Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Resol DeltaSol CS/2

-

Page 1: Application Examples

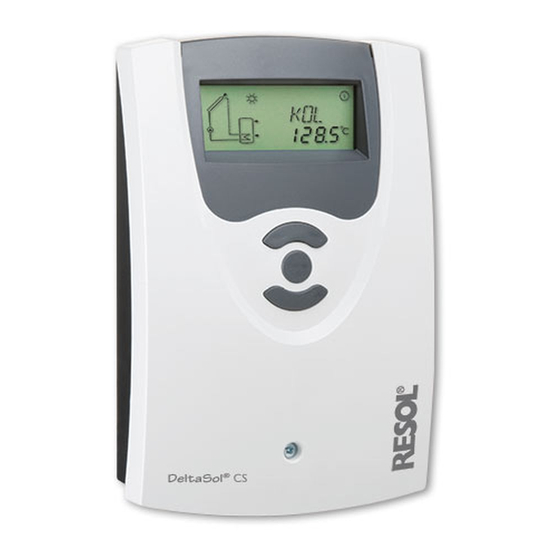

® CS/2 DeltaSol Mounting Connection Application examples Operation Troubleshooting Thank you for buying this RESOL product. Manual Read this manual carefully to get the best perfomance from this unit. Please keep this manual carefully. www.resol.com... - Page 2 Safety advice Information about the product Please pay attention to the following safety advice in order to avoid danger and Proper usage damage to people and property. The solar controller is designed for use in solar thermal systems and heating sys- tems in compliance with the technical data specified in this manual.

-

Page 3: Table Of Contents

Contents Installation ................... 5 1.1 Mounting ........................5 1.2 Electrical connection ....................6 1.3 VFD Grundfos Direct Sensor™ ................7 1.4 PWM output........................7 1.5 Data communication / Bus ..................7 1.6 Terminal allocation .......................8 Operation and function ..............11 2.1 Push buttons ....................... 11 2.2 System-Monitoring-Display .................. - Page 4 Power consumption: < 1 W (standby) • Extra-low power consumption Mode of operation: type 1.C.Y action • HE pump control Rated impulse voltage: 2.5 kV • Drainback option Data interface: RESOL VBus ® VBus ® current supply: 35 mA Functions:...

-

Page 5: Installation

Installation Mounting display The unit must only be installed • in a dry interior location • in a non-hazardous location • away from electromagnetic fields The controller must additionally be supplied from a double-pole switch with con- tact gap of at least 3 mm. Route sensor cables and power supply cables separately. cover push Î... -

Page 6: Electrical Connection

Connecting the device to the mains supply must always be the last step of the Electrical connection installation! WARNING! ESD damage! The power supply to the controller must be carried out via an external power Electrostatic discharge can lead to damage to electronic com- switch (last step!). -

Page 7: Vfd Grundfos Direct Sensor

PWM output connection terminals The speed of a HE pump is adjusted through a PWM signal. In addition to con- The controller is equipped with a RESOL VBus for data transfer with and energy ® nection to the relay, the pump must be connected to the PWM output of the supply to external modules. -

Page 8: Terminal Allocation

Terminal allocation System layout 1 The controller calculates the temperature difference between collector sensor Sensors S3 and S4 can optionally be connected for measurement purposes. S3 can S1 and store sensor S2. If the difference is larger than or identical to the adjusted optionally be used as reference sensor for the store emergency shutdown option switch-on temperature difference (DT O), the solar pump will be operated by relay (OSEM). - Page 9 Display Channels Channel Description Terminal Page INIT ODB initialisation active ODB filling time active STAB ODB stabilisation in progress Temperature collector Temperature store Temperature sensor 3 TSTT Temperatur store at the top Temperature sensor 4 Temperature flow sensor S1 / S4 / VFD Temperature return sensor S4 / VFD Temperature Grundfos Direct Sensor™...

