Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Sonatest Sitescan 150

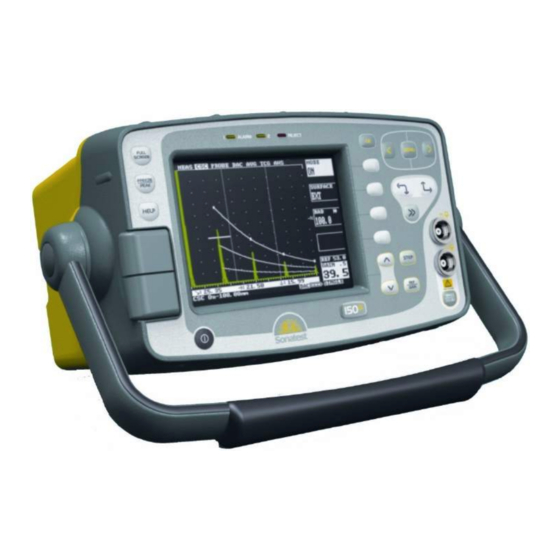

- Page 1 Sitescan 150 User’s Guide...

- Page 3 All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Sonatest Limited. Sonatest Limited Sonatest Inc.

-

Page 4: Table Of Contents

Sitescan 150 User’s Guide ~ Contents Contents 1 How to Use This User’s Guide ..................1 1.1 Typographical Conventions .................. 1 2 Disclaimers and Notices ....................2 2.1 Specific Warnings ....................2 2.2 General Warnings ....................2 2.3 Operator Training ....................2 ... - Page 5 Sitescan 150 User’s Guide ~ Contents 4.4.7 AWS Menu ....................... 29 4.4.8 API Menu......................30 4.5 UTIL Menu ......................31 4.5.1 UTIL Menu ...................... 31 4.5.2 VIDEO Menu ....................31 4.5.3 MISC Menu ..................... 32 4.5.4 AGC (Automatic Gain Control) ..............33 ...

- Page 6 Composite Video ....................88 8.3 Proportional Outputs ..................88 8.4 Synchronisation Outputs ..................88 9 Features of the Sitescan 150 ................... 89 9.1 Functional Testing Methods ................89 10 Specifications........................90 11 Warranty .......................... 93 12 Index ..........................94 Page iv...

-

Page 7: How To Use This User's Guide

Section 5: Flaw Testing gives guidelines on performing flaw testing with examples of how to calibrate the Sitescan 150 and how to set up the unit for DAC, DGS/AVG and how to use the A-Scan storage facilities. Section 6: Thickness Gauging... -

Page 8: Disclaimers And Notices

Selection of the correct test equipment based on knowledge of the application. Competent training of the instrument operator. This user’s guide provides instruction in the basic operation of the Sitescan 150 flaw detector. In addition to the methods included, many other factors can affect the use of this flaw detector. -

Page 9: Testing Limitations

Sitescan 150 User’s Guide ~ Disclaimers and Notices 2.4 Testing Limitations In ultrasonic testing, information is obtained only from within the confines of the sound beam as it propagates into the test material. Operators must exercise great caution when making inferences about the nature of the test material outside the limits of the sound beam. -

Page 10: Effects Of Temperature On Calibration

Sitescan 150 User’s Guide ~ Disclaimers and Notices 2.5.4 Effects of Temperature on Calibration The sound velocity in test pieces and the transducer wear face changes with temperature variations. All calibrations should be performed on site with test blocks at or near the same temperature as that expected on the test piece, to minimize errors. -

Page 11: Disclaimer Of Liability

Sonatest Limited in connection with the use, features and qualifications of the Sitescan 150 are based on tests believed to be reliable, but the accuracy or completeness thereof is not guaranteed. Before using the product you should determine its suitability for your intended use based on your knowledge of ultrasonic testing and the characteristics of materials. -

Page 12: Quick Start

Sitescan 150 User’s Guide ~ Quick Start 3 Quick Start 3.1 Front Panel and Optional Keyboard Controls The front panel controls consist of a series sealed, pressure sensitive, tactile buttons that allow the instrument settings to be changed and the movement through the menus on the screen. - Page 13 Sitescan 150 User’s Guide ~Quick Start This button operates in connection with the plain grey buttons next to the parameter boxes to decrease the value or step the selection in the reverse direction. In the case of transducer , it moves the signals to...

