Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for BCN3D Sigmax R19

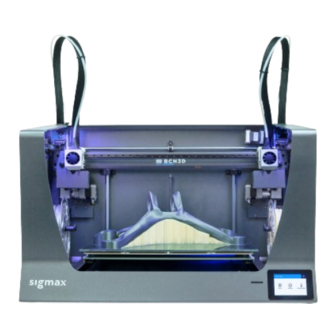

- Page 1 - R19 - User Manual User Manual...

-

Page 2: Table Of Contents

Your first dual print First Mirror/Duplication print Firmware Upgrade Functionalities Operation and maintenance Change hotend Clean and lubricate axes Hotend cleaning Filament Maintenance Plan BCN3D Technologies Technical Assistance Services Diagram Of The Sigmax R19 Terms And Conditions Open Source User Manual... -

Page 3: Introduction

Introduction Warranty Fundació Privada Center CIM (“Fundació CIM”) provides this Warranty to the consumers of the BCN3D brand products included in the sales package (“Product”). This Warranty will be valid only in the country in which the sale of the Products has been made. Fundació CIM hereby guarantee that, within the warranty period, Fundació... - Page 4 Warranty Conditions to exercise the warranty 8 If a part of the Product is repaired or replaced during the warranty period, the remaining warranty period The BCN3D warranty is granted under the following for the entire product will apply to this part. However, conditions: repairing and / or replacing a part will not extend the warranty period.

- Page 5 Warranty 4 The product must be sealed in its original packaging. 3 The damages caused by the non-compliance of the In the case of not returning the order in its original maintenance plan exposed in the User’s Manual of the and sealed packaging, BCN3D Technologies reserves Product.

- Page 6 Warranty Limitations and liability exemptions This Warranty is the sole and exclusive Warranty of Fundació CIM and the sole and exclusive responsibility of Fundació CIM for the defects present in its Products. Therefore, this Warranty replaces any other guarantee issued by Fundació CIM, whether oral or written on any method.

-

Page 7: Conformity

Conformity The CIM Private Foundation Centre declares that the Sigmax R19 printer complies with the essential requirements and any other applicable or mandatory provisions of the Directives. It complies with the essential requirements of the European Directives: 2006/42/EEC Machinery Directive... -

Page 8: Specifications

Specifications Manufacturing technology Fused Filament Fabrication (FFF) Architecture Independent dual extruder (IDEX) General dimensions 685 mm x 440 mm x 680 mm (fully assembled) Weight 20 kg (without filament spools) Printing volume 420 x 297 x 210 mm Number of extruders Nozzle diameter 0.3 / 0.4 / 0.5 Special / 0.6 Standard / 0.8 / 1mm Layer height... -

Page 9: Idex / Fff Technology

IDEX / FFF technology The Sigmax R19 is a 3D printer which uses fused filament fabrication (FFF) technology, which manufactures objects by depositing molten material in a series of layers. Objects are created using a digital model of the object, which is sliced into thin layers. - Page 10 Safety Very important. As with any other appliance, do not touch the terminals of the mains, the switch, or the power supply. There is a risk of electrocution. The other cables of the machine operate at 24V and there is no risk whatsoever. Connect the machine to an electrical outlet according to the current legislation.

-

Page 11: Safety Signage

Safety signage The following stickers have been affixed to the printer to warn users about the hazardous areas of the machine, and actions which are not recommended as they will stop the machine from working properly. 1 Pictogram: Danger. Hot surface. -

Page 12: Setting Up Your Printer

Setting up your printer Unboxing The Sigmax R19 is delivered in a well-secured cardboard box which measures 675mm x 440mm x 680mm. We recommend you to follow the steps below in order to unpack your 3D printer correctly: Retain packaging for warranty service. -

Page 13: Contents

Contents Sigmax R19: with 0.6mm hotends Quick start guide and warranty 2 Teflon tubes 4 Flat cable clips 2 Spool holders 6 Clips Glass printing surface 2 0.4mm Hotends SD card USB and Power cable 2 PLA spools Spatula and Pliers... -

Page 14: Set Up

Set up In order to ensure the safe packaging and transport of your printer some of the components have been sent unassembled. Before starting to print with the Sigmax R19 printer you need to assemble them in order to complete the setting up process. If you have any queries while assembling the machine, please contact BCN3D Technologies technical service at support@bcn3dtechnologies.com. - Page 15 Set up Place the spools holders into the spools. Fit them into the indicated holes. User Manual...

