Formech 508DT Installation, Operating And Service Manual

Desktop / floor-standing vacuum forming machines

Hide thumbs

Also See for 508DT:

- Installation, operating and service manual (60 pages) ,

- Installation, operating and service manual (30 pages) ,

- Installation, operating and service manual (42 pages)

Summary of Contents for Formech 508DT

- Page 1 Desktop / Floor-Standing Vacuum Forming Vacuum Forming Machines . . . 508DT/FS Installation, Operating and Service Manual For Parts, Service & Technical Assistance Telephone: +44 (0) 1582 469 797 Fax: +44 (0) 1582 469 646...

-

Page 2: Table Of Contents

Operating Procedures - Quick start guide default settings Basic Operation Mode 508DT/FS Operation Mode 508FS – Additional features Operating Procedures - Using custom settings Basic Operation Mode 508DT/FS - Editing the heater and time settings Operating procedures – Other settings / loading programs Warranty Heating elements... - Page 3 Service / Repair Replacing seals Replacing a heating element Electrical Troubleshooting Vacuum / Pressure Troubleshooting Cleaning Lubrication Electrical Wiring 508DT Vacuum Pump 2D351VM - 508DT only Electrical Wiring 508FS Becker Pump VT 4.10 - 508FS Only EC Certificate Manual - Formech 508DT/FS...

-

Page 4: Safety

Safety Thank you for choosing Formech. Please read and follow the below safety instructions before attempting to install or operate your machine. >Do not operate the machine until you have been trained and are fully conversant with it. >Read and understand all of this user manual. - Page 5 Care is required when operating the clamping frame to ensure that fi ngers or hands are not trapped. Keep hands clear of the heater rails when pulling the heater forwards. Manual - Formech 508DT/FS...

- Page 6 Ensure that you DO NOT work on your own when working at height. ENSURE THAT LOCAL LIFTING HANDLING AND HIGH LEVEL WORKING PROCEDURES ARE APPLIED AND MONITORED BY A PERSON RESPONSIBLE FOR HEALTH AND SAFETY. Manual - Formech 508DT/FS...

- Page 7 WHAT IS CONSIDERED TO BE FORESEEABLE MISSUSE. THE USE OF THIS MACHINE MUST BE ASSESSED, MONITORED AND CONTROLLED BY THE PERSON RESPONSIBLE FOR THE HEALTH AND SAFTEY IN THE ORGANISATION THAT OWNS AND OPERATES THIS MACHINE. Manual - Formech 508DT/FS...

-

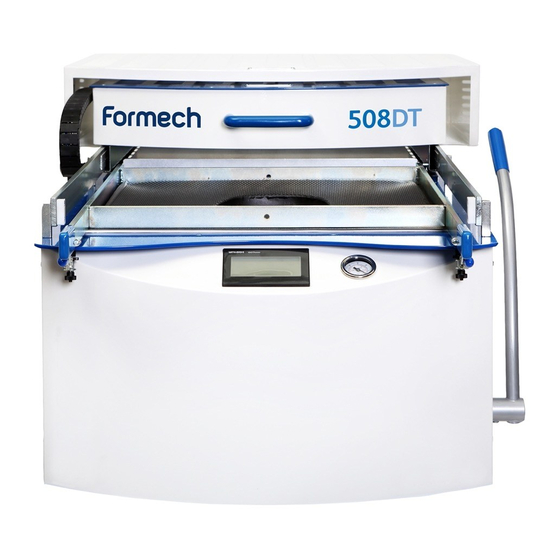

Page 8: General Arrangement 508Dt

A minimum of 2 persons are required to move the machine. In the case of the 508DT trolley, ensure that the 2 machine retaining screws are fi tted to the under side of the trolley / Machine. -

Page 9: General Arrangement 508Fs

Noise emissions on the Formech 508FS are less than 70dB(A). Machine storage The Formech 508FS must be stored in a dry environment. If the machine is not used for a long period of time, run the pump periodically (once a month). -

Page 10: General Arrangement 508Dt & 508Fs

General Arrangement 508DT & 508FS Machine footprint - 508DT & 508FS 1400mm 730mm Machine arrangement 1. Touch screen. Touch sensitive user screen to control the process with the ability to store programs in the memory. 2. Vacuum Gauge. To indicate the vacuum level achieved during moulding. - Page 11 7. Power connection. 508FS – supplied with 2.5mm cable fi tted to connect to a single phase 20amp socket. See Safety section at the beginning of this manual. 508DT – Supplied with C19 plug or C201 receptacle. Note the safety labelling.