- Page 14 This is a momentary button with no repeat action. Corresponds to the letter “F” when using the keyboard. This button selects the help menu which overlays the display. The help menu explains how the Sitescan 150 operates with a choice of three options: Using the Sitescan 150 Description of the active menu Calibration procedure.

- Page 15 Sitescan 150 User’s Guide ~Quick Start The full screen button is used to toggle between showing the A-Scan on the full display and showing it with the menus and parameter boxes as shown below: Full display is useful for maximising the size of the A-Scan while performing inspections.

- Page 16 Sitescan 150 User’s Guide ~ Quick Start Press to select the dB step value of amplifier gain as 0.1, 0.5, 1, 2, 6, 10, 14, or 20dB. The selected value is indicated at the top right-hand corner of the gain box, which is always located at the bottom right side of the screen.

- Page 17 Sitescan 150 User’s Guide ~Quick Start Used as acceptance of memory functions and when drawing Select main various measurement curves menu group Move menu Changes between Normal selection Left 4 “Soft” keys Move menu & Full screen views selection Right...

-

Page 18: Flaw Detection

Sitescan 150 User’s Guide ~ Quick Start 3.2 Flaw Detection Perform the following steps to establish a basic flaw detection mode for the Sitescan 150. Units shown are in inches. For metric units, select from the menu METRIC UNITS UTIL and use the corresponding values for the parameters. -

Page 19: Thickness Gauging

Sitescan 150 User’s Guide ~Quick Start 3.3 Thickness Gauging Perform the following steps to establish a basic thickness-gauging mode for the Sitescan 150. Units shown are in metric. For imperial units, select from the menu INCHES UTIL and use the corresponding values for the parameters. - Page 20 Sitescan 150 User’s Guide ~ Quick Start The Sitescan 150 is now configured for basic thickness gauging. Adjust parameters as necessary to optimize the calibration. For more in-depth features of the Sitescan 150, see Thickness Gauging on page 72. Page 14...

-

Page 21: Sitescan 150 Memory

Sitescan 150 User’s Guide ~Quick Start 3.4 Sitescan 150 Memory The settings of the Sitescan 150 always remain in memory when the instrument is turned off, even if the battery pack is removed. That is, whatever the settings are just prior to turning the instrument off will be the settings in place the next time the instrument is turned on. -

Page 22: Detailed Menu Description

4.1 Menu Tree This diagram represents the menu structure of the Sitescan 150; there are 4 main menu items with sub-menus below. The sub-menus are described in the following section. Page 16... - Page 23 Sitescan 150 User’s Guide ~Detailed Menu Description When The Sitescan 150 is switched on, an information screen is displayed momentarily showing the instrument serial number and software version number while a self-test is performed as shown below: Page 17...

-

Page 24: Main Menu

Sitescan 150 User’s Guide ~ Detailed Menu Description 4.2 Main Menu After the information screen disappears the main menu selections are shown on the right hand side of the screen. To select a particular menu press the plain grey button to the right of it. -

Page 25: Cal Menu

Sitescan 150 User’s Guide ~Detailed Menu Description 4.3 CAL Menu The CAL menu is the most used menu and contains those items that allow the Sitescan 150 to be easily calibrated. For full instruction on how to perform a calibration see... -

Page 26: Gate1 & Gate2 Menus

4.3.3 GATE1 & GATE2 Menus There are two gates available in the Sitescan 150 with slightly different options depending on the gate and the measurement mode chosen. The following describes the available settings for each gate with the differences between the gates stated. The gates can be identified by the fact that gate 1 has the number “1”... -

