Formech 508DT Installation, Operating And Service Manual

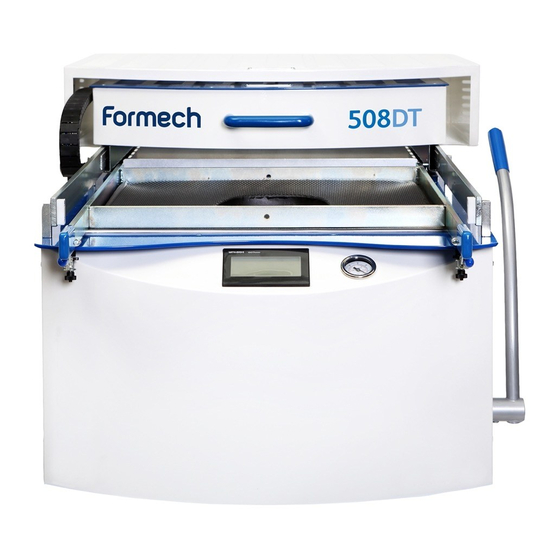

Desktop / floor-standing

vacuum forming machines

Hide thumbs

Also See for 508DT:

- Installation, operating and service manual (43 pages) ,

- Installation, operating and service manual (30 pages) ,

- Installation, operating and service manual (42 pages)

Summary of Contents for Formech 508DT

- Page 1 Desktop / Floor-Standing Vacuum Forming Machines . . . 508DT/FS Installation, Operating and Service Manual For Parts, Service & Technical Assistance Telephone: +44 (0) 1582 469 797 Fax: +44 (0) 1582 469 646...

-

Page 2: Table Of Contents

Initial Requirements (508DT &508FS) Main Menu 508DT Basic operation 508DT Settings 508DT Saving Parameters to Memory 508DT Operating using saved parameters 508FS Basic Operation Operating Procedures - Other settings / loading programs 508FS Fan system activation Manual - Formech 508DT/FS - Rev 3... - Page 3 Heating elements Vacuum system Service / Repair Replacing seals Replacing a heating element Electrical Troubleshooting Vacuum / Pressure Troubleshooting (508DT & 508FS) Cleaning Lubrication Electrical Wiring - 508DT Vacuum Pump 2D351VM - 508DT only Electrical Wiring - 508FS Becker Pump VT 4.10 - 508FS Only Pneumatics 508DT &...

-

Page 4: Safety

Safety Thank you for choosing Formech. Please read and follow the below safety instructions before attempting to install or operate your machine. > Do not operate the machine until you have been trained and are fully conversant with it. > Read and understand all of this user manual. - Page 5 Care is required when operating the clamping frame to ensure that fingers or hands are not trapped. Keep hands clear of the heater rails when pulling the heater forwards. Manual - Formech 508DT/FS - Rev 3...

- Page 6 Ensure that you DO NOT work on your own when working at height. ENSURE THAT LOCAL LIFTING HANDLING AND HIGH LEVEL WORKING PROCEDURES ARE APPLIED AND MONITORED BY A PERSON RESPONSIBLE FOR HEALTH AND SAFETY. Manual - Formech 508DT/FS - Rev 3...

- Page 7 THIS IS NOT AN EXHAUSTIVE LIST OF THE POSSIBLE MISSUSE OF THIS MACHINERY. THE USE OF THIS MACHINE MUST BE ASSESSED, MONITORED AND CONTROLLED BY THE PERSON RESPONSIBLE FOR THE HEALTH AND SAFETY IN THE ORGANISATION THAT OWNS AND OPERATES THIS MACHINE. Manual - Formech 508DT/FS - Rev 3...

-

Page 8: Introduction

Power Cable - 508DT C19 to BS 1363 Plug (UK & Ireland) C19 to CEE 7/4 Plug -Schuko Plug (EU) C19 to Nema 6/15 Plug (North America) Power Cable - 508FS 2.5mm, 3 Core – 3m Manual - Formech 508DT/FS - Rev 3... -

Page 9: General Arrangement 508Dt

General Arrangement 508DT Machine footprint (Dimensions are in mm) 1394 Manual - Formech 508DT/FS - Rev 3... -

Page 10: Electrical Specifications

Transportation / Positioning The 508DT will be supplied strapped to a Pallet or in a crate. The machine may unpacked and placed on a bench, table or 508DT trolley. Lift the machine using the clamp handles at the front of the machine and the rear rail lifting handle extensions. -

