Summary of Contents for Allen-Bradley MicroLogix 1000

- Page 1 - Allen Bradley,Rockwell,plc,servo,drive Allen-Bradley User MicroLogix 1000 Programmable Manual Controllers (Bulletin 1761 Controllers)

- Page 2 The illustrations, charts, sample programs and layout examples shown in this guide are intended solely for purposes of example. Since there are many variables and requirements associated with any particular installation, Allen-Bradley does not assume responsibility or liability (to include intellectual property liability) for actual use based on the examples shown in this publication.

-

Page 3: Table Of Contents

P–6 Allen-Bradley Support ........... . - Page 4 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Establishing Communication ..........

- Page 5 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Table of Contents Equal (EQU) ............7–3 Not Equal (NEQ) .

- Page 6 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Data Handling Instructions in the Paper Drilling Machine Application Example ..9–28 Using Program Flow Control Instructions .......

- Page 7 14–6 Calling Allen-Bradley for Assistance ........

- Page 8 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Application Example Programs .........

- Page 9 For updated information on automatic protocol switching, see chapter 3, Connecting the System. The MicroLogix 1000 programmable controllers’ VA ratings and power supply inrush specifications have been updated; see appendix A, Hardware Reference. The DF1 Full-Duplex and DH-485 configuration parameters have been updated;...

-

Page 10: Preface

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Notes: soc–ii... -

Page 11: Preface

- Allen Bradley,Rockwell,plc,servo,drive Preface Preface Read this preface to familiarize yourself with the rest of the manual. It provides information concerning: who should use this manual the purpose of this manual conventions used in this manual Allen-Bradley support P–1... -

Page 12: Who Should Use This Manual

If you do not, obtain the proper training before using this product. Purpose of this Manual This manual is a reference guide for MicroLogix 1000 controllers. It describes the procedures you use to install, wire, program, and troubleshoot your controller. This... - Page 13 Provides a general overview of the types of Using the Message communication, and explains how to establish Instruction network communication using the message instruction. Troubleshooting Your Explains how to interpret and correct problems Troubleshooting System with your MicroLogix 1000 controller system. P–3...

- Page 14 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Chapter Title Contents Provides physical, electrical, environmental, and Appendix A Hardware Reference functional specifications. Programming Explains the system status file and provides Appendix B Reference instruction execution times. Valid Addressing Modes...

- Page 15 - Allen Bradley,Rockwell,plc,servo,drive Preface Related Documentation The following documents contain additional information concerning Allen-Bradley products. To obtain a copy, contact your local Allen-Bradley office or distributor. Document Read this Document Number A procedural manual for technical personnel who use the Allen-Bradley Hand-Held...

-

Page 16: Common Techniques Used In This Manual

Technical Product Assistance If you need to contact Allen-Bradley for technical assistance, please review the information in the Troubleshooting chapter first. Then call your local Allen-Bradley representative. Your Questions or Comments on this Manual... -

Page 17: Installing Your Controller

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Installing Your Controller Installing Your Controller This chapter shows you how to install your controller system. The only tools you require are a Flat head or Phillips head screwdriver and drill. Topics include: compliance to European Union Directives hardware overview master control relay surge suppressors... -

Page 18: Compliance To European Union Directives

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Compliance to European Union Directives If this product has the CE mark it is approved for installation within the European Union and EEA regions. It has been designed and tested to meet the following directives. -

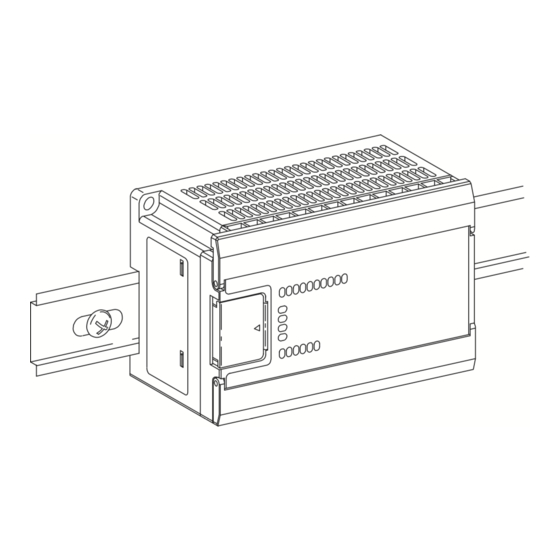

Page 19: Hardware Overview

Installing Your Controller Hardware Overview The MicroLogix 1000 programmable controller is a packaged controller containing a power supply, input circuits, output circuits, and a processor. The controller is available in 10 I/O, 16 I/O and 32 I/O configurations, as well as an analog version with 20 discrete I/O and 5 analog I/O. -

Page 20: Master Control Relay

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Master Control Relay A hard-wired master control relay (MCR) provides a reliable means for emergency controller shutdown. Since the master control relay allows the placement of several emergency-stop switches in different locations, its installation is important from a safety standpoint. - Page 21 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Installing Your Controller Using Emergency-Stop Switches When using emergency-stop switches, adhere to the following points: Do not program emergency-stop switches in the controller program. Any emergency-stop switch should turn off all machine power by turning off the master control relay.

- Page 22 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface The following illustrations show the Master Control Relay wired in a grounded system. Note The illustrations only show output circuits with MCR protection. In most applications input circuits do not require MCR protection; however, if you need to remove power from all field devices, you must include MCR contacts in series with input power wiring.

- Page 23 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Installing Your Controller Schematic (Using ANSI/CSA Symbols) 230V ac Disconnect Fuse 230V ac Output Circuits Operation of either of these contacts will Isolation remove power from the adapter external I/O Transformer circuits, stopping machine motion. Master Control Relay (MCR) 115V ac Cat.

-

Page 24: Using Surge Suppressors

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Using Surge Suppressors Inductive load devices such as motor starters and solenoids require the use of some type of surge suppression to protect the controller output contacts. Switching inductive loads without surge suppression can significantly reduce the lifetime of relay contacts. - Page 25 Installing Your Controller Suitable surge suppression methods for inductive ac load devices include a varistor, an RC network, or an Allen-Bradley surge suppressor, all shown below. These components must be appropriately rated to suppress the switching transient characteristic of the particular inductive device. See the table on page 1–10 for recommended suppressors.

- Page 26 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Recommended Surge Suppressors We recommend the Allen-Bradley surge suppressors shown in the following table for use with Allen-Bradley relays, contactors, and starters. Suppressor Catalog Device Coil Voltage Number Bulletin 509 Motor Starter...

-

Page 27: Safety Considerations

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Installing Your Controller Safety Considerations Safety considerations are an important element of proper system installation. Actively thinking about the safety of yourself and others, as well as the condition of your equipment, is of primary importance. We recommend reviewing the following safety considerations. - Page 28 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Power Distribution There are some points about power distribution that you should know: The master control relay must be able to inhibit all machine motion by removing power to the machine I/O devices when the relay is de-energized.

