Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Sapphire Audio PRO-1200 SE

- Page 1 OWNER’S MANUAL 2604 Liberator, Prescott, AZ 86301 1-866-445-3030...

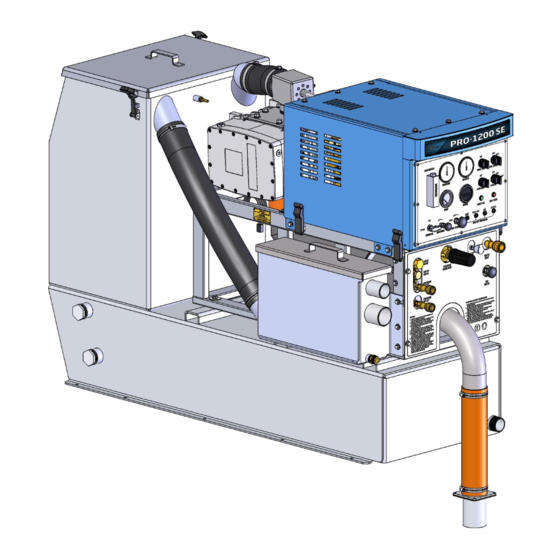

- Page 2 Congratulations on your purchase of the Pro-1200 SE direct-drive cleaning unit. This instruction and parts manual is a guide for operating and servicing your Sapphire Scientific equipment. Proper operation and service are necessary to ensure the outstanding performance of this unit. When properly maintained, your truck-mount will have a long and trouble-free life.

- Page 3 SAPPHIRE SCIENTIFIC LIMITED WARRANTY Sapphire Scientific Pro-1200 SE What Does This Warranty Cover? This warranty covers the Sapphire Scientific Model Pro-1200 SE and is provided to the original purchaser only. How Long Does This Warranty Last? This warranty runs for: Three (3) years from the date of installation on parts and labor (Excluding normal maintenance items.) Factory installed...

-

Page 4: Table Of Contents

SECTION ONE: GENERAL INFORMATION CONTACT INFORMATION ................2 WARNINGS AND CAUTIONS ...............3 SPECIFICATIONS ..................8 INSTALLATION REQUIREMENTS ..............9 RESPONSIBILITIES ..................9 RECEIVING YOUR PRO-1200 SE ..............10 SECTION TWO: OPERATION UNDERSTANDING THE SYSTEMS ..............12 PREPARATION AND OPERATION ..............17 FREEZE PROTECTION ..................29 SECTION THREE: SERVICE AND MAINTENANCE MAINTENANCE AND SERVICE CHARTS ............32... -

Page 5: Section One: General Information

JET SIZING......................... 8 INSTALLATION REQUIREMENTS .............. 9 RESPONSIBILITIES ................... 9 TRAINING ......................... 9 INSTALLATION ......................9 RECEIVING YOUR PRO-1200 SE ............... 10 ACCEPTANCE OF SHIPMENT ..................10 EQUIPMENT LISTING ....................10 Page | 1 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 6: Contact Information

Please fill in the information below so that you will have it on hand when contacting your distributor or Sapphire Scientific. Serial Number: Date of Purchase: Purchased From (Distributor): _______________________________________ Page | 2 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 7: Warnings And Cautions

Please read all warnings carefully before operating the equipment. Sapphire Scientific uses this CAUTION symbol throughout the manual to warn of the possibility of damage to equipment or personal property. Page | 3 49-139, Rev A Sapphire Scientific Pro-1200 SE... - Page 8 SECTION ONE – GENERAL INFORMATION FOR YOUR SAFETY The following warning labels are on your Pro-1200 SE console. These labels point out important WARNINGS and CAUTIONS, which must be followed at ALL times. Failure to follow these warnings could result in injury or fatality to yourself and/or others or property damage. Please follow these instructions carefully! Do NOT remove these decals.

- Page 9 7. Water under pressure at can cause severe personal injury or fatality. Shut down unit, allow to cool down, and relieve system of all pressure before removing caps, valves, plugs, fittings, filters or hardware. Page | 5 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 10 8 hour period). This equipment can produce 85 decibels at a distance of 10 feet. Please check with your local state agencies to see if OSHA standards apply to your application. 11. This unit produces high pressure. Improper use could result in injury. Page | 6 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 11 15. Ensure that you have received proper training and are familiar with the start-up and shut-down procedures prior to operation. 16. DO NOT alter or modify your Pro-1200 SE in any way. Use only replacement parts authorized by Sapphire Scientific. Modifications or use of unapproved parts could create a hazard and will void your warranty.

