Summary of Contents for York YZ

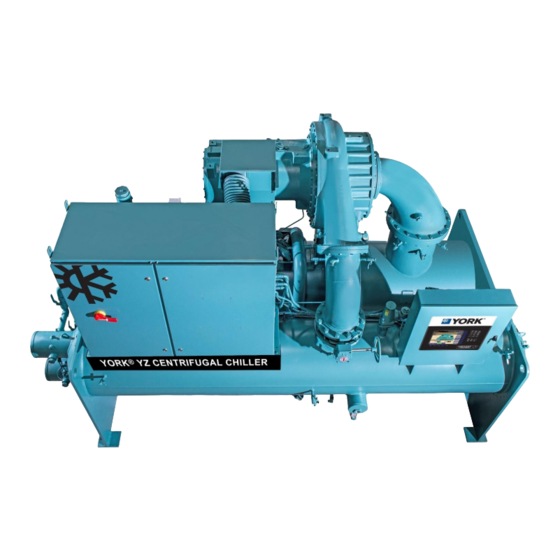

- Page 1 ENGINEERING GUIDE ® YORK YZ Centrifugal Chiller Form: 161.01-EG1 (0618) MODEL YZ MAGNETIC BEARING CENTRIFUGAL CHILLER Style A 580 through 3500 kW (165 through 1000 Tons) Utilizing R-1233zd...

-

Page 2: Table Of Contents

Table of Contents Nomenclature ............................3 Introduction ............................4 Unit Components ..........................6 Equipment Overview ..........................8 Codes and Standards ......................... 14 Chiller Options ............................ 16 Application Data ..........................17 Unit Weights & Dimensions ......................... 22 Visit YORK.com/Next for more information... -

Page 3: Nomenclature

YZ Engineering Guide Form: 161.01-EG1 (0618) Nomenclature SYSTEM YZ – MA033 AN030 P042N A Unit Mod Level Product Family VSD Name Motor Name Compressor Name MOTOR MA 033 AA Motor Family Motor Configuration Level Motor Size Code COMPRESSOR AN 030NA – AA... -

Page 4: Introduction

(ECWTs). These conditions are where chillers operate up to 99% of the time, and where operating costs add up. YZ chillers are designed to operate on a continuous basis with cold ECWT and full condenser flow at all load points, taking full advantage of real-world conditions. - Page 5 The majority of chiller components on YZ chillers have been time tested on the tens of thousands of air-cooled and water- cooled YORK® chillers operating globally. The YZ chiller employs the most advanced driveline available - an active magnetic-bearing drive to levitate the driveshaft.

-

Page 6: Unit Components

YZ Engineering Guide Form: 161.01-EG1 (0618) Unit Components OptiView™ Control Panel Variable Speed Drive Suction Line Lockout Handle Discharge Line Sight Condenser Glass Endsheet... - Page 7 YZ Engineering Guide Form: 161.01-EG1 (0618) Unit Components (Continued) VSD Coolant Reservoir Direct Drive Compressor Motor Refrigerant Purge Unit Compact Waterbox Evaporator...

-

Page 8: Equipment Overview

When selected, the initial charge of refrigerant can be supplied for each chiller from the factory. Actual shipping procedures for the chiller will depend on a number of project-specific details. YZ chillers are designed to keep installation costs low. Where installation access is not a problem, the unit can be shipped completely packaged including the unit- mounted variable speed drive, requiring minimal piping and wiring to complete the installation. - Page 9 A variable speed drive is factory-packaged and mounted on the YZ chiller. It is designed to vary the compressor motor speed by controlling the frequency and voltage of the electrical power to the motor. The capacity control logic shall automatically adjust motor speed and compressor diffuser geometry for maximum part load efficiency by analyzing information fed to it by sensors located throughout the chiller.

- Page 10 OPTIVIEW™ CONTROL CENTER Note: Please refer to the YZ Operations & Maintenance Manual (161.01-OM1) for a complete description of features and functionality. The YORK® OptiView™ Control Center is a factory mounted, wired and tested microprocessor based control system for centrifugal chillers.

- Page 11 By providing a common networking protocol through the Building Automation System (BAS), YORK® chillers not only work well individually, but also as a part of the building system. This networking protocol allows increased remote control of the chiller, as well as 24-hour performance monitoring via a remote site. In addition, compatibility is maintained with the present network of BAS communications.

