Summary of Contents for Pressura RPM10

- Page 1 PRESSURA™ ROOM PRESSURE MONITOR MODEL RPM10 AND RPM20 OPERATION AND SERVICE MANUAL P/N 6006644, REVISION A JULY 2013...

- Page 3 PRESSURA™ ROOM PRESSURE CONTROLLER MODEL RPM10 AND RPM20 OPERATION AND SERVICE MANUAL P/N 6006644, REVISION A JULY 2013 U.S. AND CANADA OTHER COUNTRIES Sales & Customer Service: Sales & Customer Service: (800) 874-2811/(651) 490-2811 (001 651) 490-2811 Fax: Fax: (651) 490-3824...

- Page 4 TSI's Customer Service department at (800) 874- 2811 or (651) 490-2811. Trademarks TSI and TSI logo are registered trademarks of TSI Incorporated. PresSura is a trademark of TSI Incorporated. BACnet is a trademark of ASHRAE. Modbus is a registered trademark of Modicon, Inc. ®...

-

Page 5: Table Of Contents

CONTENTS HOW TO USE THIS MANUAL ...................... 1 Safety Information ....................1 Description of Caution Symbol ................1 Access Code / Passcode .................. 1 PART ONE ............................. 3 User Basics ......................3 The Instrument ..................... 3 Useful User Information ..................3 Operator Panel ..................... - Page 6 Modbus Communications ................. 73 Unique to TSI ....................73 Network Points RAM Variables ............... 74 XRAM Variables ....................75 RPM10 Variable List ..................75 RPM20 Variable List ..................77 RPM20 Variable List ..................80 RPM20 Variable List ..................81 ®...

-

Page 7: How To Use This Manual

Refer to the Installation Instructions if there is any question as to whether the monitor has been installed properly. Safety Information This section gives instructions to promote safe and proper handling of Model RPM10 and RPM20 Room Monitors. There are no user-serviceable parts inside the instrument. Opening the instrument case will void the warranty. - Page 8 (This page intentionally left blank)

-

Page 9: Part One

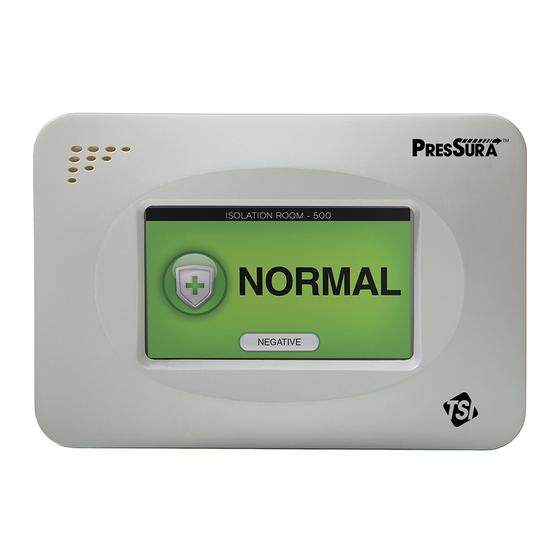

Operator Panel The Model RPM10 and RPM20 Room Monitors are easy to use. Normal vs. alarm condition and room modes are always shown on the display. In addition, the displayed can be configured to show the room pressure differential or all measurements. -

Page 10: Display Screen

Model RPM10 and RPM20 will not alarm. Operator Keys The following keys appear on the display of the Model RPM10 and RPM20 room monitor: MUTE key The MUTE key silences an audible alarm. The alarm remains silent until the MUTE TIME value has been reached or the unit returns to control set point. -

Page 11: Usb Port

Figure 3. USB Port Location Alarms The Model RPM10 and RPM20 monitors have visual (red light) and audible alarms to inform you of changing room conditions. The alarm levels (set points) are determined by facilities staff, which could be Engineering, Industrial Hygiene, or a facilities group depending on how the safety staff is organized. -

Page 12: Alarm Relays

ALARM RESET). Alarm Relays The PresSura monitors feature 2 alarm relays. The alarm relays can be field configured to either open or close to indicate an alarm condition, although they will close on loss of power. Relay 1 functions as the low alarm relay, and will activate after the alarm delay for low pressure, low flow, low temperature and low RH alarms. -

Page 13: Part Two

Part Two Technical Section The PresSura™ Room Pressure Monitor is ready to use after being properly installed and configured. The TSI through-the-wall sensor is factory calibrated, as are most pressure transducers. Figure 4 shows the Digital Interface Module (DIM) which is programmed with a default configuration that can be easily modified to fit your application. -

