Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for EverSewn Hero

-

Page 3: Important Safety Instructions

Important safety instructions IMPORTANT When using an electrical machine, basic safety precautions should always be followed, including the following: Please read the instruction manual carefully before using this machine. Keep the instruction manual at a suitable place with the machine and hand it over if you give the machine to a third party. - Page 4 10. Do not pull or push the fabric while sewing. This can result in needle breakage. 11. Switch the machine off ("O") when making any adjustments in the needle area, such as threading or changing the needle, threading the bobbin, or changing the presser foot, and the like.

- Page 5 SERVICING OF DOUBLEINSULATED PRODUCTS In a double-insulated product, two systems of insulation are provided instead of grounding. No grounding means is provided on a double-insulated product nor should a means for grounding be added to the product. Servicing a doubleinsulated product requires extreme care and knowledge of the system and should only be done by qualified service personnel.

- Page 6 SAVE THESE INSTRUCTIONS! Attention! - This machine is intended for household use only. If used intensively or commercially, regular cleaning and especially attentive care is required. - Signs of wear and tear owing to intensive or commercial use are not covered automatically, even if they occur within the warranty period.

-

Page 7: Table Of Contents

Contents GETTING READY TO SEW Principal parts of the machine .......................6 Accessories ............................7 Connecting the machine ........................8 Winding the bobbin...........................9-10 Inserting the bobbin ..........................11 Threading the upper thread ......................12-13 Using the needle threader ........................14 Using the net ............................15 Adjusting presser foot pressure ......................16 Replacing the needle ...........................16 Matching needle/ fabric/ thread ......................17 Changing the presser foot ........................18... - Page 8 ORDINARY SEWING Blind hem/ lingerie stitch........................42 Buttonhole stitch ..........................43-46 Making a buttonhole on stretch fabrics ......................46 Bar tack stitch ............................47 Eyelet Stitch............................48 Button sewing ............................49 Darning stitch ..........................50-51 Zipper insertion..........................52-53 inserting a centered zipper ..........................52 Inserting a side zipper.............................53 Narrow hemming ..........................54 Cording ..............................55 Single cording ..............................55 Triple cording ..............................55...

- Page 9 EMBROIDERY Important Embroidery information .......................74 Embroidery threads ............................74 Lower threads ..............................74 Stabilizer .................................75 Adhesive Spray...............................75 Iron-on interfacing............................76 Attaching the embroidery foot......................77 Embroidery unit overview .......................78-80 Connecting the embroidery unit........................79 Removing the embroidery unit........................80 Embroidery hoop overview ......................81-84 Attaching a stabilizer to the fabric........................81 Hopping the fabric............................82 Using embroidery sheet..........................83 Attaching the embroidery hoop........................84...

-

Page 10: Getting Ready To Sew

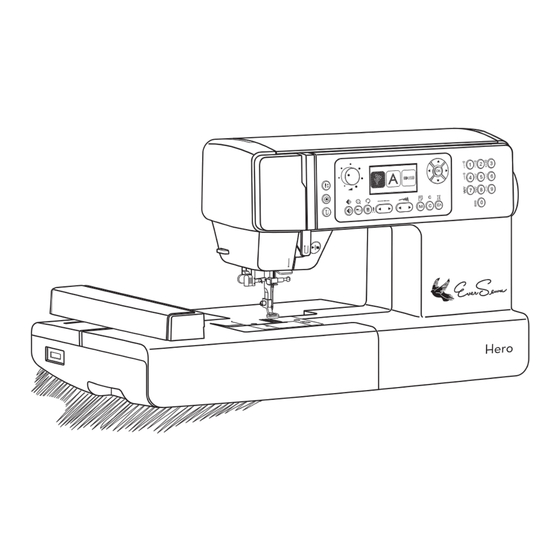

GETTING READY TO SEW Principal parts of the machine 1. Upper thread guide 2. Presser foot pressure 3. Bobbin thread guide 4. Tension dial 5. LCD display 6. Speed limiting adjustment dial 7. Face plate 8. Operation buttons 9. Thread cutter 10. -

Page 11: Accessories

GETTING READY TO SEW Accessories Standard 1. All purpose foot (T) 2. Zipper foot (I) 3. Buttonhole foot (D) 4. Overcasting foot (E) 5. Blind hem foot (F) 6. Satin stitch foot (A) 7. Button sewing foot (H) Simple embroidery foot 9. -

Page 12: Connecting The Machine

GETTING READY TO SEW Connecting the machine Before connecting the power supply, make sure that the voltage and frequency shown the rating plate is conforming with your mains power. Place the machine on a stable table. 1. Connect the power line cord to the machine by inserting the 2-hole plug into the mains plug socket. -

