Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Aerco GF-123

-

Page 1: Maintenance Instructions

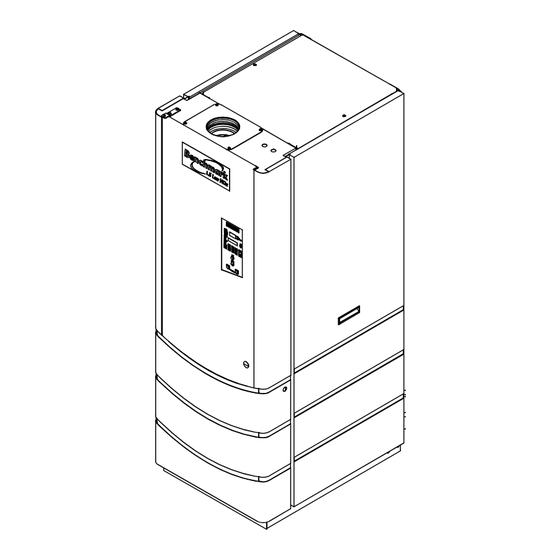

Instruction GF-123 AERCO INTERNATIONAL, Inc., Northvale, New Jersey, 07647 USA Installation, Operation & Maintenance Instructions Benchmark 2.0 Low NOx Natural Gas Fired Boiler System Condensing, Modulating Forced Draft, Hot Water Boiler 2,000,000 BTU/H Input REVISED 9/21/09 Printed in U.S.A. - Page 2 AERCO International, Inc. AERCO makes no warranty of any kind with respect to this material, including but not limited to implied warranties of merchantability and fitness for a particular application. AERCO International is not liable...

-

Page 3: Chapter 5 – Mode Of Operation

FOREWORD Foreword The AERCO Benchmark 2.0LN Boiler is a modulating unit. It represents a true industry advance that meets the needs of today's energy and environmental concerns. Designed for application in any closed loop hydronic system, the Benchmark's modulating capability relates energy input directly to fluctuating system loads. -

Page 5: Table Of Contents

CONTENTS GF-123 - AERCO BENCHMARK 2.0LN GAS FIRED LOW NOx BOILER Operating & Maintenance Instructions FOREWORD Chapter 1 – SAFETY PRECAUTIONS Para. Subject Page Para. Subject Page Warnings & Cautions Prolonged Shutdown Emergency Shutdown Chapter 2 – INSTALLATION Para. Subject Page Para. - Page 6 CONTENTS Chapter 5 – MODE OF OPERATION Para. Subject Page Para. Subject Page Introduction Boiler Management System Indoor/Outdoor Reset Mode (BMS) Constant Setpoint Mode Combination Control System Remote Setpoint Mode (CCS) Direct Drive Modes Chapter 6 – SAFETY DEVICE TESTING PROCEDURES Para.

- Page 7 CONTENTS APPENDICES Subject Page Subject Page Boiler Menu Item Descriptions Boiler Default Settings Startup, Status and Fault Dimensional and Part Drawings Messages Piping Drawings Temperature Sensor Resistance Wiring Schematics Chart Recommended Periodic Testing Indoor/Outdoor Reset Ratio Checklist Charts Benchmark Control Panel Views...

-

Page 9: Warnings & Cautions

LEAKS. precautions included in these instructions. WARNING! addition to all the requirements included in this AERCO Instruction Manual, the installation of FLUIDS UNDER PRESSURE MAY units MUST conform with local building codes, CAUSE INJURY TO PERSONNEL or, in the absence of local codes, ANSI Z223.1... -

Page 10: Emergency Shutdown

IMPORTANT turn off the electrical power supply to the The Installer must identify and indicate AERCO boiler and close the manual gas valve the location of the emergency shutdown located upstream the unit. The installer is to manual gas valve to operating personnel. -

Page 11: Introduction

• Spare Spark Igniter procedures necessary to unpack, inspect and • Spare Flame Detector install the AERCO Benchmark 2.0 Low NOx (LN) Boiler. Brief descriptions are also provided • ASME Pressure Relief Valve for each available mode of operation. Detailed •... -

Page 12: Chapter 7 – Maintenance Requirements

INSTALLATION 18" 44.5" 24" 79" 101" 30" 24" 24" REAR FRONT 4" HIGH PAD Figure 2-1 Benchmark 2.0LN Boiler Clearances WARNING KEEP THE UNIT AREA CLEAR AND FREE FROM ALL COMBUSTIBLE MATERIALS FLAMMABLE VAPORS OR LIQUIDS CAUTION While packaged shipping container, the boiler must be moved by pallet jack or forklift from the FRONT ONLY. -

