Table of Contents

Advertisement

Operating Instructions

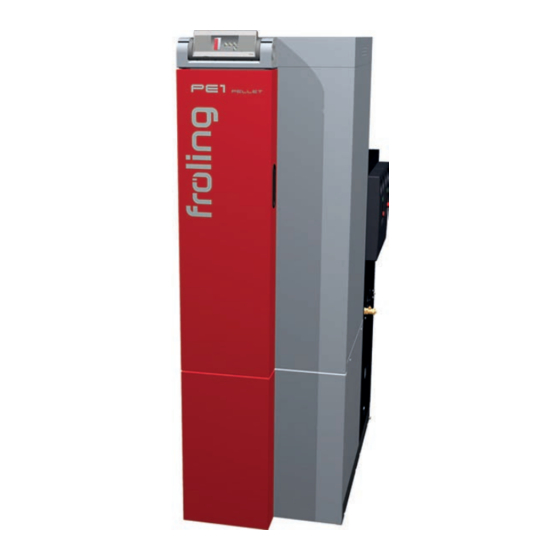

Pellet boiler PE1 Pellet (Touch)

Translation of the original German operating instructions for the operator

Read and follow the instructions and safety information!

Technical changes, typographical errors and omissions reserved!

B1000315_en | Edition 30/06/2015

Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

Advertisement

Table of Contents

Summary of Contents for Froling PE1 Pellet

-

Page 1: Operating Instructions

Pellet boiler PE1 Pellet (Touch) Translation of the original German operating instructions for the operator Read and follow the instructions and safety information! Technical changes, typographical errors and omissions reserved! B1000315_en | Edition 30/06/2015 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com... -

Page 2: Table Of Contents

Switching off the boiler 3.3.5 Switching off the power supply Boiler Servicing General information on servicing Inspection and cleaning 4.2.1 Required tools and equipment 4.2.2 Inspection Checking the system pressure Checking the safety valve Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com... - Page 3 Contents 4.2.3 Cleaning Emptying the ashcan (PE1 Pellet 7-10) Emptying the ash container (PE1 Pellet 15-35) Cleaning the grate and combustion chamber 4.2.4 Periodic inspection and cleaning Cleaning the heat exchanger Cleaning the flue gas pipe Checking the draught controller flap 4.2.5...

-

Page 4: General

General 1 General Thank you for choosing a quality product from Froling. The product features a state-of- the-art design and conforms to all currently applicable standards and testing guidelines. Please read and observe the documentation provided and always keep it close to the system for reference. -

Page 5: Pe1 Pellet Product Overview

High-limit thermostat (STL) Door switch Maintenance opening for combustion chamber (underneath the cover) Inspection glass for checking combustion Ash container for automatic ash removal (PE1 Pellet 15-35) Ashcan (PE1 Pellet 7/10) Quick start guide Operating Instructions PE1 Pellet (Touch) | B1000315_en... -

Page 6: Safety

Work with extreme care. CAUTION The dangerous situation may occur and if measures are not observed it will lead to minor injuries or damage to property. Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com... -

Page 7: Pictograms Used

Warning of injury to fingers or Warning of injury to fingers or hands, gear/chain drive hands, cutting edge Hand injury warning Warning of injury from being pulled into rotating shafts Increased CO concentration Slipping hazard warning warning Operating Instructions PE1 Pellet (Touch) | B1000315_en... -

Page 8: General Safety Information

❒ Optimum boiler performance can only be guaranteed if the flue gas system is functioning correctly. 2.4 Permitted uses The Froling Pellet boiler PE1 Pellet is designed solely for heating domestic water. Only use fuels specified in the "Permitted fuels" section. ⇨ See "Permitted fuels" [page 10]... -

Page 9: The Clean Air Act 1993 And Smoke Control Areas

Clean Air Act requirements. The Froling PE1 Pellet 7, PE1 Pellet 10, PE1 Pellet 15, PE1 Pellet 20, PE1 Pellet 25, PE1 Pellet 30 and PE1 Pellet 35 have been recommended as suitable for use in smoke control areas when burning fuels as listed under "Permitted fuels". -

Page 10: Permitted Fuels

Using non-standard fuels can also lead to serious problems with combustion. For this reason, when operating the boiler: ❒ Only use permitted fuels Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com... -

Page 11: Qualification Of Operating Staff

Austria: report to the construction authorities of the community or magistrate Germany: report new installations to an approved chimney sweep / the building authorities. Operating Instructions PE1 Pellet (Touch) | B1000315_en... -

Page 12: General Information For Installation Room (Boiler Room)

❒ Use prepared water which complies with the standards cited above for filling and makeup water ❒ Avoid leaks and use a closed heating system to maintain water quality during operation Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com... -

Page 13: Notes For Using Pressure Maintenance Systems

For the correct dimensions of the storage tank and the line insulation (in accordance with ÖNORM M 7510 or guideline UZ37) please consult your installer or Froling. ⇨ See "Addresses" [page 32] 2.7.6 Chimney connection/chimney system... - Page 14 NOTICE! Please see the technical data contained in the assembly instructions for further information about standards and regulations as well as the flue gas temperatures when clean and the other flue gas values! Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com...