-

Page 29: Power Considerations

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Installing Your Controller Power Considerations The following explains power considerations for the micro controllers. Isolation Transformers You may want to use an isolation transformer in the ac line to the controller. This type of transformer provides isolation from your power distribution system and is often used as a step down transformer to reduce line voltage. - Page 30 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Loss of Power Source The power supply is designed to withstand brief power losses without affecting the operation of the system. The time the system is operational during power loss is called “program scan hold-up time after loss of power.”...

-

Page 31: Preventing Excessive Heat

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Installing Your Controller Preventing Excessive Heat For most applications, normal convective cooling keeps the controller within the specified operating range. Ensure that the specified operating range is maintained. Proper spacing of components within an enclosure is usually sufficient for heat dissipation. -

Page 32: Controller Spacing

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Controller Spacing The following figure shows the recommended minimum spacing for the controller. (Refer to appendix A for controller dimensions.) Explosion Hazard — For Class I, Division 2 applications, this product must be installed in an enclosure. - Page 33 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Installing Your Controller Using a DIN Rail Use 35 mm (1.38 in.) DIN rails, such as item number 199-DR1 or 1492-DR5 from Bulletin 1492. To install your controller on the DIN rail: 1. Mount your DIN rail. (Make sure that the Side View placement of the controller on the DIN rail Protective Wrap...

- Page 34 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Using Mounting Screws To install your controller using mounting screws: Note Leave the protective wrap attached until you are finished wiring the controller. Mounting 1. Use the mounting template from...

-

Page 35: Wiring Your Controller

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Wiring Your Controller Wiring Your Controller This chapter describes how to wire your controller. Topics include: grounding guidelines sinking and sourcing circuits wiring recommendations wiring diagrams, input voltage ranges, and output voltage ranges 2–1... -

Page 36: Grounding Guidelines

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Grounding Guidelines In solid-state control systems, grounding helps limit the effects of noise due to electromagnetic interference (EMI). Use the heaviest wire gauge listed for wiring your controller with a maximum length of 152.4 mm (6 in.). Run the ground connection from the ground screw of the controller (third screw from left on output terminal rung) to the ground bus. -

Page 37: Sinking And Sourcing Circuits

- Allen Bradley,Rockwell,plc,servo,drive Wiring Your Controller Sinking and Sourcing Circuits Any of the MicroLogix 1000 DC inputs can be configured as sinking or sourcing depending on how the DC COM is wired on the MicroLogix. Type Definition The input energizes when high-level voltage is applied to the input terminal Sinking Input (active high). -

Page 38: Wiring Recommendations

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface 1761-L32BWB, -L32BBB (Wiring Diagrams also apply to 1761-L20BWB-5A, -L16BWB, -L10BWB, -L16BBB.) Sinking Inputs Sourcing Inputs 14–30 VDC 14–30 VDC VDC (+) for Sinking VDC (–) for Sourcing VDC (–) for Sinking... - Page 39 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Wiring Your Controller Note The diameter of the terminal screw heads is 5.5 mm (0.220 in.). The input and output terminals of the micro controller are designed for the following spade lugs: Call-out Dimension 6.35 mm (0.250 in.) 10.95 mm (0.431 in.) maximum 14.63 mm (0.576 in.) maximum 6.35 mm (0.250 in.)

- Page 40 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Remove the protective wrap before applying power to the controller. Failure to remove the wrap may cause the controller to overheat. Calculate the maximum possible current in each power and common wire.

-

Page 41: Wiring Diagrams, Discrete Input And Output Voltage Ranges

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Wiring Your Controller Wiring Diagrams, Discrete Input and Output Voltage Ranges The following pages show the wiring diagrams, discrete input voltage ranges, and discrete output voltage ranges. Controllers with dc inputs can be wired as either sinking or sourcing configurations. - Page 42 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface 1761-L32AWA Wiring Diagram 79–132V ac 79–132V ac L2/N L2/N I/10 I/11 I/12 I/13 I/14 I/15 I/16 I/17 I/18 I/19 USED USED 85–264 VAC L2/N O/10 O/11 VAC 2 VDC 1...

- Page 43 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Wiring Your Controller 1761-L10BWA Wiring Diagram (Sinking Input Configuration) Note: Refer to page 2–3 for additional configuration options. 14–30V dc VDC + VDC + + 24V – USED USED USED USED DC OUT 85–264 VAC L2/N USED USED USED...

- Page 44 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface 1761-L16BWA Wiring Diagrams (Sinking Input Configuration) Note: Refer to page 2–3 for additional configuration options. 14–30V dc VDC + VDC + + 24V – DC OUT 85–264 VAC L2/N...

- Page 45 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Wiring Your Controller 1761-L32BWA Wiring Diagram (Sinking Input Configuration) Note: Refer to page 2–3 for additional configuration options. 14-30 V dc VDC + VDC + + 24V – I/10 I/11 I/12 I/13 I/14 I/15 I/16 I/17 I/18 I/19 DC OUT...

- Page 46 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface 1761-L10BWB Wiring Diagram (Sinking Input Configuration) Note: Refer to page 2–4 for additional configuration options. 14–30 VDC 14–30 VDC VDC + VDC + USED USED USED USED USED USED DC IN + 24V –...

- Page 47 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Wiring Your Controller 1761-L16BWB Wiring Diagram (Sinking Input Configuration) Note: Refer to page 2–4 for additional configuration options. 14–30V dc 14–30V dc VDC + VDC + USED USED DC IN + 24V – VAC 1 VDC 2 VDC 3 VDC 4 VAC 1...

- Page 48 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface 1761-L32BWB Wiring Diagram (Sinking Input Configuration) Note: Refer to page 2–4 for additional configuration options. Sinking Configuration Sourcing Configuration 14–30V dc 14–30V dc VDC + VDC + I/10 I/11...

- Page 49 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Wiring Your Controller 1761-L32AAA Wiring Diagram 79–132V ac 79–132V ac L2/N L2/N I/10 I/11 I/12 I/13 I/14 I/15 I/16 I/17 I/18 I/19 USED USED 85–264 VAC L2/N O/10 O/11 VAC 1 VAC 2 VAC 3 VAC 4 VAC 1 VAC 2 VAC 3...

- Page 50 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface 1761-L16BBB Wiring Diagrams (Sinking Input Configuration) Note: Refer to page 2–4 for additional configuration options. 14–30V dc 14–30V dc VDC + VDC + USED USED Sourcing Outputs DC IN + 24V –...

- Page 51 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Wiring Your Controller 1761-L32BBB Wiring Diagram (Sinking Input Configuration) Note: Refer to page 2–4 for additional configuration options. Sinking Configuration Sourcing Configuration 14–30V dc 14–30V dc VDC + VDC + I/10 I/11 I/12 I/13 I/14 I/15 I/16 I/17 I/18 I/19...

- Page 52 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface 1761-L20AWA-5A Wiring Diagram Note: Refer to pages 2–21 through 2–23 for additional information on analog wiring. Analog 79–132V ac 79–132V ac Channels L2/N L2/N I/10 I/11 IA/0 IA/1 IA/2...

