Raymarine ST5000+ Owner's Handbook Manual

Sterndrive & hydraulic

autopilots

Hide thumbs

Also See for ST5000+:

- Quick reference (3 pages) ,

- Quick reference manual (3 pages) ,

- Owner's handbook manual (99 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Raymarine ST5000+

- Page 1 ST5000+ Sterndrive & Hydraulic Autopilots Owner’s handbook English Date: 09-2006 Document number: 81132-7-EN © 2006 Raymarine UK Limited...

- Page 3 Preface Hydraulic Sterndrive Rudder Reference Unit (Optional for Sterndrive Systems) Boat's Electrical Distribution Panel ST5000 Plus Control Head Fluxgate Compass SeaTalk Instruments D3461-1...

- Page 4 ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Raymarine Ltd, as part of its commitment to continuous improvement and updating, reserve the right to make changes, without prior notice, to the equipment, equipment specifications, and the instructions contained within this handbook.

-

Page 5: Table Of Contents

Preface Contents Preface ..................ix How this handbook is organised ........ ix Warranty ..............ix Safety information ............x EMC conformance ............x Chapter 1: Introduction ............1 1.1 Overview ..............1 1.2 Extended systems ............2 1.3 Specification ............... 2 Chapter 2: Basic Operation ........... - Page 6 ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Initiating Track mode ..........11 Automatic acquisition .......... 12 Manual acquisition ..........13 Cross track error ............14 Tidal stream compensation ........15 Waypoint arrival and advance ........15 Arrival ..............15 Skipping a Waypoint –...

- Page 7 Preface Chapter 4: Customising the ST5000 Plus ......23 4.1 User setup ..............23 Compass deviation correction ........23 Deviation display ............24 Heading alignment ............ 25 Heading mode ............25 Bar selection .............. 25 Data pages ..............25 4.2 Dealer setup .............. 28 Calibration lock ............

- Page 8 ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook 5.2 Control head .............. 39 Siting ................. 39 Mounting procedure ..........39 Surface mounting ..........40 Flush mounting ............ 41 Cable connectors ............42 Power supply connection .......... 42 Hydraulic ............. 43 Sterndrive .............

- Page 9 Preface 5.6 Hydraulic pump installation ........61 Introduction ............... 61 Cabling ..............62 Hydraulic ............. 62 Types of steering system ........... 63 Two line system ........... 64 Two line pressurised system ........ 65 Three line system ..........65 Bleeding the system ..........66 5.7 NMEA interface ............

- Page 10 viii ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Chapter 7: Maintenance ............81 General ..............81 Servicing and Safety ..........81 Advice ............... 81 Chapter 8: Fault Finding ............83 Index ..................85...

-

Page 11: Preface

Preface Preface This handbook contains information on the operation and installation of your new equipment. In order to obtain the best performance from your autopilot, please read this handbook thoroughly. How this handbook is organised This handbook is divided into the following chapters: Chapter 1: Introduces the autopilot, its features and its use. -

Page 12: Safety Information

• Make sure that all members of crew are familiar with the procedures to disengage the autopilot. Your Raymarine autopilot will add a new dimension to your boating enjoyment. However, it is the responsibility of the skipper to ensure the safety of the vessel at all times by careful observance of these basic rules. -

Page 13: Chapter 1: Introduction

Data Pages. The ST5000 Plus can share all data transmitted from other Raymarine SeaTalk instruments: • Track information, from a navigation instrument, provides waypoint control from the autopilot. -

Page 14: Extended Systems

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook 1.2 Extended systems The ST5000 Plus is compatible with other Raymarine SeaTalk instruments. Additional fixed and hand-held SeaTalk autopilot control units can be connected at secondary steering and control positions. A rudder reference unit can be fitted as an optional extra to the ST5000 Plus Sterndrive system, and will improve performance. -

Page 15: Chapter 2: Basic Operation

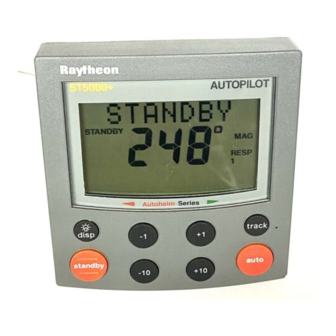

Chapter 2: Basic Operation Chapter 2: Basic Operation This chapter first provides summary diagrams of the key functions and screen layout. It then gives operating instructions for engaging the autopilot and using Auto mode, changing the lighting, and displaying Data Pages. 2.1 Key functions The autopilot is controlled using simple push-button operations, all of which are confirmed with a beep. -