Page 11: General Arrangement 508Fs

General Arrangement 508FS Machine footprint (Dimensions are in mm) 1474 1140 Manual - Formech 508DT/FS - Rev 3... -

Page 12: Mechanical Specifications

Noise emissions on the Formech 508FS are less than 70dB(A). Machine storage The Formech 508FS must be stored in a dry environment. If the machine is not used for a long period of time, run the pump periodically (once a month). -

Page 13: General Arrangement 508Dt & 508Fs

7. Air pressure outlet. The air pressure outlet allows you to supply other equipment that requires air pressure. Air is produced from the exhaust of the vacuum pump. Do not connect compressed air to this outlet. (508DT only) 7. Specification Plate. - Page 14 508FS – supplied with 2.5mm cable fitted to connect to a single phase 20amp socket. See Safety section at the beginning of this manual. 508DT – Supplied with C19 plug or C201 receptacle. Note the safety labelling. 7. Mains fuse.

- Page 15 250W Front of machine Front of machine 508FS Zoning 250W 250W 250W 250W 200W FSQ 250W 250W 200W FSQ 150W 150W 200W FSQ 300W 300W 300W 300W Front of machine Front of machine Manual - Formech 508DT/FS - Rev 3...

-

Page 16: Installation And Inital Assembly 508

Remove the 2 screws on both sides and remove the lifting bars. Store the lifting bars for future use. Slide the heater guard onto the front rail link bars. Manual - Formech 508DT/FS - Rev 3... -

Page 17: Heater Guard - 508Dt & 508Fs

The heaters are kept in the front position for transit by a screw that is positioned mid way along the front heater rail. Remove the screw from the side to allow the heaters to be moved backwards. Manual - Formech 508DT/FS - Rev 3... -

Page 18: Fitting Reducing Windows (Optional)

Do the same on the back of Reducing windows correctly secure the window to the the reducing window. Make fitted to the machine. clamp frame. the nuts and bolts finger tight. Do not use a spanner. Manual - Formech 508DT/FS - Rev 3... -

Page 19: Air Outlet Connection - 508Dt Only

Installation and Initial assembly 508 Air Outlet connection - 508DT only Fitted with an 8mm tube Air outlet connector for dome blowing. Manual - Formech 508DT/FS - Rev 3... -

Page 20: Installation And Initial Assembly (508Fs Only)

Ensure the counterweight arm is fitted to the outside of the clamp frame. & Fit and tighten the washers and nuts removed in Repeat for both sides of the clamp frame. Manual - Formech 508DT/FS - Rev 3... -

Page 21: Castor Option

If the unit is supplied with the castor wheel option and the machine is to be used before fitting the wheel castors then the auto-level and pre-stretch air will escape through the wheel mounting holes until the wheels are fitted or the fixing holes are blocked. Manual - Formech 508DT/FS - Rev 3... -

Page 22: Fitting The Rear Stabilisers

This is then bolted to the rear of the main body using four M6 cap head screws. Back Panel View Triangular support stabaliser Remove 4off M6 Cap head screw - Fit complete stabaliser assembly & replace screws Manual - Formech 508DT/FS - Rev 3... -

Page 23: Cooling Fan Option

Fix and tighten with the screw and a 2nd mounting screw for both posts. & Fix the crossmember to the fan posts using the fixings supplied. Position the fan grill towards the front of the machine. Manual - Formech 508DT/FS - Rev 3... - Page 24 Insert the mounting screws. Fit the Fixing nut to the screw & tighten. & Insert the IEC connector into the receptacle located on the electrical box. Secure the cable with the fixings supplied. Manual - Formech 508DT/FS - Rev 3...

-

Page 25: Compressed Air Connection - 508Fs Only

1/2inch BSP fitting if required. The air consumption will be dependant upon usage and therefore it varies from customer to customer. Air requirements for the 508FS: 80PSI / 5 bar Manual - Formech 508DT/FS - Rev 3... -

Page 26: Operating Procedures - Quick Start Guide

Used to save operating parameter settings. Heater Timer Shows the heater time. Press on the time value to adjust the heat timer on the operation screen. The time cannot be adjusted in manual mode. Manual - Formech 508DT/FS - Rev 3... - Page 27 / disabled at any time. 508FS only. Fan Timer This operation will latch the fan on for the time set for loaded settings. The fans will turn off when the time has elapsed. 508FS only. Manual - Formech 508DT/FS - Rev 3...