Page 27: A-Cal Menu

Sitescan 150 User’s Guide ~Detailed Menu Description 4.3.4 A-CAL Menu This menu provides automatic calibration of sound velocity and transducer zero. Gate 1 is used to select the reference echoes. See A-Cal on page for a full procedure. The actual distance to the first or thinnest reference echo in DIST1 the calibration block. -

Page 28: Meas Menu

Sitescan 150 User’s Guide ~ Detailed Menu Description 4.4 MEAS Menu The menus in this section allow the various measurement techniques to be configured; these include the general measurement set-up and specialist methods such as DAC, AVG, AWS and API. Select the menu at any time by pressing the button. - Page 29 Sitescan 150 User’s Guide ~Detailed Menu Description In this mode, gate 1 functions as a thickness monitor and MODE: measures the thickness between the first signal in the gate and the second signal in the gate that reaches or exceeds the level threshold.

-

Page 30: Csc (Curved Surface Correction)

Sitescan 150 User’s Guide ~ Detailed Menu Description 4.4.2 CSC (Curved Surface Correction) This menu allows the user to configure the Curved Surface Correction (CSC) parameters. This feature is used when testing pipes and other curved surfaces. In order for the... -

Page 31: Distance Amplitude Correction (Dac) Menu

Sitescan 150 User’s Guide ~Detailed Menu Description 4.4.4 Distance Amplitude Correction (DAC) Menu This menu is used to create DAC curves using a series of reference echoes. Once drawn, the DAC curve acts as an alarm threshold level for the gate where the level varies to match the attenuation and field characteristics of the transducer and test material combination. -

Page 32: Dgs/Avg

Sitescan 150 User’s Guide ~ Detailed Menu Description 4.4.5 DGS/AVG This menu is used to create a DGS/AVG curve that allows flaw sizing and distance compensation without requiring the standards for establishing a DAC curve or to set up a TCG correction. - Page 33 Sitescan 150 User’s Guide ~Detailed Menu Description Used to define the various reference values MODE: SET REF Used to set the curvature correction factor in dB and is taken from the transducer datasheet. Used to select the reference reflector type: Flat Bottom Hole...

-

Page 34: Aws Menu

Sitescan 150 User’s Guide ~ Detailed Menu Description 4.4.6 AWS Menu This menu is used when performing weld inspection in accordance with the American Welding Society’s Structural Welding Code, ANSI/AWS D1.1-94. It provides a convenient method to automatically calculate the Indication Rating as defined in the code. The AWS... -

Page 35: Aws Menu

Sitescan 150 User’s Guide ~Detailed Menu Description 4.4.7 AWS Menu This menu is used when performing weld inspection in accordance with the American Welding Society’s Structural Welding Code, ANSI/AWS D1.1-94. It provides a convenient method to automatically calculate the Indication Rating as defined in the code. The AWS... -

Page 36: Api Menu

Sitescan 150 User’s Guide ~ Detailed Menu Description 4.4.8 API Menu This menu is used to assist users in performing tests according to the American Petroleum Institute (API) Recommended Practice for Ultrasonic Evaluation of Pipe Imperfections using the Amplitude Distance Differential Method (ADDM). Users are referred to the publication: “API Recommended Practice 5UE, Second Edition, June 2005”... -

Page 37: Util Menu

Sitescan 150 User’s Guide ~Detailed Menu Description 4.5 UTIL Menu Press the button followed by the plain gray button next to to select these jbkr UTIL menu options. The items in this section allow the user to configure features such as units, display preferences, language, back wall echo attenuation (BEA), print options, proportional output configuration and date and time settings. -

Page 38: Misc Menu

Sitescan 150 User’s Guide ~ Detailed Menu Description 4.5.3 MISC Menu Selects one of 6 built in languages or a user selectable LANG language. The built in languages are selectable at time of ordering the Sitescan 150. Allows the user to display a vertically compressed A-Scan in... -

Page 39: Agc (Automatic Gain Control)

NOTES: When the Sitescan 150 is switched on the AGC is turned OFF. The gain value that is last set by AGC remains when AGC is switched off. ... -