Page 16: Display Layout

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook 2.2 Display layout The following illustration shows all the elements, together with a brief description, that make up the ST5000 Plus autopilot LCD display. Rudder or Steer Direction Indicator • The bar graph at the bottom of the display is normally a rudder bar for ST5000 Plus Hydraulic systems. -

Page 17: Using Auto Mode

Chapter 2: Basic Operation 2.3 Using Auto mode Engaging the Autopilot (Auto) 1. Steady the vessel on the required heading. 2. Press auto. • In Auto mode, the display shows the locked autopilot heading. CAUTION: Passage making under autopilot control is an enjoyable experience that can, if you are not careful, lead to the relaxation of the permanent watch. -

Page 18: Changing Course In Auto Mode

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Changing course in Auto mode • The +1 and +10 (starboard) and –1 and –10 (port) keys are used to change the locked heading, in increments of 1° and 10°, when the autopilot has control. -

Page 19: Returning To The Previous Locked Heading (Last Hdg)

Chapter 2: Basic Operation Returning to the previous locked heading (LAST HDG) If for any reason the vessel is steered away from the selected locked heading (for example, executing a dodge manoeuvre or selecting Standby) you can return to the previous locked heading: 1. -

Page 20: Operating Hints

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook • To cancel the off course alarm, press standby to return to hand steering. Operating hints Making major course changes • It is sound seamanship to make major course changes only when steering manually. -

Page 21: Display And Keypad Illumination

Chapter 2: Basic Operation 2.4 Display and keypad illumination Press disp for 1 second, from any mode, to enter illumination adjustment mode and turn the lights on. Subsequent presses of the disp key cycles the possible illumination settings: L3, L2, L1, OFF, L1, L2, L3 etc. where L3 is the brightest setting. The display times out to normal operation after 7 seconds of keypad inactivity. - Page 22 ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook then become “pop-ups”, and are displayed for 5 seconds when the autopilot mode is changed or a course change is made. • Press disp to display each Data Page in turn. • When the last Data Page is cycled, the display returns to the current autopilot mode display (for example, Standby).

-

Page 23: Chapter 3: Advanced Operation

Chapter 3: Advanced Operation Chapter 3: Advanced Operation This chapter provides information on: • Operation in Track mode • Adjusting the response level and rudder gain • Alarms 3.1 Operation in Track mode Track mode is used to maintain a track between two waypoints created on a GPS, Decca, or Loran navigation system. -

Page 24: Automatic Acquisition

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Automatic acquisition Automatic acquisition can only be achieved if the pilot is receiving cross track error and bearing to waypoint information (via SeaTalk or NMEA 0183). It is initiated as follows: 1. Bring the vessel to within 0.1 nm of track. 2. -

Page 25: Manual Acquisition

Chapter 3: Advanced Operation Previous Heading D3505-1 The display shows the new bearing to waypoint. Manual acquisition For manual track acquisition, when only cross track error data is available: 1. Steer the vessel to within 0.1 nm of track. 2. Bring the heading to within 5° of the bearing to the next waypoint. 3. -

Page 26: Cross Track Error

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook • Make positive positional checks at regular intervals, especially if navigational hazards are close by. Cross track error Cross track error (XTE) is the distance between the current position and a planned route. This is displayed in nautical miles (nm), statute miles (SM) or kilometres, and is taken directly from your navigator. -

Page 27: Tidal Stream Compensation

Chapter 3: Advanced Operation Tidal stream compensation Under most conditions, Track mode will hold the selected track to within ±0.05 nm (300 ft) or better. The autopilot takes account of vessel speed when computing course changes to ensure optimum performance over a wide range of vessel speeds. -

Page 28: Skipping A Waypoint - Seatalk Navigators Only

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook To accept the new target waypoint, press track. Note: When you reach the last waypoint in the track, the NO DATA alarm will sound to indicate that there is no further waypoint information. -