Page 13: Winding The Bobbin

GETTING READY TO SEW Winding the bobbin 1. Place the thread and spool holder onto the spool pin. For smaller spools of thread, place spool holder with the small side next to the spool or use the small spool holder. Note: If using special thread which winds quickly off the spool attach a net to the spool before using and use the larger spool holder. - Page 14 GETTING READY TO SEW 6. Push the bobbin to right. 7. When the bobbin winder spindle is pushed to the right, bobbin winding position, the message is shown on the LCD display. It will disappear from the LCD display when the bobbin winder spindle is pushed back to the left into the sewing position 8.

-

Page 15: Inserting The Bobbin

GETTING READY TO SEW Inserting the bobbin Attention: Turn power switch to off ("O") before inserting or removing the bobbin. When inserting or removing the bobbin, the needle must be fully raised. Remove the bobbin cover plate. Insert the bobbin in the bobbin case with the thread running in a counterclockwise direction (arrow). -

Page 16: Threading The Upper Thread

GETTING READY TO SEW Threading the upper thread Please Note: It is important to carry out the threading correctly as by not doing so several sewing problems could result. Start by raising the needle to its highest point, and also raise the presser foot to release the tension discs. - Page 17 GETTING READY TO SEW 2. Draw the thread from the spool through the upper thread guide. 3. Guide the thread around the thread guide pulling the thread through the pre-tension spring as illustrated. 4. Thread the tension module by passing the thread between the silver discs.

-

Page 18: Using The Needle Threader

GETTING READY TO SEW Using the needle threader Raise the needle to its highest position and lower the presser foot. Attention: Turn power switch to the off position ("O"). Lower the needle threader lever slowly and draw the thread through the thread guide as illustrated and then to the right. -

Page 19: Using The Net

GETTING READY TO SEW Using the net When using special threads which wind quickly off the thread spool, attach a net to the spool before using. If the net is too long, c ut the net to match the size of the spool. Thread Spool pin Spool holder... -

Page 20: Adjusting Presser Foot Pressure

GETTING READY TO SEW Adjusting presser foot pressure The presser foot pressure of the machine has been pre-set and requires no particular readjustment according to the type of fabric (light-or-heavy weight). However, if you need to adjust the presser foot pressure, turn the presser adjusting screw with a coin. -

Page 21: Matching Needle/ Fabric/ Thread

GETTING READY TO SEW Matching needle/ fabric/ thread NEEDLE, FABRIC, THREAD SELECTION GUIDE NEEDLE SIZE FABRICS THREAD 9-11 (70-80) Lightweight fabrics-thin cottons, voile, Light-duty thread in cotton, nylon, serge, silk, muslin, Qiana, interlocks, polyester or cotton wrapped cotton knits, tricot, jerseys, crepes, polyester. -

Page 22: Changing The Presser Foot

GETTING READY TO SEW Changing the presser foot Attention: Turn power switch to off ("O") when carrying out any of the below operations! Attaching the presser foot holder Raise the presser foot bar (a). Attach the presser foot holder (b) as illustrated. Attaching the presser foot Lower the presser foot holder (b) until the cut-out (c) is directly above the pin (d). -

Page 23: Type Of Presser Foot Chart

GETTING READY TO SEW Type of presser foot chart PRESSER FOOT APPLICATION NEEDLE PRESSER FOOT APPLICATION NEEDLE General sewing, Cording Patchwork stitches, Decorative stitching, Smocking, All purpose foot (T) Cording foot (M) Fagoting, etc. (Optional) Inserting zippers Narrow hemming Zipper foot (I) Hemmer foot (K) (Optional) Buttonhole sewing,... -

Page 24: Two-Step Presser Foot Lifter

Two-step presser foot lifter The presser foot lifter raises and lowers your presser foot. The second level is only used in embroidery mode to remove the hoop easily. Note: The needle must always be at the highest position. To raise or drop the feed dogs With the sewing table off the machine, the feed dog adjustment lever can be seen on the base in back of the sewing machine. -

Page 25: Information On The Lcd Display

GETTING READY TO SEW Information on the LCD Display Normal mode Normal mode display 1. Pattern 2. Pattern number 3. Reverse 4. Auto-lock 5. Suggested presser foot 6. Tension 7. Pattern group 8. Needle up position 9. Stitch length 10. Needle position 11. -