Page 14: Software Programming

2. Select the desired room mode by pressing on the desired room mode button at the bottom of the screen. NOTE: If a room mode is not selected, the PresSura monitor will return to the main running screen after a short delay, Figure 6. -

Page 15: Entering Menus

Refer to the Menu and Menu Items section for a list of the menus and their associated items. Entering Data After entering a menu item, the Model RPM10/RPM20 monitor display will change to select items. Some items have pre-defined choices selected through a drop-down menu; others allow numeric setpoints. - Page 16 Figure 9. Using a Drop-Down Selection Numeric Setpoints It is easy to enter new numeric setpoints on the PresSura Model RPM10/RPM20 monitor. On a numeric setpoint screen, the current setpoint is displayed in a box at the top left of the screen.

-

Page 17: Programming Example

Programming Example The following example demonstrates the keystroke sequence. In this example the negative low alarm set point for Room 1 will be changed from -0.01000 in H O to -0.01300 in H Unit is in normal operation. Swipe from the top right corner to the bottom left corner to access the menu system. -

Page 18: Menu And Menu Items

The menu items are always grouped by menu and then listed in menu item order, not alphabetical order. Figure 11 and Figure 12 show the PresSura Model RPM10 and RPM20 monitor menu items. Part Two... - Page 19 AO3 Sig Type Input 4 Configure Input 5 Configure Input 6 Configure Input 7 Configure See menu for items. See menu for items. See menu for items. See menu for items. Figure 11. Menu Items – Model RPM10 Monitor Technical Section...

- Page 20 Configure Rm1 Alarm AnteRm Alarm Rm2 Alarm # of Rooms Room Mode Room Mode Room Mode Rm1 Label Neg Low Alm Neg Low Alm Neg Low Alm AnteRm Label Neg Hi Alm Neg Hi Alm Neg Hi Alm Rm2 Label Pos Low Alm Pos Low Alm Pos Low Alm...

-

Page 21: Configure Menu

Number of Rooms # of Rooms The # of Rooms item selects the number of rooms the 1 Room RPM10: 1 Room Monitored Model RPM10 and RPM20 monitor will monitor and RPM20: 1 Room, control. RPM10 and 1 Room with RPM20... - Page 22 Displayed Room Pressure, All be presented on the display during normal operating mode. Use the Units item to choose the units of measure: RPM10 and RPM20 ROOM STATUS displays the room mode as negative, positive or no isolation. ROOM PRESSURE displays the room mode and the current measurement of room pressure differential.

- Page 23 The Input 2 item is only active if the # of Rooms item is set to 1 ROOM WITH ANTEROOM. The Input 2 item is not functional on the Model RPM10 Monitor. It is only active on the Model RPM20 Monitor.

- Page 24 Go to the Input 6 menu to adjust parameters such as Occupancy Sensor, sensor range associated with Input6. Room 2 Door Switch The Input 6 item is not functional on the Model RPM10 Monitor. It is only active on the Model RPM20 Monitor. Configure INPUT7 Input 7 The Input 7 item selects the desired input type for Input7.

- Page 25 Room Mode (pass code) is required to enter the menu items. The Menus Passcode item prevents unauthorized access to a menu. RPM10 and If the Passcode item is: RPM20 no code is required to enter the room mode or menu screens.

- Page 26 The Neg Low Alm item sets the negative low pressure Low Alarm +0.19500 in H alarm setpoint. A low alarm condition is defined as when the magnitude of the room pressure falls below the Neg RPM10 and Note: Neg Low Alm Low Alm setpoint. RPM20 cannot be set...

- Page 27 Exhaust Flow alarm setpoint. A minimum flow alarm is defined as when Alarm the exhaust flow is less than the Exh Low Alm setpoint. RPM10 and RPM20 Room 1 Low Sup Low Alm The Sup Low Alm item sets the minimum supply flow...

- Page 28 Calculation EXHAUST SUPPLY is normally used for positive rooms EXHAUST is normally used for negative rooms RPM10 and is used if the ACH calculation is not RPM20 desired Room Volume Room1 Vol The Room1 Vol item sets the room volume for the ACH...

