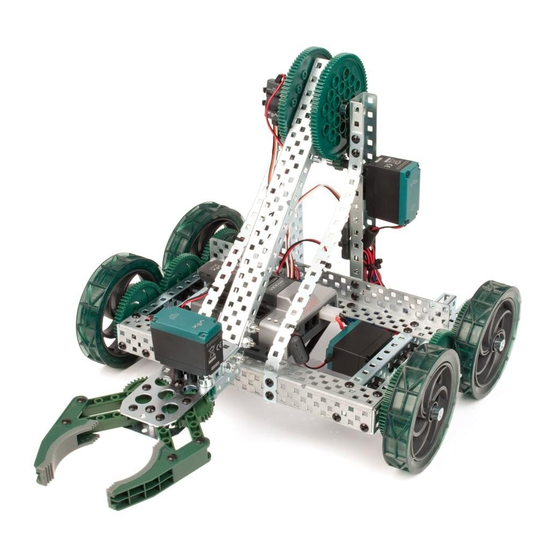

Vex Robotics CLAWBOT Assembly Manual

Hide thumbs

Also See for CLAWBOT:

- Build instructions (28 pages) ,

- Building instructions (37 pages) ,

- Build instructions (28 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Vex Robotics CLAWBOT

- Page 1 GUIDE FOR BUILDING THE CLAWBOT NOTE: This kit requires other components which are not included in order to build a complete working robot. The primary additional required component is a compatible VEX EDR robot control system.

- Page 2 REFERENCE: 5 HOLE 10 HOLE 15 HOLE [A20] CHASSIS BUMPER ANGLE, 20-HOLES LONG [R16] CHASSIS RAIL, 16-HOLES LONG [C20] C-CHANNEL, (1X2X1) 20-HOLES LONG [C15] C-CHANNEL, (1X2X1) 15-HOLES LONG [B20] BAR, 20-HOLES LONG [SH-3] VEX 3” SqUARE SHAfT [ZIP] 4” ZIP TIE...

- Page 3 REFERENCE: 20 HOLE 25 HOLE 30 HOLE [BR-I] BEARING POP-RIVET (INSIdE) [BR-O] BEARING POP-RIVET (OUTSIdE) [ST-1] [BF] 8-32 THREAdEd BEARING fLAT STANdOff (1” LONG) [CPLR] [CP] MOTOR COUPLER MOTOR COUPLER POST [COL] [SP4.8] SHAfT COLLAR wITH THIN SPACER (4.8 MM) 8-32 X 1/8”...

- Page 4 REFERENCE: [CLAW] [M393] [MC29] CLAw ASSy 2-wire Motor 393 MOTOR (shown not to scale) Module CONTROLLER 29 (shown not to scale) (shown not to scale) [BST] [VNET] [BATT] [CTX] VEX Battery Strap VEXnet key 7.2V RECHARGEABLE CORTEX (shown not to scale) (shown not to scale) (shown not to scale) BATTERy...

- Page 5 REFERENCE: 5/64” 3/32” wRENCH [NK] 8-32 kEPS NUT [11/32”] [SS-S] 1/4” MOTOR SCREw [NL] 8-32 LOCk NUT [SS-L] 1/2” MOTOR SCREw [1/4”] [5/64”] [ST-1] [S2] 1/4” SCREw [S4] 1/2” SCREw [S12] 1.5” SCREw [COL] COLLAR [5/64”] [3/32”] [BR-I] [BR] POP RIVETS [BR-O] [BF] BEARING fLAT [BF] BEARING fLAT...

- Page 6 [x2] [x2] [R16] [BF] [BF] [BF] [BR-O]x6 [BR-I]x6 [M393] [R16] [BR-I]x5 [SS-L] [BR-O]x5 [SS-S] [BF]x3 [BR-I]x5 [M393] [BR-O]x5 [SS-S] [R16] [SS-L] [BF]x3...

- Page 7 [C15] [BF] [BR-I]x4 [BF] [BR-O]x4 [C15] [BF] [BR-I]x3 [BR-O]x3 [BF] FROM STEP 5 [M393] [CPLR] [CP] [SS-L] [SS-S]...