-

Page 10: Channel Description

Adjustment Channels Channel Description Factory setting Page OHOL Option holiday cooling THOL Holiday cooling temperature 40 °C [110 °F] Option minimum limitation Minimum collector temperature 10 °C [50 °F] Option antifreeze Antifreeze temperature 4.0 °C [40.0 °F] Grundfos Direct Sensor™ <?>... -

Page 11: Operation And Function

bar and system screen. Operation and function Push buttons channel display forward (+) The system monitoring display consists of three blocks: channel display, tool (selection / ad- bar and system screen. justment mode) The channel display consists of two lines. The upper line is an alpha-numeric backward (-) 16-segment display (text display) for displaying channel names and menu items. -

Page 12: Flashing Codes

System screen Flashing codes System screen flashing codes • Pumps are flashing when the corresponding relay is switched on • Sensor symbols are flashing if the corresponding sensor display channel is selected • Sensors are flashing quickly in the case of a sensor fault •... -

Page 13: Commissioning

Commissioning forward (+) (selection / adjustment mode) UNIT: backward (-) Temperature unit selection Selection: °C, °F The three push buttons of the CS/2 controller Factory setting: °C Î Establish the power supply 2. Unit The controller runs an initialisation phase. Î... - Page 14 5. Minimum pump speed Î Adjust a minimum speed for the pump Note: If loads which are not speed-controlled (e.g. valves) are used, the value must be set to 100 %. Pump control type Selection: OnOF, PULS, PSOL, PHEA Factory setting: PSOL 4.

-

Page 15: Channel Overview

Channel overview Indication of collector temperature Display channels Note: The displayed values and adjustment channels depend on which options and functions have been selected. Only values and adjustment channels available for the individual settings selected will appear in the menu. Indication of drainback time periods Collector temperature Initialisation... - Page 16 Indication of sensors 3, 4 and VFD Indication of flow rate S3, S4, VFD Sensor temperatures Flow rate Display range: -40 … +260 °C [-40 … +500 °F] Display range: depends on the sensor type VFD: 0 … 100 °C [32 … 212 °F] Indicates the current flow rate at the VFD flow rate sensor.

-

Page 17: Adjustment Channels

Adjustment channels The display symbol Ⓢ will flash and the heat quantity value will be set to 0. Î Confirm the reset with button 3 in order to finish the reset. ∆T control In order to interrupt the RESET-process, do not press a button for about 5 s. The display returns to the display mode. - Page 18 Pump speed control DT S Nominal temperature difference Pump control type Adjustment range: 1.5 … 30.0 K [3.0 … 60.0 °Ra] Selection: OnOF, PULS, PSOL, PHEA Factory setting: 10.0 K [20.0 °Ra] Factory setting: PSOL With this parameter, the pump control type can be adjusted. The following types can be selected: Adjustment for standard pump without speed control •...

- Page 19 Minimum pump speed Maximum store temperature S MX Minimum pump speed Maximum store temp. Adjustment range: (10) 30 … 100 % Adjustment range: 4 … 95 °C [40 … 200 °F] Factory setting: 30 % Arr 3: 4 … 90 °C [40 … 190 °F] A relative minimum pump speed can be allocated to the output R1 via the adjust- Factory setting: 60 °C [140 °F] ment channel nMN.

- Page 20 Collector temperature limitation Collector cooling function Emergency shutdown of the collector Option collector cooling Adjustment range: OFF / ON Collector temperature limitation Factory setting: OFF Adjustment range: 80 … 200 °C [170 … 390 °F] Factory setting: 130 °C [270 °F] If the adjusted collector emergency shutdown temperature (EM) is exceeded, the controller switches off the solar pump (R1) in order to protect the system against overheating (collector emergency shutdown).