- Page 29 AnteRm Alarm Menu SOFTWARE MENU ITEM ITEM DESCRIPTION ITEM RANGE DEFAULT VALUE NAME Anteroom Negative Neg Hi Alm The Neg Hi Alm item sets the negative high pressure -0.19500 in H O to -0.10000 in H High Alarm alarm setpoint. A high alarm condition is defined as when +0.19500 in H the room is more negative than the Neg Hi Alm setpoint.

- Page 30 Rm2 Alarm Menu SOFTWARE MENU ITEM ITEM DESCRIPTION ITEM RANGE DEFAULT VALUE NAME Positive Mode of Room 2 Room Mode The Room Mode item selects the room pressure Negative Negative direction. This item enables all related alarms, for RPM20 Room1 pressure direction selected.

-

Page 31: Alarm Constraints

In no isolation mode all alarms are turned off. 2. The PresSura monitor is programmed with deadbands between alarm setpoints to prevent the controller from cycling between high and low alarms due to normal fluctuations. Setpoint deadbands are: ... - Page 32 7. The display can only show one alarm message. Therefore, the monitor has an alarm priority system, with the highest priority alarm being displayed. If multiple alarms exist, the lower priority alarms will not display until after the highest priority alarm has been eliminated. The alarm priority is as follows: Room 1 pressure sensor –...

-

Page 33: Alarm Config Menu

The Alarm Reset item selects how the alarms terminate Latched, Unlatched Unlatched after the unit returns to control set point. The Alarm Reset RPM10 and affects the audible alarm, visual alarm, and relay output, RPM20 which means all are latched or unlatched. -

Page 34: Interface Menu

Signal used with Relay 2. If set to: Positive Room RPM10 and HIGH ALARM the PresSura monitor will activate the relay RPM20 if a high alarm condition exists. NEGATIVE ROOM the PresSura monitor will activate the relay when the mode for Room 1 is Negative. - Page 35 BACnet communications. Baud Rate Baud Rate The Baud Rate item sets the communication speed of the Modbus: 9600 Modbus: 9600 PresSura monitor when using Modbus or BACnet BACnet: BACnet: 9600, RPM10 and communications. AutoBaud 19200, 38400,...

- Page 36 Nurse’s Station Monitor. Each unit on the network must RPM10 and have its own unique address. RPM20 NOTE: PresSura Model RPM10 and RPM20 monitors will have rooms displayed on the Nurse’s Station Monitor in order of the Nurse Address. The PresSura monitor with the lowest Nurse Address will be displayed at the top-left of the Nurse’s...

- Page 37 The AO1 Sig Type item selects the measurement that the None None Signal Type Type analog output signal will represent. RPM10 and RPM20 Analog Output AO2 Sig The AO2 Sig Type item selects the measurement that the Room 1 Pressure...

- Page 38 Interface Menu SOFTWARE DEFAULT MENU ITEM ITEM DESCRIPTION ITEM RANGE NAME VALUE Analog Output AO3 Sig The AO3 Sig Type item selects the measurement that the Room 2 Pressure None Signal Type Type analog output signal will represent. Supply Flow Exhaust Flow RPM20 None...

-

Page 39: Diagnostics Menu

The Touch Cal item starts the touchscreen recalibration process. While recalibrating the touchscreen, Touchscreen the PresSura monitor will direct the user to touch the screen in various places. RPM10 and NOTE: Recalibrating the touchscreen is best accomplished using a stylus, pen, or similar object. - Page 40 The Sensor Span item is used to match or calibrate the Set Sensor Span Sensor Span None Unit is factory PresSura TSI sensor to the average room pressure velocity Calibration calibrated and as measured by a portable air velocity meter. should not need RPM10 and adjustment.

- Page 41 Check Status The Check Status item is used to check the communication None Status status of the sensor. After pressing the button, the PresSura unit will respond with: COMM ERROR - DIM cannot communicate with sensor. Check all wiring and the pressure sensor address.

- Page 42 0 to 5 V Sensor Voltage signal when a pressure transducer is used to measure Output room pressure differential. RPM10 and RPM20 Set Maximum Signal Max The Signal Max item is used to set the maximum output 1 to 10 V...

- Page 43 The Sensor Span item is used to match or calibrate the None Unit is factory Calibration PresSura monitor TSI sensor to the average room pressure calibrated and velocity as measured by a portable air velocity meter. should not need RPM20 adjustment.

- Page 44 The Check Status item is used to check the None Status communication status of the sensor. After pressing the button, the PresSura unit will respond with: RPM20 COMM ERROR - DIM cannot communicate with sensor. Check all wiring and the pressure sensor address.

