Summary of Contents for Bin Master C-100

- Page 1 Model C-100 SmartBob Control Console OPERATORS MANUAL Please read thoroughly before installation and operation. Division of Garner Industries 7201 North 98 Street Lincoln, NE 68507-9741 (402) 434-9102 925-0270 Rev G 6/21/2017...

- Page 2 (this page intentionally left blank) 925-0270 Rev G...

-

Page 3: Table Of Contents

TABLE OF CONTENTS SAFETY SUMMARY…………………………………….………………………………………………………..…4 1.0 INTRODUCTION……..…………………………………………………………………………………………5 2.0 SPECIFICATIONS……………………………………………………………………………………………...5 3.0 INSTALLATION………………………………………………………………………………………….……...7 3.1 Mounting…………..………………………………………………………………………………….7 3.2 Connections and Wiring……………………………………………………………………....9 3.3 RS-485 Network Requirements……………………………………………………………….……12 3.4 Lightning/Surge Protection…………………………………………………….………………..14 3.5 Wiring Diagram…………………………………………………………………...………………….15 4.0 OPERATION and SETUP….……………………..………………………………………………………….16 4.1 Keypad………………………………………………………………………………..………………16 4.2 Menu System………………………………………………….……………………………………..16 4.3 Messaging System……………………………………………………………………………..……24 5.0 WARRANTY AND SERVICE…………….…………………..……………………………………………..25 5.1 Limited Warranty……………………………………………………………………………………..25 5.2 Technical Support, Customer Service and Repair……………………………………………….25 6.0 DISPOSAL……………………………………………………………………………………………………..26... -

Page 4: Safety Summary

Safety Summary Review the following safety precautions to avoid injury and prevent damage to the equipment. The product should be installed, commissioned, and maintained by qualified and authorized personnel only. Install according to installation instructions and comply with all national and local codes. Use electrical wire that is sized and rated for the maximum voltage and current of the application. -

Page 5: Introduction

The Model C-100 can interface with up to five BinMaster C-50 Expansion consoles on a dedicated RS- 485 network. The Model C-50 is for interfacing the SmartBob system to a PLC or DCS system. Each Model C-50 expansion console supports up to 6 analog I/O cards, each with 4 ports, for a total of 24 analog I/O ports per C-50. - Page 6 Interval Timer for Automatic Measurements Any number of SmartBobs on the network can be configured for an automatic measurement with a time between measurements ranging from 0 minutes (continuous) to 49 hours and 59 minutes in 1 minute increments. Vessel Parameters Vessel Height in feet: 1.00 to 299.99 in 0.01 increments Vessel Height in meters:...

-

Page 7: Installation

If the ambient temperature of the C-100 is going to exceed 122° F (50°C), consider using a fan of some type to circulate the air. - Page 8 3.1.1 Screw Mount There are three screw holes that can be used for mounting the C-100 SmartBob control console as shown in the diagram below. You will need one #8 wood screw at least 3/8” long and two #8 wood screws at least 5/8”...

-

Page 9: Connections And Wiring

3.2 Connections and Wiring A minimum configuration will require a three-wire power connection and a three-wire RS-485 connection to the SmartBob network. Optionally, there may be a two-wire 4-20mA connection, a two-wire external start connection and another three-wire RS-485 connection for the Expansion network. All wiring is fed through water-tight cordgrips and connected inside the lower wiring cabinet to pluggable terminal blocks mounted on the printed circuit board. - Page 10 Devices located at the ends of the SmartBob network must be properly terminated. For the two devices located at the ends, switch in their NTR or termination resistor. The C-100 SmartBob control console can be located anywhere along the SmartBob network and has a software menu for switching it’s termination in or out of circuit.

- Page 11 screw marked SH should be connected to the shield of the RS-485 network cable. Do NOT connect the shield to earth. These three connections at this terminal block are optional and only needed when connecting BinMaster C-50 expansion units to the system. A good quality twisted-pair shielded cable should be used for the RS-485 network.

-

Page 12: Rs-485 Network Requirements

3.2.5 4-20mA Output The 4-20mA Output connection (CN3) is a two wire terminal block located on the far left of the printed circuit board. It is identified with CN3 and labeled with 4-20. The two terminal screws marked + and – should be connected to the proper positive and negative wires of the load. - Page 13 + terminal on all other devices. Likewise, make sure that the wires connected to the – and SH terminals at the C-100 SmartBob control console are also connected to the – and SH terminals, respectively, on all other devices. Do not connect the wires or shield to anything other than that specified.

