Table of Contents

Advertisement

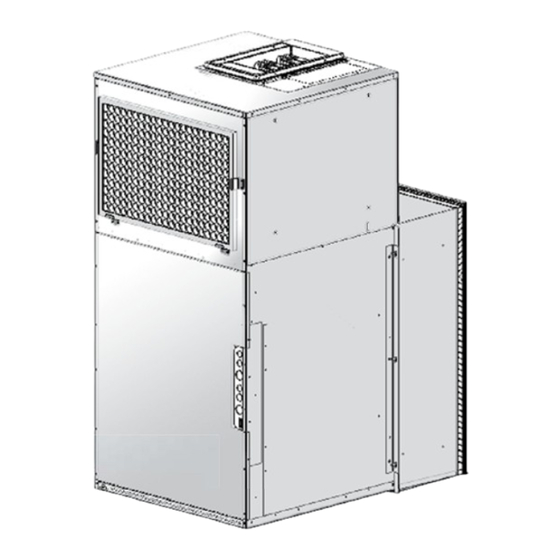

VPRC / VPRH

Single Package Vertical Air Conditioner/Heat Pump

Single Package Vertical Air Conditioner/Heat Pump

™

Th e Right Fit for Comfort

Installation,

Operation &

Maintenance Manual

ECR International Inc

2201 Dwyer Avenue

Utica, NY 13501

e-mail: info@RetroAire.com

An ISO 9001-2008 Certifi ed Company

P/N 240006980, Rev. R [02/19/2013]

Advertisement

Table of Contents

Summary of Contents for Retro Aire VPRC09

- Page 1 VPRC / VPRH Single Package Vertical Air Conditioner/Heat Pump Single Package Vertical Air Conditioner/Heat Pump ™ Th e Right Fit for Comfort Installation, Operation & Maintenance Manual ECR International Inc 2201 Dwyer Avenue Utica, NY 13501 e-mail: info@RetroAire.com An ISO 9001-2008 Certifi ed Company P/N 240006980, Rev.

-

Page 2: Table Of Contents

TABLE OF CONTENTS Receiving Information ....................3 Important Safety Information ..................4 Dimensional/Physical Data ..................... 5 Components ........................ 8 General Product Information ..................9 Control Box Location ....................10 Enclosure Preparation ....................12 Wall Sleeve Installation ....................14 Typical Chassis And Wall Sleeve, Installation ..............15 ront-Mounted Control Panel - Chassis And Wall Sleeve, Installation ........16 Side-Mounted Control Panel - Chassis And Wall Sleeve, Installation ........17 Condensate Drain ......................18... -

Page 3: Receiving Information

RECEIVING INFORMATION Shipping damage MUST be reported to the carrier IMMEDIATELY. Examine exterior. Remove cover and examine compressor and piping for signs of damage. Inspection General Information Check shipment against bill of lading. Installation shall be completed by qualifi ed agency. Retain this manual and warranty for future reference. -

Page 4: Important Safety Information

IMPORTANT SAFETY INFORMATION All fi eld wiring shall conform to requirements of authority WARNING having jurisdiction or in absence of such requirements: Tampering with VPRC/VPRH is dangerous and could • United States - National Electrical Code, ANSI/NFPA result in serious injury or death. Do not modify or change this unit. -

Page 5: Dimensional/Physical Data

DIMENSIONAL/PHYSICAL DATA Figure 1 VPRC/ VPRH Dimensions — Inches (mm) - Models 09, 12, 19 & 24 Table 1 Nominal Capacities, Dimensions, Shipping Weights And Return Air Filter Sizes Model Straight cool/Limited Range Heat pump nominal capacities Dimension 09–12 19-24 in. - Page 6 DIMENSIONAL/PHYSICAL DATA Figure 2 VPRC/ VPRH Dimensions - Model 18 Table 2 Dimensions, Shipping Weights And Return Air Filter Sizes Model Dimension in. (mm) Straight cool/Limited Range Heat pump nominal capacities 7- 3 /4 (197) 18,000 Btuh 40 (1016) 21 - 7 /16 (545) 25 (635) 14 - 13 /16 (376) 24 - 5 /8 (625)

- Page 7 DIMENSIONAL/PHYSICAL DATA Figure 3 VPRC/ VPRH Dimensions - Models 30 & 36 Table 3 Dimensions, Shipping Weights And Return Air Filter Sizes - Models 30 & 36 Model Straight Cool/Limited Range Heat Pump Nominal Capacities Dimension 30,000 36,000 Btuh in. (mm) in.

