Summary of Contents for Mec 1532ES

- Page 1 1532ES / 1932ES OPERATOR’S MANUAL This Operator’s Manual MUST BE READ AND UNDERSTOOD prior to operating your MEC Aerial Work Platform Part # 90720 Rev A Issued May 2005...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Introduction ......................iii Machine Specifications 1532ES / 1932ES ..................iv Section 1: Safety Safety Symbols ..................1-2 Safety Rules And Precautions ..............1-3 Fall Protection Notice ................1-5 Safety And Control Decal Locations ............1-6 Safety Related Decals ................1-8 Section 2: Operation Unloading Procedures ................ - Page 4 Prestart Inspection ................... 3-4 Frequent Inspection ................. 3-6 Annual Inspection ..................3-7 Troubleshooting ..................3-9 What To Check If Functions Will Not Operate ........ 3-9 Lubrication Diagram ................. 3-10 Lubrication Chart ..................3-11 Warranty Page ii May 2005 1532ES / 1932ES Operator’s Manual...

-

Page 5: Introduction

MODIFICATION MAY COMPROMISE THE SAFETY OF THE MACHINE, SUBJECTING OPERATOR(S) TO SERIOUS INJURY OR DEATH. Your MEC Scissor Lift has been designed, built, and tested to provide safe, dependable service. Only authorized, trained and qualified personnel should be allowed to operate or service the machine. -

Page 6: Machine Specifications

24 Volt DC, 25 Amps Tapering, Timed Shutoff Batteries Four 6 Volt deep-cycle; 220 Amp hours @ 20 hour rating Electric Motor 2.0 h.p. (1.49 kW): 3000 r.p.m. Meets Requirements of ANSI A92.6-1999 Section 4 Page iv May 2005 1532ES / 1932ES Operator’s Manual... -

Page 7: Section 1: Safety

SECTION 1: SAFETY Page 1-1 1532ES / 1932ES Operator’s Manual May 2005... -

Page 8: Safety Symbols

SAFETY SYMBOLS This section of the manual contains important information of the safe use of your MEC Scissors. Failure to read, understand, and follow all safety rules, warnings, and instructions will unnecessarily expose you and others to dangerous situations. For your safety and the safety of those around you, you must operate your machine as instructed in this manual. -

Page 9: Safety Rules And Precautions

Safety Rules And Precautions ♦ MEC designs self-propelled scissor lifts to be safe and reliable. They are in- tended to position personnel, along with their necessary tools and materials to overhead work locations. ♦ The owner/user/operator of the machine should not accept responsibility for the operation of the machine, unless properly trained. - Page 10 After performing this procedure, there is no means to stop the machine’s travel. MEC recommends using this procedure only in cases of emer- gency, and only for a short distance. Be on guard against machine runaway on sloping surfaces.

-

Page 11: Fall Protection Notice

Institute ANSI/SIA A92.6 Standard. It is prohibited to use an Aerial Work Platform manufactured by MEC with any portion, or all, of the guardrails removed. Lanyard anchorage points on this type of equipment are not required to conform to the applicable ANSI/SIA Standard. -

Page 12: Safety And Control Decal Locations

SAFETY AND CONTROL DECAL LOCATIONS Battery Side Hydraulics Side Front of Charger Page 1-6 May 2005 1532ES / 1932ES Operator’s Manual... - Page 13 Safety And Control Decal Locations Part # Description 90733 Manual Case 9137 Platform Capacity - 600 LBS., Large (1532ES) 90736 Platform Capacity - 500 LBS., Large (1932ES) 90722 Operator Warning 90730 Lock Warning 90721 Danger - Elec/Tip Hazards 90729 Joystick Directions 90628 Platform Capacity - 600 LBS., Small (1532ES)

-

Page 14: Safety Related Decals

USE OF THIS EQUIPMENT WITHOUT PROPERLY BLOCKING ELEVATING ASSEMBLY. 90721 15. DO NOT ATTACH OVERHANGING LOADS OR NICREASE PLATFORM SIZE. IMPROPER OPERATION OF THIS MACHINE COULD CAUSE DEATH OR SERIOUS INJURY. Page 1-8 May 2005 1532ES / 1932ES Operator’s Manual... - Page 15 PULL MANUAL ACTIVATOR BELOW 90268 TO LOWER PLATFORM. TO RETURN TO NORMAL OPERATION RESET LIFT CYLINDER VALVE. 90727 7155 LOCATE CONTROL BOX HERE 90401 FOR NORMAL OPERATION OF THIS UNIT 7155 7982 Page 1-9 1532ES / 1932ES Operator’s Manual May 2005...

- Page 16 159 kg 113 kg 444 N 227 kg 113 kg 113 kg 444 N 1-PERSON 1-PERSON 2-PERSONS 1-PERSON 2-PERSONS 1-PERSON 9137 90736 90729 90263 7156 90719 9052 90739 8391 9138 8402 8816 Page 1-10 May 2005 1532ES / 1932ES Operator’s Manual...