-

Page 14: Lightning/Surge Protection

Both the power source and an RS-485 network are a means for electrical surges to enter the C-100 SmartBob control console and do damage. Although some level of protection from electrical surges is built into the C-100 SmartBob control console, there are options to further protecting your investment. -

Page 15: Wiring Diagram

3.5 Wiring Diagram 925-0270 Rev G... -

Page 16: Operation And Setup

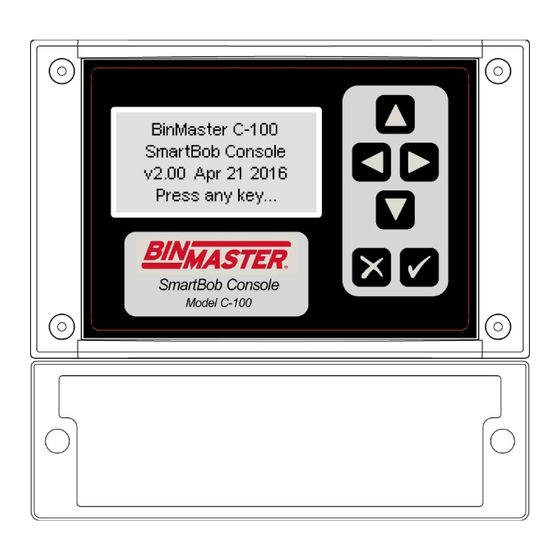

4.0 Operation and Setup The C-100 SmartBob control console is controlled and operated through the use of a 6-button icon-based keypad and a simple intuitive text-based menu system. The menu system is user-selectable in either the English or Spanish languages. - Page 17 The Scroll Up and Down Indicators, displayed as little up and down arrows towards the right of the screen, will be present when more selections or information is available off screen. The Scroll Up Indicator will be present when the user can scroll up to obtain more selections or information and the Scroll Down Indicator will be present when the user can scroll down to obtain more selections or information.

- Page 18 4.2.1 Main Menu The Main menu has two selections: Measure/View and Setup. Select Measure/View if you want to take an immediate measurement or view the results of the last measurement. Select Setup if you need to change user display preferences, setup vessel parameters, SmartBob network settings or configure the Expansion network.

- Page 19 SB-485 Termination This is a menu for setting whether the SmartBob network termination is switched In or Out of the network. If the console is the final device connected at either end of the SmartBob network choose In, otherwise choose Out. The default setting is In. The termination must be set prior to running Auto Add/Remove or any measurement process.

- Page 20 If weight calculations are disabled, this is simply for setting the overall height of the vessel, sensor offset and maximum drop. The first screen is for selecting the vessel(s) to be configured, the second screen is for entering the vessel height of the selected vessel(s), the third screen is for setting a headroom offset and the fourth for setting maximum drop distance.

- Page 21 Auto Add/Remove prior to making this selection. The default setting is Disabled. After the user selects Enabled, the C-100 console will automatically assign available I/O’s to enabled SmartBobs and then enter the I/O Assignment menu for the user to review and/or reassign if necessary.

- Page 22 Auto Add/Remove prior to using this menu. This menu will differ depending on whether the C- 50 Setup was enabled or disabled. If C-50 setup is disabled, then this menu will be for assigning any single SmartBob sensor to the C-100’s onboard I/O (External Start input and 4-20mA output). The operator simply selects the address of any single SmartBob sensor in this list, but it defaults to the first address available in the list.

- Page 23 keys to select a digit by repositioning the cursor and the keys to adjust the selected digit. Once all four digits have been entered, press the key. After the interval time has been set, a menu appears for assigning SmartBobs to the automatic measurement process.

-

Page 24: Messaging System

This is a menu that allows the operator to select either the English or Spanish language for displaying the text-based menu system. The default is English. This menu is also presented to the user when the C-100 SmartBob control console is powered up for the very first time. -

Page 25: Warranty And Service

If you are in need of an updated operator's manual, specification drawing or parts replacement list, please visit our online documentation at www.binmaster.com. Prior to shipping your Model C-100 back for repair, please call our service department for an RMA number. Along with the RMA number, you will also be provided with shipping instructions and address. -

Page 26: Disposal

6.0 Disposal This product consists of materials that may be recycled by certain recycling companies. It uses recyclable materials and is designed to be easily separated. Consult local authorities for proper disposal locations. 925-0270 Rev G... -

Page 27: Declaration Of Conformity

EMC Directive 2004/108/EC Standard EN 61326-1:2006 Product: Industrial console for a network of SmartBob sensors. Models: C-100 All test reports and documentation are held and can be obtained from BinMaster. Manufacturing Location: Lincoln, Nebraska, USA Scott McLain...

Need help?

Do you have a question about the C-100 and is the answer not in the manual?

Questions and answers