- Page 45 Input2 Config Menu Press Trans SOFTWARE DEFAULT MENU ITEM ITEM DESCRIPTION ITEM RANGE NAME VALUE Set Minimum Sensor Min The Sensor Min item is used to set the minimum reading -1.00 to + 1.00 in H Sensor Pressure of a pressure transducer used to measure room pressure Output differential.

- Page 46 For rectangular ducts WARNING: If the proper Duct Area is not programmed into the Model RPM10 and RPM20, the flow measurement will be incorrect. Thus, all the other information that uses the flow measurement, such as the flow alarms, will also be incorrect.

- Page 47 Sensor Zero The Sensor Zero item is used to re-zero the pressure NONE Zero Calibration transducer zero calibration point. RPM10 and RPM20 Set Maximum Sensor Max The Sensor Max item is used to set the maximum reading 0 to 1.00 in H 1.00 in H...

- Page 48 The Reset Cal item is used to return to the factory default None calibration, undoing any field calibration adjustments. RPM10 and When this menu item is entered, the controller will prompt RPM20 the user to verify that they want to do this by displaying the message “Reset Settings to Factory Default?”...

- Page 49 For rectangular ducts WARNING: If the proper Duct Area is not programmed into the Model RPM10 and RPM20, the flow measurement will be incorrect. Thus, all the other information that uses the flow measurement, such as the flow alarms, will also be incorrect.

- Page 50 0 to 10,000 fpm Sensor Output of a flow station used to measure supply air flow. The Sensor Max item has increments of 1000 fpm. RPM10 and RPM20 Set Minimum Signal Min The Signal Min item is used to set the minimum output...

- Page 51 The Min Flow item sets the flow rate through the venturi 0 to 10000 cfm 0 cfm valve when it is fully closed. The display will indicate a RPM10 and volumetric flow rate. Adjust the displayed value to match RPM20 the flow through the venturi valve.

- Page 52 ITEM DESCRIPTION ITEM RANGE NAME VALUE Low Flow Alarm Low Flow Sig The Low Flow Sig item sets the signal the Model RPM10 Open, Closed Closed Signal or RPM20 Room Pressure Monitor will receive to indicate a low supply flow condition.

- Page 53 While this number can be entered in increments of 1 foot, the density adjustments are in 1,000 foot increments. For example, if the PresSura will interpret Elevation settings between 0 and 999 feet as 0 feet, settings between 1000 and 1999 feet as 1000 feet, etc.

- Page 54 Input3 Config Menu Press Trans SOFTWARE DEFAULT MENU ITEM ITEM DESCRIPTION ITEM RANGE NAME VALUE Set Minimum Sensor Min The Sensor Min item is used to set the minimum reading -1.00 to + 1.00 in H Sensor Pressure of a pressure transducer used to measure room pressure Output differential.

- Page 55 RPM10 and RPM20 Input5 Config Menu Rm1 Keyswitch ITEM DESCRIPTION The Model RPM10 or RPM20 will display a message “Nothing to Configure” when Input 5 is set to Rm1 Keyswitch and the user enters the Input5 Config menu.

- Page 56 Input5 Config Menu SOFTWARE DEFAULT MENU ITEM ITEM DESCRIPTION ITEM RANGE NAME VALUE Set Minimum Sensor Min The Sensor Min item is used to set the minimum reading 0 to 100% RH 0% RH Sensor Output of the relative humidity sensor. RPM20 Set Maximum Sensor Max...

- Page 57 Input6 Config Menu Rm1 Temp SOFTWARE DEFAULT MENU ITEM ITEM DESCRIPTION ITEM RANGE NAME VALUE Adjust Sensor Sensor Span The Sensor Span item is used to adjust the calibration of -10F to +10°F 0°F Calibration the temperature sensor. The Sensor Span is an offset adjustment and can only be adjusted by ±5°F.

- Page 58 For rectangular ducts WARNING: If the proper Duct Area is not programmed into the Model RPM10 and RPM20, the flow measurement will be incorrect. Thus, all the other information that uses the flow measurement, such as the flow alarms, will also be incorrect.

- Page 59 For example, if the pressure transducer has a range of 0 in H O to +0.25 in H O 0 to +62.5 Pa), the RPM10 and Sensor Max should be set to +0.25 in H O (+62.5 Pa). RPM20...

- Page 60 For rectangular ducts WARNING: If the proper Duct Area is not programmed into the Model RPM10 and RPM20, the flow measurement will be incorrect. Thus, all the other information that uses the flow measurement, such as the flow alarms, will also be...