Page 40: Print Menu

PRINT Menu This menu allows printing of information to a suitable USB printer connected to the USB port on the Sitescan 150. Please note that this requires a printer with a USB port from the Sonatest certified list of printers. -

Page 41: P_O/P Proportional Output Control Menu

Sitescan 150 User’s Guide ~Detailed Menu Description 4.5.6 P_O/P Proportional Output Control Menu This menu controls the analogue and digital proportional outputs. Two outputs are provided. The outputs are active when the associated gate is triggered and are updated at the PRF. -

Page 42: Memory Menu

Sitescan 150 User’s Guide ~ Detailed Menu Description 4.6 MEMORY Menu Press the button then the plain grey button next to the option to access jbkr MEMORY the Memory menu. These menus allow the user to save panel settings, A-Scans and thicknesses as well as recalling an A-Scan to be used as a reference. -

Page 43: A-Log Memory Menu

Sitescan 150 User’s Guide ~Detailed Menu Description 4.6.2 A-LOG Memory Menu This menu provides storage and recall of up to 800 A-Scans with settings. The use of this feature is described fully in A-LOG, A-Scan Storage on page Used to select a storage location (1-800). Pressing the grey... -

Page 44: Ref Menu

Sitescan 150 User’s Guide ~ Detailed Menu Description 4.6.3 REF Menu This menu allows a waveform stored in A-LOG memory to be displayed as a reference on the display. Before a waveform can be recalled, it must be stored in an A-LOG location as described above. -

Page 45: T-Log Menu Sequential Mode

Readings are stored by block (1-14) and location (1-8000) number combination only. In this mode location and historical thickness data can be downloaded to the Sitescan 150 from a computer, a fixed series of four notes can be added to a location. This feature is described fully in T-LOG Thickness Storage (Sequential &... -

Page 46: Storage & Recall Of Calibration Setups

Although the last panel settings are “remembered” by the Sitescan 150’s memory, this feature is useful when the instrument is being used for many different tests requiring substantially different panel calibration settings. - Page 47 Sitescan 150 User’s Guide ~Detailed Menu Description When a panel calibration or waveform is to be stored, first calibrate the instrument as desired, or capture the waveform by pressing the button. Then select the EDIT box in the menu and notice that the window shown below overlays the display area.

-

Page 48: Edit Notes Summary

Sitescan 150 User’s Guide ~ Detailed Menu Description NOTE: When notes are displayed, the menu cursor buttons are disabled. Exit the Notes window to change to another menu. The following shows a completed notes window: 4.7.5 Edit Notes Summary The following sections provide a summary of the navigation techniques needed to edit notes using either the front panel keypad or the optional USB keyboard: 4.7.5.1... - Page 49 Sitescan 150 User’s Guide ~Detailed Menu Description Small Character & Press any key on the keyboard to edit the characters, the same Numbers applies to numbers. Capital Character Press SHIFT + the wanted character or sign. & Signs Insert a Space Press the space bar to insert a blank character at the position the cursor is currently on.

-

Page 50: Flaw Testing

Fabricated discontinuities must also be placed near the front and back surface of the calibration block to verify resolution of the transducer and instrument setting combination. Finally, it is necessary to establish the proper calibration of the Sitescan 150 in order to assure reliable flaw detection. Page 44... -

Page 51: Flaw Testing Calibration

The essence of this calibration is to set the pulser, amplifier and gate parameters to provide the necessary sensitivity and resolution. The Sitescan 150 has an automatic calibration technique that sets the necessary parameters by using a calibration block that has known thicknesses;... - Page 52 Sitescan 150 User’s Guide ~ Flaw Testing 9. The distance between the echoes is shown in the G-G measurement at the bottom of the display (in this case 125.54). It is unlikely that the value will be exactly correct as the velocity of sound in the material will not match one of the preset values.

- Page 53 Sitescan 150 User’s Guide ~Flaw Testing 12. The distance measurement is shown at the bottom of the display (in this case 151.04). From the menu adjust the value until the correct distance is shown as ZERO below: 13. As a final check move the gate across the other echoes to ensure that the correct distances are shown;...