- Page 16 Set up Move Y axis manually Insert the teflon tube until towards the front in order to it stops. work more comfortably. Insert the opposite end of the teflon tube into the hotend’s hole until it stops. When inserting the teflon tubes, set them up as vertical as possible.

- Page 17 Set up Attach the teflon tubes with the clips. User Manual...

- Page 18 Set up Put together the teflon tube with the hotend cable using the flat cable clips. User Manual...

- Page 19 Set up Connect the power supply cable. The plug is located at the rear of the machine. Insert the SD card into the reader. User Manual...

- Page 20 Set up The Sigmax features an external feeding system to use bigger spools, up to 300mm in diameter, at the back of the printer. The 3D file in STL format for the external spool support can be found both in the SD card attached and in the BCN3D website: Support -->...

-

Page 21: Getting Started

Getting started Setup Assistant 1. Welcome 2. Setup Assistant 3. Load filament Press Accept. Press Next. Welcome to BCN3D Sigmax experience! 4. Select material 6. Repeat the process for the second Follow screen’s instructions Choose PLA. in order to load the material. extruder. - Page 22 Setup Assistant 10. Z Axis calibration Place the Calibration Gauge between the nozzle and the When indicated on the screen, printing surface glass. Hold the gauge by the end and move apply a thin and uniform layer it back and forth, without pressing the platform. Raise the of glue stick on the entire platform until you feel some resistance while sliding the printing surface glass to...

- Page 23 Setup Assistant 15. X Axis calibration 16. Choose the best aligned Y Axis calibration The printer will print vertical couple of lines. The printer will print lines. horizontal lines. . Choose the best aligned couple of lines. Congratulations! Your printer has been calibrated and it is ready to print. User Manual...

-

Page 24: Mirror And Duplication Modes

Mirror and Duplication modes The Sigmax features two new printing modes: Mirror and Duplication. In these modes both toolheads work simoultaniously. To do it successfully it is key important to make sure both nozzle tips are exactly at the same height. - Page 25 Mirror and Duplication modes To avoid such distortion there are different options: 1. Enable raft in BCN3D Cura. The offset will be corrected in the first layers of the raft, so the model won’t be affected by any Z offset. 2.

-

Page 26: Installing Shims

Installing shims During the Printer Calibration process or before printing a job with Duplication or Mirror mode, the Sigmax may suggest you to install shims to correct the Z offset between nozzle tips. Once you confirm you want to install the shims, remember de number of shims to install on which ho- tend and just follow the screen instructions: Wait until the printer cools... - Page 27 Installing shims Install as many shims as Screw the bolts again. were indicated in the screen. Put the black piece again in its Turn on the machine and place and screw the bolt again. follow the instructions on the screen. User Manual...

-

Page 28: First Printing

After the calibration process has been completed, you can access the printing menu. The first object you will print with the Sigmax R19 is the Draudi figure, as it will allow you to check that everything is working properly and you are now ready to start printing your own objects. -

Page 29: Starting Out With Bcn3D Cura

Visit https:/ /www.bcn3dtechnologies.com/en/3d-printer/bcn3d-cura/ and download the suitable version of BCN3D Cura for your Operative System. Once downloaded, follow the installation wizard. Your first dual print Open BCN3D Cura previously downloaded and installed. Select Sigmax R19 in the menu Add printer. User Manual... - Page 30 Your first dual print Click Open File. Select files to print. Click the model and assign the extruder to print with. User Manual...

