Table of Contents

Advertisement

Quick Links

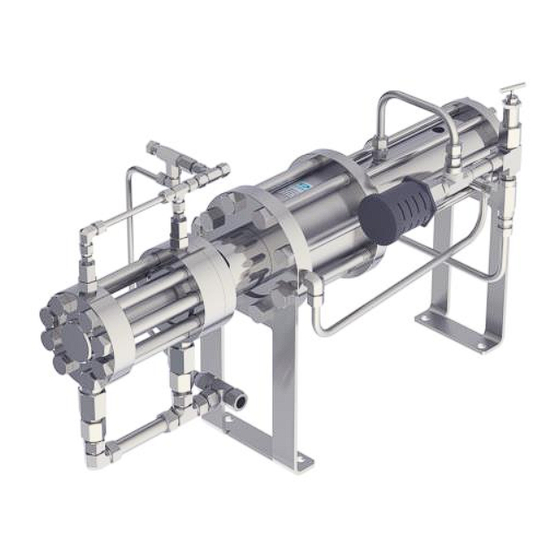

Series 5400/8400 Pneumatic Chemical Injection Pump

Operating Manual

Series 5400 & 8400

Pneumatic Chemical Injection Pump

Operating Manual

CheckPoint Headquarters

CheckPoint UK

CP Pumps & Systems FZE

CheckPoint Systems Pte Ltd

21356 Marion Lane

C2/C3 Lombard Centre

P.O. Box 262131

21 Toh Guan Road East

Mandeville, Louisiana 70471

Kirkhill Place, Kirkhill Industrial Estate

Jebel Ali Free Zone, FZS1 BL 06

#04-11 Room 1 Toh Guan Centre

United States of America

Dyce, Aberdeen AB21 0GU Scotland

Dubai, U. A. E.

Singapore 608 609

+1 (504) 340-0770

+44 (0)1224 775205

+971 (4) 8806278

+65 6261 7687

Page 1 of 13

CP/MAN-PRD-5484 REV09 EFF. DATE: 1/15/17

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Checkpoint 5400 Series

- Page 1 Series 5400 & 8400 Pneumatic Chemical Injection Pump Operating Manual CheckPoint Headquarters CheckPoint UK CP Pumps & Systems FZE CheckPoint Systems Pte Ltd 21356 Marion Lane C2/C3 Lombard Centre P.O. Box 262131 21 Toh Guan Road East Mandeville, Louisiana 70471...

-

Page 2: Table Of Contents

Series 5400/8400 Pneumatic Chemical Injection Pump Operating Manual Table of contents 1. PUMP INSTALLATION Process Design & Setup ..........................3 Connecting The Chemical Supply ......................5 Connecting The Supply Gas ........................6 2. GAS RECOVERY SYSTEMS - INSTALLATION 3. PUMP OPERATION Setting The Pump Stroke Rate ........................ -

Page 3: Pump Installation

All the components shown above are recommended by CheckPoint to maximize productivity and life of the pump in typical field or plant use. CheckPoint is available to answer your process questions or to help design and build a skid system utilizing components appropriate for your application. - Page 4 1.1.4 CheckPoint recommends use of a calibration gauge for your assurance of proper pump function and chemical delivery rate. Please read the section in this Guide entitled 3.2.1 Setting Pump Speed Using a Calibration Gauge on page 8 for more information.

-

Page 5: Connecting The Chemical Supply

Use of a pre- suction in-line chemical filter such as the CheckPoint Series FSTS and/or a ceramic or Hastelloy plunger is recommended if symptoms continue. Call CheckPoint for appropriate filter element sizing criteria. -

Page 6: Connecting The Supply Gas

1.2.4 Check that the packing nut is properly adjusted. In a new pump, proper adjustment is finger-tight, plus 1/8 of a turn. Use a packing adjustment tool (available from CheckPoint at no charge) for best results. IMPORTANT: PLEASE REVIEW Section 4.1: Packing Adjustment on page 10. - Page 7 To find the Amplification Ratio for your pump, please see Figures 2 and 3 below. NOTE: If the above formula yields a result of < 50 PSIG, use 50 PSIG as your supply pressure. FIGURE 2: AMPLIFICATION RATIO TABLE, 5400 SERIES PLUNGER DIAMETER (IN) AMPLIFICATION RATIO 0.500...

-

Page 8: Gas Recovery Systems - Installation

2.1.1 The exhaust gas can be exhausted directly to atmosphere, or can be recovered to a lower pressure gas system. If vented directly to atmosphere, CheckPoint supplies the pump with a muffler to reduce exhaust noise. 2.1.2 If recovering the exhaust gas, connect the gas recovery line from the process to the open 1/2” tubing connector on the injector. - Page 9 Operating Manual 3.1.1.4 Now ensure that the CheckPoint pump is running. Take note of the level of chemical in the gauge using the appropriate scale for the volume units you want to measure the pump’s output in. Usually the gauge will show liters on one scale and quarts or gallons on the other.

-

Page 10: Pump Maintenance

4.1.1 Use a CheckPoint T10010 packing adjuster, which is specifically designed for this purpose. If one is not available, you may order one at no charge directly from CheckPoint. In an emergency or if time is short, a 6” length of ¼”... -

Page 11: Lubrication

Set the lubricator rate as low as possible, one to two drops per minute, unless cold conditions dictate more in order to prevent freezing of the gas supply. CheckPoint offers both a small and a large in-line lubricator;... -

Page 12: Pump Does Not Stroke

If, after removal of the housing with the spool still inside, the spool will not move within the housing, call CheckPoint to order a replacement spool made of a different material. -

Page 13: Chemical Leakage From Packing Nut

5.5.3 Remember that after you repair your CheckPoint pump, it should perform as well as it did when it was new If it doesn’t, call us to determine what can be done to restore the pump to “like-new” performance.

Need help?

Do you have a question about the 5400 Series and is the answer not in the manual?

Questions and answers