-

Page 12: Specifications

1400 lbs. TORQUE VALUES Pulley Hub (At drive shaft end) 15 ft./lbs. (180 in./lbs.) JET SIZING Sapphire Scientific recommends that the total floor tool tip size be #4 or #6 Page | 8 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 13: Installation Requirements

The Pro-1200 SE Direct Drive unit weighs approximately 1400 lbs. with a full waste tank. If a water pond is being installed, an additional 1100 lbs. needs to be included. Every accessory added will add weight. -

Page 14: Receiving Your Pro-1200 Se

RECEIVING YOUR PRO-1200 SE SYSTEM ACCEPTANCE OF SHIPMENT Your Pro-1200 SE system was thoroughly tested, checked and inspected in its entirety prior to leaving our manufacturing facility. When receiving your unit, please make the following acceptance check: 1. The unit should not show any signs of damage. If there is damage, notify the deliverer immediately. -

Page 15: Section Two: Operation

GAUGE READINGS AND SETTINGS ................26 SHUT-DOWN AND DAILY MAINTANENCE ..............27 AUTOMATIC SHUT DOWNS..................28 FREEZE PROTECTION WINTERIZING YOUR UNIT WITH ANTIFREEZE ............29 REMOVING ANTIFREEZE FROM THE UNIT ............... 30 Page | 11 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 16: Understanding The Systems

The hot water then flows through the solution outlet manifold that contains a strainer and check valve. The chemical injection takes place inside the manifold. The mixture of hot water and chemical then flows through the outlet of the manifold to the cleaning tool. Page | 12 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 17: Water Requirements

Sapphire Scientific recommends that a high quality water softener be used in areas where the water hardness exceeds 3-1/2 grains. If a water softener is used, it must have a flow capacity of at least 5 GPM or greater, without any hose constrictions. Page | 13 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 18: Vacuum System

IN ACCORDANCE WITH EPA, STATE AND LOCAL LAWS, DO NOT DISPOSE OF WASTE WATER INTO GUTTERS, STORM DRAINS, STREAMS, RESERVOIRS OR ANY NON-COMPLIANT RECEPTICLE. Always check local laws and regulations regarding “gray” water disposal. The penalties for non- compliance can be serious. Page | 14 49-139, Rev A Sapphire Scientific Pro-1200 SE... - Page 19 SECTION TWO – OPERATION VACUUM SYSTEM DIAGRAM Page | 15 49-139, Rev A Sapphire Scientific Pro-1200 SE...

-

Page 20: Chemical System

CHEMICAL REQUIREMENTS The Sapphire Scientific Pro-1200 SE Direct-Drive unit’s unique last step chemical injection system can be used with a variety of water diluted chemical compounds, either acidic or alkaline, depending on the work to be performed. We recommend only using Chemspec brand of chemistry. -

Page 21: Preparation And Operation

PREPARATION AND OPERATION This section of the operator’s manual explains how to prepare, start, operate, shut down and maintain your Pro-1200 SE direct-drive cleaning unit. The Pro-1200 SE unit is easy to operate, however only trained operators should proceed. Operate this unit and equipment only in a well-ventilated area. Exhaust fumes contain carbon monoxide, which is an odorless and deadly poison that can cause severe injury or death. - Page 22 See the Shut Down and Daily Maintenance section below for more information. NEVER operate the unit with the waste tank air filter removed, damaged or not properly installed. Page | 18 49-139, Rev A Sapphire Scientific Pro-1200 SE...

-

Page 23: Lower Front Panel Diagram

SECTION TWO – OPERATION Page | 19 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 24: Instrument Panel Diagram

SECTION TWO – OPERATION Page | 20 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 25: Starting The Unit

When the valve is closed, the temperature will be at maximum. Open the valve to reduce temperature. NOTE: Let the unit run for a few minutes with the vacuum inlets partially blocked off to warm up the cleaning solution. Page | 21 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 26: Priming The Chemical Pump

Serious damage can result from using improper chemicals or mixtures. UPHOLSTERY CLEANING Use only chemicals recommended for wet cleaning of upholstery fabrics. Page | 22 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 27: Automatic Waste Pump

NEVER use a waste pump hose as a water inlet hose. NEVER dispose of waste water in a storm drain, water way or on ground areas. Always dispose of waste in accordance with Local, State and Federal laws. Page | 23 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 28: Operation

When cleaning upholstery, run the unit on low speed. Upholstery tools have a lower flow rate and smaller orifices. Only use chemicals recommended for wet cleaning of upholstery fabrics. Consult the factory for specific instructions. Page | 24 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 29: Flood Restoration/Extraction