- Page 54 Sitescan 150 User’s Guide ~ Flaw Testing Now that the Sitescan 150 has been calibrated it can be used to perform inspections using any of the techniques described in the following sections. For weld inspection using an angle beam transducer, follow the instructions in Weld Inspection Using Trigonometry Mode on page 51.

-

Page 55: Dac Operation

To establish a DAC curve, follow the following instructions: 1. Establish the basic calibration of the Sitescan 150 using the desired transducer and the proper reference block. From the menu, select the feature. - Page 56 Sitescan 150 User’s Guide ~ Flaw Testing along with the -6dB and -12dB curves, the -6dB and -14dB curves or -2dB, -6dB and - 10dB curves. These additional, automatically generated, reference curves provide a method for helping to evaluate discontinuities smaller than those in the reference block.

-

Page 57: Weld Inspection Using Trigonometry Mode

The trigonometry mode provides a convenient method for measuring the location of discontinuities when inspecting welds with angle beam transducers. Essentially, the trigonometry mode uses the thickness gauging features of the Sitescan 150 to calculate the surface distance and depth to a discontinuity from the actual beam path measured. This is accomplished by calibrating the trig mode with the actual refracted angle of the transducer being used. - Page 58 Sitescan 150 User’s Guide ~ Flaw Testing discontinuity if the user properly calibrates the Sitescan 150 and uses care to locate the desired peak amplitude signal to which a measurement is made. To calibrate and use the trigonometry mode, follow the following instructions: 1.

-

Page 59: Weld Inspection Using The Aws Menu

The AWS menu will not operate with either the DAC switched on. To set up the AWS measurements, perform the following: 1. Calibrate the Sitescan 150 for weld testing and set up the trigonometry mode by following the steps in Weld Inspection Using Trigonometry Mode on page 54. - Page 60 It is not necessary to bring the indication to the reference level to obtain the correct measurement information as the Sitescan 150 adjusts for gain offset. However, to ensure the best accuracy of calculation, it is advised to adjust the indication to be above 40% and below 100% of full screen height.

-

Page 61: Evaluation Of Pipe Imperfections Using Api 5Ue

Sitescan 150 User’s Guide ~Flaw Testing 5.6 Evaluation of Pipe Imperfections using API 5UE The Sitescan 150 is able to assist the user in making measurements in accordance with the American Petroleum Institute (API) Recommended Practice for Ultrasonic Evaluation of Pipe Imperfections using the Amplitude Distance Differential Method (ADDM). - Page 62 Sitescan 150 User’s Guide ~ Flaw Testing The Sitescan 150 automatically goes into mode. Pressing the button again FREEZE puts the API facility into measurement mode as shown below. The k value is displayed but cannot be changed while in measurement mode.

- Page 63 Sitescan 150 User’s Guide ~Flaw Testing Once the measurement has been made, pressing the button clears the current reading. To take the next measurement select peak mode by pressing the button twice. Page 57...

-

Page 64: Dgs/Avg Operation

Sitescan 150 User’s Guide ~ Flaw Testing 5.7 DGS/AVG Operation The DGS (Distance Gain Size) method, often known by its German acronym AVG (Amplituden Vergleichs Größe), allows a theoretical model to be used for assessment of ultrasonic echoes. The DGS/AVG method allows flaw sizing and distance compensation without requiring the large range of reference standards for each test which would be required in order to establish a measured DAC curve, or to set up a TCG correction. - Page 65 Sitescan 150 User’s Guide ~Flaw Testing Where is the probe effective diameter and is the wavelength (Velocity/Frequency) The echo height from a small (much less than sound field width) reflector will be proportional to its size.