- Page 31 Your first dual print Select the models by Shift+Left Click. Selected mo- Select profile. dels will be highlighted with a blue outline. Right click on any of the selected models, and select Merge Models. Click Prepare to generate the printing file. Insert the SD card in your computer and Safely remove the SD card from the com- save the file.

- Page 32 If your printed part has adhesion problems with the glass printing surface, we recommend using alternative adhesives solutions, such as 3DLac or Dimafix. You can find them at our website https:/ /www. bcn3dtechnologies.com/en/3d-printer-spare-parts/ Congratulations! You have started printing your first 3D part with the Sigmax R19. User Manual...

-

Page 33: First Mirror/Duplication Print

First Mirror /Duplication print Load files to print and move, scale or rotate the Select the printing profile for the Left Extruder. Make models as needed. sure the hotend and material loaded at Right Extruder are the same than in the Left Extruder. Select the desired printing mode in the drop-down list. -

Page 34: Firmware Upgrade

Firmware upgrade At BCN3D Technologies we want you to have a great printing experience, and to achieve this we are continually working to create new firmware upgrades for our printers. Follow this process through BCN3D Cura for checking if the latest firmware version is installed on your printer. If not, it will get the latest firmware and it will be installed. 1. - Page 35 Firmware upgrade 5. Wait until the firmware is installed. The process 6. Once the process is completed, close the window. may take a few minutes to complete. ¡Congratulations! You have upgraded the firmware of your Sigmax R19. User Manual...

-

Page 36: Functionalities

Functionalities Utilities This section contains a description of Sigmax R19 functionalities. The main menu is divided into three large groups: print, utilities and temperatures. The first Situated at the center of the main menu, allows you to covers all the standard printing functions. The second operate and maintain your printer. - Page 37 Functionalities –Printing Surface Calibration: This option allows - Printing Components Setup: Manually set up the you to level the printing surface. The process is per- nozzle sizes installed in the printer and the use of the formed by an onscreen self-test run by the printer, Filament Runout Sensor.

-

Page 38: Operation And Maintenance

Operation and maintenance Change hotend By default, the Sigmax is equipped with 0,6mm hotends, but is possible to change them to tackle different print jobs. Changing the hotend is an easy operation that can be performed in a few minutes. You will need: - Scissors or cutting pliers - 2,5mm hex key - Pliers... - Page 39 Operation and maintenance Turn off the Sigmax when the LCD indicates it. Remove the black piece to work more comfortably. Then remove the black clip. Finally, hold down the cou- pling collet and pull out the teflon tube. User Manual...

- Page 40 Operation and maintenance Unscrew the cover and remove it. Unscrew the hotend. Cut the zip tie and remove it. User Manual...

- Page 41 Operation and maintenance At the back of the toolhead carriage, press the connector to remove the cable of the hotend. Remove the old hotend and place the new one, connecting it at the back of the toolhead carriage. User Manual...

- Page 42 Operation and maintenance Place and adjust the zip tie, cutting off the excess. Screw the hotend, place the cover and screw it. User Manual...

- Page 43 Operation and maintenance Insert the teflon tube until it stops, making sure it is well placed. Put back the black clip and the black piece. Turn on the Sigmax and follow the screen Load filament and perform an autotune operation. instructions.

-

Page 44: Clean And Lubricate Axes

Operation and maintenance Clean and lubricate axes Periodically, according to the Maintenance Alerts via LCD screen, it is recommended to clean and grease the axes of the Sigmax with the lubrication kit to ensure smooth and precise performance of its mechanical components. Follow these steps: From the LCD screen, go to Utilities -->... - Page 45 Operation and maintenance Apply the lubricating oil pencil along the Z shaft bars, Clean grease and dust from the Z-axis motor spindle making sure that it does not drip. with paper or a cloth. Turn the spindle manually to access its rear. Apply the grease along the spindle of the Z-axis motor.

- Page 46 Operation and maintenance Once the process for the Z axis is finished, let’s clean and lubricate X and Y linear guides. First of all, turn off the Sigmax. During this process it’s recommended to manually move the axes in order to reach all the guide. From the center towards the ends of the linear guides of the X and Y axes, remove dirt with an absorbent paper or a cloth.

