Table of Contents

Advertisement

FORM 160.81-EG1 (502)

Model YR

Twin-Screw Compressor Liquid Chillers

Design Level A

00562VIP

200 through 430 tons (60 Hz)

ASHRAE

700 through 1500 kW (50 Hz)

90.1

COMPLIANT

170 through 365 tons (50 Hz)

600 through 1280 kW (50 Hz)

m

Rated in Accordance

Utilizing HFC-134a

with the latest edition of ARI

Metric Conversions

STANDARD 550/590

Advertisement

Table of Contents

Summary of Contents for York YR

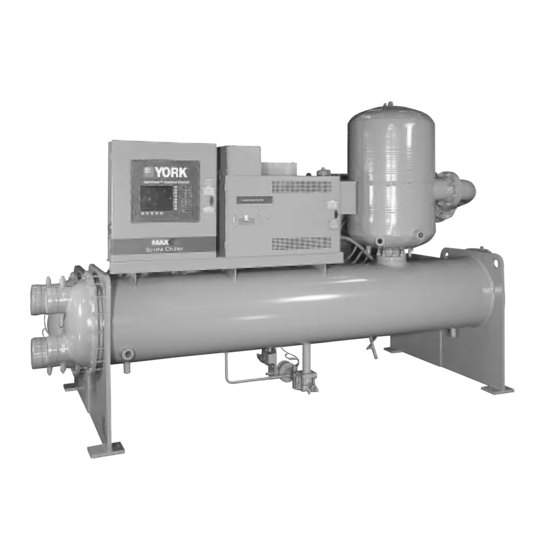

- Page 1 FORM 160.81-EG1 (502) Model YR Twin-Screw Compressor Liquid Chillers Design Level A 00562VIP 200 through 430 tons (60 Hz) ASHRAE 700 through 1500 kW (50 Hz) 90.1 COMPLIANT 170 through 365 tons (50 Hz) 600 through 1280 kW (50 Hz)

-

Page 2: Table Of Contents

Motor Voltage Variations ... 60 Hz Electrical Data ... Motor Starters ... 50 Hz Electrical Data ... Available Compressor/Shell/ Motor Combinations ... Special Features Design Level Motor Code Power Supply: – for 60 Hz 5 for 50 Hz YORK INTERNATIONAL PAGE... -

Page 3: Introduction

HIGH-EFFICIENCY OIL SEPARATOR E YR Screw Chillers utilize high-efficiency oil sepa- ration, limiting oil carry-over to less than 500 ppm. Oil is vital in screw compressors for lubrication, rotor seal- ing and cooling. -

Page 4: Ratings

Program, chillers are regularly tested in strict compli- ance with this Standard. This provides an independent, third-party verification of chiller performance. YORK YR screw chillers are designed to comply with ASHRAE Standard 90.1-1999 and 90.1-2001. The su- perior part-load performance of the YORK YR chillers far exceeds the IPLV/NPLV requirements of ASHRAE 90.1, providing superior Real World Energy savings... -

Page 5: Optiview Control Center

The control panel is com- patible with the YORK Solid State Starter (optional), Electro-mechanical (E-M) starter, or any customer sup- plied E-M starter that complies with the YORK R-1131 standard. The locations of various chiller parameters are clearly marked and instructions for specific opera- tions are provided. - Page 6 This control enhancement is stan- dard on all YR chillers. The chiller can also be left in the standard control mode for temperatures ranging between 20 and 70°F (-6.7 and 21.1°C), for applications involving a process or comfort cooling duty that requires leaving chilled liquid temperature setpoint control.

- Page 7 • Leaving Chilled Liquid Temperature Cycling Offset – Shutdown • Leaving Chilled Liquid Temperature Cycling Offset – Restart YORK INTERNATIONAL The CONDENSER screen displays a cutaway view of the chiller condenser. The liquid flow is animated to in- dicate flow through the condenser. All setpoints relat- ing to the condenser side of the chiller are maintained on this screen.