-

Page 66: Dgs/Avg ~ Frequency, Tbvel And Ers

Sitescan 150 User’s Guide ~ Flaw Testing 5.7.2 DGS/AVG ~ Frequency, TBVEL and ERS from the probe data sheet FREQ – Reference (Calibration) Block Velocity, in meters per second TBVEL This parameter is used internally and will take the same range of values as the Velocity parameter. -

Page 67: Dgs/Avg ~ T-Loss, Ref And Mat

Sitescan 150 User’s Guide ~Flaw Testing – Probe Delay Velocity, in meters per second DELAY This is the velocity of compressive sound waves in the material of the probe wedge. It is used mostly in angle probes but also in zero degree compression probes which have a delay line. -

Page 68: Dgs/Avg ~ Dvk, Ref Type And Refsize

Sitescan 150 User’s Guide ~ Flaw Testing Attenuation of Ultrasound in the material of the object under test in dB per Meter are used where the ultrasound attenuation in these materials is such that it would cause a disparity in signal heights between similar reflectors in these materials. -

Page 69: Dgs/Avg Calibration

Sitescan 150 User’s Guide ~Flaw Testing FBH – Flat Bottom Hole SDH – Side Drilled Hole Reference type SDH is converted internally to the equivalent DSR diameter according to the formulae in EN 583-2:2001 Annex B. When using reference SDH reflectors it is essential to select the correct calibration (test) block velocity ( ). -

Page 70: Adjustment

Sitescan 150 User’s Guide ~ Flaw Testing The calibration of the DGS/AVG system sets the Probes ‘absolute sensitivity’ based on the response from the reference block. Changing any parameters relating to the reference echo will invalidate the calibration, which must then be repeated. The current version of the software does not enforce this – it is the responsibility of the operator. - Page 71 Sitescan 150 User’s Guide ~Flaw Testing Gain may be adjusted with understanding – Changing the Gain setting will remove the correlation with the DGS/AVG curve, so should only be done in accordance with a specification , for example to compensate for varying material conditions (better done with the T-LOSS function).

-

Page 72: Measurement

Sitescan 150 User’s Guide ~ Flaw Testing Decreasing Gain by 6dB returns to original height, but loses measurement The Reference gain may be selected by pressing the Button. (DGS/AVG is only obcLd^fk appropriate for Single probe mode) When the Display Range or REF Gain is changed the DGS/AVG curve will recalculate at each step. -

Page 73: A-Log, A-Scan Storage

A-Scan and its settings will allow for easy follow-up inspection of the same indication on the test piece. Simply unfreeze the display after recalling and the Sitescan 150 is ready to repeat the same inspection. Be sure to use the same transducer that was used for the original recording. -

Page 74: To Recall An A-Scan

Sitescan 150 User’s Guide ~ Flaw Testing 6. Press the button to store the waveform and instrument settings; the display will show a dialogue box: At the prompt, press the button again to store the A-Scan or press the CONFIRM button to continue without storing the A-Scan. -

Page 75: To Delete A Stored A-Scan

Sitescan 150 User’s Guide ~Flaw Testing press the button to recall it. To remove the notes review window, set the MODE back to STORE RECALL DELETE 5.8.3 To Delete a Stored A-Scan Follow the steps above but set the parameter to... -

Page 76: Peak Echo & Hold Dynamics

Sitescan 150 operate more like an older analogue flaw detector. Only the trailing edge is modified so that depth measurements using FLANK and PEAK are not effected. - Page 77 This is a quick and useful to way to make comparisons between echoes. Hold mode can be activated by pressing the button three times. Pressing the button again will return the Sitescan 150 to its normal mode of operation. Page 71...

-

Page 78: Thickness Gauging

This will allow for verification of the calibration. It is possible to calibrate the Sitescan 150 using a generic test block and only one known sample thickness of the material under inspection. This is a less desirable method because there is no way of verifying the calibration. - Page 79 This established the sound velocity for the test material. Finally, it is necessary to establish the proper calibration of the Sitescan 150 in order to assure accurate and reliable thickness testing. The essence of this calibration is to set the pulser and amplifier characteristics to provide sharp leading edges on the echoes.