-

Page 28: Initial Requirements (508Dt &508Fs)

The rear of the clamp is spring loaded. The pre-load spring tension at the rear of the clamping frame can be adjusted by moving the position Manual - Formech 508DT/FS - Rev 3 of the two lock nuts (508FS only) – see section dealing with adjustment. -

Page 29: Main Menu

HELP screen language options are changed by pressing on the language button to select the language required. Press to open the Load Options screen: Press to open the operating screen in manual mode. Manual - Formech 508DT/FS - Rev 3... -

Page 30: 508Dt Basic Operation

The Save button will use the settings of the timers shown and import them to the settings screen to edit and save as required. The following section explains the 508DT vacuum forming process: • Pull the Heater forwards over the clamped plastic. -

Page 31: 508Dt Settings

The heater power and timer parameters may be edited before saving into memory. The timer button will open a Pop-up keypad for adjustment of the parameter. When complete, press the save button on the settings screen to select a memory slot to save. There are 20 memory locations. Manual - Formech 508DT/FS - Rev 3... -

Page 32: 508Dt Saving Parameters To Memory

Heater power settings can be adjusted as previously described using the settings button. When the SAVE button is pressed the actual heat time, including its negative count, will be carried over to the settings screen for editing and saving as previously described. Manual - Formech 508DT/FS - Rev 3... -

Page 33: 508Fs Basic Operation

The manual operating heat timer function is also the same showing only a single count up timer. There are 4 main differences between the 508FS & the 508DT as follows: 1. There is a pre-stretch function to allow the plastic material to be stretched prior to forming. - Page 34 Release the clamp frame to remove the moulding for inspection. Review the results and determine the parameters required to produce the forming. Use the save settings feature to set and record the values for later recall. Manual - Formech 508DT/FS - Rev 3...

-

Page 35: Operating Procedures - Other Settings / Loading Programs

When saved parameters are loaded the timer will count DOWN and the fan will turn OFF at the end of the time. Press again to restart the fan and timer. Manual - Formech 508DT/FS - Rev 3... -

Page 36: Optional Extras

2. Formech has available 2 standard sizes of reducing windows for the 508, with apertures of 228 x 204mm and 432 x 229 mm. Formech can also produce special size reducing windows. For more information please contact our sales department. -

Page 37: Tools

Repairs to the vacuum circuit can be costly. The use of talc as a release agent is not recommended. It may clog the vacuum pump, valves and hoses. MDF Baseboard Aluminium Baseboard Manual - Formech 508DT/FS - Rev 3... -

Page 38: 508Dt/Fs Standard Baseboard

M6 CSK machine screws x 19mm (3/4”) long to bolt the board to the table (platen) 213.5mm (8.40”) R10mm (0.39”) 427mm (16.81”) 442mm (17.40”) 477mm (18.78”) 12mm (1/2”) 508DT and 508FS standard base board 7mm (.275”) Diameter holes Manual - Formech 508DT/FS - Rev 3... -

Page 39: 508Dt/Fs Reducing Window Baseboard

Attach MDF board to steel plate with screws or strips of high bonding double sided tape 7mm (0.275”) Diameter holes 508DT and 508FS baseboard construction for reducing windows Manual - Formech 508DT/FS - Rev 3... -

Page 40: Plastics

Formech has available a Vacuum Forming Guide which will cover some of these topics in more details. Please contact Formech to gain access to this guide. -

Page 41: Post Forming Operations

Formech has available a Vacuum Forming Guide which will cover some of these topics in more details. Please contact Formech to gain access to this guide. -

Page 42: Warranty

Warranty Reliability and a long service life are synonymous with the Formech brand. However, as with any machinery, certain parts will require periodic replacement. Seals The silicon seals applied to the mould table and to the top aperture of the machine (clamp) are seen as being consumable parts, their service life will depend on how the machine is treated and how often it is used. -

Page 43: Service / Repair

4. With a sharp blade cut a 45° mitre joint at all corners. Fill gaps in the joints with sealant. Remove the masking tape before the sealant has set. For best performance leave seal to set overnight. Manual - Formech 508DT/FS - Rev 3... -

Page 44: Replacing A Heating Element

If all appears OK then set the defective zone to 100% and check the voltage at the zone using a suitable volt meter. 3- If no voltage is present then contact Formech for service and advice. If a single element is found to be faulty then it will require replacement. Follow below: Unplug the machine from the mains. - Page 45 Replace the connector cover and test are secured. the heater. Finally reassemble the heater top cover and retaining plate for the front fixings. Manual - Formech 508DT/FS - Rev 3...

