Summary of Contents for Pfaff 8362-004

-

Page 1: Instruction Manual

® Industrial 8362 -004 -045 INSTRUCTION MANUAL This instruction manual applies to machines from the following serial numbers onwards: # 15186 296-12-18 496/002 Betriebsanleitung engl. 06.09... - Page 2 This Instruction Manual is valid for all models and subclasses listed in the chapter "Specifications ". The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or in part, is only permitted with our previous authorization and with written reference to the source.

-

Page 3: Table Of Contents

Replacing the feed rollers ..................9 - 2 Adjusting the feed-roller clearance ................9 - 3 .03.01 Adjusting the feed-roller clearance on the PFAFF 8362-004 ........9 - 3 .03.02 Adjusting the feed-roller clearance on the PFAFF 8362-045 ........9 - 3 Adjusting the heat-sealing pressure ................ -

Page 4: Contents

Changing the hot wedge on the PFAFF 8362-004 ........... 11 - 2 .03.02 Grinding in the hot wedge (only on the PFAFF 8362-004) ........11 - 3 .03.03 Replacing the heating wedge on the PFAFF 8362-045 ..........11 - 4 Replacing the fuse .................... -

Page 5: Safety

Safety Safety Directives This machine was built in accordance with the European regulations listed in the Conformity decalaration and Manufacturer’s declaration In addition to this Instruction manual, also observe all generally accepted, statutory and other regulations and legal requirements - also those of the country in which the machine will be operating - and all valid environmental-protection regulations! The regionally valid regulations of the social insurance society for occupational accidents or other supervisory organisations are to be strictly adhered to! -

Page 6: Safety Symbols

Safety Safety symbols Danger! Points to be observed. Danger point! Danger of injury to operating or specialist personnel! Hot surface! Danger of burns to operating or specialist personnel! Electric voltage! Danger to operating or specialist personnel from electric voltage! Important points for the user ●... -

Page 7: Specialist Personnel

Safety Specialist personnel .05.02 Specialist personnel are persons with a specialist education in the fields of electrics, electronics and mechanics. They are responsible for the lubrication, maintenance, repair and adjustment of the machine. The specialist personnel is obliged to observe the following points and must: ●... -

Page 8: Proper Use

Proper use Proper use The PFAFF 8362 is a heating-wedge manual heat-sealing machine with self-drive. The machine manufactures overlapping heat-seals, with or without a test channel, on plastics suitable for this purpose (thermoplastics), such as truck awnings, pool covers, roof and building insulations etc. -

Page 9: Specifications

................230 V ± 10%, 50/60 Hz, 1 Phase can be reconnected to: ................115 AC, L/N/PE Power consumption: 8362-004 ........................400 W 8362-045 ........................500 W Heating performance: ..................400 W / 220 V Motor: ....................24V, 2,5 A regulated Heat-sealing pressure: .................... -

Page 10: Disposal Of The Machine

Disposal of the machine Disposal of the machine ● The proper disposal of the machine is the responsibility of the customer. ● The materials used on the machine are steel, aluminium, brass and various plastics. The electrical equipment consists of plastics and copper. ●... -

Page 11: Transport Packaging And Storage

Transport packaging and storage Transport packaging and storage Transport to the customer’s premises Within Germany, the machine is delivered without packaging. Machines are packaged for export. Transport within the customer’s premises The manufacturer carries no liability for transport within the customer’s premises or to other locations where it is to be used. -

Page 12: Explanation Of The Symbols

Explanation of the symbols Explanation of the symbols In the following section of this Instruction manual, certain tasks or important pieces of information are accentuated by symbols. The symbols used have the following meanings: Note, information Clean, care Lubrication, greasing, oiling Servicing, repair, adjustment, maintenance 6 - 1... -

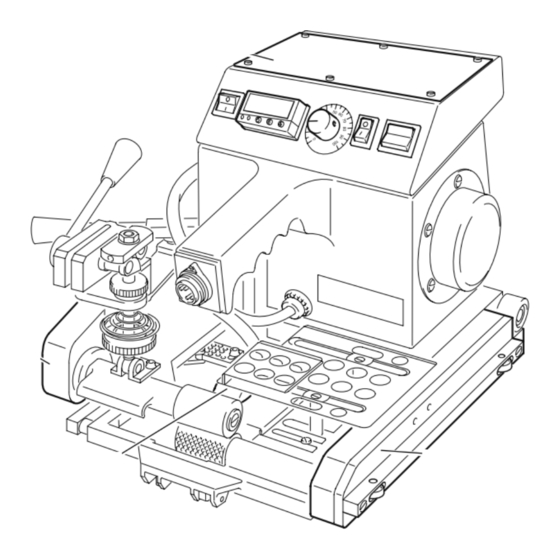

Page 13: Controls

Controls Controls Summary of the control elements Fig. 7 - 01 1. Mains switch, see Chapter 7.02. 2. Microprocessor controller for the heat-sealing temperature, see Chapter 7.03. 3. Controller for the heat-sealing speed, see Chapter 7.04. 4. Selection switch for the operating mode, see Chapter 7.05. 5. -