- Page 53 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Wiring Your Controller 1761-L20BWA-5A Wiring Diagram (Sinking Input Configuration) Note: Refer to page 2–3 for additional discrete configuration options. Refer to pages 2–21 through 2–23 for additional information on analog wiring. Analog 14–30V dc Channels VDC (–) VDC (+) VDC (+) VDC (–)

- Page 54 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface 1761-L20BWB-5A Wiring Diagram (Sinking Input Configuration) Note: Refer to page 2–4 for additional discrete configuration options. Refer to pages 2–21 through 2–23 for additional information on analog wiring. Analog 14–30V dc...

-

Page 55: Minimizing Electrical Noise On Analog Controllers

A system may malfunction due to a change in the operating environment after a period of time. We recommend periodically checking system operation, particularly when new machinery or other noise sources are installed near the MicroLogix 1000 system. Grounding Your Analog Cable Use shielded communication cable (Belden #8761). -

Page 56: Wiring Your Analog Channels

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Wiring Your Analog Channels Analog input circuits can monitor current and voltage signals and convert them to serial digital data. The analog output can support either a voltage or a current function. -

Page 57: Analog Voltage And Current Input And Output Ranges

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Wiring Your Controller Analog Voltage and Current Input and Output Ranges Analog Voltage Input Range –10.5V dc 10.5V dc 24V dc –24V dc É É É É É É É É É É É É É É É É... -

Page 58: Wiring Your Controller For High-Speed Counter Applications

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Wiring Your Controller for High-Speed Counter Applications To wire the controller for high-speed counter applications use input terminals I/0, I/1, I/2, and I/3. Refer to chapter 12 for information on using the high-speed counter. -

Page 59: Connecting The System

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Connecting the System Connecting the System This chapter describes how to wire your controller system. The method you use and cabling required to connect your controller depends on what type of system you are employing. This chapter also describes how the controller establishes communication with the appropriate network. -

Page 60: Connecting The Df1 Protocol

MicroLogix 1000 Programmable Controllers User Manual Preface Connecting the DF1 Protocol There are two ways to connect the MicroLogix 1000 programmable controller to your personal computer using the DF1 protocol: using an isolated point-to-point connection, or using a modem. Descriptions of these methods follow. - Page 61 9-Pin Using a Modem You can also use modems to connect a personal computer to one MicroLogix 1000 controller (using DF1 full-duplex protocol) or to multiple controllers (using DF1 half-duplex protocol), as shown in the illustration that follows. Do not attempt to use DH-485 protocol through modems under any circumstance.

- Page 62 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Modem Cable Personal Computer Modem DF1 full-duplex protocol (to 1 controller) DF1 half-duplex master protocol (to multiple controllers) Optical Isolator (recommended) Micro Controller 1761-CBL-PM02 Modem DF1 full-duplex protocol or...

-

Page 63: Connecting To A Dh-485 Network

- Allen Bradley,Rockwell,plc,servo,drive Connecting the System Connecting to a DH-485 Network Note Only Series C or later MicroLogix 1000 discrete controllers and all MicroLogix 1000 analog controllers support DH-485 network connections. MicroLogix 1000 (Series C or later discrete or MicroLogix 1000 analog) - Page 64 Allow enough extra cable to prevent chafing and kinking in the cable. Use these instructions for wiring the Belden #3106A or #9842 cable. (If you are using standard Allen-Bradley cables, see the Cable Selection Guide on page 3–12.) 3–6...

- Page 65 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Connecting the System Connecting the Communication Cable to the DH-485 Connector Note A daisy-chained network is recommended. We do not recommend the following: Belden Belden Belden #3106A or #3106A or #3106A or #9842 #9842 #9842 Connector Connector Connector Incorrect...

- Page 66 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface The table below shows connections for Belden #3106A. For this Wire/Pair Connect this Wire To this Terminal Shield/Drain Non-jacketed Terminal 2 – Shield Blue Blue Terminal 3 – (Common) White with Orange Stripe Terminal 4 –...

-

Page 67: Connecting The Aic

In addition, if a MicroLogix 1000 controller powers an AIC+ that is connected to the network, network activity will not be disrupted should the MicroLogix 1000 controller be removed from the AIC+. The figure that follows shows the external wiring connections and specifications of the AIC+. - Page 68 MicroLogix 1000 provides power to the AIC+ via port 2.) DH-485 Network Connection MicroLogix 1000 (Series C or later discrete and all analog) PC to port 1 connection from or port 2 port 1 or port 2...

- Page 69 24V dc (Not needed in this configuration User supplied modem cable since the MicroLogix 1000 provides power to the AIC+ via port 2.) For additional information on connections using the AIC+, see the Advanced Interface Converter (AIC+) and DeviceNet Interface (DNI) Installation Instructions, Publication 1761-5.11.

- Page 70 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Cable Selection Guide 1747-CP3 1761-CBL-AC00 External Power Selection Power Supply Cable Length Connections from to AIC+ Switch Setting Required 1747-CP3 7 7 C 3m (9.8 ft) SLC 5/03 or SLC 5/04 processor, channel 0...

- Page 71 45 cm (17.7 in) SLC 5/03 or SLC 5/04 processors, channel 0 port 2 external 2m (6.5 ft) 1761-CBL-PM02 external MicroLogix 1000 port 1 PanelView 550 through NULL modem adapter port 2 external DTAM Plus / DTAM Micro port 2...

- Page 72 If you are making a cable to connect to port 2, you must configure your cable to connect to the Allen-Bradley cable shown above. On port 1, pin 4 is electronically jumpered to pin 6. Whenever the AIC+ is powered on, pin 4 will match the state of pin 6.

- Page 73 This connection must be made whether or not an external 24V dc supply is used. In normal operation with the MicroLogix 1000 programmable controller connected to port 2 of the AIC+, the controller powers the AIC+. Any AIC+ not connected to a controller requires a 24V dc power supply.

- Page 74 Installing and Attaching the AIC+ Take care when installing the AIC+ in an enclosure so that the cable connecting the MicroLogix 1000 controller to the AIC+ does not interfere with the enclosure door. Carefully plug the terminal block into the DH-485 port on the AIC+ you are putting on the network.

-

Page 75: Establishing Communication

Primary Protocol bit, S:0/10. The default setting for this bit is DF1 (0). If the primary protocol bit is set to DF1, the MicroLogix 1000 controller will attempt to connect using the configured DF1 protocol; either full-duplex or half-duplex slave. -

Page 76: Devicenet Communications

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface DeviceNet Communications You can also connect a MicroLogix to a DeviceNet network using the DeviceNet Interface (DNI), catalog number 1761-NET-DNI. For additional information on connecting the DNI, see the Advanced Interface Converter (AIC+) and DeviceNet Interface (DNI) Installation Instructions, Publication 1761-5.11. -

Page 77: Programming Overview

- Allen Bradley,Rockwell,plc,servo,drive Programming Overview Programming Overview This chapter explains how to program the MicroLogix 1000 programmable controller. Read this chapter for basic information about: principles of machine control understanding file organization and addressing understanding how processor files are stored and accessed... -

Page 78: Principles Of Machine Control

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Principles of Machine Control The controller consists of a built-in power supply, central processing unit (CPU), inputs, which you wire to input devices (such as pushbuttons, proximity sensors, limit switches), and outputs, which you wire to output devices (such as motor starters, solid-state relays, and indicator lights). - Page 79 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Programming Overview With the logic program entered into the controller, placing the controller in the Run mode initiates an operating cycle. The controller’s operating cycle consists of a series of operations performed sequentially and repeatedly, unless altered by your program logic.