Page 26: Memory Mode

GETTING READY TO SEW Memory mode Memory mode display 1. Selection frame Memory module with unit 3. Empty m emory module 4. C urrent memory module 5. Pattern number and pattern 6. Auto-stop 7. Mirror 8. Needle up position 9. Sound on Elongation 11. -

Page 27: Embroidery Mode

GETTING READY TO SEW Embroidery mode Embroidery mode display - type selection display 1. Built-in Embroidery pattern 2. Built-in Embroidery letter 3. Designs from USB Embroidery mode display - Built-in Embroidery pattern 1. Type mode 2. Indication - select page up/down 3. - Page 28 GETTING READY TO SEW Embroidery mode display - Designs from USB 1. Type mode 2. Cursor 3. Loading pattern Embroidery mode display - editing display 1. Embroidery field 2. Available embroidery hoop 3. Unavailable embroidery hoop (appear in gray) 4. Multi color 5.

-

Page 29: Buttons Of The Machine

GETTING READY TO SEW Buttons of the machine Start/stop button Reverse/ Exit button Auto-lock/ Trace button Needle up/down position button Speed limiting adjustment dial 6. OK button Arrow buttons 8. Direct pattern selection and number buttons Mirror button Elongation/ Resize button Twin needle/ Rotate button Stitch length adjustment/ Stitch forward/back button Stitch width adjustment/ Color forward/back button... -

Page 30: Operation Buttons

GETTING READY TO SEW Operation buttons Start/stop button The machine will start running when Start/stop button is pressed and will stop when pressed the second time. The machine will rotate slowly at the beginning of the sewing. Reverse/ Exit button Reverse is pressed to sew in reverse. -

Page 31: Arrow Buttons

GETTING READY TO SEW Needle up/ down position button With the Needle up/ down position button, you decide whether the needle shall stop in the up position or in the material when you stop sewing. Press the button so the arrow on the LCD points upward "... -

Page 32: Direct Pattern Selection And Number Buttons

GETTING READY TO SEW Direct pattern selection and number buttons Direct pattern selection Press the buttons to select the utility patterns shown beside the number button when the mode button is set at the Direct mode. Number buttons Except the Direct pattern mode, the other mode can be selected by pressing the desired numbers. -

Page 33: Function Buttons

GETTING READY TO SEW Function buttons Mirror button Except the Direct Patterns 0 and the patterns 86-98 from the Group Patterns "A", the other patterns can be mirror imaged by pressing the mirror button. The machine will continue to sew the reflected pattern until the mirror button is pressed again. - Page 34 GETTING READY TO SEW Stitch length adjustment/ Stitch forward/back button When you select a stitch the machine will automatically set the recommended stitch length which will be indicated by numbers on the LCD display. The stitch length can be adjusted by pressing the stitch length adjustment buttons.

- Page 35 GETTING READY TO SEW Memory/ Setup button Press the memory button to enter the memory mode, and store the combinations of characters or decorative stitches. The Direct mode patterns and he patterns 86- 98 from Group Patterns "A" cannot be memorized.

-

Page 36: Sewing Basics

SEWING BASICS Pattern chart Direct patterns A Group Patterns B Group Patterns... - Page 37 SEWING BASICS lphabet - Block style lphabet - Script style a lphabet...

-

Page 38: Thread Tension

SEWING BASICS Thread tension - Basic thread tension setting: "4" Tight Loose - The recommend thread tension for embroidering is "2" - "6". - To increase the tension, turn the dial to the next number up. To reduce the tension, turn the dial to the next number down. - Proper setting of tension is important to good sewing. -

Page 39: Useful Skills

SEWING BASICS Useful skills Reverse Reverse stitching is used to secure the threads at the beginning and at the end of a seam. Press the reverse button and sew 4-5 stitches. The machine will sew forward when the button is released. Free arm Free-arm sewing is convenient for sewing tubular areas such as pant hems and cuffs. -

Page 40: Cutting The Thread

SEWING BASICS Cutting the thread The thread cutter serves two purposes. 1. Cut the thread after threading the needle 2. Cut the thread after finishing a seam. To cut the thread after completing your work raise the presser foot. Remove the fabric, draw the threads to the left side of the face cover and cut using the thread cutter. -

Page 41: Selecting Stitch

SEWING BASICS Selecting stitch Ten of the most frequently used utility stitches can quickly be selected with the d irect pattern selection and number buttons Select the desired stitch from those shown on the top cover. 1. Turn on the sewing machine. 2. - Page 42 SEWING BASICS 6. Select the desired pattern that you sew. Use the number buttons Press the number buttons for selecting the pattern needed. For example: pattern 36 Please Note: Press the OK utton can return to the pattern browser display. Use the arrow buttons Press the arrow buttons...

