Summary of Contents for Carbolite 3508 P1

- Page 1 Operating Instructions Temperature Controller EUROTHERM °C RUN/HLD 1200 96.0 3508 A/MAN RUN/HOLD Type 3508 English MC19-1.22...

- Page 2 3508 Controller Note: For the purposes of this manual the Eurotherm 3504 range is functionally identical to the 3508 range. MC19-1.22...

- Page 3 3508 Controller Contents Using This Manual PID Control Basic Operation Controller Layout (Home display) Keys Quick Start Guide Operation as a simple controller Changing the Setpoint Resetting the programmer Operating the current program Understanding User Levels Setting up the controller Maximum output power setting Customer ID.

-

Page 4: Using This Manual

This manual covers the operation of: 3508 P1 – Controller/Programmer The 3508 P1 is a digital temperature controller which uses PID algorithms to give excellent temperature control when properly set. This controller can store and run a single program of up to 20 segments. -

Page 5: Basic Operation

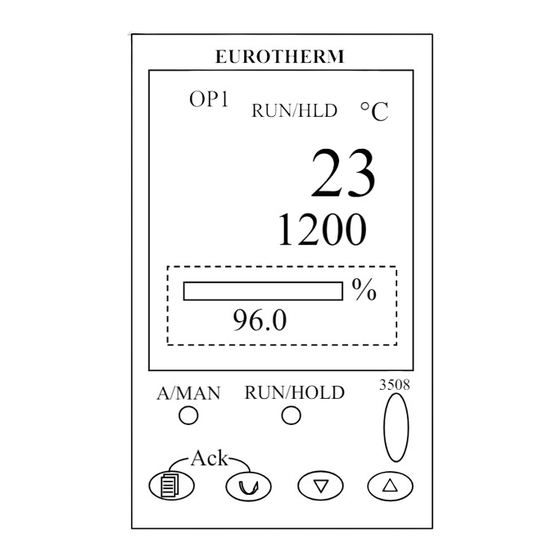

Basic Operation 2 Basic Operation Controller Layout (Home display) Measurement units EUROTHERM °C Measured temperature RUN HLD Alarm indicator Setpoint temperature (SP) when basic controlling Power output 1200 indicator Program Setpoint temperature (PSP) Program status when a program is running indicators. -

Page 6: Quick Start Guide

Quick Start Guide 3 Quick Start Guide Operation as a simple controller When switched on the controller goes through a short test routine and then shows the measured temperature. Below it is shown the setpoint temperature (SP) and percentage of power output. - Page 7 Quick Start Guide 2. Press up to select level 2. After a short pause the display will show “Access Pass code”. 3. Press up or down to enter the pass code 9, Pass is momentarily displayed. After a short pause the display will return to home, the controller is now in level 2.

-

Page 8: Setting Up The Controller

Quick Start Guide 4 Setting up the controller Before using the controller (or during its lifetime) certain parameters may have to be set, depending on specific requirements. To do this the Controller must be set to supervisor Level 2, see section 3.5. Maximum output power setting Press page ... -

Page 9: Programming

Programming 5 Programming Programming Notes Programs can be created in Level 1 or Level 2 of the 3508. For the P10 and P25, new programs can be created while the current program is running. To avoid unwanted heating at the end of a program, set the controller SP temperature to zero before running a program. -

Page 10: Wait Segments

‘WaitVal’ set for that segment. * The fixed threshold used by deviation parameters is set in the configuration level of the programmer and if required should be requested when purchasing a furnace from Carbolite Gero. Program Cycling The Cycles parameter sets the number of times the program will run. -

Page 11: Creating A Program

Programming Creating a Program From the home display, press page three times to get to the programming page, the display will show “ProgEdit 1”. Program number On P10 or P25 models press up or down to select a new program number. The display will show that new programs have only one segment. -

Page 12: Running A Program

Programming GoBack Cycles (visible only for GoBack segments) Press scroll until the display shows “GoBack Cycles”. Press up or down to set a value. Call Cycles (Visible only for call segments) Press scroll until the display shows “Call Cycles”. Press up or down to set a value. End Type (Visible only for End segments) Press scroll ... -

Page 13: Program Status

Programming 5.10 Program Status While a program is running the home display shows 3 values: Top: Measured temperature Centre: Program setpoint (PSP) Bottom: Power output percentage To see more detail: Press page once to go to the program status page. The top and centre values from the home page remain on the display. -

Page 14: Alarms

Programming Power fail during Time-to-target segments: The ramp rate will be that of the current segment. The ramp rate is maintained, but the time remaining is recalculated. If there is a power interruption while controlling to Setpoint, when power is restored the controller automatically calls for maximum power. - Page 15 Programming Finish the program with an End segment: Press scroll until Segment Type is displayed. Press up or down to select ‘End’ Press scroll until End Type is displayed. Press up or down to select ‘Reset’ Press page ...

-

Page 16: Program Example 2

Programming 5.14 Program Example 2 The following sequence of entries creates and runs the program shown graphically below. Turn the Setpoint to ‘0’ by Pressing down Press page until Prog, Segments Used is displayed. On P10 and P25 models press up ... -

Page 17: Options

To reveal or hide parameters in the controllers it is necessary to go into configuration modes, a security code is needed. Please consult Carbolite Gero. Digital Communications – RS232 If the RS232 option is supplied, then the furnace or oven is fitted with one subminiature D- socket connected to the controller communications (comms) module. -

Page 18: Alarm Option

Programming To change the address value access the level 2 list. In level 2 press the page key until the COMMS parameter is displayed. Press up Alarm Option When an alarm board is fitted with free contacts for customer use, the contacts are taken to a panel plug on the control panel, wired as indicated: n/o contacts Controller... -

Page 19: Navigation Diagrams

Navigation 7 Navigation Diagrams Operator Level 1 - No Program Running Current Programming program Page page ProgEdit ProgStat Home Customer display Program Program Identity number number Segments Program used Status Read only Holdback Program value Setpoint Controller Identity... -

Page 20: Operator Level 1 - Program Running

Navigation Operator Level 1 - Program Running Current Programming Page program page Home Customer ProgStat previous display Identity program nr diagram Segment nr Read only & type Controller Segment time identity remaining when using & more than program status Change program status Program... -

Page 21: Supervisor Level 2

Navigation Supervisor Level 2 To enter Level 2 Access Access Home Press & Press to Press to Home Goto Pass display hold for 3 select select display Level 1 code seconds Level 2 code 9 (Level 1) (Level 2) Level 2... -

Page 22: Controller Fault

SafeOp SafeOp Turns the power off. Element The heating device used in the furnace or oven. Thermocouple The temperature sensing device used in the furnace or oven. Furnace or Oven This refers to the product purchased from Carbolite Gero. MC19-1.22... - Page 23 Navigation MC19-1.20...

- Page 24 Furnace and Oven products, please contact: Carbolite Gero Service Telephone: +44 (0)1433 624242 Fax: +44 (0)1433 624243 Email: ServiceUK@carbolite-gero.com Carbolite Gero Limited, Parsons Lane, Hope, Hope Valley, S33 6RB, England. Telephone: +44 (0)1433 620011 Fax: +44 (0)1433 621198 E-mail: info@carbolite-gero.com MC19 –...

Need help?

Do you have a question about the 3508 P1 and is the answer not in the manual?

Questions and answers