Page 29: Safety

Chapter 3: Advanced Operation Safety Passage making in Track mode removes the chores of compensating for wind and tidal drift, and will aid precise navigation. However, it is important to maintain an accurate log with regular plots. Position confirmation at the start of a passage At the start of a passage you must always confirm the fix given by the position transducer, using an easily identifiable fixed object. -

Page 30: Adjusting Autopilot Performance

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook 3.2 Adjusting autopilot performance The response level and rudder gain can be adjusted during normal operation using a combined key-press. Alternatively, you can set up these two control displays as default Data Pages (see Section 2.5). The default calibration settings for response level and rudder gain, as specified in Dealer Setup, are restored whenever the system is powered Changing the response level (AutoSeastate) -

Page 31: Changing The Rudder Gain

Chapter 3: Advanced Operation Changing the rudder gain Press the +1 and -1 keys together for 1 second to display the Rudder Gain screen, and adjust the setting in the same way as for the response level. Refer to Chapter 6, Post installation procedures, for instructions on how to check that the rudder gain is set correctly. -

Page 32: Large Cross Track Error

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Large cross track error LARGE XTE This alarm is activated when the cross track error exceeds 0.3 nm (see Section 3.1, Operation in Track mode). The alarm is cleared if the heading recovers or the course is changed, or if the operating mode is changed. -

Page 33: Low Battery

Chapter 3: Advanced Operation • Waypoint advance is requested by pressing track for 1 second in Track mode (SeaTalk Navigators only). • When the Man Overboard (MOB) function is activated in Track mode. When the alarm sounds, the pilot continues on its current heading, but displays the bearing to the next waypoint and the direction in which the boat will turn to take up that bearing. -

Page 34: Shallow Alarm

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook • The watch timer starts counting. • When the timer reaches 3 minutes, the text on the display starts flashing to indicate the last minute of Watch alarm. • When the timer reaches 4 minutes, the audible Watch alarm is activated. -

Page 35: Chapter 4: Customising The St5000 Plus

Chapter 4: Customising the ST5000 Plus Chapter 4: Customising the ST5000 Plus The ST5000 Plus provides setup and configuration options that are used to adjust the settings for the ST5000 Plus itself, the compass, and the autopilot. Note: You should perform the post installation procedures described in Chapter 6 before adjusting any other calibration features. -

Page 36: Deviation Display

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Adjusting User Setup Values Deviation display (DEVIATION) The deviation screen shows the current deviation value, calculated from the correction procedure (Swing Compass). You cannot edit this value. -

Page 37: Heading Alignment

Chapter 4: Customising the ST5000 Plus Heading alignment (ALIGN HDG) The heading alignment screen is used to align the autopilot compass with the ship’s compass. • Steer your vessel onto a known heading. • Adjust the displayed heading using the -1, +1, -10 and +10 keys. •... - Page 38 ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook The available pages are as follows: Data Displayed as Speed Knots SPEED KTS LOG XXXX.X Trip TRIP XXX.X Average Speed, Knots AV. SPD KTS Wind Direction E.g. WIND PORT Wind Speed WIND KTS Depth Metres DEPTH M Depth Feet...

- Page 39 Chapter 4: Customising the ST5000 Plus The default settings are: Data Default Page Setting Setting XTE Cross Track Error BTW Bearing to Waypoint DTW Distance to Waypoint NOT USED NOT USED NOT USED NOT USED For each setup page, scroll forwards or backwards through the available data pages, using the +1 or -1 keys.

-

Page 40: Dealer Setup

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook 4.2 Dealer setup Dealer Setup allows you to customise the autopilot to your boat. However, the factory default settings will provide safe performance for the initial sea trial, and fine tuning is not normally required. The flow chart on the next page shows you how to enter Dealer Setup, scroll through the setup displays, adjust the values and exit. - Page 41 Chapter 4: Customising the ST5000 Plus D3583-1a...