- Page 8 • Condenser Pressure • Condenser Saturation 1. The MOTOR “soft” key on the HOME screen, when pressed, shows a picture of either a YORK Electro- Mechanical Starter or a Solid State Starter, depend- ing on chiller configuration. The Programmable pulldown demand to automatically limit motor load- ing can be used to minimize building demand charges.

- Page 9 • Pulldown Demand Limit • Pulldown Demand Time • Print YORK INTERNATIONAL The SETUP is the top level of the general configura- tion parameters. It allows programming of the time and date, along with specifications as to how the time will be displayed.

- Page 10 Display Only • Model Number • Panel Serial Number • Chiller Serial Number • YORK Order Number • System Information • Condenser and Evaporator Design Load Information • Nameplate Information The OPERATIONS screen permits definition of param- eters pertaining to operation of the chiller.

-

Page 11: Display Messages

• Slot Numbers Programmable: • Page Up • Page Down • Print YORK INTERNATIONAL DISPLAY MESSAGES The Control Center continuously monitors the operat- ing system, displaying and recording the cause of any shutdowns (Safety, Cycling or Normal). The condition of the chiller is displayed at the System Status line that contains a message describing the operating state of the chiller;... - Page 12 • Shutdown – Requesting Fault Data . . . • High Instantaneous Current • High Phase (X) Heatsink Temperature – Running • 105% Motor Current Overload • Motor or Starter – Current Imbalance • Open SCR • Phase Rotation YORK INTERNATIONAL FORM 160.81-EG1...

-

Page 13: Mechanical Specifications

Mechanical Specifications GENERAL Each YORK M E YR Screw Chiller will be completely factory-packaged including evaporator, condenser, com- pressor, motor, OptiView control center and all inter- connecting unit piping and wiring. The chiller will be painted prior to shipment and will be packaged to pro- tect the unit during shipment. -

Page 14: Refrigerant System

2. Digital programming of setpoints through the uni- versal keypad including: a. leaving chilled liquid temperature b. percent current limit c. pull-down demand limiting d. six-week schedule for starting and stopping the chiller, pumps and tower e. remote reset temperature range YORK INTERNATIONAL FORM 160.81-EG1... - Page 15 6. Cycling shutdowns enunciated through the display and the status bar, and consists of system status, system details, day, time, cause of shutdown, and YORK INTERNATIONAL type of restart required. Cycling shutdowns with a fixed speed drive will include: a. multiunit cycling – contacts open b.

- Page 16 The entire assembly has been thoroughly leak tested at the factory prior to shipment. The YORK chiller in- cludes service valves conveniently located to facili- tate transfer of refrigerant to a remote refrigerant stor- age/recycling system.

-

Page 17: Accessories & Modifications

NEMA-1 enclosures, designed for 115V-1-50/60 Hz. STARTER – FIELD INSTALLED A field installed, electro-mechanical compressor motor starter is available, selected for proper size and type for job requirements and in accordance with YORK En- gineering Standard R-1131 for Starters. FORM 160.81-EG1... -

Page 18: Marine Water Boxes

65°F (18.3°C) for 50% to 0% loads. FORM 160.81-EG1 TO OBTAIN THIS METRIC VALUE KILOWATTS (kW) KILOWATTS (kW) KILOWATTS (kW) LITERS / SECOND (L/s) MILLIMETERS (mm) MILLIMETERS (mm) KILOGRAMS (kg) METERS / SECOND (m/s) KILOPASCALS (k Pa) KILOPASCALS (k Pa) YORK INTERNATIONAL... -

Page 19: Application Data

E Chillers, and will ensure the reli- ability and trouble-free life for which this equipment was designed. While this guide is directed towards normal, water-chilling applications, the YORK sales represen- tatives can provide complete recommendations on other types of applications. -

Page 20: Multiple Units

FIG. 1 – PARALLEL EVAPORATORS PARALLEL CONDENSERS Series Arrangement (Refer to Fig. 2) – The chillers may be applied in pairs with chilled water circuits con- YORK INTERNATIONAL FORM 160.81-EG1 LD00507... -