-

Page 8: Components

COMPONENTS Models 09–24 Models 30–36 Supply Supply Supply Supply Outside louver Outside louver Return Return Return Return Wall sleeve, Wall sleeve, custom for application custom for application Front — 09, 12, 18, 19, 24 Front — 30, 36 Indoor coil (behind fi lter) Outdoor coil Control/power box Alternate control box location... -

Page 9: General Product Information

GENERAL PRODUCT INFORMATION Product Description • Microprocessor Control Board – Random start timer prevents multiple units • VPRC/VPRH 09–36 single package vertical air from simultaneous start-ups. conditioner (SPVAC) and heat pump (SPVHP). – Fan purge — fan remains on for 60 seconds •... -

Page 10: Control Box Location

CONTROL BOX LOCATION Control Box Location Relocating Control Box • VPRC/VPRH control box is factory mounted in front DANGER position, unless otherwise specifi ed. Electrical shock hazard. Disconnect power to unit • Control box can be factory mounted for front, left or before servicing or accessing control compartment. - Page 11 ENCLOSURE PREPARATION Rough Openings Proper Clearances Access opening — allows unit insertion. Provide minimum • For proper air fl ow and sound levels minimum clearance opening dimensions. (See Figure 21, Page 33, for of 4 inches (102 mm) [models 09–18] or 6 inches, (152 dimensions of opening when using optional return access mm) [models 24–36] between enclosure and chassis be panel assembly.)

-

Page 12: Enclosure Preparation

ENCLOSURE PREPARATION Figure 7 Exploded View Of Typical Installation (Chassis shown is typical of models 09–24) 30/36 chassis (models 09–24 shown at right) The Right Fit for Comfort P/N 240006980, Rev. R [02/2013]... - Page 13 ENCLOSURE PREPARATION Exploded View Of Typical Installation (Chassis shown is typical of models 09–24) Access opening (for unit insertion/removal) — See unit dimensions in Figures 2, 3, 4, Pages 5-7. See Table 6, page 11 for minimum recommended opening dimensions. Allow for extra height of hydronic coil module, if used.

-

Page 14: Wall Sleeve Installation

WALL SLEEVE INSTALLATION Verify Wall Sleeve Depth Figure 8 Determining wall sleeve depth Wall sleeve depth must be suitable for overall wall Specify overall wall thickness when thickness. (Figure 8). ordering the wall sleeve — it will be supplied to meet the required depth. Consult manufacturer for available wall sleeves. -

Page 15: Typical Chassis And Wall Sleeve, Installation

TYPICAL CHASSIS AND WALL SLEEVE, INSTALLATION Figure 10 Typical VPRC/VPRH Installation, With Platform To Install Outside Louver • Install studs on inside of louver. Louvers will pass through clearance holes in wall sleeve fl ange. • Place outside louver in position. •... -

Page 16: Front-Mounted Control Panel - Chassis And Wall Sleeve, Installation

RONT-MOUNTED CONTROL PANEL - CHASSIS AND WALL SLEEVE, INSTALLATION GENERAL INSTALLATION CONTINUED Hydronic Coil (Optional) Figure 11 Foam Gasket & Weather Angles (09– Install hydronic coil option BEFORE placing chassis in wall 24) Front Control Panel Installations sleeve. See pages 35-37. Supply air connection (return is in front) Inspect Foam Insulation... -

Page 17: Side-Mounted Control Panel - Chassis And Wall Sleeve, Installation

SIDE-MOUNTED CONTROL PANEL - CHASSIS AND WALL SLEEVE, INSTALLATION Inspect Foam Insulation Figure 13 Foam Gasket & Weather Angles • Verify foam insulation strips around condenser opening (09–24) Right-Side Control Panel are intact (see Figure 13 and 14). Replace if necessary. Installations •... -

Page 18: Condensate Drain

CONDENSATE DRAIN Condensate drain Accessory drain stub kit is available for models VPRC/ VPRH 09,12,19,and 24. Optional fi eld installed kit is Models VPRC/VPRH 09,12,19, and 24 are designed designed for use with building’s internal drain system, so condensate generated during cooling operation is and must be installed prior to operation. -

