Katronic Technologies KATflow 150 Operating Instructions Manual

Ultrasonic flowmeter

Hide thumbs

Also See for KATflow 150:

- Operating instructions manual (48 pages) ,

- Quick start manuals (3 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Katronic Technologies KATflow 150

- Page 1 Operating Instructions KA Tflow 150 Ultrasonic Flowmeter...

- Page 2 Operating Instructions KATflow 150 Version V21EN160420 Copyright © 2016 All rights reserved.

-

Page 3: Table Of Contents

KATflow 150 Operating Instructions Table of Contents Page 1 Safety instructions, legal requirements, warranty, return policy....5 1.1 Symbols used in these operating instructions........5 1.2 Safety instructions.................5 1.3 Warranty....................6 1.4 Return policy..................6 1.5 Legislative requirements................6 2 Introduction...................... 7 2.1 System Configuration................8 3 Installation...................... - Page 4 5.4.3 HART compatible output............35 5.4.4 Analogue current output 0/4 ... 20 mA........35 5.4.5 Analogue voltage output 0-10 v..........35 5.4.6 Analogue frequency output 2...10k Hz........36 5.4.7 Digital Open-Collector output............36 5.4.85 Digital relay output..............36 5.5 Input configurations................37 5.5.1 PT100 inputs................37 5.5.2 Analogue current input 0/4 ... 20 mA.........37 5.6 Heat quantity measurement (HQM).............37 5.7 Sound velocity measurement (SVM)...........38 5.8 Dual-channel flow calculations (maths functions)........38...

-

Page 5: Safety Instructions, Legal Requirements, Warranty, Return Policy

KATflow 150 1 Safety instructions, legal requirements, warranty, return policy Safety instructions, legal requirements, war- ranty, return policy Symbols used in these operating instructions Danger This symbol represents an immediate hazardous situation which could result in serious injury, death or damage to the equipment. Where this symbol is shown, do not use the equipment further unless you have fully understood the nature of the hazard and have taken the required precautions. -

Page 6: Warranty

KATflow 150 1 Safety instructions, legal requirements, warranty, return policy Warranty Any product purchased from KATRONIC is warranted in accordance with the relevant product documentation and as specified in the sales contract provided it has been used for the purpose for which it has been designed and operated as outlined in these operating instructions. -

Page 7: Introduction

2 Introduction Introduction Clamp-on trans- The KATflow 150 is an ultrasonic flowmeter employing clamp-on sensors for the measurement of liquids in full, enclosed pipes. Flow measurements can be under- it-time flowmeter taken without interruption of the process or interference with the integrity of the pipeline. -

Page 8: System Configuration

KATflow 150 2 Introduction System configuration A maximum of 2 sensor pairs can be installed - if two pairs are installed these can be configured either in a 1-pipe dual-path or a 2-pipe single path configuration. Illustration 3: KF150 with direct sensor connection in a 1 pipe 2 path configuration... -

Page 9: Installation

3.1.3 Identification of components The following items are typically supplied (please refer to your delivery note for a detailed description): KATflow 150 ultrasonic flowmeter Clamp-on sensors (one pair for single channel operation, two pairs for dual channel operation) Sensor connection cable(s) if not direct sensor connection ... -

Page 10: Clamp-On Sensor Installation

KATflow 150 3 Installation Clamp-on sensor installation The correct selection of the sensor location is crucial for achieving reliable meas- urements and high accuracy. Measurement must take place on a pipe in which sound can propagate (see Acoustic propagation) and in which a rotationally sym- metrical flow profile is fully developed (see Straight pipe lengths). - Page 11 KATflow 150 3 Installation For a free inlet or outlet pipe section: Select the measuring point at a location where the pipe cannot run empty. Correct Disadvantageous Correct Disadvantageous For a vertical pipe: Select the measuring point at a location where the liquid flows upward to ensure that the pipe is completely filled.

- Page 12 KATflow 150 3 Installation Disturbance source: 2 x 90°-elbows in different planes Inlet Outlet L ≥ 40 D L ≥ 5 D Disturbance source: T-section Inlet Outlet L ≥ 50 D L ≥ 10 D Disturbance source: diffuser Inlet Outlet L ≥...