-

Page 12: Installation And Inital Assembly 508

Installation and Inital assembly 508 Your Formech Machine is supplied with: E C Machinery Directive 2006/42/EC Declaration of conformity We hereby certify that the machinery stipulated below complies with all the relevant provisions of the EC Machinery Directive and the National Laws and regulations adopting this Directive. -

Page 13: Lifting And Handling - 508Dt Only

Installation and Inital assembly 508 Lifting and Handling - 508DT only The machine is shipped with two lifting bars fi xed to the rear of the heater rails. Once the machine has been positioned on either the trolley or the table top, remove the lifting bars before the heater guard can be fi xed in place. -

Page 14: Heater Guard - 508Dt & 508Fs

Installation and Inital assembly 508 Heater Guard - 508DT & 508FS Slide the heater guard rails onto the front rail link bars as shown. Take care to fi t evenly so that the front and rear rails meet and the fi xing holes are aligned. -

Page 15: Air Outlet Connection - 508Dt

Installation and Initial assembly 508 Air Outlet connection - 508DT only Fitted with an 8mm tube Air outlet connector for dome blowing. Manual - Formech 508DT/FS... -

Page 16: Installation And Initial Assembly (508Fs Only)

Ensure the counterweight arm is fi tted to the outside of the clamp frame. & Fit and tighten the washers and nuts removed in Repeat for both sides of the clamp frame Manual - Formech 508DT/FS... -

Page 17: Castor Option

If the unit is supplied with the castor wheel option and the machine is to be used before fitting the wheel castors then the auto-level and pre-stretch air will escape through the wheel mounting holes until the wheels are fitted or the fixing holes are blocked. Manual - Formech 508DT/FS... -

Page 18: Fitting The Rear Stabilisers

M6 cap head screws. Back Panel View Triangular support stabaliser Remove 4off M6 Cap head screw - Fit complete stabaliser assembly & replace screws White Crossbar with returns upwards - Fit to triangles before fitting to machine Manual - Formech 508DT/FS... -

Page 19: Cooling Fan Option

Fix and tighten with the screw and a 2nd mounting screw for both posts. & Fix the crossmember to the fan posts using the fi xings supplied. Position the fan grill towards the front of the machine. Manual - Formech 508DT/FS... - Page 20 Position the fan unit on the crossmember. Insert the mounting screws. Fit the Fixing nut to the screw & tighten. & Insert the IEC connector into the receptacle located on the electrical box. Secure the cable with the fi xings supplied. Manual - Formech 508DT/FS...

-

Page 21: Compressed Air Connection - 508Fs Only

Compressed air connection - 508FS only 8mm tube air supply outlet valve for use with ancillary equipment (eg. Air blow gun). 10mm tube air inlet connection. Air requirements for the 508FS: 80PSI / 5 bar Manual - Formech 508DT/FS... -

Page 22: Optional Extras

2. Formech has available 2 standard sizes of reducing windows for the 508, with apertures of 228 x 204mm and 432 x 229 mm. Formech can also produce special size reducing windows. For more information please contact our sales department. -

Page 23: Heater Layout

Heater Layout Zoning 508DT Front of machine Front of machine Zoning 508FS Front of machine Front of machine Manual - Formech 508DT/FS... -

Page 24: Operating Procedures - Quick Start Guide Default Settings

6mm and to give the board a mitred edge with clearance from the edge of the forming aperture. The 508DT/FS has built-in default settings which allow the operator to use the machine without entering values for the heaters or heating time. - Page 25 The Release button will only mould. activate when pressed. When Release is pressed the Vacuum will stop and the button will appear. FINISH Manual - Formech 508DT/FS...

-

Page 26: Operation Mode 508Fs - Additional Features

•Pull the heater forwards and a new cycle will The Formech 508FS has additional features begin from 3. above – ensure a new sheet of covered in the next section (9-10) plastic is clamped. -

Page 27: Operating Procedures - Using Custom Settings

Operating Procedures - Using custom settings Basic Operation Mode 508DT/FS - Editing the heater and time settings 11. Press the new edit button 12. Press . Press the new edit button to adjust the heater zone adjust and record the Heater and Time power settings. - Page 28 Operating Procedures - Using custom settings Basic Operation Mode 508DT/FS - Editing the heater and time settings 19. Press standby settings (15), and select the required standby % level. The standby level powers the heater to this proportion of the zone profi le set when the heater is in the rear position.