- Page 47 Operation and maintenance Clean again the X and Y guides with an absorbent paper or a cloth. Apply the lubricating oil pencil along the linear guides of the X and Y axes, with special emphasis on their superior and inferior faces. Make sure there is no excess oil dripping. User Manual...

-

Page 48: Hotend Cleaning

Operation and maintenance Hotend Cleaning It is recommended to clean the hotend periodically and, especially, every time you switch materials. Ideally, use a piece of nylon filament to perform this operation. Operating the printer via the LCD screen, go to Select the hotend to clean and, in case there’s Utilities -->... - Page 49 Operation and maintenance Wait until the hotend heats up. Push the nylon filament through the hotend until it comes out clean of residues. Press NEXT and keep pushing until new notice. Wait while the hotend cools down. Finally, when indicated in the screen, pull out the Repeat the process until the removed filament tip piece of filament.

-

Page 50: Filament

Filament The Sigmax R19 printer gives the best printing results Printing overhangs is easier if the layer fan is used. when printing with BCN3D Filaments, although it accepts many other materials from other It has average mechanical properties, although it manufacturers. - Page 51 Filament Nylon PVA (Polyvinyl alcohol) is a water-soluble polymer, Nylon (polyamide) is an extensively used material for its ideal to work as support material for multi-material 3D unique mechanical and chemical properties. Printing. Thanks to characteristics like durability, flexibility and Optimized for the FFF manufacturing process, our PVA resistance to corrosion, Nylon is ideal for multiple works seamlessly with PLA, TPU, PET-G and Nylon,...

- Page 52 Filament General considerations To ensure good adhesion between the printing surface and the 3D printed part, you will need to use an adhesive product that will be applied to the printing surface before start printing. For general materials, we recommend using the glue stick included with the printer or a generic lacquer.

-

Page 53: Maintenance Plan

Maintenance Plan We recommend you carry out the maintenance procedures described in the table below in order to keep your prin- ter running optimally. The procedures are grouped depending on frequency they should be performed is shown on the right. FREQUENCY ACTION TO PERFORM Keep the printer free of dust and in a dry, cool place... -

Page 54: Bcn3D Technologies Technical Assistance Services

BCN3D Technologies Technical Assistance Services If you do not find a solution to your problem in this manual, please contact the BCN3D Technologies team through any of the following channels: Technical Assistance You can contact the technical assistance services by email, and we will answer you as quickly as possible. - Page 55 Diagram of Sigmax R19 Teflon tube Filament entry Extruder Filament Spool Hotend cable Switch Spool holder Platform 0.6 mm Hotend Power plug Purge Tank USB port Glass printing surface External feeding support SD Card reader External feeding guide Touchscreen Filament Runout Sensor...

- Page 56 Diagram of Sigmax R19 User Manual...

-

Page 57: Terms And Conditions

Terms and conditions Overall Vision 2 Defective goods The terms “we”, “us” and “our” refer to BCN3D Techno- If you detect any defect in the operation of the product, logies. The terms “you” and “your” refer to the person you have 7 working days from the reception of the or entities that purchase any service or product. - Page 58 Terms and conditions How to make a return? • The refunds will be carry out between the 1st and 10th of the month according the return acceptan- In order to make a return first, you will have to contact ce. For example, if the return becomes effective us to sales@bcn3dtechnologies.com, explaining the on April 15, the money will be paid between May 1 reason of your willingness to return or substitute one...

-

Page 59: Open Source

CAD/CAM software to the code read by the machine to print physical objects. Sigmax R19 printers use many open source tools and technologies, such as Marlin software and the Cura pre-pro- cessed software. The first controls all the printer´s components, while the second converts the 3D file into G-code, a language the machine is able to understand. - Page 60 MX-R19-2018-3...

Need help?

Do you have a question about the Sigmax R19 and is the answer not in the manual?

Questions and answers