- Page 80 Sitescan 150 User’s Guide ~ Thickness Gauging 12. To calibrate the Sitescan 150 for thickness readings, follow the steps outlined in A-Cal on page 75. Alternately, you can use an iterative process from the menu of setting on the thinnest calibration block sample and the...

-

Page 81: A-Cal

The A-CAL feature automates this process so that only two readings are required, one on the thin sample and one on the thick sample. The Sitescan 150 then calculates the correct offset and span factors and sets the velocity and zero. Any time the test material is changed (velocity) or the transducer is changed (zero);... - Page 82 Note that this is a convenient method for determining the velocity of sound in an unknown material. Once the Sitescan 150 is calibrated on a known material, all that needs to be known is one fixed thickness point and the velocity can be determined.

-

Page 83: T-Log Thickness Storage (Numeric)

Sitescan 150 User’s Guide ~Thickness Gauging 6.3 T-LOG Thickness Storage (Numeric) The T-LOG menu provides a convenient method to store thickness readings for record keeping and analysis. The maximum number of readings that can be stored is 8,000. When using... -

Page 84: T-Log Thickness Storage (Sequential & Download)

32 characters. The text strings of 32 characters are subsequently displayed on the Sitescan 150 as two lines of 16 characters each in a table at the bottom of the screen, when the Sitescan 150 is in the Sequence mode. Generally, the first 16 characters are used to identify the location so as to direct the operator to the proper point for a thickness reading. - Page 85 Sitescan 150 User’s Guide ~Thickness Gauging 6. To attach one of the four available notes with the reading, press the plain grey select button next to the option, and using the buttons, select NOTES OBSTRC (obstruction), (poor surface contact), or...

-

Page 86: T-Log Editing And Printing

Sitescan 150 User’s Guide ~ Thickness Gauging 6.5 T-Log Editing and Printing The T-LOG menu provides capability for the deletion of thickness reading stored with the T- LOG feature. With the T-LOG mode set to , it is possible delete a single location, DELETE all locations within a block, or all blocks (all readings). -

Page 87: To Print Thickness Logs

Sitescan 150 User’s Guide ~Thickness Gauging 3. Set the Block number to by pressing the plain grey button next to the BLOCK parameter and using the button if not already selected. The location number will be automatically set to 4. Press the button to delete the thickness reading for all of the blocks and locations. -

Page 88: Power Supply

7 Power Supply The Sitescan 150 is powered by a Lithium-Ion battery pack, which is shown below. The battery pack attaches to the rear of the Sitescan 150 with two thumbscrews and connects to the instrument via two terminal contact points. - Page 89 Please note that the specified temperature range of the battery may exceed that of the Sitescan 150. In such cases, the Sitescan 150 may not work properly because it is out of its operating temperature range.

-

Page 90: Battery Charging

10 (the default) or for 9 hours with a brightness of 20. The battery pack can be charged while mounted to the Sitescan 150 by use of the connector on the front panel. Alternately, the battery pack can be charged separate from the Sitescan 150 by using its own connector shown above allowing continued operation of the Sitescan 150 with the use of multiple battery packs. - Page 91 Sitescan 150 User’s Guide ~ Power Supply WARNING – The CH700 is a battery charger only. Any attempt to use it to power a Sitescan 150, without a battery fitted, WILL damage your CH700-P battery charger. Page 85...

-

Page 92: Interface Connections

Sitescan 150 User’s Guide ~ Interface Connections 8 Interface Connections There is a 6-pin connector on the front of the Sitescan 150 as shown below: This connector is used to connect the flaw detector to a PC using a modified USB cable; this allows information to be transferred to the computer using Sonatest’s program SDMS. -

Page 93: Rs232

Sitescan 150 User’s Guide ~ Interface Connections 8.1 RS232 The RS232 port on the Sitescan 150 allows for bi-directional communication between the instrument and a personal computer. Various control commands are available within three general categories; Write parameter values, Read parameter values, and Action commands. -