-

Page 43: Straight Stitches And Needle Position

SEWING BASICS Straight stitches and needle position A-00 Changing the needle position These setting apply only to Direct Patterns A Group Pattern 00. The pre-set position is "3.5", center position. Press the stitch width adjustment button left " ..", the needle position will move to the left. -

Page 44: Stretch Stitch

SEWING BASICS Stretch stitch Straight stretch stitch It assures you of a stitch that is strong and flexible and will give with the fabric without breaking. Good for easy to ravel and knit fabrics. It is good for joining durable fabric such as denims. These stitches can also be used as a decorative top stitch. -

Page 45: Overcasting Stitches

ORDINARY SEWING Overcasting stitches Sewing overcasting stitches along the edges of fabric to prevent them from fraying. Using the overcasting foot 2.0~3.0 Change the presser foot to the overcasting foot (E). Sew the fabric with the fabric edge against the guide of the overcasting foot. -

Page 46: Ordinary Sewing

ORDINARY SEWING Blind Hem Secure the bottoms of skirts and pants with a blind hem, this stitch will sew without stitches showing on right side of fabric. : Blind hem/ lingerie for firm fabrics A-03 A-04 A-03 : Blind hem for stretch fabrics 1.0~2.0 2.5~4.0 A-04 : Blind hem for stretch fabrics... -

Page 47: Buttonhole Stitch

ORDINARY SEWING Buttonhole stitch Buttonhole sewing to match the size of the button is possible. For stretch fabric or thin fabric, it is recommended to use a stabilizer for a better buttonhole finish. : For thin or medium fabric A-86 : For thin or medium fabric 0.3~1.0 2.5~7.0 A-88 : For horizontal buttonholes on thick... -

Page 48: Buttonhole Stitch

ORDINARY SEWING Select the buttonhole stitch. Adjust the stitch width and the stitch length to the desired width and density. Position the fabric under the presser foot with the front end of the buttonhole mark aligned with the center line on the buttonhole foot. - Page 49 ORDINARY SEWING * Buttonholes are sewn from the front of the presser foot to the back, as shown. A-86 A-88 A-89 A-87 A-90 A-91 A-92 Raise the presser foot and cut thread. To sew over same buttonhole, raise the presser foot (will return to original position).

-

Page 50: Making A Buttonhole On Stretch Fabrics

ORDINARY SEWING Cut the center of the buttonhole being careful not to cut any stitches on either side. Use a pin as a stopper at the bar tack so you do not cut too much. Please Note: When cutting the buttonhole with the seam ripper, do not place your hands in the cutting direction, otherwise injuries may result. -

Page 51: Bar Tack Stitch

ORDINARY SEWING Bar tack stitch Bar tack stitch is used to reinforce points subject to strain, such as pocket corners and openings. A-97 A-98 0.4~1.0 1.0~3.0 Extend the button holder plate and set to the desire bar tack length. Adjust the stitch width and stitch length to personalize the stitches. -

Page 52: Eyelet Stitch

ORDINARY SEWING Eyelet stitch Eyelet stitches are used for making belt holes and other similar applications. A-94 : Select for sewing eyelets on belts , etc A-94 A-95 A-95 : Select for sewing eyelets on belts , etc 5.0 6.0 7.0 Press the "-"... -

Page 53: Button Sewing

ORDINARY SEWING Button sewing A-96 2.4~4.5 Change the presser foot to the button sewing foot. Move the drop feed control to " " to lower the feed dogs. Position the work under the foot. Place the button in the desired position, lower the foot. Select zig zag pattern. -

Page 54: Darning Stitch

ORDINARY SEWING Darning stitch Darning a small hole or a tear before it becomes larger can save a garment. Choose a fine thread in a color as color as close to your garment possible. A-93 1.0~2.0 3.5~7.0 Baste the upper fabric and the under fabric together. -

Page 55: Darning Stitch

ORDINARY SEWING Position the fabric so that the needle is 2mm (1/16 inch) in front of the area to be darned, and then lower the presser foot lever. Please Note: When lowering the presser foot, do not push in the front of the presser foot, otherwise the darning will not be sewn with the correct size. -

Page 56: Zipper Insertion

ORDINARY SEWING Zipper Insertion This foot can be set to sew on each side of the zipper, the The edge of the foot guides the zipper to ensure straight placement. Attention: Zipper foot should be used for sewing width center needle position straight stitch only. It is 1.5~3.0 possible that needle could hit the presser foot and break when sewing other patterns. -