- Page 61 Adjustment signal. The flow signal is multiplied by the K-Factor so that the flow measurement matches the actual flow, determined RPM10 and with a pitot tube traverse or other reference measurement. RPM20 NOTE: K-Factor modifies the entire range of the calibrated flow, not just a single point.

- Page 62 The Min Flow item sets the flow rate through the venturi 0 to 10000 cfm 0 cfm valve when it is fully closed. The display will indicate a RPM10 and volumetric flow rate. Adjust the displayed value to match RPM20 the flow through the venturi valve.

- Page 63 ITEM DESCRIPTION ITEM RANGE NAME VALUE Low Flow alarm Low Flow Sig The Low Flow Sig item sets the signal the Model RPM10 Open, Closed Close Signal and RPM20 Room Pressure Controller will receive to indicate a low exhaust flow condition.

- Page 64 (This page intentionally left blank) Part Two...

-

Page 65: Calibration

4. Save the reading and exit the menu system. Pressure Transducer Calibration NOTE: This calibration process is to configure the PresSura monitor to match the reading from the pressure transducer. If the pressure transducer itself needs to be calibrated, refer to the instructions that come with the pressure transducer. -

Page 66: Flow Calibration

Remove the tubing from the high and low ports of the transducer. c. Enter the PRESSURE ZERO item on the PresSura monitor. d. Reconnect tubing to the high and low ports of the pressure transducer, using the mark to connect the high pressure tubing to the high port. - Page 67 g. The low flow calibration is complete. 4. Enter the HIGH CAL item to perform the high flow calibration submenu with the following items: VOLTAGE INPUT Current voltage from pressure transducer Current flow rate UNCALIBRATED FLOW ZERO VOLTAGE Voltage from pressure transducer during Flow Station Pressure Transducer Zero CALIBRATED FLOW Input actual flow as measured with reference instrument here...

- Page 68 Supply/Exhaust Switch Calibration NOTE: Flow switches are optional and may not be installed in your system. Flow switches do not actually measure the flow, but are designed to provide an open or closed signal to indicate the presence or absence of flow.

-

Page 69: Maintenance And Repair Parts

The Model RPM10 and RPM20 PresSura Room Pressure Monitors require minimal maintenance. Periodic inspections of system components as well as an occasional pressure sensor cleaning are all that are needed to ensure that the PresSura monitor is operating properly. System Component Inspection It is recommended that the pressure sensor be periodically inspected for accumulation of contaminants. -

Page 70: Pressure Sensor Cleaning

WARNING If you are using a liquid to clean the sensor, turn off power to the RPM10 / RPM20 PresSura Monitor. Do not use compressed air to clean the velocity sensors. -

Page 71: Hardware Test

the laboratory HVAC system can sometimes be difficult. TSI recommends confirming all hardware is operating correctly before troubleshooting software problems. Hardware Test Three tests need to be performed in order to determine all hardware is functioning correctly. The tests are broken down into: ... - Page 72 Enter the View Inputs item to view all inputs with real-time updates. Figure 15. View Inputs screen in Diagnostics menu The Model RPM10/RPM20 monitor will display “Unconfigured” for any inputs that have not been configured. Go to the Configure menu to configure these inputs appropriately.

-

Page 73: Troubleshooting Chart

If the monitor passes each of the tests, the mechanical piece parts are all functioning correctly. Troubleshooting Chart Symptom Possible Cause Corrective Action Display is blank. Fuse is blown. Measure voltage at pins 1 and 2 on DIM 2-pin connector. The voltage should nominally be 24 VAC. - Page 74 Symptom Possible Cause Corrective Action Pressure Problem with Check SENSOR STAT and confirm NORMAL is displayed. sensor red LED sensor (slow If ERROR is displayed, correct error. is blinking uniform blink). (Figure 17). Communication Unit is communicating with DIM. This is normal. (fast burst of non-uniform blinking).

- Page 75 SELECT key. Return to the LON item, monitor. select the SERVICE PIN option and press the SELECT key. ® (LonWorks Selecting GO UNCONFIG will reset the PresSura monitor’s only) authentication key, allowing the SERVICE PIN to install or ® reclaim the PresSura monitor to the LonWorks network.