-

Page 80: Understanding File Organization

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Understanding File Organization The processor provides control through the use of a program you create, called a processor file. This file contains other files that break your program down into more manageable parts. - Page 81 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Programming Overview Program Files Program files contain controller information, the main ladder program, interrupt subroutines, and any subroutine programs. These files are: System Program (file 0) – This file contains various system related information and user-programmed information such as processor type, I/O configuration, processor file name, and password.

-

Page 82: Understanding How Processor Files Are Stored And Accessed

Understanding How Processor Files are Stored and Accessed The MicroLogix 1000 programmable controller uses two devices for storing processor files: RAM and EEPROM. The RAM provides easy access storage (i.e., its data is lost on a power down), while the EEPROM provides long-term storage (i.e., its data is not lost on a power down). - Page 83 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Programming Overview Download When the processor file is downloaded to the micro controller, it is first stored in the volatile RAM. It is then transferred to the non-volatile EEPROM, where it is stored as both backup data and retentive data. EEPROM Backup Data CPU Workspace...

- Page 84 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Power Down When a power down occurs, only the retentive data is transferred from the RAM to the EEPROM. (The program files do not need to be saved to the EEPROM since they cannot be modified during normal operation.) If for some reason power is lost...

- Page 85 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Programming Overview If retentive data was lost on power down, the backup data from the EEPROM is transferred to the RAM and used as the retentive data. In addition, status file bit S2:5/8 (retentive data lost) is set and a recoverable major error occurs when going to run.

-

Page 86: Addressing Data Files

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Addressing Data Files For the purposes of addressing, each data file type is identified by a letter (identifier) and a file number. File File Identifier Type Number Output Input... - Page 87 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Programming Overview You assign logical addresses to instructions from the highest level (element) to the lowest level (bit). Addressing examples are shown in the table below. To specify the Use these parameters: address of a: Word within an integer file File Type File Number File Delimiter...

- Page 88 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface You can also address at the bit level using mnemonics for timer, counter, or control data types. The available mnemonics depend on the type of data. See chapters 6 through 13 for more information.

- Page 89 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Programming Overview In this example, the processor uses the following addresses: Value: Base Address: Offset Value in S:24 Offset Address: Source N7:10 N7:20 Destination N7:50 N7:60 Addressing File Instructions – Using the File Indicator (#) The file instructions below manipulate data table files. These files are addressed with the # sign.

-

Page 90: Applying Ladder Logics To Your Schematics

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface When entering values into an instruction or data table element, you can specify the radix of your entry using the “&” special operator. The radixes that can be used to enter data into an instruction or data table element are: Integer (&N) -

Page 91: Developing Your Logic Program - A Model

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Programming Overview The programming device allows you to enter a ladder logic program into the micro controller. In the following illustration, the electromechanical circuit shows PB1 and PB2, two pushbuttons, wired in series with an alarm horn. PB1 is a normally open pushbutton, and PB2 is normally closed. - Page 92 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Program Development Program Development Process Checklist Prepare a general description of how you want your Design automated process to operate. Functional Specification Identify the hardware requirements. Perform Match inputs and outputs with actions of the process.

-

Page 93: Using Analog

- Allen Bradley,Rockwell,plc,servo,drive Using Analog Using Analog This chapter describes the operation of the MicroLogix 1000 analog controllers. Topics include: I/O Image I/O Configuration Input Filter and Update Times Converting Analog Data 5–1... -

Page 94: I/O Image

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface I/O Image The input and output image files of the MicroLogix 1000 analog controllers have the following format: Address Input Image Output Image Address I:0.0 Discrete Input Word 0 Discrete Output Word 0 O:0.0... -

Page 95: I/O Configuration

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Analog I/O Configuration The analog input channels are single-ended (unipolar) circuits and can be individually enabled or disabled. The default is all input channels enabled. The two voltage inputs accept 10.5V dc, and the two current inputs accept 21 mA. - Page 96 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface The total update time for each channel is a combination of the Update Time and the Settling Time. When more than one analog input channel is enabled, the maximum update for each channel is equal to one ladder scan time plus the channel’s Update...

-

Page 97: Converting Analog Data

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Analog Converting Analog Data The analog input circuits are able to monitor current and voltage signals and convert them to digital data. There are six terminals assigned to the input channels that provide two voltage inputs, two current inputs and two return signals (commons). The analog outputs can support either a current or voltage function. - Page 98 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface 10.5V input value = input voltage(V) 32,767 The Input Value is the decimal value of the word in the input image for the corresponding analog input. For example, if an input value of 16,021 is in the input image, the calculated value is: 10.5V...

-

Page 99: Using Basic Instructions

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions Using Basic Instructions This chapter contains general information about the basic instructions and explains how they function in your application program. Each of the basic instructions includes information on: what the instruction symbol looks like typical execution time for the instruction how to use the instruction In addition, the last section contains an application example for a paper drilling... -

Page 100: About The Basic Instructions

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Timer/Counter Instructions Instruction Purpose Purpose Page Page Mnemonic Name Timer On-Delay Counts timebase intervals when the instruction is 6–11 true. Timer Off-Delay Counts timebase intervals when the instruction is 6–12... -

Page 101: Bit Instructions Overview

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions Bit Instructions Overview These instructions operate on a single bit of data. During operation, the controller may set or reset the bit, based on the logical continuity of ladder rungs. You can address a bit as many times as your program requires. Note Using the same address with multiple output instructions is not recommended. -

Page 102: Examine If Closed (Xic)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Examine if Closed (XIC) Use the XIC instruction in your ladder program to determine if a bit is On. When the instruction is executed, if the bit addressed is on (1), then the instruction is evaluated as true. -

Page 103: Output Energize (Ote)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions Output Energize (OTE) Use an OTE instruction in your ladder program to turn On a bit when rung conditions are evaluated as true. Execution Times An example of a device that turns on or off is an output wired to a pilot light (µsec) when: (addressed as O0:0/4). - Page 104 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Using OTL When you assign an address to the OTL instruction that corresponds to the address of a physical output, the output device wired to this screw terminal is energized when the bit is set (turned on or enabled).

-

Page 105: One-Shot Rising (Osr)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions One-Shot Rising (OSR) The OSR instruction is a retentive input instruction that triggers an event to occur [OSR] one time. Use the OSR instruction when an event must start based on the change of state of the rung from false to true. -

Page 106: Timer Instructions Overview

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Timer Instructions Overview Each timer address is made of a 3-word element. Word 0 is the control word, word 1 stores the preset value, and word 2 stores the accumulated value. - Page 107 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions Timer Accuracy Timer accuracy refers to the length of time between the moment a timer instruction is enabled and the moment the timed interval is complete. Timing accuracy is –0.01 to +0 seconds, with a program scan of up to 2.5 seconds. The 1-second timer maintains accuracy with a program scan of up to 1.5 seconds.