Page 21: Refrigerant Relief Piping

FIG. 2 – SERIES EVAPORATORS PARALLEL CONDENSERS BRINE APPLICATIONS The YR Screw Chiller, utilizing the Frick Refrigeration com- pressor, is a good match for the high head requirements of low temperature brine applications. This is particularly true of thermal ice storage systems, typically requiring 22°F (–5.6°C) to 24°F (–4.4°C) leaving brine temperatures. -

Page 22: Electrical Considerations

380/400 50 HZ Starters – The chiller is available with a factory-mounted and wired YORK Solid State Starter for 200 - 600 volt applications. Other types of remote mounted starters are available. These electro-mechanical starters must be furnished in accordance with YORK Standard R- 1131. -

Page 23: 60 Hz Electrical Data

NOTE: FLA = Full-load Amps; LRA = Locked Rotor Amps; PF = Power Factor; EFF = Motor Efficiency 100% Loading is Percentage of Maximum Motor Load; not of Specific Application YORK INTERNATIONAL The locked rotor amperes (LRA) are read directly from Max. -

Page 24: Motor Starters

TB, TC, TD VB, VC, VD WB, WC, WD WB, WC, WD XB, XC, XD FORM 160.81-EG1 PF EFF PF EFF ACROSS THE LINE 200-600 200-600 380-415 380-415 CLOSED — — YORK INTERNATIONAL MAX. KW (hp) 210.2 (267) 231.9 (292) - Page 25 OPTIVIEW GRAPHIC CONTROL CENTER MOTOR END YORK INTERNATIONAL OPTIONAL UNIT MOUNTED SOLID STATE STARTER CONDENSER LIQUID LINE SIGHT GLASS VARIABLE ORIFICE FORM 160.81-EG1 2-STAGE HIGH EFFICIENCY OIL SEPARATOR COMPRESSOR 00562VIP...

-

Page 26: Dimensions - Std

WITH ISOLATION WITHOUT ISOLATION VALVES VALVES 1" SINGLE 1" DUAL 1" DUAL 1" SINGLE 1-1/4" SINGLE NONE ISOLATION VALVE NOTE: OPTIONAL RELIEF VALVE NOTE: ONLY SUPPLIED ON UNITS WITH OPTIONAL ISOLATION VALVES CONDENSER EVAPORATOR LD07981 SECTION A - A YORK INTERNATIONAL... - Page 27 EVAPORATORS W & X DIM. 1 PASS 2 PASS — — DIM. REAR HEAD 2 PASS YORK INTERNATIONAL EVAPORATOR – CONDENSER SHELL CODES T1 COMPRESSORS V - V W - W W - W W - W 4267 mm 12'–0"...

-

Page 28: Evaporators, Compact Water Boxes (Ft.-In.)

2'–6-1/2" 2'–0-3/4" 1'–5-1/2" 1'–4-3/4" 2'–8-3/4" FORM 160.81-EG1 1-PASS NOZZLE ARRANGEMENTS NO. OF EVAP. PASSES 2-PASS NOZZLE ARRANGEMENTS NO. OF EVAP. PASSES 3-PASS NOZZLE ARRANGEMENTS NO. OF EVAP. PASSES 3-PASS 1'–3-1/2" 1'–3" 2'–6-1/2" 1'–3-1/2" 1'–5-1/2" 1'–4-3/4" 2'–8-3/4" 1'–5-1/2" YORK INTERNATIONAL LD07615... -

Page 29: Evaporators, Compact Water Boxes (Mm)

4. Connected piping should allow for removal of compact water boxes for tube access and cleaning. 5. Rear of unit is defined as side of chiller opposite control center. YORK INTERNATIONAL REAR OF UNIT EVAPORATOR 1"... -

Page 30: Condensers, Compact Water Boxes (Ft.-In.)

