Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Ytc YT-1200L

- Page 1 Pneumatic Positioner YT-1200 Series USER'S MANUAL Ver 1.01...

-

Page 3: Manufacturer Warranty

Introduction Thank you for choosing YTC product. Each product is fully inspected after the production to offer you the highest quality. In order to fully utilize the product, we strongly recommend users to read this manual carefully and understood. The manual should be given to the end-user. -

Page 4: Product Description

Product Description Main Features and Functions The product can operate normally in very extreme environment, such as vibration and temperature. The durability has been proven after testing 2 million cycles at the minimum. Response time is very short and accurate. ... -

Page 5: Label Description

Label Description Model: Indicates model name and any options (if any) Input Signal: Indicates current input signal range. Supply Pressure: Indicates the range of supply pressure. Serial Number: Indicates unique serial number. Suffix Symbol YT-1200 series follows suffix symbols as below. -

Page 6: Specification

Specification... -

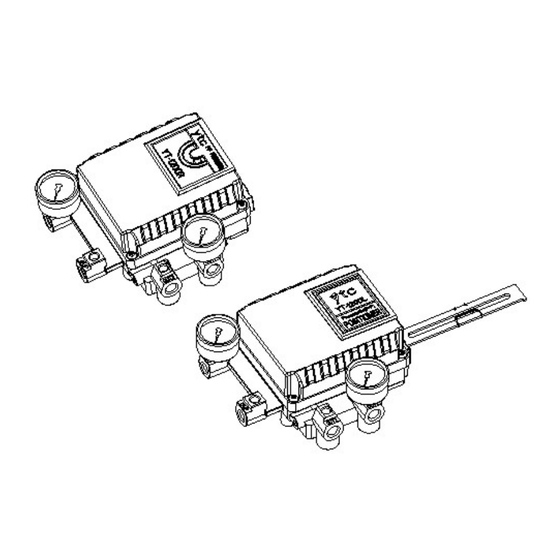

Page 7: Parts And Assembly

Parts and Assembly... - Page 8 Dimensions...

-

Page 9: Safety Warning

③ Spanners for hexagonal-head bolts YT-1200 Installation YT-1200L should be installed on linear motion valve such as globe valve or gate valve using spring return type diaphragm or piston actuator. Before installation, be sure to check for following installation components. - Page 10 NOT TIGHTEN COMPLETELY. Connect YT-1200L feedback lever to the actuator clamp. The gap on the YT-1200L feedback lever is 65mm. The connection bar thickness should be less than 6.3mm. <Fig 2> Connect air filter regulator to the actuator temporarily. Set supply pressure of the regulator in order to position the actuator damp at 50% of valve stroke.

- Page 11 Both of 0% and 100%, the feedback lever should not touch the lever stopper, which is located on the backside of YT-1200L. <fig 7> If the feedback lever touches the stopper, YT- 1200L should be installed further away from the center of the yoke.

- Page 12 YT-1200R Installation YT-1200R should be used for rotary motion valve, that is ball valve, butterfly valve using rack and pinion, scotch yoke or complex type actuator, which its stem rotates 90 degrees. Before installation, be sure to check for following installation components. ①...

- Page 13 Bracket Information YT-1200R is supplied with standard bracket. The bracket can be used for fork lever and NAMUR bracket. Please see <fig 8> for more detailed information. 1. Standard actuator stem height (H) is 20, 30, or 50 mm. After check “H”, assemble with the bracket as shown in <fig 8 &...

- Page 14 3. Set rotation position of the actuator stem at zero point, “0%”. For a single type of actuator, it is easy to check zero point, because the actuator stem is positioned at zero point when there is no supply pressure. If double acting actuator is used, check actuator stem’s rotation direction (clockwise or counter-clockwise) by supplying pressure.

- Page 15 7. Tighten YT-1200R base and the bracket with hexagon-headed bolts and plate washer. It is recommended to tighten four bolts after checking YT-1200R’s position. <fig 13>...

-

Page 16: Piping Connection

Piping Connection Note To avoid entering moisture, oil, or dust into the product, please carefully make selection of supply pressure compressor. It is recommended to attach air filter regulator <YT-200> before supply port of YT- 1200. Supply Pressure Condition ①... - Page 17 Double Acting Actuator For YT-1200 series double acting type, when inputting current signal, supply pressure is our from OUT1 port. Please refer to <fig 16 & 17> Adjustment Adjustment – Cam ① Direction of actuator's stem rotation must be checked when supply signal is supplied. When actuator's stem rotates clockwise, the face of cam must be shown "DA."...

- Page 18 After setting zero point, confirm the span point. This step must be repeated until both points are properly set. ③ If 1/2 split range is used, YT-1200L can be used after span and zero point are set. For YT-1200R with 1/2 split range, the span spring must be changed.

- Page 19 Adjustment – A / M Switch <Auto / Manual> 1. A / M switch adjusts the valve operation to automatic or manual. 2. YT-1200 series is set as “A” / Automatic as default. If user wants to set as “M” / Manual, the setting can be adjusted by turning the switch counter-clockwise.

-

Page 20: Troubleshooting

③ Check if the positioner’s nozzle has been blocked. Also, check if the pressure is supplied to the positioned and the pressure is being exhausted through the nozzle. If the nozzle has been blocked by any substances, please send the unit to YTC for repair. - Page 21 ① In case of double acting actuator, check if seat adjustment has been properly done. Please contact YTC for any further inquiries regarding the seat adjustment. ② Backlash can occur when feedback lever and lever spring is loosen. To avoid backlash, adjust the lever spring.

Need help?

Do you have a question about the YT-1200L and is the answer not in the manual?

Questions and answers