- Page 108 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Addressing Examples T4:0/15 or T4:0/EN Enable bit T4:0/14 or T4:0/TT Timer timing bit T4:0/13 or T4:0/DN Done bit T4:0.1 or T4:0.PRE Preset value of the timer T4:0.2 or T4:0.ACC Accumulator value of the timer T4:0.1/0 or T4:0.PRE/0 Bit 0 of the preset value...

-

Page 109: Timer On-Delay (Ton)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions Timer On-Delay (TON) Use the TON instruction to delay the turning on or off of an output. The TON TIMER ON DELAY (EN) Timer instruction begins to count timebase intervals when rung conditions become true. Time Base (DN) Preset... -

Page 110: Timer Off-Delay (Tof)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Timer Off-Delay (TOF) Use the TOF instruction to delay turning on or off an output. The TOF instruction TIMER OFF DELAY (EN) Timer begins to count timebase intervals when the rung makes a true-to-false transition. - Page 111 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions On returning to the REM Run or REM Test mode, the following can happen: Condition Result If the rung is true: TT bit is reset. DN bit remains set. EN bit is set. ACC value is reset.

-

Page 112: Retentive Timer (Rto)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Retentive Timer (RTO) Use the RTO instruction to turn an output on or off after its timer has been on for a RETENTIVE TIMER ON (EN) Timer preset time interval. The RTO instruction is a retentive instruction that lets the timer... -

Page 113: Counter Instructions Overview

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions On returning to the REM Run or REM Test mode or when power is restored, the following can happen: Condition Result TT bit remains set. If the rung is true: EN bit remains set. ACC value remains the same and resumes incrementing. - Page 114 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Entering Parameters Accumulator Value (ACC) This is the number of false-to-true transitions that have occurred since the counter was last reset. Preset Value (PRE) Specifies the value which the counter must reach before the controller sets the done bit.

- Page 115 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions Addressing Examples C5:0/15 or C5:0/CU Count up enable bit C5:0/14 or C5:0/CD Count down enable bit C5:0/13 or C5:0/DN Done bit C5:0/12 or C5:0/OV Overflow bit C5:0/11 or C5:0/UN Underflow bit C5:0/10 or C5:0/UA Update accumulator bit C5:0.1 or C5:0.PRE Preset value of the counter C5:0.2 or C5:0.ACC Accumulator value of the counter C5:0.1/0 or C5:0.PRE/0 Bit 0 of the preset value...

-

Page 116: Count Up (Ctu)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Count Up (CTU) The CTU is an instruction that counts false-to-true rung transitions. Rung COUNT UP (CU) Counter transitions can be caused by events occurring in the program (from internal logic or... -

Page 117: Count Down (Ctd)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions Count Down (CTD) The CTD is a retentive output instruction that counts false-to-true rung transitions. COUNT DOWN (CD) Counter Rung transitions can be caused by events occurring in the program such as parts Preset (DN) Accum... -

Page 118: Reset (Res)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Reset (RES) Use a RES instruction to reset a timer or counter. When the RES instruction is (RES) executed, it resets the data having the same address as the RES instruction. -

Page 119: Basic Instructions In The Paper Drilling Machine Application Example

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions Basic Instructions in the Paper Drilling Machine Application Example This section provides ladder rungs to demonstrate the use of basic instructions. The rungs are part of the paper drilling machine application example described in appendix E. - Page 120 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Rung 2:3 Starts the conveyor in motion when the start button is pressed. However, another condition must also be met before we start the conveyor: the drill must be in its fully retracted position (home).

- Page 121 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Basic Instructions Adding File 6 This subroutine controls the up and down motion of the drill for the paper drilling machine. Drill Home Drill On/Off O/1 Drill Retract O/2 Drill Forward O/3 Drill Depth Rung 6:0 This section of ladder logic controls the up/down motion of the drill for the book drilling machine.

- Page 122 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Rung 6:2 When the drill is retracting (after drilling a hole), the body of the drill actuates the DRILL HOME limit switch. When this happens the DRILL RETRACT signal is turned off, the DRILL SEQUENCE START bit is turned off to indicate the drilling process is complete, and the conveyor is restarted.

-

Page 123: Using Comparison Instructions

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Comparison Instructions Using Comparison Instructions This chapter contains general information about comparison instructions and explains how they function in your application program. Each of the comparison instructions includes information on: what the instruction symbol looks like typical execution time for the instruction how to use the instruction In addition, the last section contains an application example for a paper drilling... -

Page 124: About The Comparison Instructions

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface About the Comparison Instructions Comparison instructions are used to test pairs of values to condition the logical continuity of a rung. As an example, suppose a LES instruction is presented with two values. -

Page 125: Equal (Equ)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Comparison Instructions Equal (EQU) Use the EQU instruction to test whether two values are equal. If source A and EQUAL Source A source B are equal, the instruction is logically true. If these values are not equal, the Source B instruction is logically false. -

Page 126: Less Than Or Equal (Leq)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Less Than or Equal (LEQ) Use the LEQ instruction to test whether one value (source A) is less than or equal to LESS THAN OR EQUAL Source A another (source B). If the value at source A is less than or equal to the value of Source B source B, the instruction is logically true. -

Page 127: Masked Comparison For Equal (Meq)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Comparison Instructions Masked Comparison for Equal (MEQ) Use the MEQ instruction to compare data of a source address with data of a MASKED EQUAL Source reference address. Use of this instruction allows portions of the data to be masked Mask by a separate word. -

Page 128: Limit Test (Lim)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Limit Test (LIM) Use the LIM instruction to test for values within or outside a specified range, LIMIT TEST Low Lim depending on how you set the limits. Test... - Page 129 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Comparison Instructions If the Low Limit has a value greater than the High Limit, the instruction is false when the Test value is between the limits. If the Test value is equal to either limit or outside the limits, the instruction is true, as shown below.

-

Page 130: Comparison Instructions In The Paper Drilling Machine Application Example

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Comparison Instructions in the Paper Drilling Machine Application Example This section provides ladder rungs to demonstrate the use of comparison instructions. The rungs are part of the paper drilling machine application example described in appendix E. - Page 131 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Comparison Instructions Beginning a Subroutine in File 7 This section of ladder keeps track of the total inches of paper the current drill bit has drilled through. As the current bit wears out, a light illuminates on the operator panel, below, to warn the operator to change the drill bit.

- Page 132 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface 1/4 in. 102,000 Thousands 1/4 in. increments | | have occurred | +GEQ–––––––––––––––+ +–+GRTR THAN OR EQUAL+–––––––––––––––––––––––––––––––––( )–––––+ | | |Source A N7:11| | |Source B 102| | +––––––––––––––––––+ 1/4 in.