2'–4-3/4" 1'–3" 1'–9-3/4" 2'–11-3/4" 2'–6-3/4" 1'–3-1/2" 1'–11" 3'–2-1/2" FORM 160.81-EG1 1-PASS NOZZLE ARRANGEMENTS NO. OF COND. 2-PASS NOZZLE ARRANGEMENTS NO. OF COND. 3-PASS NOZZLE ARRANGEMENTS NO. OF COND. 3-PASS 1'–3" 1'–9-3/4" 2'–11-3/4" 1'–3" 1'–3-1/2" 1'–11" 3'–2-1/2" 1'–3-1/2" YORK INTERNATIONAL LD07982... -

Page 31: Condensers, Compact Water Boxes (Mm)

4. Connected piping should allow for removal of compact water boxes for tube access and cleaning. 5. Front of unit is defined as side of chiller where control center is mounted. YORK INTERNATIONAL CONDENSER 1"... -

Page 32: Floor Layout, Neoprene Isolators (In.)

ISOLATOR TO BE CENTERED UNDER SUPPORT FOOT HEIGHT FORM 160.81-EG1 END SHEET DIMENSION "C" From Fig. 3 (pgs. 26 & 27) 7" 6" 1/2" 4-1/2" 5-1/2" 1/2" 3/8" STEEL PLATE 1" DEFLECTED HEIGHT UNIT WEIGHT 16,366 TO 28,835 LBS. LD07610 YORK INTERNATIONAL... -

Page 33: Floor Layout, Neoprene Isolators (Mm)

152.4 76.2 DIMENSIONS ARE TYPICAL ALL 4 CORNERS 203.2 13 mm STEEL PLATE UNIT WEIGHT UP TO 7,423 KGS. YORK INTERNATIONAL NEOPRENE ISOLATORS FLOOR LAYOUT EVAPORATOR CONDENSER DIMENSION "A" From Fig. 3 (pgs. 26 & 27) ISOLATOR TO BE CENTERED... -

Page 34: Floor Layout, Spring Isolators (In. And Mm)

FORM 160.81-EG1 Dimensions – Floor Layout SPRING ISOLATORS (Pgs. 26 & 27) (Pgs. 26 & 27) LD07378 ALL DIMENSIONS ARE IN INCHES (Pgs. 26 & 27) (Pgs. 26 & 27) ALL DIMENSIONS ARE IN MILLIMETERS LD07379 YORK INTERNATIONAL... -

Page 35: Unit Weights

8,900 XCXD 19,950 9,049 XDXB 19,670 8,922 XDXC 19,940 9,045 XDXD 20,260 9,190 SOLID STATE STARTER WEIGHT SIZE 7L, 14L 26L, 33L YORK INTERNATIONAL OPERATING REFRIGERANT WEIGHT CHARGE (LBS) (KG) (LBS) 13,110 5,948 13,200 5,988 13,350 6,053 13,250 6,013 13,340... -

Page 36: Guide Specifications

Guide Specifications GENERAL Furnish and install where indicated on the drawings YORK M E Rotary Screw Liquid Chilling Unit(s). Each unit shall produce a capacity of GPM of from °F to with _____ GPM of condenser water at °F. Power input shall not exceed (NPLV) of _____. - Page 37 Vent and drain connections with plugs shall be provided on each water box. Refrigerant System The YR chiller is equipped with a refrigerant metering device consisting of a fully modulating variable orifice controlled via the OptiView Control Center. This control...

- Page 38 Condenser - pressure transducer out of range h. Auxiliary safety - contacts closed i. Discharge - high temperature j. Discharge - low temperature k. Oil - low differential pressure l. Oil or condenser transducer error m.Oil - clogged filter YORK INTERNATIONAL FORM 160.81-EG1...

- Page 39 High supply line voltage l. Logic board processor m.Logic board power supply n. Phase loss YORK INTERNATIONAL 7. Security access to prevent unauthorized change of setpoints, to allow local or remote control of the chiller, and to allow manual operation of the variable orifice and slide valve position.

- Page 40 All interconnecting water piping is factory installed and rated for 150 PSIG working pres- sure. Optional unit-mounted circuit breaker includes P.O. Box 1592, York, Pennsylvania USA 17405-1592 Copyright © by York International Corporation 2002 Form 160.81-EG1 (502) Supersedes 160.81-EG1 (302) ground fault protection and provides 65,000 amp.

Need help?

Do you have a question about the YR and is the answer not in the manual?

Questions and answers

How to change sss model from 26 to 14