-

Page 17: Section 2: Operation

SECTION 2: OPERATION Page 2-1 1532ES / 1932ES Operator’s Manual May 2005... -

Page 18: Unloading Procedures

NOTE: The brakes are automatically released for driving and will automatically apply when the machine stops. ♦ Before placing the machine into service, all operators must read and under- stand the contents of this Operator’s Manual. Page 2-2 May 2005 1532ES / 1932ES Operator’s Manual... -

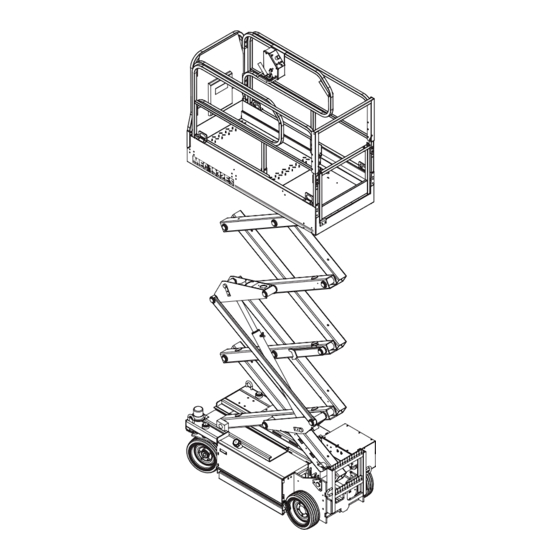

Page 19: Primary Machine Components

PRIMARY MACHINE COMPONENTS Control Box Platform Roll-out Extension Deck Main Platform Deck Beams Base Control Panel Lift Cylinder Ladder Base Page 2-3 1532ES / 1932ES Operator’s Manual May 2005... -

Page 20: Operator Controls

5 Emergency Stop Use to stop all functions in an emergency. Push for emergency Button stop. To reset turn clockwise. 6 Hour Meter Indicates total elapsed time the machine has been operated. Page 2-4 May 2005 1532ES / 1932ES Operator’s Manual... - Page 21 WINDY OR GUSTY CONDITIONS ADDITIONAL 30,000 VOLTS OR LESS. DEATH OR SERIOUS INJURY DEATH OR SERIOUS INJURY WILL RESULT FROM CONTACT WILL RESULT FROM IMPROPER OR INADEQUATE CLEARANCE USE OF THIS EQUIPMENT 90721 Page 2-5 1532ES / 1932ES Operator’s Manual May 2005...

-

Page 22: Platform Controls

OPERATOR CONTROLS (continued) 8391 PLATFORM CONTROLS 90729 Page 2-6 May 2005 1532ES / 1932ES Operator’s Manual... - Page 23 7 ft (2.13 m). “OFF” position is the normal mode. 4 Horn (Optional) Press button to sound warning horn. 5 Emergency Stop Push to stop all functions in emergency. Reset by turning Button clockwise. Page 2-7 1532ES / 1932ES Operator’s Manual May 2005...

-

Page 24: Prestart Inspection

NOTE: If the machine fails to operate, inspect the motor controller inside the motor compartment. A green LED located on the controller should be illuminated. If the LED is not illuminated, refer to the troubleshooting section. Page 2-8 May 2005 1532ES / 1932ES Operator’s Manual... -

Page 25: Base Control Operation And Checks

♦ Check for proper operation and hydraulic leaks. Rotate the maintenance lock into position before inspecting any items inside or around scissor arms. ♦ Rotate the maintenance lock into position. Lower platform to the stowed position. Page 2-9 1532ES / 1932ES Operator’s Manual May 2005... -

Page 26: Platform Control Operation And Checks

Enable bar or returning control handle to center position will stop motion of drive. ♦ Test the “Emergency Stop” function. While driving in both directions. Reset “Emer- gency Stop” by rotating the switch clockwise. Page 2-10 May 2005 1532ES / 1932ES Operator’s Manual... -

Page 27: Operation

Travel speed is proportional and is controlled by the movement of the controller handle. The further it is moved the faster the speed will be. The controller handle returns to neutral (center) position when released. Page 2-11 1532ES / 1932ES Operator’s Manual May 2005... -

Page 28: Braking

With selector switch in the “Base” position, press and hold the Lift/ Lower toggle switch in the “Down” position until the desired platform height is reached or until the platform reaches the stowed position. Page 2-12 May 2005 1532ES / 1932ES Operator’s Manual... -

Page 29: Extending The Roll-Out Extension Deck

2/3 charge illumination within a few minutes indicates that the batteries are fully charged. DO NOT OPERATE THE UNIT WHILE CHARGING. BE SURE TO DISCONNECT THE CHARGER FROM THE OUTLET BEFORE MOVING THE UNIT. Page 2-13 1532ES / 1932ES Operator’s Manual May 2005... -

Page 30: Shutdown Procedure

♦ Push in the manual brake release valve located on the main manifold. ♦ Using the hand pump in the battery compartment, pump valve until pressure is built. ♦ Machine is now ready for towing. Page 2-14 May 2005 1532ES / 1932ES Operator’s Manual... - Page 31 FREELY ON SLOPES. BE ON GUARD AGAINST RUNAWAY. DO NOT DRIVE MACHINE WITH BRAKES RELEASED. To Reset Brakes: ♦ Brakes will reset when drive function is activated or reset by pulling on manual brake release valve. Page 2-15 1532ES / 1932ES Operator’s Manual May 2005...