Page 19: Electrical Connections

ELECTRICAL CONNECTIONS Electrical Connections Power Cord With Integral Safety Protection WARNING All VPRC/VPRH units that are cord connected to power supply are equipped with power cord with integral sensor: Electrical shock hazard. Disconnect all power • Provides personal shock protection. before removing chassis, performing any cleaning, servicing, or maintenance. - Page 20 ELECTRICAL CONNECTIONS Heat Pump With Electric Heat (VPRH only) Thermostat Wiring Single-Stage Thermostat Select thermostat compatible with cooling/single stage heat/heat pump system. • Thermostat should have “R”, “Y”, “O” and “G” terminals. RetroAire™ units are single stage heating only. • Electric heat and heat pump will not operate simultaneously.

-

Page 21: Final Inspection And Start-Up

FINAL INSPECTION AND START-UP Cooling CAUTION Set wall thermostat to cool mode. Set thermostat Moving parts can cause injury. Use caution when below room temperature setting. testing unit. Failure to do so could result in minor or After few minutes of operation, cool air should moderate injury. -

Page 22: Test Mode

FINAL INSPECTION & START-UP General Figure 17 HP Jumper (selects heat pump or Installation and wiring shall be in accordance with straight cooling) requirements of authority having jurisdiction In absence of such requirements refer to: • USA- National Electrical Code, ANSI/NFPA 70. •... - Page 23 FINAL INSPECTION & START-UP Figure 19 Circuit Board TEST JUMPER HEAT PUMP JUMPER Made in USA P/N 240006980, Rev. R [02/2013]...

-

Page 24: Sequence Of Operation

SEQUENCE OF OPERATION Initial Power-Up Or Power Restoration Cooling Operation • If room temperature is above thermostat setting, When power is applied, either for fi rst time or after power reversing valve (VPRH only) will be energized. failure, board will initialize. •... -

Page 25: Maintenance

MAINTENANCE Repair if necessary. WARNING Seasonal Start-Up And Maintenance Electrical shock hazard. Disconnect power to Beginning of cooling and heating seasons, complete VPRC/VPRH before servicing or accessing control mechanical check should be performed and maintenance/ compartment. Failure to do so could result in severe inspections performed as described below. -

Page 26: Troubleshooting

TROUBLESHOOTING WARNING NOTICE Electrical shock hazard. Disconnect power to unit Have qualifi ed technician conduct troubleshooting before servicing or accessing control compartment. procedures. Failure to do so could result in severe personal injury or death. Symptom Suggestion No heat or cooling •... -

Page 27: Selection Chart

TROUBLESHOOTING Indoor Motor Speed Tap Selection Table 7 VPRC/VPRH Indoor motor speed tap • For information on indoor motor speed tap selection, selection chart please refer to “Indoor Motor Speed Tap Selection Chart” label attached to chassis of VPRC/VPRH Model In. -

Page 28: Electrical Specifi Cations

ELECTRICAL SPECIFICATIONS Table 9 Legend For Electrical Specifi cations Full Load Amps Minimum Maximum Over current Protection Device H-WIRE Hard Wired MOCP Amps (HACR-type breakers or time-delay fuses) Heater Amps Outdoor Fan Motor Horse Power Rated Load Amps Htr # Heater Option Number (see Figure 1) Total Cooling Amps Indoor Fan Motor... -

Page 29: Electrical Specifications

ELECTRICAL SPECIFICATIONS Table 10 VPRC/VPRH 09 Electrical Specifi cation Power Supply Indoor Outdoor Compressor Electric Heat Unit Electrical Ratings Volt — Fan Motor Fan Motor 1–60 Volt Htr # Volt MCA MOCP Plug 0 or 8 0.8* 6–15P 2454 11.8 12.6 15.7 6–20P... - Page 30 ELECTRICAL SPECIFICATIONS Table 12 VPRC/VPRH 18 Electrical Specifi cations Power Indoor Fan Outdoor Supply Compressor Electric Heat Unit Electrical Ratings Motor Fan Motor Volt 1–60 Volt Htr # Volt MCA MOCP Plug 0 or 8 1.0* 10.0 6–15P 2454 11.8 12.8 16.0 6–20P...