-

Page 133: Using Math Instructions

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Math Instructions Using Math Instructions This chapter contains general information about math instructions and explains how they function in your logic program. Each of the math instructions includes information on: what the instruction symbol looks like typical execution time for the instruction how to use the instruction In addition, the last section contains an application example for a paper drilling... -

Page 134: About The Math Instructions

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface About the Math Instructions These instructions perform the familiar four function math operations. The majority of the instructions take two input values, perform the specified arithmetic function, and output the result to an assigned memory location. - Page 135 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Math Instructions Overflow Trap Bit, S:5/0 Minor error bit (S:5/0) is set upon detection of a mathematical overflow or division by zero. If this bit is set upon execution of an END statement or a Temporary End (TND) instruction, the recoverable major error code 0020 is declared.

-

Page 136: Add (Add)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Add (ADD) Use the ADD instruction to add one value (source A) to another value (source B) Source A and place the result in the destination. Source A and B can either be a word address Source B or constant. -

Page 137: Subtract (Sub)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Math Instructions Subtract (SUB) Use the SUB instruction to subtract one value (Source B) from another (source A) SUBTRACT Source A and place the result in the destination. Source A and B can either be a word address Source B or constant. -

Page 138: 32-Bit Addition And Subtraction

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface 32-Bit Addition and Subtraction You have the option of performing 16-bit or 32-bit signed integer addition and subtraction. This is facilitated by status file bit S:2/14 (math overflow selection bit). - Page 139 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Math Instructions Add 16–bit value B3:1 to 32–bit value B3:3 B3:2 Add Operation Binary Decimal Addend B3:3 B3:2 0000 0000 0000 0011 0001 1001 0100 0000 0003 1940 203,072 Addend B3:1 0101 0101 1010 1000 55A8 21,928 0000 0000 0000 0011 0110 1110 1110 1000...

-

Page 140: Multiply (Mul)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Multiply (MUL) Use the MUL instruction to multiply one value (source A) by another (source B) MULTIPLY Source A and place the result in the destination. Source A and B can either be a word address Source B or constant. -

Page 141: Divide (Div)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Math Instructions Divide (DIV) Use the DIV instruction to divide one value (source A) by another (source B), and DIVIDE Source A place the rounded quotient in the destination. If the remainder is 0.5 or greater, the Source B destination is rounded up. -

Page 142: Double Divide (Ddv)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Double Divide (DDV) The 32-bit content of the math register is divided by the 16-bit source value and the DOUBLE DIVIDE Source rounded quotient is placed in the destination. If the remainder is 0.5 or greater, the Dest destination is rounded up. -

Page 143: Clear (Clr)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Math Instructions Clear (CLR) Use the CLR instruction to set the destination to zero. All of the bits reset. CLEAR Dest Execution Times (µsec) when: True False 20.80 4.25 Updates to Arithmetic Status Bits With this Bit: The Controller: S:0/0 Carry (C) -

Page 144: Scale Data (Scl)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Scale Data (SCL) When this instruction is true, the value at the source address is multiplied by the rate SCALE Source value. The rounded result is added to the offset value and placed in the destination. - Page 145 - Allen Bradley,Rockwell,plc,servo,drive Using Math Instructions The following example takes a 0V to 10V analog input from a MicroLogix 1000 analog controller and scales the raw input data to a value between 0 and 100%. The input value range is 0V to 10V which corresponds to 0 to 31,207 counts. The scaled value range is 0 to 100 percent.

-

Page 146: Math Instructions In The Paper Drilling Machine Application Example

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Math Instructions in the Paper Drilling Machine Application Example This section provides ladder rungs to demonstrate the use of math instructions. The rungs are part of the paper drilling machine application example described in appendix E. - Page 147 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Math Instructions Rung 7:6 When the number of 1/4 in. increments surpasses 1000, finds out how many increments are past 1000 and stores in N7:20. Add 1 to the total of 1000 1/4 in. increments, and re-initializes the 1/4 in. increments accumulator to how many increments were beyond 1000.

- Page 148 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Notes: 8–16...

-

Page 149: Using Data Handling Instructions

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Using Data Handling Instructions This chapter contains general information about the data handling instructions and explains how they function in your application program. Each of the instructions includes information on: what the instruction symbol looks like typical execution time for the instruction how to use the instruction In addition, the last section contains an application example for a paper drilling... -

Page 150: About The Data Handling Instructions

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Instruction Purpose Purpose Page Page Mnemonic Name Move Moves the source value to the destination. 9–15 Masked Move Moves data from a source location to a selected 9–16 portion of the destination. -

Page 151: Convert To Bcd (Tod)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Convert to BCD (TOD) Use this instruction to convert 16-bit integers into BCD values. TO BCD Source Dest The source must be a word address. The destination parameter can be a word address in a data file, or it can be the math register, S:13 and S:14. - Page 152 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Example The integer value 9760 stored at N7:3 is converted to BCD and the BCD equivalent is stored in N7:0. The maximum BCD value is 9999. TO BCD Source...

-

Page 153: Convert From Bcd (Frd)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Convert from BCD (FRD) Use this instruction to convert BCD values to integer values. FROM BCD Source Dest The source parameter can be a word address in a data file, or it can be the math register, S:13. - Page 154 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Note To convert numbers larger than 9999 BCD, the source must be the Math Register (S:13). You must reset the Minor Error Bit (S:5.0) to prevent an error. Example The BCD value 32,760 in the math register is converted and stored in N7:0.

- Page 155 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Clearing S:14 before executing the FRD instruction is shown below: MOVE Source N7:2 0001 0010 0011 0100 4660 Dest S:13 4660 CLEAR Dest S:14 FROM BCD MPS displays S:13 Source S:13 00001234 and S:14 in BCD.

-

Page 156: Decode 4 To 1 Of 16 (Dcd)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Decode 4 to 1 of 16 (DCD) When executed, this instruction sets one bit of the destination word. The particular DECODE 4 to 1 of 16 Source bit that is turned On depends on the value of the first four bits of the source word. -

Page 157: Encode 1 Of 16 To 4 (Enc)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Encode 1 of 16 to 4 (ENC) When the rung is true, this output instruction searches the source from the lowest to ENCODE 1 of 16 to 4 Source the highest bit, and looks for the first set bit. The corresponding bit position is Dest written to the destination as an integer as shown in the table below. -

Page 158: Copy File (Cop) And Fill File (Fll) Instructions

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Updates to Arithmetic Status Bits The arithmetic status bits are found in Word 0, bits 0–3 in the controller status file. After an instruction is executed, the arithmetic status bits in the status file are... - Page 159 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Using COP This instruction copies blocks of data from one location into another. It uses no status bits. If you need an enable bit, program an output instruction (OTE) in parallel using an internal bit as the output address. The following figure shows how file instruction data is manipulated.

- Page 160 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Using FLL The following figure shows how file instruction data is manipulated. The instruction fills the words of a file with a source value. It uses no status bits. If you need an enable bit, program a parallel output that uses a storage address.

-

Page 161: Move And Logical Instructions Overview

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Move and Logical Instructions Overview The following general information applies to move and logical instructions. Entering Parameters Source is the address of the value on which the logical or move operation is to be performed. - Page 162 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Overflow Trap Bit, S:5/0 Minor error bit (S:5/0) is set upon detection of a mathematical overflow or division by zero. If this bit is set upon execution of an END statement, or a TND instruction, a major error occurs.