-

Page 42: Calibration Lock

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Feature Options/ Default Setting Range Stern Hydr Setting Calibration lock ON or OFF Pilot type 5000 STRN, HYDR 5000 STRN 5000 HYDR Rudder gain 1 to 9 Response 1 (AutoSeastate) or 2 (no AutoSeastate) Turn rate limit 5 to 20 Align Rudder... -

Page 43: Pilot Type

Chapter 4: Customising the ST5000 Plus Pilot type The default settings should be retained (5000 STRN for sterndrive systems, and 5000 HYDR for hydraulic systems). Rudder gain This is the power-on rudder gain setting and should be adjusted to the setting that gives the best steering performance as described in Chapter 6. -

Page 44: Off Course Alarm

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook If your boat is fitted with a rudder reference transducer, set the autopilot rudder limit as follows: 1. Manually set the rudder to each end stop (port and starboard), and in each case use the rudder bar on the display, to determine the end-stop angle. -

Page 45: Drive Type

Chapter 4: Customising the ST5000 Plus Setting Setting Effect Effect Recommended for: Recommended for: Setting Setting Setting Effect Effect Effect Recommended for: Recommended for: Recommended for: No trim correction Slow trim correction Heavy displacement vessels, with full keel or transom rudder. Medium trim correction Heavy displacement vessels. -

Page 46: Latitude

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook the effect of amplifying rudder response on northerly headings in the northern hemisphere, and on southerly headings in the southern hemisphere. Set AutoAdapt to nth in the northern hemisphere, or Sth in the southern hemisphere. -

Page 47: Rudder Damping

Chapter 4: Customising the ST5000 Plus Rudder damping Set this option if your system includes a rudder reference unit and the drive “hunts” when trying to position the rudder. Test this when your vessel is moored dockside, by pressing auto and then +10. If the helm overshoots and has to drive back or starts to hunt back and forth, you need to increase the damping level. - Page 48 ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook...

-

Page 49: Chapter 5: Installation

To minimise the risk of operating problems: • All Raymarine equipment and cables connected to it should be: • At least 1 m (3 ft) from any equipment transmitting or cables carrying radio signals e.g. -

Page 50: Suppression Ferrites

If your Raymarine equipment is going to be connected to other equipment using a cable not supplied by Raymarine , a suppression ferrite MUST always be fitted to the cable close to the Raymarine unit. Cabling • Avoid running cables through bilges where possible •... -

Page 51: Control Head

Chapter 5: Installation 5.2 Control head 24mm 17mm 110mm (4.33in) (0.95in) (0.67in) D3242-1 Siting The control head is completely waterproof and should be sited where it • Within easy reach of the steering position • Viewed straight on, or with a maximum viewing angle of 30° •... -

Page 52: Surface Mounting

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Note: Adjacent control heads, or instruments, must have a 6 mm (1/4 in) gap between them to allow sun covers to be fitted. Surface mounting To fit a surface mount control head: 1. -

Page 53: Flush Mounting

Chapter 5: Installation Flush mounting To fit a flush mount control head: 1. Ensure that the panel on which you intend to mount the control head is between 3 mm and 20 mm thickness. 2. Apply the flush mount template (supplied near the rear of this handbook) to the selected location and mark out the aperture into which the control head will sit. -

Page 54: Cable Connectors

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Cable connectors • All connections, except for the SeaTalk cables, are made via spade connectors. • When fitting the spade connectors, make sure the connector fits securely over the blade and not between the connector and its plastic insulating boot –... -

Page 55: Hydraulic

SeaTalk cables are not supplied with the equipment, as different installations have different cabling requirements. SeaTalk cables The following table lists the standard SeaTalk cables available from your Raymarine dealer: Part No: Description D187 Flat to a male round connector – 0.15 m (6 in) long D188 Flat to a female round connector –... -

Page 56: Cable Types

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Part No: Description D285 Flat moulded plugs at both ends – 3 m (9 ft 9 in) long D286 Flat moulded plugs at both ends – 6 m (19 ft 6 in) long D287 Flat moulded plugs at both ends –... -

Page 57: Mounting Location For Steel-Hulled Vessels

Chapter 5: Installation • To avoid deviation of both compasses, the fluxgate compass should be installed at least 0.8 m (2.5 ft) away from the steering compass. • The fluxgate compass must be positioned as far away as possible from large iron masses, such as the engine and other magnetic devices, which may cause deviation and reduce the sensitivity of the sensor. -

Page 58: Installing The Fluxgate Compass

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook 6ft (1.8m) 4ft (1.2m) 4ft (1.2m) Installing the fluxgate compass Attach the fluxgate compass to a bulkhead using the four self-tapping screws provided. Note: A label is supplied to warn people of the area in which the compass is mounted. -

