Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Memmert Waterbath WNB 7-45

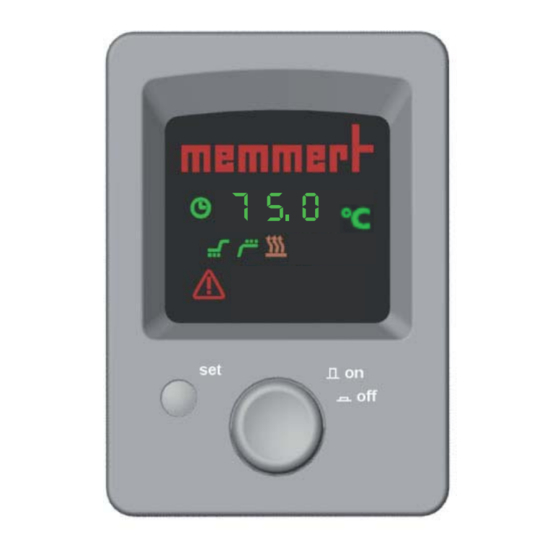

- Page 1 BASIC Waterbath WNB 7-45 Operating Instructions 7 5. 0 page 1 BASIC...

-

Page 2: Table Of Contents

1 General notes and safety notes ......................3 1.1 Transport ..........................3 2 Technical data ............................. 4 2.1 Material quality ........................5 2.2 Electrical equipment ........................5 2.3 Note on EMC (electromagnetic compatibility) ................5 2.4 Brief technical description ......................5 2.5 Standard equipment ........................6 3 Installation ............................ -

Page 3: General Notes And Safety Notes

1 General notes and safety notes You have purchased a technically fully proven product which has been produced in Germany with the use of high-grade materials and the application of the latest manufacturing techniques; it has been factory tested for many hours. In addition we guarantee the supply of spare parts over 10 years. -

Page 4: Technical Data

2 Technical data Model Volume [liter] Usable bath length A [mm] Usable bath width B [mm] Usable bath depth C [mm] Housing length D [mm] Housing width E [mm] Housing height (with flat cover) F [mm] Housing height (with gable cover) G [mm] Weight [kg] Current consume [A] 10,4... -

Page 5: Material Quality

2.1 Material quality Memmert is using stainless steel ( Mat.Ref. 1.4301) for the external casing as well as for the interior, an outstanding material because of its high stability, optimum hygienic features and corrosion resistance against many (not all!) chemical combinations (Attention e.g. at chlorine combinations!). -

Page 6: Standard Equipment

2.5 Standard equipment • Electronic fuzzy-supported PID process controller with delayed programme start and programmable hold time. The controller has permanent power matchinig and an autodiagnostic system for rapid fault finding • Recessing push/turn control for simple operation of bath •... -

Page 7: Initial Start-Up

3.1 Initial start-up When the bath is started up for the first time, it should be supervised continuously until steady conditions have been reached. 3.2 Start-up - waterbath Mains The mains connection cable must be placed away from any hot surface. connection Filling min. -

Page 8: Bath Construction And Operation

4 Bath construction and operation relatively largest heat loss (since minimum heat loss (since furthest away from the heated ribs) very close to the heated ribs) bath Insulation heating elements The large-area heating positioned on three sides produces a natural, continuous water circulation. The illustration shows that the heat loss of the thermofluid is largest at the centre of the bath (1) since the liquid is furthest away from the heating at this point. -

Page 9: Switching On

4.2 Switching on The bath is switched on by pressing the push/turn control. Bath switched off. The push/turn control is Bath switched on and can be operated using pushed in and protected against damage. the push/turn control and the SET key. 4.3 Setting the parameters A parameter can be selected by rotating the push/turn control;... -

Page 10: Temperature Setpoint

4.3.1 Temperature setpoint Adjustment range: 90°C 10°C to 95°C or ca. 100°C with activation of the boiling mode Setting and indication accuracy: The bath starts to heat up immediately 0,1°C to the set temperature. °C Rotate the push/turn control until the symbol flashes. -

Page 11: Hold Time Of The Setpoint Temperature

4.3.3 Hold time of the setpoint temperature Adjustment range: 90°C 1 min bis 99.59 hrs Setting accuracy: 1 min hold 6h Indication accuracy: The bath switches off the heating after <10 hrs: 1 min the end of the selected hold time. In this ≥10 hrs: 1 hr case the hold time includes the heating- up time. -

Page 12: Monitoring The Programme Sequence

6 Monitoring the programme sequence During the delayed switch-on the symbol 90°C flashes and the display alternates between °C residual time and actual temperature delay 6h hold 6h Bath does not heat up °C After the end of the delayed switch-on the 90°C symbol goes dark and the bath heats up to °C... -

Page 13: Temperature Monitor And Protection Devices

7 Temperature monitor and protection devices 7.1 Mechanical temperature monitor: temperature limiter All waterbaths are fitted with a mechanical temperature limiter (TB) Protection Class 1 to DIN 12880. If the electronic control unit should fail during operation and the fixed factory-set maximum temperature is exceeded by approx. -

Page 14: Use Of The Cover (Special Equipment)

8 Use of the cover (special equipment) Gable cover The gable cover (may be ordered as already mounted special equipment) should always be closed in order to prevent evaporation of thermostating liquid and to obtain optimal temperature distribution. The gable shape of the cover makes sure that condensed water will not drop down into the loads. -

Page 15: Cooling System (Special Equipment)

10 Cooling system (special equipment) cold water If the waterbath is fitted with a cooling device supply for quicker cooling of the bath liquid, the “cold water supply“ has to be connected by a hose to a cold water supply line. The “warm water discharge“... -

Page 16: Check List For Fault Rectification

Communication to power unit interrupted E - L In case of a malfunction contact an authorized service station for Memmert equipment or please inform the Memmert service department. In case of queries always specify model and serial number (on the rating label) 13 Action on supply failure After a failure of the supply, operation continues with the previously set parameters. -

Page 17: Ce Conformity Of Declaration

15 CE Conformity of Declaration E E C Declaration of Conformity Manufacturer´s name and address: MEMMERT GmbH + Co. KG Äußere Rittersbacher Straße 38 D-91126 Schwabach Product: Waterbath Type: Sizes: 7 / 10 / 14 / 22 / 29 / 45... -

Page 18: Address And Customer Service

E-mail: sales@memmert.com Internet: www.memmert.com Customer service: Phone: 00 49 9122 / 925-143 or 00 49 9122 / 925-126 E-mail: service@memmert.com In case of queries always specify model and serial number (on the rating label) © by MEMMERT GmbH+Co.KG BASIC page 18... -

Page 19: Index

17 Index address 18 heating, large-area 8 TB 13 alarm symbol 13 hinge bolts 15 technical data 4 ambient conditions 4 hold time of the setpoint temperature 11 temperature fluctuation 5 ambient temperature 16 temperature limiter (TB) 13 autodiagnostic system 6 temperature measurement 5 temperature monitor 13 indications 8... - Page 20 27.06.2006 Waterbath BASIC englisch D10329 BASIC page 20...

Need help?

Do you have a question about the Waterbath WNB 7-45 and is the answer not in the manual?

Questions and answers