- Page 76 Symptom Possible Cause Corrective Action Analog output Monitor is Enter the DIAGNOSTICS menu, Analog Outpt item. Use does not work connected to Output 1, Output 2 or Output 3 button to adjust the output. properly. incompatible Change the output value while measuring the output with a equipment.

-

Page 77: Specifications

Appendix A Specifications* Digital Interface Module Display Range ........-0.20000 to +0.20000 in H O (-50 to +50 Pa): TSI Sensor -1.00 to +1.00 in H O (-250 to +250 Pa): Pressure Transducer Resolution ......... 5% of reading or 0.00001 in H O (0.0025 Pa): TSI Sensor 5% of reading or 0.001 in H O (0.25 Pa): Pressure... - Page 78 Outputs–Three (3)Total Output 1 ........None Output 2 ........Room 1 Pressure Out, Exhaust Flow Out (0 to 10 VDC / 4-20 mA) Output 3 ........Room 2 Pressure Out, Exhaust Flow Out, Supply Flow Out (0 to 10 VDC / 4-20 mA) Alarm Contacts ......

-

Page 79: Network Communications

PresSura room monitors functions. This information is not useful to the DDC system and is therefore deleted. Skipping numbers in the sequence will not cause any communication problems. If a variable is not used by the particular PresSura room monitors, it will be reported with a value of -1. -

Page 80: Network Points Ram Variables

Network Points RAM Variables RAM variables use the Modbus command 04 Read Input Registers. RAM variables are read only variables that correspond to what is shown on Digital Interface Module (DIM) display. TSI offers a number of different models, so if a feature is not available on a unit, the variable is set to 0. Variable Information Provided to Master Variable Name... -

Page 81: Xram Variables

“menu items” that are configured from the monitor keypad. The calibration and control items are not accessible from the DDC system. This is for safety reasons since each room is individually setup for maximum performance. RPM10 Variable List Variable Variable Name... - Page 82 RPM10 Variable List Variable Variable Name Address Read/Write Integer DDC system receives Input 7 Read Exhaust Pressure Flow Configuration Exhaust Linear Flow Exhaust Venturi Exhaust Switch None Room 1 Mode Read/Write Positive Negative No Isolation Room 1 Low Alarm Read/Write...

-

Page 83: Rpm20 Variable List

Modbus Communications (continued) RPM10 Variable List Variable Variable Name Address Read/Write Integer DDC system receives Output 3 Signal Read None Type Output 3 Range Read If Pressure: Displayed in inches H Host DDC system must divide value by 100,000 to report pressure correctly... - Page 84 RPM20 Variable List Variable Variable Name Address Read/Write Integer DDC system receives Relay 2 Read High Alarm Configuration Negative Room Mode Positive Room Mode Input 1 Read TSI Sensor Configuration Pressure Transducer Input 2 Read TSI Sensor Configuration Pressure Transducer None Input 3 Read...

- Page 85 Modbus Communications (continued) RPM20 Variable List Variable Variable Name Address Read/Write Integer DDC system receives Room 1 Positive Read/Write Displayed in inches H High Alarm Setpoint Host DDC system must divide value by 100,000 to report pressure correctly Low Exhaust Alarm Read/Write Displayed in cfm Low Supply Alarm...

-

Page 86: Rpm20 Variable List

RPM20 Variable List Variable Variable Name Address Read/Write Integer DDC system receives Room 2 Negative Read/Write Displayed in inches H2O. High Alarm Setpoint Host DDC system must divide value by 100,000 to report pressure correctly Room 2 Positive Read/Write Displayed in inches H2O. Low Alarm Setpoint Host DDC system must divide value by 100,000 to report pressure correctly... -

Page 87: Rpm20 Variable List

Modbus Communications (continued) RPM20 Variable List Variable Variable Name Address Read/Write Integer DDC system receives Status Index Read Normal Room 1 Negative Low Alarm Room 1 Negative High Alarm Room 1 Positive Low Alarm Room 1 Positive High Alarm Low Exhaust Alarm Low Supply Alarm Low Temperature Alarm High Temperature Alarm... -

Page 88: Lonworks ® Object

® LonWorks Object The Model RPM20-LON supports LonWorks communications. Contact TSI if you have a model RPM20 without LonWorks and you need LonWorks communications. Node Object Network Variables SNVT Description SNVT Name SNVT Type Number nciLocation SCPTLocation nciOutInHt SCTPalrmInbT nciIndex SCPTdevMajVer nciVersion SCPTdvMinVer... -