-

Page 13: Pipe Preparation

KATflow 150 3 Installation Pipe preparation Clean dirt and dust from around the area of the pipework where the sensors are to be placed. Remove loose paint and rust with a wire brush or file. Firmly bonded paint does not necessarily need to be removed provided the flow- meter diagnostics indicate sufficient signal strength. -

Page 14: Flowmeter Installation

3 Installation Flowmeter installation 3.6.1 Wall mounting The KATflow 150 is a wall mounted device and can be installed using suitable screws and wall plugs according to the following drawings. Flowmeter outline di- mensions Drawing 1: Outline dimensions KATflow 150 ultrasonic flowmeter... -

Page 15: Wall Mounting

KATflow 150 3 Installation Drilling aid for wall mounting 243.5 Make sure that the ambient temperature is within the -10 ... 60 °C operating tem- perature range specified for the flowmeter unit. -

Page 16: Electrical Connections

KATflow 150 3 Installation 3.6.2 Electrical connections Please note that in order to supply the unit with MAINS POWER, the equipment Electrical wiring must be protected by suitably sized switches and circuit breakers. 100 ... 240 V AC, 50/60 Hz 10 W 9 ... -

Page 17: Clamp-On Sensor Mounting

KATflow 150 3 Installation Clamp-on sensor mounting Before the sensors can be mounted Sensor mounting the installation location should have been determined, a sensor mounting method should be chosen, the flowmeter must be mechanically and electrically installed, ... -

Page 18: Correct Positioning Of The Sensors

KATflow 150 3 Installation 3.7.3 Correct positioning of the sensors Correct sensor position Illustration 8: Correct positioning of the sensors Always mount the transducer pair so that the free front edges of the sensors face each other. There is a different engraving on the top of each transducer. The transducers are mounted correctly if the engravings on the two transducers form an arrow. - Page 19 KATflow 150 3 Installation Press the sensors firmly onto the pipe. There should be no air pockets between the transducer surface and the pipe wall. Using a measuring tape, adjust the sensor separation distance as sugges- ted by the flowmeter. When the sensor positioning screen (Section 3.3) is displayed, the middle bar allows fine adjustment of the sensor location.

-

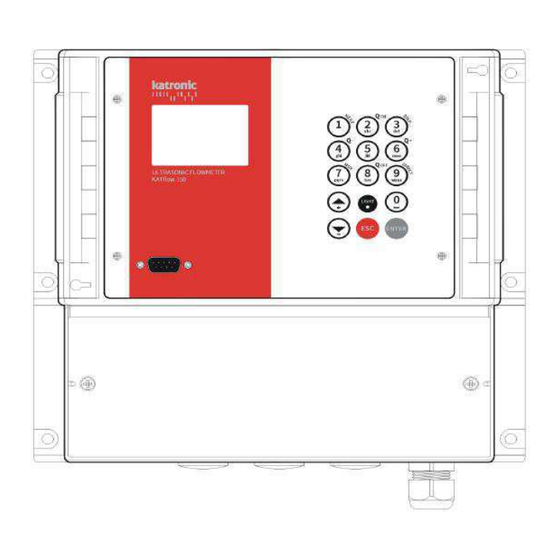

Page 20: Operation

KATflow 150 4 Operation Operation Switching On/Off The flowmeter is switched on by connecting the power supply to the instrument. Switching On/Off Disconnecting the external supply switches off the flowmeter. Keypad and display Display Keypad RS 232 Serial Interface 4.2.1... - Page 21 KATflow 150 4 Operation Character entry: > Character entry: = Reset positive total value MUltipleXer Character entry: Toggle (where mul- ti-channel functions are provided) Character entry: = Stop totaliser function Character entry: Move menu/list selection item Character backspace clear Character entry:...

-

Page 22: Display Functions

KATflow 150 4 Operation Table 3: Menu structure 4.2.2 Display functions Main measurement display Display icons Menu header Display line 1 Display line 2 Date, time (optional) Illustration 12: Main display functions Display icons Display icon Function Not used Datalogger recording... -

Page 23: Quick Setup Wizard

KATflow 150 4 Operation Time/date set Clock error Error recorded in error log No error detected Serial communication on (RS232 and/or RS485) Serial communication off "L", "LT" or "T" Displays whether flow is laminar, turbulent or mixed Table 4: Display icons... - Page 24 KATflow 150 4 Operation Enter outside pipe diameter using alphanumer- ical keys and confirm by pressing <ENTER>. Use key <UP> as character backspace clear to correct for data entry errors. If 0 is entered, an additional screen appears that allows entering the pipe circumference.