Page 14: Mains Switch

Controls Mains switch By pressing the mains switch 1 the machine is switched on or off. Position "0 0 0 0 0 " : Machine is switched off Position "1 1 1 1 1 " : Machine is switched on When switching off the machine, please observe the notes in Chapter 8.02... -

Page 15: Controller For The Heat-Sealing Speed

Controls Controller for the heat-sealing speed ● The heat-sealing speed can be altered by turning controller 1. Fig. 7 - 04 Selection switch for the operating mode The operating mode can be selected by pressing switch 1. Position "0": Feed rollers start after the hot wedge has been engaged Position "1": Feed rollers run constantly Fig. -

Page 16: Selection Switch For The Operating Direction

● The hot wedge can be engaged and disengaged with lever 1. When disengaging the hot wedge, take care to see that lever 1 clicks into position. The adjacent illustration shows the standard machine version (PFAFF 8362-004). Fig. 7 - 07 7 - 4... -

Page 17: Lever For Lowering The Feed Roller

Controls Lever for lowering the feed roller ● Lever 1 is used to lower and raise the top feed roller 2. The adjacent illustration shows the standard machine version (PFAFF 8362-004). Fig. 7 - 08 7 - 5... -

Page 18: Commissioning The Machine

Before starting the machine for the first time, inspect the entire heat-sealing machine for transport damage. If damage is apparent, inform the transport company and your PFAFF agent. Connecting the machine to the power supply ● Check if the machine can be operated with available voltage (see chapter 3 Specifications). -

Page 19: Switching The Machine On/Off

Commissioning the machine Switching the machine on/off To switch the machine on move switch 1 to position "1". To switch the machine off move switch 1 to position "0". Danger of burns from the hot wedge! Immediately after the machine has been switched off, the hot wedge is still hot! Fig. -

Page 20: Preparation

Preparation Preparation All Preparation work must only be carried out by appropriately trained persons! The machine is to be separated from the power supply at the on/off switch or by pulling the plug out of the socket whenever carrying out preparation work! Always allow the machine to cool down before all preparation work! Danger of burning! Seal types... -

Page 21: Replacing The Feed Rollers

Preparation Replacing the feed rollers The feed rollers must be changed in accordance with the material, the thickness of the foil and the type of seal desired. The following chart serves as an orientation aid: Foil material Foil thickness Lower feed-roller Upper feed-roller PVC ( soft ) >... -

Page 22: Adjusting The Feed-Roller Clearance

The clearance is correct when one ply of the workpiece material can just be pulled out from between the feed rollers when the upper feed-roller is lowered. Adjusting the feed-roller clearance on the PFAFF 8362-004 03.01 Turn the machine off! -

Page 23: Adjusting The Heat-Sealing Pressure

The feed rollers may not, however, leave pressure marks in the material. Use a lower heat-sealing pressure for soft materials (e.g. PVC) than for hard materials (e.g. PE). Adjusting the heat-sealing pressure on the PFAFF 8362-004 04.01 Turn the machine off! -

Page 24: Adjusting The Clearance Between The Heating Wedge And The Feed Rollers

Heating wedge concave Heating wedge convex (for thin materials) (for thick materials) Fig. 9 - 07 Adjusting the heating-wedge clearance on the PFAFF 8362-004 05.01 Turn the machine off! Wait until the heating wedge is cool! Danger of burning! ● Loosen screw 1. -

Page 25: Adjusting The Heating-Wedge Clearance On The Pfaff 8362-045

Preparation Adjusting the heating-wedge clearance on the PFAFF 8362-045 05.02 ● Loosen nut 1. ● By turning stop screw 2, adjust the heating-wedge clearance in accordance with the material thickness. ● Tighten nut 1. Fig. 9 - 09 9 - 6... -

Page 26: Adjusting The Workpiece Guides

Preparation Adjusting the workpiece guides The setting of the workpiece guides determines how much the workpieces overlap. The width of the overlap can be the same size or larger than the seal width. Overlap width Fig. 9 - 10 Adjusting the upper rear workpiece guide 06.01 Turn the machine off! Wait until the heating wedge is... -

Page 27: Adjusting The Lower Rear Workpiece Guide

Preparation Adjusting the lower rear workpiece guide 06.02 Turn the machine off! Wait until the heating wedge is cool! Danger of burning! ● Loosen screws 1 (2 screws). ● Move workpiece guide 2 parallel to the direction of sealing. ● Tighten screws 1. Fig. - Page 28 Preparation Adjusting the heat-sealing temperature and speed All machine settings are determined by the workpiece which is to be sealed. The perfect sealing temperature and speed are to be found by making a test seal. Fig. 9 - 14 ● After pressing button 1 the heat-sealing temperature can be altered with keys 2 and 3. The value set for the heat-sealing temperature appears on the display.