Page 89: Description Of Lon Snvts

SNVT Description SNVT Name SNVT Type Number Maximum Time Without Sending nciMaxSendTime SCPTmaxSendTime Update Minimum Time Before Sending nciMinSendTime SCPTminSendTime Update Room 1 Pressure Minimum Update nciSndDeltaP1 SCPTsndDelta Change SCPTsndDelta Anteroom Pressure Minimum nciSndDeltaP2 Update Change SCPTsndDelta Room 2 Pressure Minimum Update nciSndDeltaP2 Change SCPTsndDelta... -

Page 90: Model Rpm10 And Rpm20 Bacnet

Firmware Revision: 1.00.00 BACnet Protocol Revision: Version 1, Revision 8 Product Description: TSI's PresSura monitors are designed to maintain the room pressure differential of isolation rooms, operating rooms and other critical environments. These models are capable of acting as a stand-alone ®... - Page 91 Multistate Value Object Yes Dynamically Create: Yes Dynamically Delete: Optional Properties: Reliability, State_Text Writable properties: Present_Value, Out_Of_Service Proprietary Properties: None Property Range Restrictions: None Data Type: Unsigned Int ® Model RPM10 and RPM20 BACnet MS/TP Protocol Implementation Conformance Statement...

- Page 92 Data Link Layer Options: BACnet IP, (Annex J) BACnet IP, (Annex J), Foreign Device ISO 8802-3, Ethernet (Clause 7) ANSI/ATA 878.1, 2.5 Mb. ARCNET (Clause 8) ANSI/ATA 878.1, RS-485 ARCNET (Clause 8), baud rate(s) ____________ ...

-

Page 93: Bacnet ® Ms/Tp Object Set

® BACnet MS/TP Object Set RPM10 PresSura Monitor Writable Device Object Type Instance *Units Description Object Value Notes and Range Analog Input in H O, Pa Room1 Pressure Analog Input cfm, l/s, m Supply Flow Rate Analog Input Air Changes Per... - Page 94 RPM10 PresSura Monitor Writable Device Object Type Instance *Units Description Object Value Notes and Range Multi-State Input 2 None Value Configuration Multi-State Input 3 Supply Pressure Flow Value Configuration Supply Linear Flow Supply Venturi Flow Supply Switch None Multi-State Input 4...

-

Page 95: Rpm20 Pressura Monitor

RPM20 PresSura Monitor Writable Device Object Type Instance *Units Description Object Value Notes and Range Analog Input in H O, Pa Room1 Pressure Analog Input cfm, l/s, m Supply Flow Rate Analog Input Air Changes Per Hour Analog Input % RH... - Page 96 RPM20 PresSura Monitor Writable Device Object Type Instance *Units Description Object Value Notes and Range Analog Value °F, °C Room 1 Low 50 to 100 °F Temperature Alarm Analog Value °F, °C Room 1 High 50 to 100 °F Temperature Alarm...

- Page 97 RPM20 PresSura Monitor Writable Device Object Type Instance *Units Description Object Value Notes and Range Binary Input Room 2 Occupancy Occupied (Normal) Unoccupied Binary Value Room 1 High Alarm Disable Enable Binary Value Room 1 Low Alarm Disable Enable Binary Value...

- Page 98 RPM20 PresSura Monitor Writable Device Object Type Instance *Units Description Object Value Notes and Range Multi-State Value Input 7 Exhaust Pressure Flow Configuration Exhaust Linear Flow Exhaust Venturi Flow Exhaust Switch Room 2 Keyswitch None Multi-State Value Room 1 Mode...

- Page 99 RPM20 PresSura Monitor Writable Device Object Type Instance *Units Description Object Value Notes and Range Multi-State Value Device Type RPM20 Multi-State Value Units Value in H O, cfm, F Pa, lps, C Pa, m /hr, C *The units are based on the value of the Units Value object. When the Units Value is set to 1, the units are in English form.

- Page 100 (This page intentionally left blank) Appendix B...

-

Page 101: Wiring Information

Appendix C Wiring Information Back Panel Wiring Input / Output PIN # / Comm Signal Description 1, 2 Input 24 VAC/DC Power in Digital Interface Module (DIM). 24 V Power for TSI Pressure Sensors 24 VAC 3, 4 Output 0 to 10 VDC Input 1 5, 6 Input... - Page 102 OUTPUT 2 OUTPUT 3 EXH CNTRL OUTPUT 2 WARNING: Monitor must be wired exactly as wire diagram shows. Making modifications to the wiring may severely damage the unit. Figure 18: Wiring Diagram –Through-The-Wall Sensor Wiring to Model RPM10/RPM20 Appendix C...