Page 59: Cabling

Chapter 5: Installation Cabling 1. Route the fluxgate compass cable back to the control head. 2. Connect the five core cable (colour for colour) to the Compass terminals. D3282-1 5.4 Rudder reference transducer The rudder reference transducer is supplied with the ST5000 Plus Hydraulic system, and is available as an optional extra (Catalogue No. -

Page 60: Control Dimensions

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook • Care must be taken during installation to ensure the transducer arm is opposite the cable entry when the rudder is amidships. Failure to position the arm correctly could result in damage if the arm is driven onto its end stops by the steering system. -

Page 61: Cabling

Chapter 5: Installation Cabling 1. Run the rudder reference transducer cable back to the control head. 2. Connect the 4 wires (colour for colour) to the Rudder terminals. D3283-2... -

Page 62: Sterndrive Actuator Installation

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook 5.5 Sterndrive actuator installation The Sterndrive Actuator can be fitted to power assisted sterndrive systems made by Volvo, Mercruiser, OMC and Yamaha. • The ST5000 Plus for the Mercruiser 95 system (Part Number Z329) includes a special installation kit (D309). - Page 63 Chapter 5: Installation 2. Secure the assembly with the supplied split pin. 3. Install the adaptor pin bracket onto the cable end sheath. Note: The adaptor pin bracket must sit against, but not on, the shoulder on the cable end sheath. Also, the securing bolts must be on the sternside of the steering cable end sheath.

-

Page 64: Installation For Mercruiser 93/Omc/Yamaha

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Girdle tube 10. Slowly turn the steering system from hard over to hard over. 11. Make sure that there is no contact between the drive unit and the adaptor pin bracket and any part of the engine or steering system. - Page 65 Chapter 5: Installation CAUTION: The solid and sprung location pins must be fully engaged in the actuator girdle tube. Failure to do so will result in autopilot failure. 9. Position the drive unit pushrod over the top of the adaptor pin and retain with the safety clip.

-

Page 66: Installation For Mercruiser 95 (Z329)

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Installation for Mercruiser 95 (Z329) This section describes how to assemble the Sterndrive Actuator to anti- feedback, power assisted steering systems fitted to Mercruiser engines manufactured after 1993 (D309). Important Pre-installation check... Before you install any of the autopilot components, make sure there is sufficient space between the complete drive unit and the engine manifold. - Page 67 Chapter 5: Installation 6. Assemble the spring washers (9) to the four bolts (8) 7. Fit the clamp (10) around the spool valve cable connection. 8. Tighten the bolts (8) until the main support bracket is secure. 9. Assemble the shaft of the Sterndrive Actuator (1) to the pivot assembly (5) pin –...

-

Page 68: Mounting In A Restricted Area

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Mounting in a restricted area If an obstruction prevents installation of the drive unit as supplied, the main body can be rotated relative to the mounting bracket as follows: Fixing Screw Lock Nut Front Cover D409-1 1. -

Page 69: Installing The Universal I/O Drive

Chapter 5: Installation Installing the Universal I/O Drive The Universal I/O Drive can be used with both Volvo and Mercruiser engines. As the method of fitting to both engine types is similar, a common procedure is given. Differences between the two engine types are shown in the accompanying illustrations: 1. - Page 70 ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Steering cable rod Tiller block Adaptor pin Fitting Mercruiser adaptor pin D4532-1B 3. Secure the adaptor pin with the supplied split pin. 4. Fit the supplied hexagonal bracket centrally on the existing steering cable securing nut as shown in the appropriate following illustration.

- Page 71 Chapter 5: Installation Hexagonal bracket Ensure adaptor pin and hexagonal bracket are in line Fitting hexagonal clamp to Mercruiser D4587-1B 5. Insert the Universal I/O Drive cable into the clamp on the hexagonal bracket, so that the recess on the cable engages with the protrusion in the clamp.

- Page 72 ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Rod end Fitting cable to Mercruiser D4534-1B 7. Secure the rod end on the adaptor pin with the split pin supplied. 8. Fit the Universal I/O Drive assembly in a suitable, safe position, remote from the engine, using the clamps and tie-wraps provided.