-

Page 32: Emergency Systems And Procedures

ELEVATED, HAVE AN EXPERIENCED OPERATOR USE THE EMERGENCY LOWERING PROCEDURE TO SAFELY LOWER THE PLATFORM. NEVER CLIMB DOWN BEAM ASSEMBLY WHEN PLATFORM IS RAISED. BEFORE LOWERING PLATFORM RETRACT THE DECK EXTENSION. Page 2-16 May 2005 1532ES / 1932ES Operator’s Manual... -

Page 33: Emergency Lowering

2. Pull manual activator (override valve) on main manifold to lower platform to desired height. 3. To return to normal operation, turn knurled knob on lift cylinder clockwise. Valve will automatically lock. Cylinder Valve 8599 8599 Manual Activator Page 2-17 1532ES / 1932ES Operator’s Manual May 2005... - Page 34 Page 2-18 May 2005 1532ES / 1932ES Operator’s Manual...

-

Page 35: Section 3: Maintenance

SECTION 3: MAINTENANCE Page 3-1 2033ES / 2633ES Operator’s Manual May 2005... -

Page 36: General Maintenance Tips

♦ Use only recommended lubricants. Improper lubricants or incompatible lubricants may be as harmful as no lubrication. ♦ Watch for makeshift “fixes” which can jeopardize safety as well as lead to more costly repair. Page 3-2 May 2005 1532ES / 1932ES Operator’s Manual... - Page 37 Inspection and maintenance should be performed by qualified personnel familiar with the equipment. Fluid leaks under pressure may not always be visible. Check for pin hole leaks with a piece of cardboard, not your hand. Page 3-3 1532ES / 1932ES Operator’s Manual May 2005...

-

Page 38: Prestart Inspection

Inspect the platform control. Ensure the load capacity is clearly marked. ________ Check the hydraulic system pressure (See Machine Specification). If the pressure is low, determine the reason and repair in accordance with accepted procedures as outlined in the service manual. Page 3-4 May 2005 1532ES / 1932ES Operator’s Manual... - Page 39 ________ 11. Check the platform controls for proper operation. Check all switches and push buttons, as well as ensuring that the drive controller returns to neutral. DATE_______________________ INSPECTED BY_______________________ Page 3-5 1532ES / 1932ES Operator’s Manual May 2005...

-

Page 40: Frequent Inspection

Check that all adjustable flow valves are locked, check setting if any are not locked. ________ Check that the platform does not drift down with a full load. ________ Check the electrical motor brushes. DATE______________________ INSPECTED BY______________________ Page 3-6 May 2005 1532ES / 1932ES Operator’s Manual... -

Page 41: Annual Inspection

♦ Keep inspection records up-to-date. ♦ Record and report all discrepancies to your supervisor. ANNUAL INSPECTION TO BE PERFORMED IN ACCORDANCE WITH THE ANNUAL INSPECTION REPORT SHOWN ON THE FOLLOWING PAGE Page 3-7 1532ES / 1932ES Operator’s Manual May 2005... - Page 42 Maintenance Locks: Operational Tilt Sensor Secure Emergency Stop: Generator Operational Breaks All Circuits Converter Comments: Signature/Mechanic: Date: Signature/Owner-User: Date: White Copy - Dealer Yellow Copy - Customer P/N 90728 Rev. 0 Page 3-8 May 2005 1532ES / 1932ES Operator’s Manual...

-

Page 43: Troubleshooting

♦ Batteries fully charged? ♦ Check emergency stop buttons at both base and platform? ♦ Hydraulic fluid level low? ♦ Obvious fluid leak or damaged component? ♦ Are any wires pulled out or loose? Page 3-9 1532ES / 1932ES Operator’s Manual May 2005... -

Page 44: Lubrication Diagram

LUBRICATION DIAGRAM Hydraulic Lubrication Page 3-10 May 2005 1532ES / 1932ES Operator’s Manual... -

Page 45: Lubrication Chart

Change Every Three Months Or 300 Hours, Which- ever Occurs First For Severe Usage. Lithium N.L.G. #2 EP Wheel Weekly or Every 25 Purge Old Grease Motor Hours, Mount Whichever Occurs First Page 3-11 1532ES / 1932ES Operator’s Manual May 2005... - Page 46 Page 3-12 May 2005 1532ES / 1932ES Operator’s Manual...

- Page 47 (1) year from date of registered sale or date the unit left the factory if not registered. MEC Aerial Platform Sales Corp. further warrants the structural weldments of the main frame and scissor arms to be free from defects in material or workmanship for five (5) years from date of registered sale or date unit left the factory if not registered.

- Page 48 Aerial Platform Sales Corp. 4780 E. Jensen Ave. • Fresno, CA 93725 USA Ph: 1-866-379-7278 • 559-263-9626 • Fax: 559-263-9631 www.mecawp.com...

Need help?

Do you have a question about the 1532ES and is the answer not in the manual?

Questions and answers