- Page 31 ELECTRICAL SPECIFICATIONS Table 14 VPRC/VPRH 24 Electrical Specifi cations Power Indoor Outdoor Supply Compressor Electric Heat Unit Electrical Ratings Volt — Motor Motor 1–60 Volt Volt MCA MOCP Plug 0 or 1.5* 14.6 6–20P 2454 11.8 13.3 16.6 6–20P 3000 13.0 14.5 18.2...

- Page 32 ELECTRICAL SPECIFICATIONS Table 15 VPRC/VPRH 30 Electrical Specifi cations Power Supply Indoor Fan Outdoor Compressor Electric Heat Unit Electrical Ratings Volt — Motor Fan Motor 1–60 Volt Volt MOCP Plug 20.6 4089 19.7 22.7 28.4 5000 21.7 24.7 31.0 208/ 13.0 17.3 230V...

-

Page 33: Optional - Return Air Access Panel

OPTIONAL - RETURN AIR ACCESS PANEL Optional Return Air Access Panel • Verify installation will provide adequate clearance and (With access to control panel. Filter) • Work closely with other trades to locate opening for return air access panel. NOTICE •... -

Page 34: Optional - Hydronic Coil

OPTIONAL - HYDRONIC COIL HH Series Hydronic Coil Option Install threaded rods through slots in brackets (Figure 23), place washer and nut on threaded rod, tighten (Available for VPRC / VPRH models 09-24 only) nut. Secure upper end of threaded rod to angle iron or 2 x 4 inch (51 x 102 mm) wood. - Page 35 OPTIONAL - HYDRONIC COIL Figure 23 Hydronic Coil Option (front/right application shown) 10-inch round (254 mm) duct collar Return line automatic balancing valve, with drain cock in y. Chassis top panel Z brackets (factory-supplied) Supply line automatic balancing valve Z bracket mounting screws (included) Flanges and nuts —...

- Page 36 OPTIONAL - HYDRONIC COIL Figure 24 VPRC/VPRH Hydrocoil Specifi cations (Entering Air Temperature on 70°F, dry bulb/58°F, wet bulb) Entering H2O Head Loss, Ft/H Unit Size CFM (L/s) GPM (L/s) Btu/h (kW) Temp F C (see note 1) 1 (0.163) 7300 2.14 2 (0.126)

-

Page 37: Optional Carrier 50Qt/Et Replacement - Installation

OPTIONAL CARRIER 50QT/ET REPLACEMENT — INSTALLATION Condenser Louver Replacement Figure 25 Aluminum Vertical Bar Louver • Existing Carrier wall sleeve can be retained in all Without Block-Off, Can Be Used applications, provided VPRC/VPRH unit is installed as With The VPRC/VPRH as is required for 50QT/ET option. - Page 38 OPTIONAL CARRIER 50QT/ET REPLACEMENT — INSTALLATION VPRC/VPRH Models 09–12 only NOTICE Attach three baffl es included in chassis kit to back of condenser coil. See Figure 29. Level chassis so condensate or wind-driven rain will fl ow from base pan. Installer, test and confi...

-

Page 39: Operational Performance Data

Btuh (kW) Ratio (2.5 mm (5.1 mm (7.6 mm w.c.) w.c.) w.c.) CFM (L/s) CFM (L/s) CFM (L/s) (L/s) 9,000 VPRC09 0.75 330 (156) 300 (142) 250 (118) (2.64) 9,000 VPRH09 0.75 9,000 (2.64) 330 (156) 300 (142) 250 (118) (2.64) -

Page 40: Start-Up Report

START-UP REPORT In order for Technical Service to better serve you, please Include Model Number, Serial Number, and Date of complete the following information. installation. Have this information ready when calling. Technical Support Department: (800) 228-9364 Model Number Date: Technician: Serial Number Mode: Cooling... - Page 41 NOTES Made in USA P/N 240006980, Rev. R [02/2013]...

- Page 42 NOTES The Right Fit for Comfort P/N 240006980, Rev. R [02/2013]...

- Page 43 NOTES Made in USA P/N 240006980, Rev. R [02/2013]...

- Page 44 ECR International Inc 2201 Dwyer Avenue Utica, NY 13501 e-mail: info@RetroAire.com An ISO 9001-2008 Certifi ed Company...

Need help?

Do you have a question about the VPRC09 and is the answer not in the manual?

Questions and answers