Page 94: Composite Video

Sitescan 150 User’s Guide ~ Interface Connections 8.2 Composite Video The composite video output is for connecting the Sitescan 150 to a compatible video monitor or projector. The output is either NTSC (USA/Japan) or PAL (UK/Europe), depending on the VIDEO selection in the UTIL menu. The screen update rate is 50Hz in PAL and 60Hz in NTSC. -

Page 95: Features Of The Sitescan 150

Sitescan 150 User’s Guide ~ Features of the Sitescan 150 9 Features of the Sitescan 150 The Sitescan 150 is a user-friendly ultrasonic digital flaw detector and thickness gauge, which is simple to use and provides the experienced ultrasonic operator with a full-function device that incorporates many productivity enhancing features. -

Page 96: Specifications

Sitescan 150 User’s Guide ~ Specifications 10 Specifications Feature Details Test Range 0 – 5mm (0.2in) up to 0 – 10,000 mm (400 in.) at steel velocity. Variable in 1mm &10mm steps Velocity 1,000 to 9,999m/s continuously variable. Probe Zero 0 to 999.999 μs, continuously variable. - Page 97 Sitescan 150 User’s Guide ~ Specifications Feature Details Measurement Modes Mode 1 Signal Monitor Mode 2 Depth and amplitude of first signal in gate. Mode 3 Echo-to-Echo distance measurement. (single gate) Mode 4 Trigonometric display of beam path, surface distance and depth of indication, curve surface correction and X-OFFSET for probe index.

- Page 98 Sitescan 150 User’s Guide ~ Specifications Feature Details Notes Alphanumeric labelling for panel and A-log allows the user to enter Notes for storage with panel settings and A-scans. Display Freeze For capturing the current A-scan image. Peak Memory For echodynamic pattern determination.

-

Page 99: Warranty

Sonatest. Sonatest will make good by repair or by the supply of a replacement or by equivalent adjustment of the price at our sole option, any defects which under proper use appear in... -

Page 100: Index

Sitescan 150 User’s Guide ~ Index 12 Index BEA(Backwall Echo Attenuator) · 32 Beam · 3, 7, 24, 45, 49, 50, 52, 53, 54, 59, A 71, 73, 90, 92 Beam Path Distance · 24, 52 A-CAL Menu · 22 Blank ·... - Page 101 Sitescan 150 User’s Guide ~ Index Convex · 25 E Corrosion · 73 Couplant · 4 Echo Dynamic · 7, 57, 71 Coupling · 4, 27, 28, 50, 62, 71 Edit Notes · 43, 70 Crack Diffraction · 90 Summary · 43 Critical Operating Factors ·...

- Page 102 Sitescan 150 User’s Guide ~ Index Gate · 21, 22, 23, 24, 26, 31, 32, 34, 36, Main Menu Selection · 19 46, 47, 48, 50, 51, 54, 56, 65, 67, 74, MEAS · 6, 12, 14, 19, 23, 25, 26, 29, 30,...

- Page 103 Sitescan 150 User’s Guide ~ Index P R P_O/P Proportional Output Control Range · 4, 12, 14, 20, 21, 34, 46, 50, 53, Menu · 36 59, 61, 65, 66, 67, 70, 73, 74, 76, 84, PAL · 16, 32, 89, 91, 93 85, 91 Panel ·...

- Page 104 Sitescan 150 User’s Guide ~ Index Sound Velocity · 3, 4, 22, 45, 73, 74, 90 T-Min · 92 Specific Warnings · 2 Training · 2, 3 Specifications · 3, 91 Transducer (Probe) Zero Procedure · 3 split screen · 9, 33 Transducer Condition ·...

- Page 105 Sitescan 150 User’s Guide ~ Index Weld Inspection Using Trigonometry W Mode · 45, 49, 52, 54 Width · 2, 20, 21, 24, 26, 28, 60, 64, 67, Warranty · 94 71, 77, 91 Wave · 2, 20, 56, 62, 67, 90, 91 Wavelength ·...

Need help?

Do you have a question about the Sitescan 150 and is the answer not in the manual?

Questions and answers