Table of Contents

Advertisement

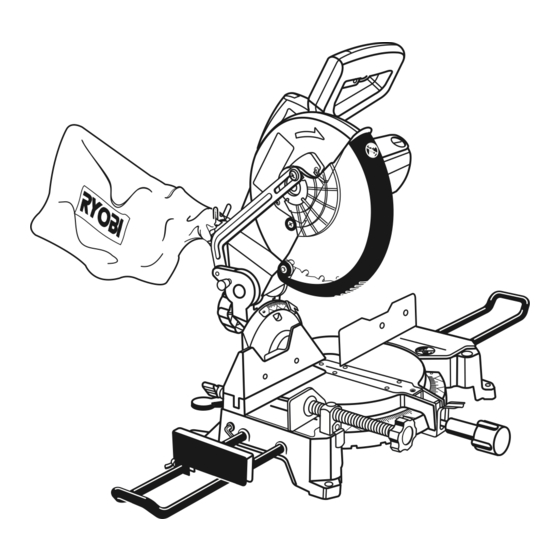

Your miter saw has been engineered and manufactured to Ryobi's high standard for dependability, ease of operation, and

operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING:

To reduce the risk of injury, the user must read and understand the operator's manual before using

this product.

Thank you for buying a Ryobi product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

OPERATOR'S MANUAL

10 in. Compound Miter Saw

TS1353DXL - Double Insulated

Advertisement

Table of Contents

Summary of Contents for Ryobi TS1353DXL

- Page 1 Your miter saw has been engineered and manufactured to Ryobi’s high standard for dependability, ease of operation, and operator safety. When properly cared for, it will give you years of rugged, trouble-free performance. WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using this product.

-

Page 2: Table Of Contents

n Introduction ... 2 n General Safety Rules ... 3-4 n Specific Safety Rules... 4-5 n Symbols... 6-7 n Electrical ... 8 n Glossary of Terms... 9 n Features... 10-12 n Tools Needed... 12 n Loose Parts ... 13 n Assembly ... 14-21 n Operation... -

Page 3: General Safety Rules

WARNING: Read and understand all instructions. Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury. READ ALL INSTRUCTIONS n KNOW YOUR POWER TOOL. Read the operator’s manual carefully. Learn the applications and limitations as well as the specific potential hazards related to this tool. -

Page 4: Specific Safety Rules

If a work clamp and length stop are used together, they must both be installed on the same side of the saw table to prevent the saw from catching the loose end and kicking up. - Page 5 NEVER leave the saw unattended while connected to a power source. n TURN OFF TOOL and wait for saw blade to come to a complete stop before moving workpiece or changing settings.

-

Page 6: Symbols

Some of the following symbols may be used on this tool. Please study them and learn their meaning. Proper interpreta- tion of these symbols will allow you to operate the tool better and safer. SYMBOL NAME Volts Amperes Hertz Watt Minutes Alternating Current Direct Current... -

Page 7: Save These Instructions

The following signal words and meanings are intended to explain the levels of risk associated with this product. SYMBOL SIGNAL DANGER: WARNING: CAUTION: CAUTION: SERVICE Servicing requires extreme care and knowledge and should be performed only by a qualified service technician. For service we suggest you return the product to your nearest AUTHORIZED SERVICE CENTER for repair. -

Page 8: Electrical Connection

DOUBLE INSULATION Double insulation is a concept in safety in electric power tools, which eliminates the need for the usual three- wire grounded power cord. All exposed metal parts are isolated from the internal metal motor components with protecting insulation. Double insulated tools do not need to be grounded. -

Page 9: Glossary Of Terms

The area over, under, behind, or in front of the blade. As it applies to the workpiece, that area which will be or has been cut by the blade. The distance that the tip of the saw blade tooth is bent (or set) outward from the face of the blade. Snipe (planers) Depression made at either end of a workpiece by cutter blades when the workpiece is not properly supported. -

Page 10: Product Specifications

Cutting Capacity with Miter at 45°/Bevel 45°: Maximum nominal lumber sizes:...2 x 4 BEVEL SCALE “NO HANDS ZONE” MITER TABLE POSITIVE BASE STOP(S) SAW ARM SWITCH TRIGGER LOWER BLADE GUARD “NO HANDS ZONE” BOUNDARY LINE LABEL MITER SCALE THROAT PLATE... -

Page 11: Spindle Lock Button

BLADE WRENCH STORAGE See Figure 1. A blade wrench is packed with the saw. One end of the wrench is a phillips screwdriver and the other end is a hex key. Use the hex key end when installing or removing blade and the phillips end when removing or loosening screws. -

Page 12: Bevel Lock Knob

The left side is larger providing additional support. It has a sliding feature for clearance of the saw arm when making bevel or compound cuts. Loosen the fence screw before attempting to slide the miter fence. -

Page 13: Loose Parts

The following items are included with your Compound Miter Saw: n Miter Lock Handle n Dust Bag n Dust Guide n Stop Block n Small Wing Screw n Clamp Brackets (2) n Clamp Bracket Screws (2) n Table Extensions (2) -