-

Page 163: Move (Mov)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Move (MOV) This output instruction moves the source data to the destination location. As long as MOVE Source the rung remains true, the instruction moves the data each scan. Dest Execution Times (µsec) when: True False... -

Page 164: Masked Move (Mvm)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Masked Move (MVM) The MVM instruction is a word instruction that moves data from a source location MASKED MOVE Source to a destination, and allows portions of the destination data to be masked by a Mask separate word. - Page 165 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Operation When the rung containing this instruction is true, data at the source address passes through the mask to the destination address. See the following figure. MASKED MOVE Source B3:0 Mask F0F0 Dest B3:2 B3:2 before move...

-

Page 166: And (And)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface And (AND) The value at source A is ANDed bit by bit with the value at source B and then BITWISE AND Source A stored in the destination. Source B... -

Page 167: Or (Or)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Or (OR) The value at source A is ORed bit by bit with the value at source B and then stored BITWISE INCLUS OR Source A in the destination. Source B Dest Truth Table Execution Times (µsec) when:... -

Page 168: Exclusive Or (Xor)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Exclusive Or (XOR) The value at source A is Exclusive ORed bit by bit with the value at source B and BITWISE EXCLUS OR Source A then stored in the destination. -

Page 169: Not (Not)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Not (NOT) The source value is NOTed bit by bit and then stored in the destination (one’s Source complement). Dest Truth Table Execution Times (µsec) when: Dest = NOT A True False Dest 28.21 6.92... -

Page 170: Negate (Neg)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Negate (NEG) Use the NEG instruction to change the sign of a value. If you negate a negative NEGATE Source value, the result is a positive; if you negate a positive value, the result is a negative. -

Page 171: Fifo And Lifo Instructions Overview

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions FIFO and LIFO Instructions Overview FIFO instructions load words into a file and unload them in the same order as they were loaded. The first word in is the first word out. LIFO instructions load words into a file and unload them in the opposite order as they were loaded. - Page 172 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Control is the address of the control structure. The control structure stores the status bits, the stack length, and the position value. Do not use the control file address for any other instruction.

-

Page 173: Fifo Load (Ffl) And Fifo Unload (Ffu)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions FIFO Load (FFL) and FIFO Unload (FFU) FFL and FFU instructions are used in pairs. The FFL instruction loads words into a user-created file called a FIFO stack. The FFU instruction unloads words from the FIFO stack in the same order as they were entered. -

Page 174: Lifo Load (Lfl) And Lifo Unload (Lfu)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface FFU Instruction Execution Times When rung conditions change from false-to-true, the controller sets the FFU enable (µsec) when: bit (EU). This unloads the contents of the element at stack position 0 into the... - Page 175 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions LFL Instruction Execution Times When rung conditions change from false-to-true, the controller sets the LFL enable (µsec) when: bit (EN). This loads the contents of the Source, N7:10, into the stack element True False indicated by the Position number, 9.

-

Page 176: Data Handling Instructions In The Paper Drilling Machine Application Example

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Data Handling Instructions in the Paper Drilling Machine Application Example This section provides ladder rungs to demonstrate the use of data handling instructions. The rungs are part of the paper drilling machine application example described in appendix E. - Page 177 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Data Handling Instructions Rung 7:3 Converts the BCD thumbwheel value from BCD to integer. This is done because the controller operates upon integer values. This rung also ”debounces” the thumbwheel to ensure that the conversion only occurs on valid BCD values.

- Page 178 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Rung 7:4 Ensures that the operator cannot select a paper thickness of 0. If this were allowed, the drill bit life calculation could be defeated resulting in poor quality holes due to a dull drill bit.

-

Page 179: Using Program Flow Control Instructions

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Program Flow Control Instructions Using Program Flow Control Instructions This chapter contains general information about the program flow instructions and explains how they function in your application program. Each of the instructions includes information on: what the instruction symbol looks like typical execution time for the instruction how to use the instruction... -

Page 180: About The Program Flow Control Instructions

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface About the Program Flow Control Instructions Use these instructions to control the sequence in which your program is executed. Jump (JMP) and Label (LBL) Use these instructions in pairs to skip portions of the ladder program. - Page 181 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Program Flow Control Instructions Using LBL This input instruction is the target of JMP instructions having the same label number. You must program this instruction as the first instruction of a rung. This instruction has no control bits. You can program multiple jumps to the same label by assigning the same label number to multiple JMP instructions.

-

Page 182: Jump To Subroutine (Jsr), Subroutine (Sbr), And Return (Ret)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Jump to Subroutine (JSR), Subroutine (SBR), and Return (RET) The JSR, SBR, and RET instructions are used to direct the controller to execute a JUMP TO SUBROUTINE SBR file number separate subroutine file within the ladder program and return to the instruction . - Page 183 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Program Flow Control Instructions Nesting Subroutine Files Nesting subroutines allows you to direct program flow from the main program to a subroutine and then on to another subroutine. You can nest up to eight levels of subroutines. If you are using an STI subroutine, HSC interrupt subroutine, or user fault routine, you can nest subroutines up to three levels from each subroutine.

- Page 184 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Using SBR The target subroutine is identified by the file number that you entered in the JSR instruction. This instruction serves as a label or identifier for a program file as a regular subroutine file.

-

Page 185: Master Control Reset (Mcr)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Program Flow Control Instructions Master Control Reset (MCR) Use MCR instructions in pairs to create program zones that turn off all the (MCR) non-retentive outputs in the zone. Rungs within the MCR zone are still scanned, but Execution Times scan time is reduced due to the false state of non-retentive outputs. -

Page 186: Temporary End (Tnd)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Temporary End (TND) This instruction, when its rung is true, stops the controller from scanning the rest of (TND) the program file, updates the I/O, and resumes scanning at rung 0 of the main Execution Times program (file 2). -

Page 187: Immediate Input With Mask (Iim)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Program Flow Control Instructions Immediate Input with Mask (IIM) This instruction allows you to update data prior to the normal input scan. Data from IMMEDIATE INPUT w MASK Slot a specified input is transferred through a mask to the input data file, making the data Mask available to instructions following the IIM instruction in the ladder program. -

Page 188: Program Flow Control Instructions In The Paper Drilling Machine Application Example

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Program Flow Control Instructions in the Paper Drilling Machine Application Example This section provides ladder rungs to demonstrate the use of program flow control instructions. The rungs are part of the paper drilling machine application example described in appendix E. -

Page 189: Using Application Specific Instructions

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions Using Application Specific Instructions This chapter contains general information about the application specific instructions and explains how they function in your application program. Each of the instructions includes information on: what the instruction symbol looks like typical execution time for the instruction how to use the instruction In addition, the last section contains an application example for a paper drilling... -

Page 190: About The Application Specific Instructions

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Instruction Purpose Purpose Page Page Mnemonic Name Selectable Timer Initiates a Selectable Timed Interrupt. 11–20 Interrupt Start Interrupt Associated with Selectable Timed Interrupts or HSC 11–20 Subroutine Interrupts. About the Application Specific Instructions These instructions simplify your ladder program by allowing you to use a single instruction or pair of instructions to perform common complex operations. -

Page 191: Bit Shift Instructions Overview

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions Bit Shift Instructions Overview The following general information applies to bit shift instructions. Entering Parameters Enter the following parameters when programming these instructions: File is the address of the bit array you want to manipulate. You must use the file indicator (#) in the bit array address. - Page 192 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Bit Address is the address of the source bit. The status of this bit is inserted in either the first (lowest) bit position (BSL) or last (highest) bit position (BSR).