-

Page 73: Cable Connection

Chapter 5: Installation Cable connection 1. Fit the cable supplied with the drive unit – make sure the connector is locked in place by turning the locking ring clockwise. 2. Route the cable back to the control head. 3. Secure the cable close to the drive unit – make sure there is sufficient free length to allow for movement of the drive unit. -

Page 74: Cabling

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook accordance with the manufacturers instructions before breaking into the system. On non pressurised systems, temporarily fit a solid plug to the upper helm reservoir vent – this will minimise fluid loss during installation. It is most important to keep the steering system free of dirt as the valves in both the manual helm pump and the autopilot pump will stick if the hydraulic fluid is contaminated. -

Page 75: Types Of Steering System

Chapter 5: Installation Types of steering system There are three basic types of hydraulic steering system: • Two line system • Three line system • Two line pressurised system Typical connection points for autopilot pumps are illustrated for each type. In all cases it is strongly recommended that you consult the steering gear manufacturer. -

Page 76: Two Line System

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook If the vessel has two steering positions, check valves will already be installed to ensure independent operation of the two wheels. Minimisation of hydraulic fluid loss during connection of the drive unit will help to reduce the time and effort required later to bleed the system of trapped air. -

Page 77: Two Line Pressurised System

Chapter 5: Installation Two line pressurised system A two line pressurised system has an external pressurised reservoir to reduce the chances of inducing air into the system. This also reduces any sponginess due to pipe expansion. The autopilot pump is connected to the system as shown below. Note: A uniflow check valve may be required if one is... -

Page 78: Bleeding The System

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Z068 double pilot check valve (Raymarine uniflow check valve) Note: Only required if a check valve is not contained in the helm pump. Bleeding the system Correct bleeding of the hydraulic system is one of the most important steps when installing the hydraulic pump. -

Page 79: Nmea Interface

Chapter 5: Installation 4. Turn the helm to port to counter the rudder movement. Note: Monitor the reservoir tank at all times and top up with the manufacturers recommended fluid as required. If air is left in the system the steering will feel spongy, particularly when the wheel is rotated to the hardover position. -

Page 80: Data Formats

ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook Data formats The following NMEA 0183 wind and navigation data can be decoded by ST5000 Plus. Data NMEA 0183 Course Over Ground VTG, RMC, RMA Speed Over Ground VTG, RMC, RMA Cross Track Error APB, APA, RMB, XTE Bearing to Waypoint APB, BWR, BWC, RMB... -

Page 81: Chapter 6: Post Installation Procedures

Chapter 6: Post Installation Procedures Chapter 6: Post Installation Procedures Once you have installed the system, you need to confirm that the system is wired correctly and is also set up to suit your type of boat. This chapter provides instructions for the following procedures: •... -

Page 82: Operating Sense

ST5000 Plus Sterndrive & Hydraulic Autopilots Operating sense The operating sense defines the direction the helm will be applied when a course change key is pressed or the vessel goes off course. Check the operating sense as follows: 1. Press auto. 2. -

Page 83: Seatalk Interface

Chapter 6: Post Installation Procedures SeaTalk interface If the ST5000 Plus has been linked to other SeaTalk instruments via SeaTalk, the link can be checked as follows: 1. Press standby. 2. Select display illumination level 3 on any other SeaTalk instrument or autopilot control unit. -

Page 84: Initial Sea Trial

ST5000 Plus Sterndrive & Hydraulic Autopilots 5. Carry out the Rudder limits procedure in Dealer Setup (see Chapter 4). 6.3 Initial sea trial EMC conformance Always check the installation before going to sea to make sure that it is not affected by radio transmissions, engine starting etc. In some installations, it may not be possible to prevent the equipment from being affected by external influences. -

Page 85: Automatic Compass Deviation Correction

Chapter 6: Post Installation Procedures • In conditions of light wind and calm water, so that autopilot performance can be assessed without the influence of strong winds or large waves • In waters clear of any obstructions Note: At any time during the sea trial you can press standby to return to hand steering. -

Page 86: What If I Turn The Boat Too Quickly

ST5000 Plus Sterndrive & Hydraulic Autopilots D3460-1 4. Press the +1 or -1 key to change the setting from OFF to YES. The TURN BOAT page is then displayed. D3451-1 5. Keeping the boat speed below 2 knots, turn your vessel in slow circles. -

Page 87: Can I Cancel The Process

Chapter 6: Post Installation Procedures D3452-1 Can I cancel the process? You can abort the correction process by pressing the DISP key to move on to the Deviation screen. If you wish to attempt deviation correction again, you can step back to the Swing Compass page or keep pressing disp to cycle through the calibration options until the page is displayed again. -