- Page 103 Monitor must be wired exactly as wire diagram shows. Making modifications to the wiring may severely damage the unit. Figure 19: Optional Room 2 and Anteroom Through-The-Wall Sensor Wiring to Model RPM20 NOTE: Model RPM10 does not support Room 2 or Anteroom Through-The-Wall Sensors. Wiring Information...

- Page 104 PRESSURE TRANSDUCER TRANSDUCER (ANTEROOM) (ROOM2) 24 VAC OUT 24 VAC OUT Figure 21. Optional Room 2 and Anteroom Pressure Transducer Sensor Wiring to Model RPM20 NOTE: Model RPM10 does not support Room 2 or Anteroom Pressure Transducer Sensors. Appendix C...

- Page 105 EXH CNTRL OUTPUT 2 OUTPUT 3 NURSE COMM BAC/LON/MOD SUPPLY EXHAUST AIRFLOW SWITCH AIRFLOW SWITCH Figure 22. Optional Supply / Exhaust Flow Switch Wiring to Model RPM10/RPM20 24V IN 24V OUT INPUT 1 RELAY 1 RELAY 2 SENS COMM ALARM ALARM...

- Page 106 BAC/LON/MOD EXH CNTRL OUTPUT 2 OUTPUT 3 SUPPLY LINEAR EXHAUST LINEAR FLOW STATION FLOW STATION Figure 24. Optional Supply/Exhaust Linear Flow Station Wiring to Model RPM10/RPM20 24V IN 24V OUT INPUT 1 SENS COMM RELAY 1 RELAY 2 ALARM ALARM...

- Page 107 RPM 20: ROOM 2 RPM 10 & RPM 20: ROOM 1 RPC 30: ROOM 1 Figure 26. Optional Door Switch Wiring to Model RPM10/RPM20 NOTE: Model RPM10 does not support Room 2 Door Switch. 24V IN 24V OUT INPUT 1...

- Page 108 INPUT 2 INPUT 3 INPUT 4 NURSE COMM BAC/LON/MOD EXH CNTRL OUTPUT 2 OUTPUT 3 EXH CNTRL OUTPUT 2 OUTPUT 3 Figure 29. Optional Keyswitch Wiring to Model RPM10/RPM20 NOTE: Model RPM10 does not support Room 2 Keyswitch. Appendix C...

- Page 109 DO NOT WIRE + EMERGENCY REMOTE ALARM (ROOM 1) REMOTE ALARM (ROO ON 8694-4 - NC Figure 30. Optional Keyswitch with Remote Alarm Wiring to Model RPM10/RPM20 NOTE: Model RPM10 does not support Room 2 Keyswitch with remote alarm. Wiring Information...

- Page 110 OUTPUT 2 OUTPUT 3 NURSE COMM BAC/LON/MOD EXH CNTRL OUTPUT 2 OUTPUT 3 NURSE COMM NURSE COMM NURSE COMM 100 O 100 O 100 O 100 O REFERENCE REFERENCE Figure 32. Optional Nurses Station Communications Wiring to Model RPM10/RPM20 Appendix C...

- Page 111 BAC/LON/MOD BAC/LON/MOD 100 O 100 O 100 O REFERENCE Figure 33. Optional Modbus and BACnet MS/TP Communications Wiring to 100 O 100 O Model RPM10/RPM20 REFERENCE 24V IN 24V OUT INPUT 1 RELAY 1 RELAY 2 SENS COMM ALARM ALARM...

- Page 112 (This page intentionally left blank) Appendix C...

-

Page 113: Access Codes / Passcode

Appendix D Access Codes / Passcode The Model RPM10 and RPM20 Room Monitors may prompt you to enter an access code to change the room mode or to enter the menu system. The access code screen is shown below in Figure 35. - Page 114 (This page intentionally left blank) Appendix C...

- Page 115 TSI Incorporated – Visit our website www.tsi.com for more information. Tel: +1 800 874 2811 India Tel: +91 80 67877200 Tel: +44 149 4 459200 China Tel: +86 10 8219 7688 France Tel: +33 491 11 87 64 Singapore Tel: +65 6595 6388 Germany Tel: +49 241 523030 P/N 6006644 Rev.

Need help?

Do you have a question about the RPM10 and is the answer not in the manual?

Questions and answers