- Page 12 This automatic, self-contained, high-efficiency purge unit collects non-condensable gases to be removed from the chiller. The YORK® purge is factory assembled, mounted, piped, and wired, and operates automatically. Purge exhaust cycles are monitored, and if excessive, provide warning of a potential system leak to the OptiView™...

- Page 13 The standard unit has been designed as a complete factory-packaged chiller, which minimizes the joints from which refrigerant can leak. The entire assembly is thoroughly leak tested at the factory prior to shipment. The YZ chiller includes service valves conveniently located to facilitate transfer of refrigerant to a remote refrigerant storage/recycling system.

-

Page 14: Codes And Standards

Chiller standards and codes vary based on factory source. Any of the standards and codes listed below can be met when ordering the YZ chiller. Work with your local sales contact for a unit that will meet your local codes and standards. - Page 15 YZ Engineering Guide Form: 161.01-EG1 (0618) BEC – Business Environment Council SASO – Saudi Standards, Metrology and Quality Organization ESMA – Emirates Authority for Standardization and Metrology LEED EA4 enhanced refrigerant management credit BREEAM Refrigerant Credit – Building Research Establishment Environmental Assessment Method SOUND RATINGS ...

-

Page 16: Chiller Options

YZ Engineering Guide Form: 161.01-EG1 (0618) Chiller Options ITEM DESCRIPTION STANDARD OPTIONAL Harmonic Filter None Input harmonic filter 60 Hz: 460V, 400V, 380V Incoming customer wiring 50 Hz: 415V, 400V, 380V VSD cooling heat exchanger protection None Sediment accumulator (for condenser fluid lines) 0.711 mm and 0.889 mm... -

Page 17: Application Data

LOCATION YZ chillers are virtually vibration free and may generally be located at any level in a building where the construction will support the total system operating weight. The unit site must be a floor, mounting pad or foundation which is level within 6.5 mm (1/4") and capable of supporting the operating weight of the unit. - Page 18 YZ chillers will operate successfully in VPF systems. With a minimum allowable evaporator tube velocity of 0.5m/s (1.5 fps) for standard tubes at part load rating conditions, YZ chillers will accommodate the wide variation in flow required by many chilled water VPF applications.

- Page 19 There are several common unit arrangements for this type of application. The YZ chiller has been designed to be readily adapted to the requirements of these various arrangements. Parallel Arrangement - Chillers may be applied in multiples with chilled and condenser water circuits connected in parallel between the units.

- Page 20 YZ Engineering Guide Form: 161.01-EG1 (0618) Depending on the number of units and operating characteristics of the units, loading and unloading schemes should be designed to optimize the overall efficiency of the chiller plant. It is recommended to use an evaporator bypass piping arrangement to bypass fluid around evaporator of any unit which has cycled off at reduced load conditions.

- Page 21 YZ Engineering Guide Form: 161.01-EG1 (0618) ELECTRICAL CONSIDERATIONS Unit input conductor size must be in accordance with applicable electrical codes, for the unit full load amperes (FLA). Please refer to the submittal drawings for the FLA and Minimum Current Ampacity (MCA) specific to each application.

-

Page 22: Unit Weights & Dimensions

YZ Engineering Guide Form: 161.01-EG1 (0618) Unit Weights & Dimensions Min. of 610 mm (2 ft) Min. of 915 Min. of mm (3 ft) 610 mm (2 ft) Service Clearance... - Page 23 YZ Engineering Guide Form: 161.01-EG1 (0618) Unit Weights & Dimensions (Continued) D - Tube Heat Exchanger Maximum A - Height B - Width C - Length Removal Size Shipping Weight Clearance 1.8 m (5.9’) FB2910/CA2110 2.3 m (7.4’) 3.1 m (10’) 3.1 m (10’)

- Page 24 YZ Engineering Guide Form: 161.01-EG1 (0618) Visit YORK.com/Next to learn more SAVE OUR NATURAL RESOURCES. THINK BEFORE YOU PRINT. Copyright© by Johnson Controls 2017 Form: 161.01-EG1 Issue Date: June 2018 Supersedes: 161.01-EG1 (1217) Subject to change without notice ALL RIGHTS RESERVED WORLDWIDE...

Need help?

Do you have a question about the YZ and is the answer not in the manual?

Questions and answers