-

Page 46: Electrical Troubleshooting

Before any maintenance work is carried out both electrical and air supplies must be locked in the OFF position or the mains lead removed (508DT). Only a qualified electrical technician may work on any parts carrying mains voltage and should be responsible for ensuring that the machine is in a safe condition before allowing services to be restored. - Page 47 If the supply is present but the motor hums and does not run, the capacitor may be faulty or has become disconnected. Check the connections to the capacitor by carefully removing its black cover. Manual - Formech 508DT/FS - Rev 3...

-

Page 48: Vacuum / Pressure Troubleshooting (508Dt & 508Fs)

Service / Repair Vacuum / Pressure Troubleshooting (508DT & 508FS) If the vacuum appears to be weak or non-existent check the following: Raise table in the up position. Turn the vacuum on. Place your finger over the vacuum If the vacuum gauge reading of hole and check the reading you get 22”Hg or higher is normal. -

Page 49: Cleaning

Lubrication The 508DT & 508FS require minimum lubrication. Apply general purpose grease to the table guide bars when required to assist with table movement. Apply a small amount of fine silicone oil or fine oil to the heater slide bars when required to assist free movement of the heater. -

Page 50: Electrical Wiring - 508Dt

Electrical Wiring - 508DT Manual - Formech 508DT/FS - Rev 3... -

Page 51: Vacuum Pump 2D351Vm - 508Dt Only

> Easily changed from pressure to vacuum and vice versa > Accessory regulating valve and gauge available > All models 240V single phase Specifications Model Typical Applications Typical Performance Max Pressure 2D351VM Vacuum filtration ult. vacuum 51mm Hg 30l/min at 30psi Manual - Formech 508DT/FS - Rev 3... - Page 52 Vacuum Pump 2D351VM - 508DT only Typical arrangement Manual - Formech 508DT/FS - Rev 3...

-

Page 53: Electrical Wiring - 508Fs

Electrical Wiring - 508FS Manual - Formech 508DT/FS - Rev 3... -

Page 54: Becker Pump Vt 4.10 - 508Fs Only

Becker Pump VT 4.10 - 508FS Only Spare parts list VT 4.10 Manual - Formech 508DT/FS - Rev 3... - Page 55 SPACING COLLAR 945363 00000 SOCKET HEAD SCREW 949451 00000 WASHER 968104 00000 RUBBER SLEEVE 029600 16300 BOLT 736001 99613 VACUUM REGULATING VALVE 727502 06000 BLOW-OFF VALVE 951232 00000 SCREW PLUG 951224 00000 SCREW PLUG Manual - Formech 508DT/FS - Rev 3...

-

Page 56: Pneumatics 508Dt & 508Fs

Pneumatics 508DT & 508FS Manual - Formech 508DT/FS - Rev 3... -

Page 57: Major Parts Listing 508Dt & 508Fs

Major Parts Listing 508DT & 508FS Description Part No Quartz Heating Element, 150W FSQ, Zone 1, (508DT) HEQ02 Quartz Heating Element, 200W SQE, Zone 2,3, (508DT) HEQ11 Quartz heating Element, 250W SQE, Zone 4, (508DT) HEQ12 Quartz Heating Element, 125W HSQ, Zone 2, (508DT) - Page 58 1/4" BSPT to 10mm Hose Tail Elbow (508DT) 1/4" BSPT to 10mm Hose Tail Straight (508DT) Pipe Clip - Small plastic, Type C, 1/4" Tube (508DT) Pipe Clip - Small plastic, Type F, 3/8" Tube Toggle Clamp Complete, Small Blue (508DT)

-

Page 59: Ec Certificate

Is in conformity with the provisions of the following other EC Directives: 2014/35/EU 2014/30/EU 2011/65/EU Technical File Compiled by: A. Berry at address below. Formech International Limited, Unit 4, Thrales End Farm, Thrales End Lane, Harpenden ………………………………………………………………………………………………………… Hertfordshire AL5 3NS, United Kingdom ………………………………………………………………………………………………………… Significant harmonised standards applied:... - Page 60 South America Telephone: 608.424.2524 spares@formechinc.com Formech International Limited Unit 4, Thrales End Farm, Thrales End Lane, Harpenden, Hertfordshire, AL5 3NS U.K. Tel: +44 (0)1582 469 797 Fax: +44 (0)1582 469 646 Email: info@formech.com Manual - Formech 508DT/FS - Rev 3...

Need help?

Do you have a question about the 508DT and is the answer not in the manual?

Questions and answers