-

Page 25: Measurements

KATflow 150 4 Operation Select transducer configuration (number of passes) using cursor keys. Auto Automatically 1 pass, diagonal mode 2 passes, reflection mode 3 passes, diagonal mode 4 passes, reflection mode..etc. Confirm by pressing <ENTER>. Use cursor keys to select Start Measurement. -

Page 26: 3-Line Display Format

KATflow 150 4 Operation 4.4.2 3-line display format Display screen Operation The three-line display screen is configure- able to show flow, totalizers and diagnostic functions. Change to diagnostic displays by pressing <DISP> and to totalizer screens by press- ing <NEXT>. -

Page 27: Dual Channel Display Mode

KATflow 150 4 Operation 4.4.5 Dual PV display (multi-channel meters) Display screen Operation Line 1 shows the PV on the selected channel. Line 2 shows the selected units. Line 3 shows the PV on the other channel (in its selected units) Change to diagnostic displays by pressing <DISP>... -

Page 28: Commissioning

KATflow 150 5 Commissioning Commissioning Menu structure Menu structure Main menu Menu level 1 Menu level 2 Description/settings Quick Start Setup Wizard Indication of sensor type and serial number if Sensor type automatically detected, otherwise select from list ↑↓ K1N,K1L,K1E,K1Ex,K1P,... - Page 29 KATflow 150 5 Commissioning Temperature -30 ... 300 °C Select from list ↑↓ Liner Material None, Epoxy, Rubber, PVDF, PP, Glass, Cement, User (liner c-speed) Only if lining material selected Liner c-speed 600 ... 6553.0 m/s Liner thickness Only if lining material selected 1.0 ...

- Page 30 KATflow 150 5 Commissioning Lining Select from material list ↑↓ Material Thickness 1 ... 99 mm C-speed 600 ... 6553.0 m/s Passes Select from list ↑↓ Passes Display Select channel Channel 1, Channel 2 Select from unit list ↑↓ Select line of...

- Page 31 KATflow 150 5 Commissioning Defines output behaviour in the event of error Error Select from list ↑↓ Pulse Out Select from list ↑↓ Source Select from unit list ↑↓ Units Select from list ↑↓ Mode Alarm (select on point, off point)

- Page 32 KATflow 150 5 Commissioning Zero calibration settings Zero Cal Zero Perform auto zero calibration Track Track zero offset Delta Zero flow delta time offset in ns, read from sensor PROM or entered directly for special sensors Timeup Upstream transit-time offset in µs, allows for fixed...

- Page 33 KATflow 150 5 Commissioning Reload factory default settings, except for date Defaults and time Key Lock Locks the keypad until password is entered (four number keys followed by “ENTER”). See also “Password” above. Diagnostics Shows control unit temperature Temperature Percentage of unused datalogger memory,...

-

Page 34: Diagnostics

KATflow 150 5 Commissioning Table 6: Firmware menu structure Diagnostics Diagnostic screens can be viewed directly during measurement using the 3/DISP and 1/NEXT keys, or through the menu structure. Display settings Customer specific settings for data to be displayed can be achieved using the ap- propriate menu items to select units for the top, middle and bottom lines. -

Page 35: Hart Compatible Output

KATflow 150 5 Commissioning 5.4.3 HART compatible output The KF100 can also be configured with an optional module which responds to out- put commands conforming to the HART protocol. Please refer to customer support for further information. HART® is a registered trademark of the HART Communication Foundation. -

Page 36: Analogue Frequency Output 2

KATflow 150 5 Commissioning 5.4.6 Analogue frequency output (passive) Frequency outputs may be assigned to process values in the “mode” section of the output menu. The outputs can be programmed and scaled within the menu struc- ture. Wiring Electrical Galvanically isolated from main electronics and from other I/O's. -

Page 37: Input Configurations

KATflow 150 5 Commissioning Input configuration 5.5.1 PT100 inputs Inputs Wiring Electrical 3 and 4 wire options. Galvanically isolated from main electronics and from other I/O's. characterist- Temperature: Range -50 ... 400 °C. Resolution: 0.01 K. Accuracy: ±0.1 K. 5.5.2 Analogue current input 0/4 ... -

Page 38: Sound Velocity Measurement (Svm)

KATflow 150 5 Commissioning Sound velocity measurement (SVM) The measured sound velocity (SOS) is available as a Process Value and a dia- gnostic function (where specified) during measurement and may be applied to a Process Output by selecting “C m/s” from the appropriate menu. -

Page 39: Maintenance

KATflow 150 6 Maintenance Maintenance KATflow flowmeters are maintenance free concerning the flow measurement func- tions. Within the scope of periodic inspections, regular inspection for signs of dam - age or corrosion is recommended for the transducers, the junction box if installed, and the flowmeter housing. -

Page 40: Troubleshooting

KATflow 150 7 Troubleshooting Troubleshooting Should there be the need to call customer service, please let us know the following details: Model code Serial number SW, HW revision Error log list Possible error messages may include the following:... - Page 41 KATflow 150 7 Troubleshooting COMM HS1 ERR Hardware Internal communication Power on/off, otherwise error call customer support COMM READ AVE Hardware Internal communication Power on/off, otherwise error call customer support COMM READ RAW Hardware Internal communication Power on/off, otherwise error...