-

Page 29: Operating Procedures - Other Settings / Loading Programs

Operating procedures – Other settings / loading programs Operation Mode 508DT / 508FS 26. After forming test mouldings manually, if the used times are required to be saved press button. SAVE TIMES JUST USED 27. To load a program previously SAVED press button. -

Page 30: Warranty

Warranty Reliability and a long service life are synonymous with the Formech brand. However, as with any machinery, certain parts will require periodic replacement. The silicon seals applied to the mould table and to the top aperture of the machine (clamp) are seen as being consumable parts, their service life will depend on how the machine is treated and how often it is used. -

Page 31: Service / Repair

4. With a sharp blade cut a 45° mitre joint at all corners. Fill gaps in the joints with sealant. Remove the masking tape before the sealant has set. For best performance leave seal to set overnight. Manual - Formech 508DT/FS... -

Page 32: Replacing A Heating Element

If all appears OK then set the defective zone to 100% and check the voltage at the zone using a suitable volt meter. 3- If no voltage is present then contact Formech for service and advice. If a single element is found to be faulty then it will require replacement. - Page 33 Replace the screws are secured. connector cover and test the heater. Finally reassemble the heater top cover and retaining plate for the front fi xings. Manual - Formech 508DT/FS...

-

Page 34: Electrical Troubleshooting

Before any maintenance work is carried out both electrical and air supplies must be locked in the OFF position or the mains lead removed (508DT). Only a qualifi ed electrical technician may work on any parts carrying mains voltage and should be responsible for ensuring that the machine is in a safe condition before allowing services to be restored. -

Page 35: Cleaning

Lubrication The 508DT & 508FS require minimum lubrication. Apply general purpose grease to the table guide bars when required to assist with table movement. Apply a small amount of fine silicone oil or fine oil to the heater slide bars when required to assist free movement of the heater. -

Page 36: Electrical Wiring 508Dt

Electrical Wiring - 508DT Manual - Formech 508DT/FS... -

Page 37: Vacuum Pump 2D351Vm - 508Dt Only

Vacuum Pump 2D351VM - 508DT only Features > Oil free with stainless steel valves > Good quality, low noise > Easily changed from pressure to vacuum and vice versa > Accessory regulating valve and gauge available > All models 240V single phase... - Page 38 Vacuum Pump 2D351VM - 508DT only Typical arrangement Manual - Formech 508DT/FS...

-

Page 39: Electrical Wiring 508Fs

Electrical Wiring - 508FS Manual - Formech 508DT/FS... -

Page 40: Becker Pump Vt 4.10 - 508Fs Only

Schieber, Rotor Vane, Palette, Empujador Wartung 909519 00000 Filterpatrone, Filter cartridge, Cartouche Filtrante, Cartuccia filtro, Maintenance Cartucho de filtro Entretien erforderliche Bestellmenge / necessary order quantity / quantité nécessaire / quantità di ordinazione necessari / cantidad necesario Manutenzione Mantenimiento www.becker-international.com Manual - Formech 508DT/FS... - Page 41 068000 27600 SPACING COLLAR 945363 00000 SOCKET HEAD SCREW 949451 00000 WASHER 968104 00000 RUBBER SLEEVE 029600 16300 BOLT 736001 99613 VACUUM REGULATING VALVE 727502 06000 BLOW-OFF VALVE 951232 00000 SCREW PLUG 951224 00000 SCREW PLUG Manual - Formech 508DT/FS...

-

Page 42: Ec Certificate

Is in conformity with the provisions of the following other EC Directives: 2004 / 108/EC – EMC 2006 / 95/EC – LVD Technical File Compiled by: A. Berry at address below. Formech International Limited, Unit 4, Thrales End Farm, Thrales End Lane, Harpenden ………………………………………………………………………………………………………… Hertfordshire AL5 3NS, United Kingdom …………………………………………………………………………………………………………... - Page 43 For Parts, Service & Technical Assistance North and South America Telephone: 312.396.4072 Fax: 312.396.4073 spares@formechinc.com Formech International Limited Unit 4, Thrales End Farm, Thrales End Lane, Harpenden, Hertfordshire, AL5 3NS U.K. Tel: +44 (0)1582 469 797 Fax: +44 (0)1582 469 646 Email: info@formech.com...

Need help?

Do you have a question about the 508DT and is the answer not in the manual?

Questions and answers