3. Drain recovery tank as needed. Return machine to normal settings when done. DUAL WAND OPERATION The direct drive Pro-1200 SE has sufficient capacity for dual wand operation with minimal pressure loss at each wand. The pump pressure and temperature can remain at the same levels as for single wand operation. -

Page 30: Gauge Readings And Settings

NOTE: The setting is also dependent on the type of chemical used and the concentration ratio of chemical to water. Always use the LOWEST flow rate that properly cleans the affected areas. Excessive chemicals can cause damage to the items being cleaned. Page | 26 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 31: Shut-Down And Daily Maintanence

11. Make sure the waste tank is drained into an approved source. NEVER dispose of wastewater in a storm drain, water way or on ground areas. Always dispose of waste in accordance with Local, State, and Federal laws. Page | 27 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 32: Automatic Shut Downs

2. A red high temperature light will illuminate along with machine shut down if the engine coolant temperature reaches 240 degrees. Page | 28 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 33: Freeze Protection

5 seconds in the flow meter. Turn the chemical valve to ON. Ensure that the flow meter indicates flow while the attached tools solution valves are open. After 25 seconds, turn the chemical valve to the OFF position. Page | 29 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 34: Removing Antifreeze From The Unit

DO NOT drain used anti-freeze on the ground or into storm drains. Dispose of anti-freeze only in an approved location. Observe Local, State and Federal laws when disposing of antifreeze. Page | 30 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 35: Section Three: Service And Maintenance

WYE STRAINER ......................45 INLET PRESSURE REGULATOR .................. 45 PRESSURE REGULATING UNLOADER ................ 46 TROUBLESHOOTING HEAT ISSUES / MISCELLANEOUS ................48 VACUUM PUMP (BLOWER) ..................49 WATER PUMP......................50 CHEMICAL SYSTEM....................51 Page | 31 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 36: Maintenance And Service Charts

SECTION THREE – SERVICE AND MAINTENANCE PRO-1200 SE MAINTENANCE CHART DAILY MAINTENANCE Vacuum Pump Check vacuum pump oil level. Fill to proper level. Do not overfill. (1) Vacuum Pump Spray WD-40 (or Equivalent) into the lubrication cup for 10 seconds. - Page 37 (2) Change water pump crankcase oil after first 50 hours of operation (3) Check pulley and hub set screws after first 50 hours of operation, and again at 100 hours of operation. (4) Every 1000 hours or yearly, whichever comes first. Page | 33 49-139, Rev A Sapphire Scientific Pro-1200 SE...

-

Page 38: Maintenance

This section of the operator’s manual contains the service and maintenance information for the Pro- 1200 SE unit. A planned preventative maintenance program will ensure that your Pro-1200 SE has optimum performance, long operating life, and a minimum amount of down time. -

Page 39: Vacuum Pump

Plug the vacuum ports and spray a water displacement/lubricant into the vacuum lubrication cup for 10 seconds. This procedure should be done at the end of every working day. Drain, flush and replace the oil every 1000 hours or yearly, whichever comes first. Page | 35 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 40: Water Pump

When removing the vacuum inlet filter, grip the plastic hexagon section of the filter. Grasping filter by the screen will damage or destroy the filter. Applying grease to the threads will allow easier removal of filter when cleaning or replacement is required. Page | 36 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 41: Drive Belts, Pulleys And Hubs

Check and inspect the chemical selector and metering valves every 200 hours. This will prevent leaks and add to the overall life of the valves. VACUUM HOSES To ensure maximum hose life, Sapphire Scientific recommends that you wash out the hoses with fresh water daily. Page | 37 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 42: High Pressure Solution Hoses

All high-pressure solution hoses must be rated for 3000 PSI at 250 deg. F. Thermoplastic hoses do not meet this requirement and should not be used. Severe burns and injury may result if the hoses do not meet these requirements. Page | 38 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 43: Drive Shaft Maintenance

SECTION THREE – SERVICE AND MAINTENANCE DRIVE SHAFT MAINTENANCE Apply lubricating grease to your Pro-1200 SE drive shaft zerk fittings at both ends of the shaft every 250 hours. Use only Mystik® JT-6® Hi-Temp Grease No. 2. Mystik® JT-6® is a high-temperature lithium-complex grease rated to 550°... - Page 44 Locate the three (3) zerk fittings. Use one pump of grease for each u-joint fitting and up to three pumps maximum for the slip yoke fitting. The drive shaft splines should also be lubricated with the same grease as the zerk fittings. Page | 40 49-139, Rev A Sapphire Scientific Pro-1200 SE...