-

Page 193: Bit Shift Left (Bsl)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions Bit Shift Left (BSL) When the rung goes from false-to-true, the controller sets the enable bit (EN bit 15) (EN) BIT SHIFT LEFT File (DN) and the data block is shifted to the left (to a higher bit number) one bit position. The Control Bit Address Length... -

Page 194: Bit Shift Right (Bsr)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Bit Shift Right (BSR) When the rung goes from false-to-true, the controller sets the enable bit (EN bit 15) BIT SHIFT RIGHT (EN) File (DN) and the data block is shifted to the right (to a lower bit number) one bit position. The... -

Page 195: Sequencer Instructions Overview

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions Sequencer Instructions Overview The following general information applies to sequencer instructions. Effects on Index Register S:24 The value present in the index register S:24 is overwritten when the sequencer instruction is true. The index register value will equal the position value of the instruction. - Page 196 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Entering Parameters Enter the following parameters when programming these instructions: File is the address of the sequencer file. You must use the file indicator (#) for this address. Sequencer file data is used as follows:...

- Page 197 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions Status bits of the control structure include: – Found Bit FD (bit 08) – SQC only. When the status of all non-masked bits in the source address match those of the corresponding reference word, the FD bit is set.

- Page 198 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Using SQO This output instruction steps through the sequencer file whose bits have been set to control various output devices. When the rung goes from false-to-true, the instruction increments to the next step (word) in the sequencer file.

- Page 199 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions The following figure indicates how the SQO instruction works. (EN) SEQUENCER OUTPUT File #B3:1 (DN) Mask 0F0F Dest Control R6:05 Length Position Destination O:0.0 External Outputs Associated with O:0 0000 0101 0000 1010 Mask Value 0F0F 0000...

- Page 200 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Applications of the SQC instruction include machine diagnostics. The following figure explains how the SQC instruction works. (EN) SEQUENCER COMPARE File #B3:8 (DN) Mask FFF0 (FD) Source Control R6:3...

-

Page 201: Sequencer Load (Sql)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions Sequencer Load (SQL) The SQL instruction stores 16-bit data into a sequencer load file at each step of (EN) SEQUENCER LOAD File sequencer operation. The source of this data can be an I/O or internal word address, (DN) Source Control... - Page 202 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Status bits of the control structure include: – Error Bit ER (bit 11) is set when the controller detects a negative position value, or a negative or zero length value. When the ER bit is set, the minor error bit (S5:2) is also set.

-

Page 203: Selectable Timed Interrupt (Sti) Function Overview

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions The instruction loads data into a new file element at each false-to-true transition of the rung. When step 4 is completed, the done bit (DN) is set. Operation cycles to position 1 at the next false-to-true transition of the rung after position 4. If the source were a file address such as #N7:40, files #N7:40 and #N7:30 would both have a length of 5 (0–4) and would track through the steps together per the position value. - Page 204 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface If while an STI is pending, the STI timer expires, the STI lost bit (S:5/10) is set. When the STI subroutine scan is completed, scanning of the program resumes at the point where it left off, unless an STI is pending.

- Page 205 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions Note that STI execution time adds directly to the overall scan time. During the latency period, the controller is performing operations that cannot be disturbed by the STI interrupt function. Interrupt Priorities Interrupt priorities are as follows: User Fault Routine High-Speed Counter...

-

Page 206: Selectable Timed Disable (Std) And Enable (Ste)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Selectable Timed Disable (STD) and Enable (STE) These instructions are generally used in pairs. The purpose is to create zones in SELECTABLE TIMED DISABLE which STI interrupts cannot occur. - Page 207 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions Program File 3 SELECTABLE TIMED ENABLE SELECTABLE TIMED DISABLE STI interrupt execution will not occur between STD and STE. SELECTABLE TIMED ENABLE 11–19...

-

Page 208: Selectable Timed Start (Sts)

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Selectable Timed Start (STS) Use the STS instruction to condition the start of the STI timer upon entering the SELECTABLE TIMED START File REM Run mode – rather than starting automatically. You can also use it to set up or... -

Page 209: Application Specific Instructions In The Paper Drilling Machine Application Example

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions Application Specific Instructions in the Paper Drilling Machine Application Example This section provides ladder rungs to demonstrate the use of application specific instructions. The rungs are part of the paper drilling machine application example described in appendix E. - Page 210 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Rung 4:0 Resets the hole count sequencers each time that the low preset is reached. The low preset has been set to zero to cause an interrupt to occur each time that a reset occurs.

- Page 211 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions Rung 4:1 Keeps track of the hole number that is being drilled and loads the correct HSC preset based on the hole count. This rung is only active when the ”hole selector switch” is in the ”3-hole” position. sequencer uses step 0 as a null step upon reset.

- Page 212 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Rung 4:2 Is identical to the previous rung except that it is only active when the ”hole selector switch” is in the ”5-hole” position. | hole |hole 5 hole...

- Page 213 efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using Application Specific Instructions Rung 4:3 Is identical to the 2 previous rungs except that it is only active when the ”hole selector switch” is in the ”7-hole” position. | hole |hole 7 hole | selector |selector preset | switch...

- Page 214 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Notes: 11–26...

-

Page 215: Using High-Speed Counter Instructions

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using High-Speed Counter Instructions Using High-Speed Counter Instructions This chapter contains general information about the high-speed counter instructions and explains how they function in your application program. Each of the instructions includes information on: what the instruction symbol looks like typical execution time for the instruction how to use the instruction In addition, the last section contains an application example for a paper drilling... -

Page 216: About The High-Speed Counter Instructions

- Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface About the High-Speed Counter Instructions The high-speed counter instructions used in your ladder program configure, control, and monitor the controllers’ hardware counter. The hardware counter’s accumulator increments or decrements in response to external input signals. When the high-speed counter is enabled, data table counter C5:0 is used by the ladder program for monitoring the high-speed counter accumulator and status. -

Page 217: High-Speed Counter Instructions Overview

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive Using High-Speed Counter Instructions High-Speed Counter Instructions Overview Use the high-speed counter to detect and store narrow (fast) pulses, and its specialized instructions to initiate other control operations based on counts reaching preset values. These control operations include the automatic and immediate execution of the high-speed counter interrupt routine (file 4) and the immediate update of outputs based on a source and mask pattern you set. - Page 218 - Allen Bradley,Rockwell,plc,servo,drive MicroLogix 1000 Programmable Controllers User Manual Preface Counter Up Enable Bit CU (bit 15) is used with all of the high-speed counter types. If the HSC instruction is true, the CU bit is set to one. If the HSC instruction is false, the CU bit is set to zero.