-

Page 42: Technical Data

KATflow 150 8 Technical Data Technical data Sound Speed* Shear Wave (at 25 ºC) Material ft/s Steel, 1% Carbon, hardened 3,150 10,335 Carbon Steel 3,230 10,598 Mild Steel 3,235 10,614 Steel, 1% Carbon 3,220 10,565 302 Stainless Steel 3,120 10,236... - Page 43 KATflow 150 8 Technical Data All data given at 25 ºC (77 ºF) unless otherwise stated Change Kinematic Viscosity Sound Speed v/ºC Chemical Specific Substance ft/s m/s/ºC mm x10-6 ft Formula Gravity Acetic anhydride (CH3CO)2O 1.082 (20 ºC) 1,180 3,871.4 0.769...

- Page 44 KATflow 150 8 Technical Data 1,328.7 Methane 0.162 (-89 ºC) 17.5 (-89 ºC) (-128 ºF) Methanol CH4O 0.791 (20 ºC) 1,076 3,530.2 0.695 7.478 Methyl acetate C3H6O2 0.934 1,211 3,973.1 0.407 4.379 Methyl alcohol CH4O 0.791 1,076 3,530.2 0.695 7.478...

- Page 45 KATflow 150 8 Technical Data 1,170 3,838.6 Tetrachloroethane C2H2Cl4 1553 (20 ºC) 1.19 12.804 (20 ºC) (68 ºF) Tetrachloro-ethene C2Cl4 1.632 1,036 3,399 Tetrachloro-Methane CCl4 1.595 (20 ºC) 3,038.1 0.607 6.531 Tetrafluoro-methane 875.24 (- 2,871.5 1.75 (-150 ºC) 6.61 (Freon 14) 150 ºC)

- Page 46 KATflow 150 8 Technical Data 93.2 1517 4977 95.0 1519 4984 96.8 1521 4984 98.6 1523 4990 100.4 1525 4997 102.2 1527 5010 104.0 1528 5013 105.8 1530 5020 107.6 1532 5026 109.4 1534 5033 111.2 1535 5036 113.0 1536 5040 114.8...

- Page 47 KATflow 150 8 Technical Data 190.4 1551 5089 192.2 1551 5089 194.0 1550 5086 195.8 1549 5082 197.6 1549 5082 199.4 1548 5079 201.2 1547 5076 203.0 1547 5076 204.8 1546 5072 206.6 1545 5069 208.4 1544 5066 210.2 1543 5063 212.0...

-

Page 48: Specification

KATflow 150 9 Specification Specification General Measuring principle : Ultrasonic time difference correlation principle Flow velocity range : 0.01 ... 25 m/s Resolution : 0.25 mm/s Repeatibility : 0.15 % of measured value ±0.015 m/s Accuracy : Volume flow ± 1 ... 3 % of measured value depending on application, ±... - Page 49 KATflow 150 9 Specification Process inputs / Process Outputs (maximum of ten per instrument) Inputs Temperature : PT 100, three or four-wire circuit, measuring range - 50 ... 400 °C, resolution 0.1K, accuracy ±0.2 K Current : 0 ... 20 mA active or 4 ... 20 mA passive, U = 30 V, R = 50 Ohm, accuracy 0.1 % of MV...

-

Page 50: Index

KATflow 150 10 Index Index Acoustic coupling gel Negative separation distance Analogue current input Outer Diameter Analogue current output Output Configuration Analogue frequency output Output settings Analogue voltage output Packaging Certificate of Conformity Passes Commissioning Pipe material selection Customer Return Note (CRN) -

Page 51: Appendix A

KATflow 150 Appendix A Appendix A Certificate of Conformity... -

Page 52: Appendix B

Appendix B KATflow 150 Appendix B Customer Return Note (CRN) Company Address Name Tel. No. E-mail Instrument model Katronic contract no. (if known) Serial number Sensor type(s) Sensor serial number(s) The enclosed instrument has been used in the following environment (please √):...

Need help?

Do you have a question about the KATflow 150 and is the answer not in the manual?

Questions and answers