- Page 8 [A2O] FROM STEP 1 [S2] [NK] [S2] [NK] FROM STEP 1 [S2] [NK] FROM STEP 7 [S2] [NK] FROM STEP 2 FROM STEP 8 [NK]x2 [S2]x2...

- Page 9 FROM STEP 3 [S2] FROM STEP 9 [S2] [NK]x2 [A2O] [S2]x3 [S2]x3 FROM STEP 10 [NK]x3 [NK]x3 [S2]x2 FROM STEP 4 [NK]x2 FROM STEP 11...

- Page 10 FROM STEP 6 FROM STEP 12 [NK]x2 [S2]x2 [G60] [COL] FROM STEP 13 PUSH COLLARS TOGETHER BEfORE TIGHTENING SET SCREwS [SH-3] fULLy INSERT SHAfT INTO MOTOR! [COL] PUSH COLLARS [SP4.8]x2 TOGETHER BEfORE TIGHTENING SET [G60]x2 SCREwS [COL]x2 [SH-3]x2 [COL]x2 [W4]x2...

- Page 11 PUSH COLLARS TOGETHER BEfORE TIGHTENING SET SCREwS [G60] [COL] [SH-3] fULLy INSERT SHAfT INTO MOTOR! [COL] PUSH COLLARS PUSH COLLARS TOGETHER BEfORE TOGETHER BEfORE TIGHTENING SET SCREwS TIGHTENING SET SCREwS [SH-3]x2 [COL]x2 [W4]x2 [SP4.8]x2 [G60]x2 [COL]x2 [S2] [G84] [ST-1] [S2] [G84]...

- Page 12 [S4] [S4] [S4] [S4] [NK]x4 [CLAW] [NL]x2 [S12]x2 [COL]x2 [SP4.8]x2 [SH-3] [G12]x2 [COL] ROBOT fRONT fULLy INSERT SHAfT INTO MOTOR FROM BEfORE TIGHTENING SHAfT COLLARS STEP 17...

- Page 13 [COL] SqUEEZE TOGETHER BEfORE TIGHTENING COLLARS! [COL] [COL] FROM STEP 20 [SH-3] [COL] ROBOT fRONT FROM STEP 21 *CHECK THAT ARM ROTATES UP AND DOWN SMOOTHLY WITH ONLY MINOR MOTOR RESISTANCE [NK]x4 [BST]x2 ROBOT fRONT [S4]x4 MOUNT BATTERY STRAP UNDER CHASSIS...

- Page 14 [S4]x4 [CTX-VNET] [NK]x4 [S2]x4 [NK]x4...

- Page 15 [B20] [S2]x4 [NK]x4 ROBOT fRONT...

- Page 16 CLAW MOTOR RIGHT DRIVE ARM MOTOR MOTOR ROBOT fRONT LEFT DRIVE MOTOR CONFIGURATION BASED ON CORTEX MICROCONTROLLER DEFAULT CODE. ROBOT VEXnet GAME...

- Page 17 PLUG IN WITH RED WIRE TOWARD CENTER OF CONTROLLER MOTOR PORT 1 LEFT DRIVE MOTOR CONNECT MOTOR PORT 6 BLACk TO BLACk CLAW MOTOR CONNECT MOTOR PORT 7 BLACk TO REd ARM MOTOR PLUG IN WITH RED WIRE TOWARD CENTER OF CONTROLLER MOTOR PORT 10 RIGHT DRIVE MOTOR CLAW OPEN/CLOSE...

- Page 18 HIGH SPEED/LOW TORQUE MOTORS (Optional Configuration): To modify the VEX 2-Wire Motor 393 into “High Speed Mode” simply swap out the final gear ratio using the included change gears with the following procedure: 2. Lift off the top cover. Do not disturb the 1.

- Page 19 Expand and conquer. Once you’ve mastered the CLAWBOT, we challenge you to move onto even more advanced robot designs. Of course, all VEX mechanical gears, wheels, hardware and structural metal parts are cross-compatible for endless design possibilities. with hundreds more upgrade parts and accessories, the creative possibilities for your robot designs are limitless.

- Page 20 In addition to having a great time and building amazing robots, through their participation in the VEX Robotics Competition and their work within their team, students learn many academic and life skills. Local VEX Robotics competitions are held in many different cities, states and countries.

Need help?

Do you have a question about the CLAWBOT and is the answer not in the manual?

Questions and answers