Page 57: Inserting A Side Zipper

ORDINARY SEWING Inserting a side zipper - Baste the zipper opening on the garment. - Fold back to the left seam allowance. Reverse stitches Turn under the right seam allowance to form 3mm fold. Basting stitching Wrong side - Attach the zipper foot. Attach the right side of the presser foot pin to the holder when sewing the left side of the zipper. -

Page 58: Narrow Hemming

ORDINARY SEWING Narrow hemming The hemmer foot is used to stitch the narrow rolled hems usually found on shirt tails, table linens and along the edge of frills. * The hemmer foot accessory is optional. It is not included with this machine. 1.5~3.0 3.0~3.5 Fold edge of fabric over about 3mm, then fold it... -

Page 59: Cording

ORDINARY SEWING Cording Used for embellishing 1 to 3 cords or decorative threads. Sew over one strand of cording to create a pretty swirled design on a jacket or vest or sew over three strands of cording for border trims. Pearl cotton, knitting yarn, embroidery floss, lace thread, fine wool or lily yarn can be used for cording. -

Page 60: Satin Stitch Sewing

ORDINARY SEWING Satin stitch sewing A-13 A-14 A-15 A-16 A-17 A-18 A-19 A-20 A-21 A-22 A-23 A-24 0.3~2.0 2.5~7.0 A-25 A-26 A-27 A-28 A-29 A-30 A-31 A-32 A-33 A-34 A-35 A-36 Use the satin stitch foot for satin stitching and sewing decorative stitches. -

Page 61: Gathering

ORDINARY SEWING Gathering The Gathering Foot is used for gathering fabrics. Ideal for clothing as well as home decor, works best on thin to medium weight fabrics. * The Gathering foot accessory is optional. It is not included with this machine. Gathered fabric Remove the presser foot holder and attach the gathering foot, lowering the tension setting to... -

Page 62: Smocking

ORDINARY SEWING Smocking The decorative stitch created by stitching or embroidering over gathers is called "smocking". It is used to decorate the front of blouses or cuffs. The smocking stitch adds texture and elasticity to fabric. A-08 A-09 Use the all purpose foot to sew straight lines 1cm (3/8 inch) apart, across the area to be smocked. -

Page 63: Free Motion Darning, Embroidery And Monogramming

ORDINARY SEWING Free motion darning, embroidery and monogramming 3.5~5.0 Move the drop feed control to " " to lower the feed dogs. Remove the presser foot holder, and attach the embroidery foot to the presser foot holder bar. Press the embroidery foot on firmly from behind with your index finger and tighten the screw. -

Page 64: Embroidery

ORDINARY SEWING Embroidery Select zigzag stitch pattern and adjust the stitch width as desired. Stitch along the outline of the design by moving the embroidery hoop. Make sure to maintain a constant speed. Fill in the design working from the outline towards the inside. -

Page 65: Quilting

ORDINARY SEWING Quilting Sandwiching batting between the top and bottom layers of fabric is call "Quilting". The top layer is usually formed by multiple geometrically shaped pieces of materials joined together. Attaching the edge/ quilting guide * The Quilting foot accessory is optional. It is not included with this machine. -

Page 66: Patchwork Stitching

ORDINARY SEWING Patchwork stitching A-07 A-08 A-09 Open the seam allowances and presses it flat. Place the center of the presser foot on the seam line of the joined pieces of fabric and sew over the seam. Fagoting A-07 Stitching across an open seam is called "fagoting". It is used on blouses and children's clothing. -

Page 67: Scallop Stitch

ORDINARY SEWING Scalloping The wave-shaped repeating pattern that looks like shells is called "scalloping". It is used on the collars of blouses and to decorate the edges of projects. Scallop hem A-11 - Fold the fabric right side together in and sew along the edge. -

Page 68: Walking Foot

ORDINARY SEWING Walking foot * The walking foot accessory is optional. It is not included with this machine. Always try to sew first without the walking foot accessory which should be used only when necessary. It is easier to guide the fabric and you have a better view of the seam when using the standard, regular foot on your machine. -

Page 69: Mirror

ORDINARY SEWING Mirror Please Note: - Direct Patterns 0 and Patterns 86-98 from Group Pattern "A" cannot be mirror imaged. - Mirror imaged patterns can also be combined with other patterns. Select the stitch. Pressing the mirror button The LCD display icon for mirror imaging of the pattern appears. -

Page 70: Elongation

ORDINARY SEWING Elongation A-13 A-14 A-15 A-16 A-17 A-18 A-19 A-20 A-21 A-22 A-23 A-24 0.3~1.0 2.5~7.0 A-25 A-26 A-27 A-28 A-29 A-30 A-31 A-32 A-33 A-34 A-35 A-36 The stitch can be elongated up to five times its normal length by pressing the elongation button Press the elongation button. -

Page 71: Using The Twin Needle

ORDINARY SEWING Using the twin needle * The twin needle is optional. It is not include with the accessories. 2.0~5.0 Insert the twin needle. Attention: When using twin needles, use the all purpose foot (T) regardless of what kind of sewing foot will be carried out. - Page 72 ORDINARY SEWING Press the twin needle button " ". The LCD display will display the twin needle icon " " and the machine automatically reduces the maximum width for twin needle sewing by 2mm. Two lines of stitching are sewn parallel to each other.