-

Page 15: Safety Devices

(protection against overheating/excessive pressure) SAFETY VALVE When the boiler pressure reaches a maximum of 3 bar, the safety valve opens and the heated water is blown off in the form of steam. Operating Instructions PE1 Pellet (Touch) | B1000315_en... -

Page 16: Residual Risks

/ flash fires) which can lead to serious accidents! Take the following precautions: ❒ Only use fuels specified in the "Permitted fuels" section of these operating instructions. Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com... -

Page 17: Emergency Procedure

❒ Keep all the doors on the boiler closed ❒ Open all mixing valve taps, switch on all pumps. ➥ The Froling heating circuit control performs this function in automatic operation. ❒ Leave the boiler room and close the door ❒... -

Page 18: Operating The System

Take the following precautions: ❒ Initial startup should be carried out with an authorised installer or with Froling customer services The individual steps for initial start-up are explained in the operating instructions for... -

Page 19: Filling The Pellet Store

Slick surfaces in the fuel store present a slipping hazard! Unauthorised access prohibited! Keep children away! Keep the fuel store locked and store the key in a safe place! No fire, open flames or smoking in the store! Operating Instructions PE1 Pellet (Touch) | B1000315_en... -

Page 20: Heating Up The Boiler

❒ Turn off the main switch ➥ Boiler controller is switched off ➥ There is no power supply to any of the boiler components NOTICE! Frost protection function is no longer active! Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com... -

Page 21: Boiler Servicing

❒ Clean the boiler following the instructions in the instruction manual. Follow the boiler operating instructions. NOTICE We recommend that you keep a maintenance book in accordance with ÖNORM M7510 of the Technical Directive for Fire Prevention (TRVB) Operating Instructions PE1 Pellet (Touch) | B1000315_en... -

Page 22: Inspection And Cleaning

▪ Furnace tool, cleaning brush for heat exchanger pipes (included in delivery) ▪ Only for PE1 Pellet 7-10: Transport hook for ashcan (included in delivery) ▪ Only for PE1 Pellet 25-35: Mounting bracket for burner insert (included in delivery) ▪ Spanner or box wrench set ▪... -

Page 23: Cleaning

❒ Hang the transport hook opposite the locking lever, take the ashcan to the emptying point and empty it Emptying the ash container (PE1 Pellet 15-35) 1. Open the insulated door of the boiler 2. Open the clamps on the left and right of the ash container 3. -

Page 24: Cleaning The Grate And Combustion Chamber

❒ Open both fasteners on the ash container cover ➥ PE1 Pellet 15-20: Clamps from the sides ➥ PE1 Pellet 25-35: Turn-lock fasteners from the top ❒ Remove cover and empty ash container Cleaning the grate and combustion chamber PE1 Pellet 25-35 1. -

Page 25: Periodic Inspection And Cleaning

2. Place the WOS springs on a suitable surface and clean with a brush. 3. Clean the heat exchanger pipes with the brush provided. Ensure that the brush has been pushed through completely and is only then pulled back up. Repeat the procedure several times. Operating Instructions PE1 Pellet (Touch) | B1000315_en... -

Page 26: Cleaning The Flue Gas Pipe

❒ Check that the hot water and drinking water (if fitted) safety valves work correctly and in accordance with the manufacturer’s instructions Pressure reducing valve ❒ Check any existing pressure reducing valve for wear and correct function in accordance with the manufacturer's instructions Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com... -

Page 27: Magnesium Corrosion Protection Anode

NOTICE! Rinse DHW tank before starting up again in accordance with EN 14336 ❒ Clean the outer parts with a wet cloth whenever necessary ➥ Avoid cleaning agents which are abrasive or contain solvents Operating Instructions PE1 Pellet (Touch) | B1000315_en... -

Page 28: Emissions Measurement By Chimney Sweep Or Regulatory Body

Heating Plant Regulations (Feuerungsanlagen-Verordnung). 4.5 Replacement parts With Froling original replacement parts in your boiler, you are using parts that match perfectly. As the parts fit together so well, installation times are shortened and a long service life is maintained. -

Page 29: Disposal Information

❒ Ensure that they are disposed of in an environmentally friendly way in accordance with waste management regulations in the country (e.g. AWG in Austria) ❒ You can separate and clean recyclable materials and send them to a recycling centre. Operating Instructions PE1 Pellet (Touch) | B1000315_en... -

Page 30: Troubleshooting

Once the temperature falls below approx. 75°C, the STL (high-limit thermostat) can be reset mechanically: ❒ Unscrew the cap on the STL (high-limit thermostat) ❒ Unlock the STL (high-limit thermostat) by pressing with a screwdriver Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com... -

Page 31: Faults With Fault Message

Trace and remove the fault and then: ❒ Tap the “Cancel” symbol ➥ Status LED constant or flashing green light (depending on operating status) - Green constant: Boiler switched on - Green flashing: Boiler switched off Operating Instructions PE1 Pellet (Touch) | B1000315_en... -

Page 32: Appendix

6.1.1 Address of manufacturer FRÖLING Heizkessel- und Behälterbau GesmbH Industriestraße 12 A-4710 Grieskirchen AUSTRIA TEL 0043 (0)7248 606 0 FAX 0043 (0)7248 606 600 INTERNET www.froeling.com 6.1.2 Address of the installer Stamp Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com...

Need help?

Do you have a question about the PE1 Pellet and is the answer not in the manual?

Questions and answers