-

Page 29: Heat Sealing

Heat sealing Heat sealing The machine must only be operated by appropriately trained personnel! The operating personnel is also responsible for ensuring that only authorized personnel are allowed into the area of potential danger around the machine! The heat-sealing principle The two workpieces which are to be connected are heated into a semi-liquid state in the area of the seal by being brought into contact with an electrically warmed heating wedge. -

Page 30: Inserting The Workpieces

Heat sealing Inserting the workpiece Fig. 10 - 02 ● Raise top feed roller with lever 1. ● Slide the lower workpiece 2 as far as it will go into the lower feed guide. ● Slide the upper workpiece 3 as far as it will go into the upper feed guide. ●... -

Page 31: Aligning The Workpieces

Heat sealing Aligning the workpieces Fig. 10 - 04 Fig. 10 - 03 Fig. 10 - 05 Fig. 10 - 06 When aligning the workpieces on the sealing surface, take care to ensure that they overlap a little more than the overlap setting (Fig. 10-03 and Fig. 10-04). The position of the workpieces will then be corrected by the feed guides as the material is fed into the heat-sealing machine. -

Page 32: Heat-Sealing The Workpieces

Heat sealing Heat-sealing the workpieces Guiding the machine manually 04.01 Fig. 10 - 07 ● Connect the machine to the power supply (see chapter 8.01 Connecting the machine to the power supply). ● Set operating mode "0", see Chapter 7.05 Selection switch for the operating mode. In operating mode "1"... -

Page 33: Heat-Sealing With A Guide

Heat sealing Heat-sealing with a guide 04.02 Roof battens, rectangular tubes etc. can be used to make a guide. Fig. 10 - 08 Stopping the machine ● Disengage the hot wedge (the feed rollers stop), see Chapter 7.07 Lever for engaging the hot wedge. -

Page 34: Testing The Seal

Heat sealing Testing the seal All tests are only to be carried out on cold seals. Testing the seal strength 06.01 The seal strength (pull resistance) can only be established by a destructive test. This is done by way of a tearing test on the workpieces which can either be done manually or with a tension dynamometer (for finding out the seal strength more exactly). -

Page 35: Care And Maintenance

Care and maintenance Care and maintenance Check cable and plug connections ............Daily before use Clean the heating wedge ................. Daily before use Replace the heating wedge................As required Replace the feed rollers .................. As required Lubricate drive chains ..................As required Tension the drive chains ................. -

Page 36: Changing The Hot Wedge On The Pfaff 8362-004

If the heating cartridges are defective or the hot wedge is very worn down and an optimum sealing result can no longer be achieved by adjustment, the hot wedge must be changed and, on the PFAFF 8362-004, ground in. Changing the hot wedge on the PFAFF 8362-004 .03.01 Fig. 11 - 02 Fig. -

Page 37: Grinding In The Hot Wedge (Only On The Pfaff 8362-004)

Care and maintenance Grinding in the hot wedge (only on the PFAFF 8362-004) .03.02 The tip of the hot wedge should match the shape of the feed hopper between the top and bottom feed roller. During the heat-sealing operation the entire surface of the wedge tip must touch the workpiece. -

Page 38: Replacing The Heating Wedge On The Pfaff 8362-045

Care and maintenance Replacing the heating wedge on the PFAFF 8362-045 03.03 Switch off the machine! Allow heating wedge to cool! Danger of burning! ● Knock pin 1 downwards out of its housing (dia. 2 mm). ● Pull out the plug of the heating wedge 2 on the front of the machine. -

Page 39: Replacing The Fuse

Care and maintenance Replacing the fuse Fig. 11 - 06 Fig. 11 - 07 The fuse protects the machine from serious damage in cases of overload or short circuit. Switch off the machine! Remove the mains lead! Danger from electric voltage! ●... -

Page 40: Lubricating The Drive Chains

SAE 40 and a density of 1.06 g/cm at 20°C (in accordance with DIN 8195). We recommend PFAFF chain oil Part no. 280-1-120 106. Fig. 11 - 08 Tensioning the drive chain of the lower feed-roller Fig. 11 - 09 ●... -

Page 41: Tensioning The Drive Chain Of The Upper Feed-Roller

Care and maintenance Tensioning the drive chain of the upper feed-roller The chain tensioner of this drive chain is maintenance free. Fig. 11 - 10 ● Should the slack of the chain become too large, the spring pre-tension of the chain tensioner 1 can be increased. - Page 42 Circuit diagrams 91-211 674-95 Version 31.01.00 Reference list for the circuit diagram Controller for heat-sealing temperature Power unit Motor board drive unit Drive unit Hooter Sensor (heating cartridge 1) Sensor (heating cartridge 2) Heating cartridge 1 Heating cartridge 2 Potentiometer (heat-sealing speed controller) Solid state relay Fuse Fuse...

- Page 43 95-211 905-95 Circuit diagrams Version 06.01 12 - 2...

- Page 44 PFAFF Industriesysteme und Maschinen AG Hans-Geiger-Str. 12 - IG Nord D-67661 Kaiserslautern Phone: +49 - 6301 3205 - 0 Fax: +49 - 6301 3205 1386 E-mail: info@pfaff-industrial.com Hotlines: Technical service: +49 - 175/2243-101 Application consultance: +49 - 175/2243-102 Spare-parts hotline:...