-

Page 73: Memory

ORDINARY SEWING Memory Combined patterns can be stored for later use. Since stored patterns are not lost after the sewing machine is turned off, they can be recalled at any time. This is convenient for patterns, such as names, that will be used often. Please Note: - Multiple patterns selecting from pattern groups can be combined together. - Page 74 ORDINARY SEWING 4. Press the pattern group selection button to enter the pattern group selection display. Select the desired pattern group. (E.g. For pattern group "A") 5. Press the OK button to into pattern browser, the display containing the various stitches in the selected pattern group appears.

-

Page 75: Editing Patterns

ORDINARY SEWING Editing patterns 1. Press the memory button to enter the memory mode. 2. Use the arrow buttons to select the number of the memory module. (For example: M3) 3. Press the OK Button, the LCD display containing the various types of stitches will open and the cursor stay in 1st position. -

Page 76: Clearing Patterns

ORDINARY SEWING Clearing patterns 1. Use the arrow buttons to move the cursor to the pattern that you want to delete. 2. Press the clear/ return button to delete the selected pattern and all patterns in the back will be moved one memory position forward. -

Page 77: Recalling And Sewing The Memorized Pattern

ORDINARY SEWING Recalling and sewing the memorized pattern 1. Press the memory button to enter the memory mode. 2. Use the arrow buttons to select the number of the memory module. (For example: M3) 3. Press the OK Button, the LCD display containing the various types of stitches will open. -

Page 78: Embroidery

Embroider threads A good thread is essential for embroidery to avoid poor stitch formation, thread ® breakage, etc. EverSewn is recommending using Isacord thread for your embroidery. Polyester threads Polyester with a brilliant sheen is a hard wearing colorfast thread and has a high tensile strength which is suitable for all types of embroidery. -

Page 79: Stabilizer

EMBROIDERY Stabilizer: ® EverSewn is recommending using OESD stabilizer for your embroidery. Tear-away stabilizers - Excess is easily torn away. - One or more layers can be used. - Available in different weights. - For more stability, apply to the wrong side of the material with temporary adhesive spray before hooping. -

Page 80: Iron-On Interfacing

EMBROIDERY Iron-on interfacing Iron-on interfacings are available in a variety of weights. Iron-on interfacings should be selected to suit the material being used. Use an iron-on interfacing which is easily removable from the material. Iron-on interfacings are pressed (fused) to the wrong side of the material Application: To provide body and shape for the materials onto which designs will be placed, use the appropriate stabilizer. -

Page 81: Attaching The Embroidery Foot

EMBROIDERY Attaching the embroidery foot Attention: Turn power switch to off ("O") when carrying out any of the below operations! Raise the presser foot to the second stage. Press the lever (a) and the foot will disengage. Loosen the screw (b) counterclockwise to remove the presser foot holder (c). -

Page 82: Embroidery Unit Overview

EMBROIDERY Embroidery unit overview 1. Embroidery surface 2. Embroidery carriage 3. USB port 4. Embroidery unit release button 5. Hoop-securing lever 6. Embroidery hoop holder 7. Embroidery unit connection 8. Embroidery unit detection device 9. Embroidery unit connector plug Note: - Do not touch the embroidery unit detection device... -

Page 83: Connecting The Embroidery Unit

EMBROIDERY Connecting the embroidery unit Attention: - Turn power switch to off ("O") when carrying out any of the below operations! - The foot control is disabled as long as the embroidery unit is connected. Remove the sewing table to the left side. Slide the embroidery unit onto the machine arm. -

Page 84: Removing The Embroidery Unit

EMBROIDERY Removing the embroidery unit Remove the embroidery hoop, and make sure the embroidery carriage return to the home position. Attention: - To remove the embroidery hoop, please refer page 84. - To return the embroidery carriage, please refer page 98. Turn power switch to off ("O")! Remove the embroidery unit connector plug. -