-

Page 45: General Service Adjustments

(1/2” deflection in the center of the belts, half way between the pulleys). While checking the alignment, tighten the nuts that hold the water pump to the base. Over tightening of belts may cause damage to pump casing, causing it to fail. Page | 41 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 46: Solution Manifold Check Valve And Strainer

ORING, 7/8 ID X 1-1/16 OD 15-007 SPRING, CHECK VALVE ASSY. 27-010 POPPET, CHECK VALVE ASSY 27-004 INSERT, SEAT-CHK VLV ASSY TM 27-011 SEAT, CHECK VALVE ASSY. 41-008 ORING, ½ ID 5/8 OD Page | 42 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 47: Chemical Pump

The chemical pump should be rebuilt every 500 hours. This involves changing the diaphragm and plastic disc, check valves, and inspecting the disk. DO NOT attempt to reuse O-rings after the check valves have been removed. Replace all O-rings when servicing check valves. Page | 43 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 48: Packing Nut Adjustment

SECTION THREE – SERVICE AND MAINTENANCE PACKING NUT ADJUSTMENT Four items on the Pro-1200 SE have a packing nut. 1. The chemical selector 2. The chemical metering valve 3. The temperature control knob 4. The hot water knob Inspect the packing nut for proper tension on the chemical metering and chemical selector valves every 200 hours. -

Page 49: Wye Strainer

Inspect and clean at least once a month. Hard water deposits can build and reduce water flow. The inlet pressure regulator comes pre-set at the factory. PRESSURE REGULATOR SCREEN Page | 45 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 50: Pressure Regulating Unloader

3. Remove the adjusting cap from the pressure regulator, loosen the valve nut and remove the stem with long nose pliers. 4. Clean and lubricate stem. 5. Reassemble pressure regulator STEM O-RINGS VALVE NUT O-RINGS O-RINGS ADJUSTING CAP Page | 46 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 51: Troubleshooting

CHEMICAL, VACCUM, HEAT TRANSFER, SAFETY and WIRING systems featured in this unit. If there are malfunctions occurring on this unit which you do not understand, refer back to the OPERATION section of this manual and review SYSTEM. Page | 47 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 52: Heat Issues / Miscellaneous

Pump out circuit breaker on instrument panel After inspecting waste pump to determine the cause of the has tripped overloaded circuit, press reset button. Check valve dirty or damaged Clean or replace as necessary. Page | 48 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 53: Vacuum Pump (Blower)

Replace the vacuum pump. Vacuum relief valve requires adjustment. Readjust the vacuum relief valve. With vacuum fully blocked and speed set to high, set vacuum break to 13-14 in. HG Page | 49 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 54: Water Pump

Repair or replace valve. Hose inner lining is constricted. Remove restriction or replace hose. Air leak in chemical supply line, priming valve or Check for air leaks. Replace faulty parts. metering valve. Page | 50 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 55: Chemical System

Measure the pump volume. If the pump volume is less than Defective cylinder in the water pump. normal, refer to “Loss of Pump Volume” in the Troubleshooting section in this manual. Page | 51 49-139, Rev A Sapphire Scientific Pro-1200 SE... - Page 56 PROBABLE CAUSE SOLUTION In areas with inlet water pressure in excess of 60 PSI the addition Inlet water pressure too high of an RV inlet water pressure regulator may be needed. Page | 52 49-139, Rev A Sapphire Scientific Pro-1200 SE...