Page 88: Further Heading Alignment Adjustment

ST5000 Plus Sterndrive & Hydraulic Autopilots D3459-1 8. Use the +1 and -1, keys, or the +10 and -10 keys, to increase or decrease the displayed heading, until it agrees with the ship’s steering compass or a known transit bearing. 9. -

Page 89: Checking Autopilot Operation

Chapter 6: Post Installation Procedures If the average heading error is more than 5°, you should perform the compass deviation correction procedure again, circling slower and in move favourable conditions. Checking autopilot operation Having calibrated the compass the following procedure is recommended to familiarise yourself with autopilot operation: 1. -

Page 90: Checking The Rudder Gain

ST5000 Plus Sterndrive & Hydraulic Autopilots Checking the rudder gain The factory set rudder gain level will provide stable control for initial sea trials. However, vessels can vary widely in their response to the helm, and further adjustment to the rudder gain may improve the autopilot’s steering characteristics. - Page 91 Chapter 6: Post Installation Procedures These actions are most easily recognised in calm sea conditions where wave action does not mask basic steering performance. 2. To make a temporary adjustment to the rudder gain, press the -1 and +1 keys together for 1 second to display the Rudder Gain screen, then press +1 or -1 to change the level.

- Page 92 ST5000 Plus Sterndrive & Hydraulic Autopilots...

-

Page 93: Chapter 7: Maintenance

• Some products generate high voltages, and so never handle the cables/connectors when power is being supplied to the equipment. • Always report any EMC related problem to your nearest Raymarine dealer. We will use any such information to improve our quality standards. - Page 94 ST5000 Plus Sterndrive & Hydraulic Autopilots Owner’s Handbook...

-

Page 95: Chapter 8: Fault Finding

Chapter 8: Fault Finding Chapter 8: Fault Finding All Raymarine products are subjected to a comprehensive test procedure prior to packing and shipping. In the unlikely event that a fault does occur with your autopilot, the following check list should help identify the problem and provide a cure. - Page 96 ST5000 Plus Sterndrive and Hydraulic Autopilots Owner’s Handbook Position information not received • Navigator not transmitting the correct position data. The autopilot will not auto advance to the next waypoint • No bearing to waypoint information received from the navigator. A series of rotating dashes are displayed on screen •...

-

Page 97: Index

Index Index Advice 81 Alarms 19 Auto mode 5 AutoAdapt 33 Automatic Deadband 18 Automatic track acquisition 12 AutoRelease 77 AutoSeastate 18 AutoTack Default angle 32 AutoTrim Default setting 32 Bar graph 4 Cabling 81 Calibration 23–35 Changing course 6 Compass alignment 75 Compass deviation correction 23, 73 Course changes 6... - Page 98 ST5000 Plus Sterndrive and Hydraulic Autopilots Owner’s Handbook Engaging the autopilot 5 Fault finding 83 Functional test 69–70 Graph use 25 Heading 7 Heading alignment 25 Heading alignment adjustment 76 Heading mode 25 Illumination 9 Installation 37–68 Interfaces 70 Key functions 3 Large Cross Track Error alarm 14 LAST HDG 7 Latitude 34...

- Page 99 Index Performance 18 Pilot type 31 Previous heading 7 Response level 18 Default setting 31 Rudder bar 25 Rudder damping 35 Rudder gain 19, 31, 78 Rudder offset 31 Sea trial 72 SeaTalk data displays 9 SeaTalk interface 71 Servicing 81 Setup 23–35 Shallow alarm 22 Standby mode 5...

- Page 100 ST5000 Plus Sterndrive and Hydraulic Autopilots Owner’s Handbook...

- Page 101 DRILL ONE 18MM (23/32IN) DIAMETER HOLE DRILL TWO 2.4MM (3/32IN) DIAMETER HOLES Plug template D3441-1a...

- Page 103 Flush Mount Template 4 holes 6 mm diameter Shaded area to be removed 109 mm D4437-2...

- Page 105 RUDDER POSITIONED AMIDSHIPS DRILL THREE 3MM (1/8IN) HOLES CABLE POSITION D3440-1...

- Page 108 www.raymarine.com...

Need help?

Do you have a question about the ST5000+ and is the answer not in the manual?

Questions and answers