- Page 21 System cooling function DTCF OSYC Switch-off temperature diff. Option system cooling Adjustment range: 0.5 … 29.5 K [1.0 … 59.0 °Ra] Adjustment range: OFF / ON Factory setting: 15.0 K [30.0 °Ra] Factory setting: OFF Note: This function will only be available if the collector cooling function (OCC) is deactivated.

- Page 22 Collector minimum limitation option THOL Holiday cooling temperature Collector minimum limitation Adjustment range: 20 … 80 °C [70 … 175 °F] Adjustment range: OFF / ON Factory setting: 40 °C [110 °F] Factory setting: OFF When the store cooling function is activated, the controller aims to cool down the store during the night in order to prepare it for solar loading on the following day.

- Page 23 Heat quantity measurement OHQM: Antifreeze temperature Heat quantity measurement Adjustment range: -40.0 … +10.0 °C [-40.0 … +50.0 °F] Adjustment range: OFF / ON Factory setting: 4.0 °C [40.0 °F] Factory setting: OFF The antifreeze function activates the loading circuit between the collector and If OHQM is activated, the heat quantity gained can be calculated and displayed.

- Page 24 Heat quantity measurement with a VFD Grundfos Direct Sensor™ Heat transfer fluid: 0 : Water Heat quantity measurement with a VFD Grundfos Direct Sensor™ is possible in all system layouts. 1 : Propylene glycol 2 : Ethylene glycol In order to use a VFD Grundfos Direct Sensor™ for heat quantity measurement, proceed as follows: 3 : Tyfocor LS / G-LS...

- Page 25 Time period - switch-on conditions ODB: tDTO: Drainback option Time period - switch-on conditions Adjustment range: OFF / ON Adjustment range: 1 … 100 s Factory setting: OFF Factory setting: 60 s Note: The parameter tDTO is used for adjusting the time period during which the When the drainback option ODB is activated, the cooling functions switch-on condition DT O must be permanentely fulfilled.

- Page 26 Operating mode Unit UNIT: Temperature unit selection Operating mode Selection: °C, °F Adjustment range: OFF, Auto, ON Factory setting: °C Factory setting: Auto In this adjustment channel, the display unit for temperatures and temperature dif- For control and service work, the operating mode of the controller can be man- ferences can be chosen.

-

Page 27: Troubleshooting

Troubleshooting On the display the symbols ☍ and ⚠ appear. fuse Sensor defect. An error code instead of a temperature is displayed Made in Germany in the sensor display channel. 100 ... 240 V~ DeltaSol CS/2 ® 50-60 Hz IP 20 888.8 - 88.8 1 (1) A 240 V~... -

Page 28: Various

Pump starts up very late Display off. Check the power supply. Is it disconnected? Switch-on temperature difference ∆Ton to large? Change ∆Ton and ∆Toff correspond- ingly. Check the supply line The fuse of the controller could be and reconnect it. blown. - Page 29 Store cools down at night Control the non-return valve in Further pumps which are connect- Collector circuit pump runs during warm water circulation - o.k. ed to the solar store must also be Check controller: the night? checked. Manual operation active? Tube collector function active? Store Clean or replace it cooling or antifreeze function active?

-

Page 30: Accessories

RESOL SP10 Article no.: 180 110 70 Large Display GA3 The RESOL Large Display GA3 is designed for simple connection to RESOL con- trollers via the RESOL VBus ® . It is used for visualizing the data issued by the con- troller: collector and store temperature as well as heat quantity produced in the solar system. - Page 31 Thus, controller access and data charting can graphic display. Transfer data with an SD memory card or use the LAN interface to be effected from every workstation of the network. A full version of the RESOL view and process data on your PC.

- Page 32 This mounting- and operation manual including all parts is copyrighted. Anoth- some examples. They can only be used at your own risk. No liability is assumed for er use outside the copyright requires the approval of RESOL – Elektronische incorrect, incomplete or false information and / or the resulting damages.

Need help?

Do you have a question about the DeltaSol CS/2 and is the answer not in the manual?

Questions and answers