Page 85: Embroidery Hoop Overview

EMBROIDERY Embroidery hoop overview Inner hoop 2. Ribs for fitting the e mbroidery sheet Center mark Outer hoop Embroidery hoop connector Hoop size Adjustment screw Attaching a stabilizer to the fabric Attention: Always use stabilizer material when sewing embroidery projects. The needle may break or bend if you embroider without using a stabilizer material for thin fabrics or stretch fabrics. -

Page 86: Hopping The Fabric

EMBROIDERY Hopping the fabric 1. Loosen the embroidery hoop adjustment screw on the outer hoop. Separate the inner and outer hoop by removing inner hoop upward. 2. Make the fabric with right side upward. Place the fabric with the stabilizer material on top of the outer hoop. -

Page 87: Using Embroidery Sheet

EMBROIDERY Using embroidery sheet 1. Make a mark with a chalk pen at the center of the position for the pattern to be embroidered. 2 Place the embroidery sheet on the inner hoop. 3. Line the mark on the fabric up with the base line on the embroidery sheet. -

Page 88: Attaching The Embroidery Hoop

EMBROIDERY Attaching the embroidery hoop Raise the needle . Raise the presser foot to the second stage. Place the embroidery hoop under the presser foot. Attaching the embroidery hoop, make the embroidery hoop connector into the embroidery hoop holder from front to back until it clicks. Attention: Do not embroider fabrics that are too thick. -

Page 89: Embroidery Design Types

EMBROIDERY Embroidery design types An embroidery pattern can be selected from the following types available. Use the right/ left arrow buttons for selecting and press the OK button to into. Built-in Embroidery pattern There are total 40 patterns. The patterns are completed by changing the upper thread according to the instructions displayed on the display. -

Page 90: Built-In Embroidery Pattern

EMBROIDERY Built-in embroidery pattern Into the built-in embroidery pattern chose the first icon and press the OK button The pattern selection display is displayed. There will be 3 patterns on the display and using the right/left arrow buttons switching. To move forward or back by 3 patterns, press the up/down arrow buttons Or just press the number buttons for selection directly. -

Page 91: Built-In Embroidery Letter

EMBROIDERY Built-in embroidery letter Into the built-in embroidery letter chose the second icon and press the OK button The letter selection display is displayed. Press the arrow buttons for letter selecting. Press the OK button for enter. Press the C button for deleting. - Page 92 EMBROIDERY When selecting letters or writing a word for embroidering, the display is not showing the written word but it is showing " " only. On the editing display the embroidery design may be moved forward/backward & right/left, resized from 80% - 120% or rotate, for detailed description see page 94.

-

Page 93: Designs From Usb

- The machine can only read and use files generated from EZ Converter application Software with .zhs format. You can download this Software for free from our EverSewn website. - New Embroidery Designs can be purchased for example on www.embroideryonline.com - Embroidery data must be stored in root directory in USB storage device. - Page 94 EMBROIDERY To download from the USB storage device, use the up/down arrow button to choose the USB icon and press the OK Button Attention: If the funnel-shaped icon pops on, it indicates that data transfer is in progress, be sure to wait and not to interrupt until this icon disappears.

- Page 95 EMBROIDERY When uploading Designs from USB storage device, the display is not showing the design but it is showing " " only. On the editing display the embroidery design may be moved forward/backward & right/left, resized from 80% - 120% or rotate. After editing, press the Auto-lock/ Trace button to check the position of embroidering pattern on the embroidery hoop.

-

Page 96: Starting To Sew Embroidery

EMBROIDERY Starting to sew embroidery After the preparations are done, you can try embroidering. Prepare embroidery thread of the color shown on the display. Set the embroidery thread, thread the needle and embroidery foot. Pass the thread through the embroidery foot hole, and hold it lightly in your left hand. - Page 97 EMBROIDERY Raise the presser foot. Cut the thread at the beginning of the stitching. Lower the presser foot. Press the start/stop button to continue embroidering. When the first color is completed, the machine stops automatically. The raise presser foot message is displayed, raise the presser foot to the second stage.

-

Page 98: Editing The Embroidery Design

EMBROIDERY Editing the embroidery design Basic setting You can edit and combine designs to create original embroidery. After selecting the embroidery pattern, press OK button the editing display will display. Embroidery hoop These flash if the pattern was resized, the layout was adjusted, or the recommended embroidery hoop size was changed. - Page 99 EMBROIDERY Resize the design Press the button to resize the embroidery design. You can change the size of embroidery design from 80% to 120% of the original size. When you press, the resize window will open. Use the arrow buttons to change size, the size will change 5% each time you press the arrow button.