Page 14: Mounting Holes

This saw has been shipped with the saw arm secured in the down position. To release the saw arm, push down on the top of the saw arm, cut the tie-wrap, and pull out on the lock pin. n Lift the saw arm by the handle. Hand pressure should remain on the saw arm to prevent sudden rise upon release of the tie wrap. -

Page 15: Work Clamp

DUST BAG See Figure 10. A dust bag is provided for use on this miter saw. It fits over the exhaust port on the upper blade guard. To install it, remove dust guide from exhaust port. Then, squeeze the two metal clips to open the mouth of the bag and slide it on the exhaust port. -

Page 16: Stop Block

The stop block is included with the table extensions and is useful as a stop for making repetitive cuts to the same length. It can be installed on either side of the saw base: n Slide the stop block on the back arm of either table extension, then insert the table extensions into the saw base. - Page 17 See Figures 16 - 17. WARNING: A 10 in. blade is the maximum blade capacity of the saw. Never use a blade that is too thick to allow outer blade washer to engage with the flats on the spindle. Larger...

- Page 18 NOTE: The hex key bolt has left hand threads. Turn bolt counterclockwise to tighten. n Using the hex key provided with the saw, tighten bolt securely. n Remove the hex key and store it in a safe place for future use.

-

Page 19: Squaring The Miter Table To The Fence

FENCE See Figures 20 - 23. n Unplug the saw. n Push down on the saw arm and pull out the lock pin to release the saw arm. n Raise saw arm to its full raised position. n Loosen the miter lock handle approximately one-half turn. - Page 20 SQUARING THE BLADE TO THE FENCE See Figures 24 - 26. n Unplug the saw. n Pull the saw arm all the way down and engage the lock pin to hold the saw arm in transport position. n Loosen the miter lock handle approximately one-half turn.

- Page 21 SQUARING THE BLADE TO THE MITER TABLE See Figures 28 - 30. n Unplug the saw. n Pull the saw arm all the way down and engage the lock pin to hold the saw arm in transport position. n Loosen the miter lock handle approximately one-half turn.

-

Page 22: Operation

NOTE: The blade provided is fine for most wood cutting operations, but for fine joinery cuts or cutting plastic, use one of the accessory blades available from the Ryobi dealer. WARNING: Before starting any cutting operation, clamp or bolt the compound miter saw to a workbench. - Page 23 0° and 45°. n Pull out the lock pin and lift saw arm to its full height. n Loosen the miter lock handle. Rotate the miter lock handle approximately one-half turn to the left to loosen.

- Page 24 Pull out the lock pin and lift saw arm to its full height. n Loosen the miter lock handle. Rotate the miter lock handle approximately one-half turn to the left to loosen.

- Page 25 Use the optional work clamp or a C-clamp to secure the workpiece when possible. n Before turning on the saw, perform a dry run of the cutting operation just to make sure that no problems will occur when the cut is made.

-

Page 26: Cutting Compound Miters

CUTTING COMPOUND MITERS To aid in making the correct settings, the compound angle setting chart below has been provided. Since compound cuts are the most difficult to accurately obtain, trial cuts should be made in scrap material, and much thought and planning made, prior to making the required cut. -

Page 27: Cutting Crown Molding

CUTTING CROWN MOLDING This compound miter saw does an excellent job of cutting crown molding. In general, compound miter saws do a better job of cutting crown molding than any other tool made. In order to fit properly, crown molding must be compound mitered with extreme accuracy. -

Page 28: Clamping Wide Workpieces

Bevel Angle Type of Cut Setting Left side, inside corner 1. Top edge of molding against fence 33.85 ° 2. Miter table set right 31.62 3. Save left end of cut Right side, inside corner 1. Bottom edge of molding against fence 33.85 °... -

Page 29: Travel Pivot Adjustment

The saw arm should rise completely to the up position by itself. n If the saw arm does not raise by itself or if there is play in the pivot joints, have saw repaired by at your nearest RYOBI AUTHORIZED SERVICE CENTER. -

Page 30: General Maintenance

Loosen the bevel lock knob by turning the knob counterclockwise. WARNING: When servicing, use only identical Ryobi replacement parts. Use of any other parts may create a hazard or cause product damage. WARNING:... -

Page 31: Changing Batteries

See Figures 44 - 45. n Unplug the saw. n Remove the laser guide from the saw and lay it on a flat surface with the two phillips screws facing upward. n Remove the screws and separate the laser guide cover from the laser guide support. -

Page 32: Parts Ordering / Service

Ryobi Authorized Service Center. Be sure to provide all pertinent facts when you call or visit. Please call 1-800-525-2579 for your nearest Ryobi Authorized Service Center. You can also check our web site at www.ryobitools.com for a complete list of Authorized Service Centers.

Need help?

Do you have a question about the TS1353DXL and is the answer not in the manual?

Questions and answers