-

Page 57: Section Four: Parts And Accessories

PULLEY SHAFT HOUSING ..................80 CENTER CONSOLE ....................81 MISCELLANEOUS COMPONENTS ................82 INSTALL KIT ......................83 DECALS ........................84 WATER FLOW WATER FLOW DIAGRAM ..................85 ELECTRICAL ELECTRICAL DIAGRAM ..................... 86 Page | 53 49-139, Rev A Sapphire Scientific Pro-1200 SE... - Page 58 SECTION FOUR – PARTS AND ACCESSORIES 71-1200SM15, KIT, CONSOLE PRO-1200 SE Page | 54 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 59 SECTION FOUR – PARTS AND ACCESSORIES 71-1200SM15, KIT, CONSOLE PRO-1200 SE (BOM) Page | 55 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 60 SECTION FOUR – PARTS AND ACCESSORIES 69-648, ASSY, SUBMOUNT WASTE TANK Page | 56 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 61 SECTION FOUR – PARTS AND ACCESSORIES 68-371, KIT, 90 DEG THRU-STEP EXHAUST Page | 57 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 62 SECTION FOUR – PARTS AND ACCESSORIES 69-733, ASSEMBLY, VACUUM HOSE PORT Page | 58 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 63 SECTION FOUR – PARTS AND ACCESSORIES Page | 59 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 64 SECTION FOUR – PARTS AND ACCESSORIES Page | 60 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 65 SECTION FOUR – PARTS AND ACCESSORIES Page | 61 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 66 SECTION FOUR – PARTS AND ACCESSORIES 70-1200SM15, ASSEMBLY, CONSOLE - BOM TABLE Page | 62 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 67 SECTION FOUR – PARTS AND ACCESSORIES 69-646, ASSEMBLY, FRAME AND ENCLOSURES Page | 63 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 68 SECTION FOUR – PARTS AND ACCESSORIES 69-646, ASSEMBLY, FRAME AND ENCLOSURES - BOM TABLE Page | 64 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 69 SECTION FOUR – PARTS AND ACCESSORIES 69-647, ASSEMBLY, INSTRUMENT PANEL Page | 65 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 70 SECTION FOUR – PARTS AND ACCESSORIES 69-647, ASSEMBLY, INSTRUMENT PANEL – BOM TABLE Page | 66 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 71 SECTION FOUR – PARTS AND ACCESSORIES 69-680, ASSEMBLY, VACUUM PUMP Page | 67 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 72 SECTION FOUR – PARTS AND ACCESSORIES 69-644, ASSEMBLY, HEAT EXCHANGER ENGINE COOLANT Page | 68 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 73 SECTION FOUR – PARTS AND ACCESSORIES Page | 69 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 74 SECTION FOUR – PARTS AND ACCESSORIES 69-679, ASSEMBLY, GENERAL WATER PUMP Page | 70 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 75 SECTION FOUR – PARTS AND ACCESSORIES 69-679, ASSEMBLY, GENERAL WATER PUMP BOM TABLE Page | 71 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 76 SECTION FOUR – PARTS AND ACCESSORIES 69-352, ASSEMBLY, SOLUTION MANIFOLD Page | 72 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 77 SECTION FOUR – PARTS AND ACCESSORIES 69-675, ASSEMBLY, PRESSURE REGULATOR BRACKET Page | 73 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 78 SECTION FOUR – PARTS AND ACCESSORIES Page | 74 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 79 SECTION FOUR – PARTS AND ACCESSORIES 69-721, ASSEMBLY, HOT WATER VALVE Page | 75 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 80 SECTION FOUR – PARTS AND ACCESSORIES 69-714, ASSEMBLY, PREFILTER BOX Page | 76 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 81 SECTION FOUR – PARTS AND ACCESSORIES 69-717, ASSEMBLY, CHEMICAL JUG Page | 77 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 82 SECTION FOUR – PARTS AND ACCESSORIES Page | 78 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 83 SECTION FOUR – PARTS AND ACCESSORIES Page | 79 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 84 SECTION FOUR – PARTS AND ACCESSORIES 69-726, ASSEMBLY, PULLEY SHAFT HOUSING Page | 80 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 85 SECTION FOUR – PARTS AND ACCESSORIES Page | 81 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 86 SECTION FOUR – PARTS AND ACCESSORIES MISCELLANEOUS COMPONENTS Page | 82 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 87 SECTION FOUR – PARTS AND ACCESSORIES Page | 83 49-139, Rev A Sapphire Scientific Pro-1200 SE...

- Page 88 DECALS 44-066, WARNING, 44-067, WARNING, READ MANUAL 44-083, WARNING, HIGH ELECTRICAL SHOCK PRESSURE 44-082, DANGER, ROTATING 44-084, CAUTION, HOT SURFACE MACHINERY 44-085, WARNING, ROTATING MACHINERY 44-250, DECAL, PRODUCT PRO-1200 SE Page | 84 49-139, Rev A Sapphire Scientific Pro-1200 SE...

-

Page 89: Water Flow Diagram

SECTION FOUR – PARTS AND ACCESSORIES Page | 85 49-139, Rev A Sapphire Scientific Pro-1200 SE... -

Page 90: Electrical Diagram

SECTION FOUR – PARTS AND ACCESSORIES ELECTRICAL DIAGRAM Page | 86 49-139, Rev A Sapphire Scientific Pro-1200 SE...

Need help?

Do you have a question about the PRO-1200 SE and is the answer not in the manual?

Questions and answers