- Page 100 EMBROIDERY Rotate the design Press the button to rotate the embroidery design. It will rotate 90 degrees clockwise each time when you press the button. The icon for rotate of the pattern appears. It will rotate 90 degrees clockwise each time when you press the button, the angle of design will be shown.

-

Page 101: Advanced Setting

EMBROIDERY Advanced setting Press the button to open setup program and change the embroidery mode setting, ress the again to save the set and leave setup program. In the setup program, the machine settings or function for embroidery can be customized or executed. - Page 102 EMBROIDERY Embroidery carriage return Select this function, press the OK button and the carriage will move to the home position. Attention: - The needle must be in the highest position - Do not return the carriage with the mbroidery hoop attached.

-

Page 103: Load A Design After Interruption

EMBROIDERY Load a Design after interruption Press the button to open the type selection display. Use the right/ left arrow buttons to choose the design from Built-in Embroidery designs or from USB storage device. Press the OK button to confirm the selection. - Page 104 EMBROIDERY Press the button to move the design to the last embroidered color. Press the button to move the design to the last embroidered stitch position. Lower the presser foot and press start/stop button to start to embroider. Note: Always remember all made design editings in case of any interruption to be able to continue embroidering the design.

-

Page 105: Appendix

APPENDIX Warning functions Warning message Presser foot is not ready for sewing This message is displayed when the Start/stop button or needle up/down position button is pressed while the presser foot is raised. Presser foot is not raised This message is displayed when the embroidery unit will initialize while the embroidery foot is lowered. - Page 106 APPENDIX BH lever is not lifted This message is displayed when the stitch other than the buttonhole or darning stitch was selected and the start/stop button was pressed while the buttonhole lever is down. BH lever is not lowered This message is displayed when t he buttonhole or darning stitch was selected and the start/stop button was pressed while the buttonhole lever is raised.

- Page 107 APPENDIX Press the OK button to confirm The carriage of the embroidery unit will move This message is displayed when the embroidery unit is initializing. To raise the needle. This message is displayed when the embroidery unit is attached and the power is turned on with the needle in the down position.

- Page 108 APPENDIX Delete pattern? This message is displayed when the machine is in embroidery mode and you pressed the button The embroidery pattern is completed. This message is displayed when the embroidery is completed. Press ok button to return to the pattern selection display. Can not recognize the data.

-

Page 109: Warning Sound

APPENDIX Warning sound - When operating correctly: 1 beep - When the memory is full with 20 units of pattern: 3-short beeps - When operating incorrectly: 3-short beeps - When the sewing machine is in trouble and can't sew: 3-short beeps It means that the thread is twisted or jammed and the hand wheel axle can't move. -

Page 110: Buzzer Sound

APPENDIX Buzzer sound Hold on the button and turn on the power switch. The buzzer sound can be set on/ off by pressing the arrow buttons Sound on Sound off Pressing the OK button The Buzzer sound setting mark will appear on the LCD display when you have set it. -

Page 111: Maintenance

APPENDIX Maintenance Attention: Disconnect the power cord from the wall socket before cleaning the display and sewing machine surface, otherwise injury or electrical shock may result. Cleaning the screen If the front panel is dirty, wipe it gently with a soft, dry cloth. Do not use any organic solvents or detergents. - Page 112 APPENDIX Clean the bobbin holder with a brush. Remove the needle, presser foot and presser foot holder. Remove the screw holding the needle plate and remove the needle plate. Clean the feed dog and bobbin case with a brush. Also clean them, using a soft, dry cloth.

-

Page 113: Trouble Shooting Guide

APPENDIX Trouble shooting guide Before calling for Service, check the following items. If the problem still persists, contact the EverSewn customer support at: service@eversewn.com or call 1-844-EVERSEW (1-844-383-7739) Problem Cause Correction Reference 1. The machine is not threaded correctly. 1. Rethread the machine. - Page 114 APPENDIX Problem Cause Correction Reference 1. The needle is too thick for the fabric. 1. Select a finer needle. Seam 2. The stitch length is adjusted wrong. 2. Readjust the stitch length. gather or pucker 3. The thread tension is too tight. 3.

- Page 115 APPENDIX Problem Cause Correction Reference 1. The thread is tangled and the bobbin 1. Remove the tangled thread. When the case, etc., is plugged up. bobbin case is plugged up, clean the race. 2. The thread tension is incorrect. 2. Adjust the tension of the upper thread. 3.

- Page 116 021H4BXXXX(EN)

Need help?

Do you have a question about the Hero and is the answer not in the manual?

Questions and answers