Summary of Contents for WoodFast C1000X

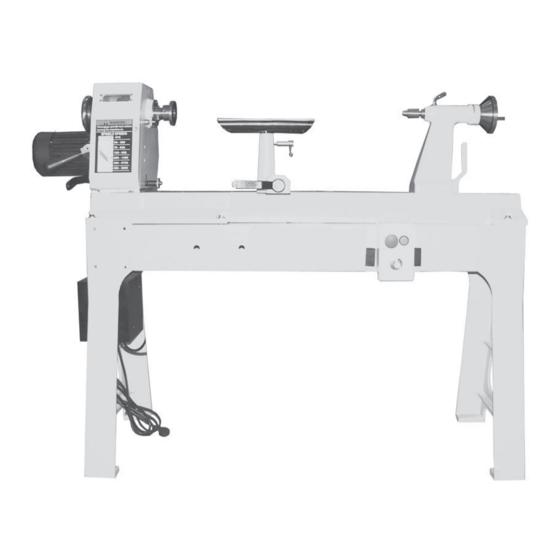

- Page 1 Instruction Wood Lathe C1000X Manual IMPORTANT For your safety read instructions carefully before assembling or using this product. Save this manual for future reference.

- Page 2 Index GENERAL INFORMATION Foreword MACHINE DESCRIPTION Machine identification Getting to know your machine Technical specification Recommended protective clothing Noise emission Prescribed use of the machine Hazards Additional safety instructions for table saw INSTALLATION Identification of saw unit components Determine Lathe Location in Workshop Stand Assembly Bolting Lathe to Stand Mounting Transducer box to Stand leg...

-

Page 3: General Information

1. General Information FOREWORD This manual must be read and understood before operating the machine. This will provde a better working knowledge of the machine, for increased safety and to obtain the best results. 2. Machine Description MACHINE IDENTIFICATION There is a identification label fixed to the machine, containing the manufacturer's data, year of construction, serial number and specifications. -

Page 4: Technical Specification

2.3 TECHNICAL SPECIFICATION SPECIFICATION C1000X Swing over bed 520mm Working distance between centers 950mm Spindle speed electronic variable speed 50-3850rpm Headstock&tailstock spindle Sleeve adjustment 100mm Motor power output 1.5HP Net weight 209KGS 2.4 RECOMMENDED PROTECTIVE CLOTHING • Non-slip footwear is recommended. - Page 5 2.8 ADDITIONAL SAFETY INSTRUCTIONS FOR WOOD LATHE SAFETY IS A COMBINATION OF OPERATOR COMMON SENSE AND ALERTNESS AT ALL TIMES WHEN THE WOOD LATHE IS BEING USED. WARNING: FOR YOUR OWN SAFETY, DO NOT ATTEMPT TO OPERATE YOUR WOOD LATHE UNTIL IT IS COMPLETELY ASSEMBLED AND INSTALLED ACCORDING TO THE INSTRUCTIONS.

-

Page 6: Installation

3. Installation CAUTION Many of the items are very heavy. We recommend that assistance is sought before trying to lift the larger components. 3.1 IDENTIFICATION OF LATHE UNIT COMPONENTS A. 1 x Lathe Bed including Transducer B. 2 x Stand Body C. -

Page 7: Determine Lathe Location In Workshop

CAUTION 3.4 Bolting Lathe to Stand Many of the items are very heavy. We recommend that 1. Lift lathe body by the bed only, not by the head stock or tail assistance is sought before trying to lift the larger components. stock assemblies. -

Page 8: Adjustment

4. Adjustment 4.4 Tightening or Loosening Motor Belt 1. Turn the belt tighting handle alignning to the headstock locking handle (Fig.09). Rotate the belt tighting handle upwards to tighten the motor belt. 4.1 Removing Spur Center from the Headstock Turn the belt tighting handle aligning to the motor to lock the belt Insert the knockout bar into the headstock spindle from the handle tension. -

Page 9: Swiveling Headstock

Fig.15 Fig.12 locking position 4.8 Adjusting Tailstock 4.6 Swiveling Headstock 1. Loosen cam lever (A-Fig.16) to move the tailstock along the Pull the position pin out with your right hand, at the same time lathe bed to desired position. Tighten lever. loosen the locking handle and swivel the headstock with your left 2. -

Page 10: Variable Speed Switch

Fig.18 Fig.20 2. The 24 position indexing feature (A-Fig.21) allows accurate pat- tern work on projects such as straight fluting, grooving, drilling, lay out and more. This feature also allows the user to lock the spindle for removing face plates, chucks and other accessories without needing two tools. -

Page 11: Troubleshooting

5. Troubleshooting Fig.17 IIMPORTANT: When carrying out any adjustments turn off switch and make sure electrical leads are disconnected from mains power. -

Page 12: Diagrams & Components

6. Diagrams & Components... - Page 14 Description Description Key No. Part No. Key No. Part No. Lock nut M20 Motor M20GB889D2Z F8040504 Washer 20 Carriage bolt WSH20GB95Z JL94010115 Cam spindle Mounting plate JL94010111 JL94010301A Mounting plate Set screw M8X30 JL94010113 M8X30GB70D3Z Set screw M5X12 Handwheel M5X12GB70D3B JL94010105A Pin 5X40 Set screw M8X16...

- Page 15 Description Key No. Part No. Rear stand body JL94040003 Front stand body JL94040004 Hex bolt M10X25 M10X25GB5783Z Spring washer 10 WSH10GB93Z Flat washer 10 WSH10GB97D1Z Stand leg JL94040001 Set screw M5X20 M5X20GB819Z Mounting plate JL91042001 Switch JL91042000 Locking bar JL91042100 Available for optional Rear Turning Attachment (Part No.117 through Part No.129) Tool rest support...

Need help?

Do you have a question about the C1000X and is the answer not in the manual?

Questions and answers