Page 13: Supply And Return Piping

INSTALLATION If installing a Combination Control Panel (CCP) system, important identify BOILER RETURN Combination Mode Boilers in advance and place them in the proper physical location. Refer to Chapter 5 for information on Combination Mode EXHAUST Boilers. MANIFOLD SUPPLY AND RETURN PIPING The Benchmark 2.0LN Boiler utilizes 4”... -

Page 14: Gas Supply Piping

4 inches W.C. for GAS SUPPLY PIPING both FM and IRI gas trains when the unit is firing at maximum input. The gas supply pressure to AERCO Benchmark 2.0LN the unit must be of sufficient capacity to provide... -

Page 15: Ac Electrical Power Wiring

AC ELECTRICAL POWER WIRING service switch) must be installed near the unit for normal operation and maintenance. All The AERCO Benchmark 2.0LN Electrical Power electrical connections should be made in Wiring Guide, GF-2060LN, must be consulted accordance with the National Electrical Code prior to connecting any AC power wiring to the and/or with any applicable local codes. - Page 16 INSTALLATION In addition to the terminal strips shown in Figure 2-9, the I/O Box also contains a pre-wired temperature transmitter which receives inlet air temperature sensor readings and transmits this signal to the variable frequency drive (VFD) contained in the Boiler. The VFD utilizes this input signal to adjust the rotation speed of the blower.

- Page 17 Figure 2-10 are described in the strip. Polarity must be maintained and the shield following paragraphs. must be connected only at the AERCO BMS. The boiler end of the shield must be left floating. For additional instructions, refer to Chapter 5, CAUTION paragraph 5.6 in this manual.

- Page 18 COMMON terminals and must be similar to These terminals provide a 4 to 20 mA output to AERCO BALCO wire sensor Part No. 12449. A the VFD to control the rotational speed of the resistance chart for this sensor is provided in blower.

- Page 19 Boiler, if desired. The circuit is labeled specified in AERCO’s GF-2050, must be used REMOTE INTL’K IN and is located inside the I/O for safety and code compliance. Since the unit is Box on the front panel. The circuit is 24 VAC...

- Page 20 2.13.3 Sealed Combustion information concerning sealed combustion air). If the sealed combustion air option is not being The AERCO Benchmark 2.0LN Boiler is UL used, an inlet screen will be attached at the air listed for 100%-sealed combustion. For sealed...

-

Page 21: Introduction

CONTROL PANEL OPERATING PROCEDURES CHAPTER 3 CONTROL PANEL OPERATING PROCEDURES 3.1 INTRODUCTION The information in this Chapter provides a guide to the operation of the Benchmark 2.0 Low NOx Boiler using the Control Panel mounted on the front of the unit. It is imperative that the initial startup of this unit be performed by factory trained personnel. - Page 22 CONTROL PANEL OPERATING PROCEDURES Table 3-1 Operating Controls, Indicators and Displays ITEM CONTROL, INDICATOR OR DISPLAY FUNCTION LED Status Indicators Four Status LEDs indicate the current operating status as follows: COMM Lights when RS-232 communication is occurring MANUAL Lights when the unit is being controlled using the front panel keypad.

- Page 23 CONTROL PANEL OPERATING PROCEDURES Table 3-1 Operating Controls, Indicators and Displays – Continued ITEM CONTROL, INDICATOR OR DISPLAY FUNCTION MENU Keypad Consists of 6 keys which provide the following functions for the Control Panel Menus: MENU Steps through the main menu categories shown in Figure 3- 2.

-

Page 24: Control Panel Menus

CONTROL PANEL OPERATING PROCEDURES around after the first or last available option 3.3 CONTROL PANEL MENUS is reached. The Control Panel incorporates an extensive 6. To change the value or setting of a menu structure which permits the operator to set displayed menu option, press the CHANGE up, and configure the unit. -

Page 25: Operating Menu

CONTROL PANEL OPERATING PROCEDURES time-out after 1 hour. Therefore, the correct 3.4 OPERATING MENU password must be reentered when required. In The Operating Menu displays a number of key addition to permitting password entries, the operating parameters for the unit as listed in Setup Menu is also used to enter date and time, Table 3-2. -

Page 26: Configuration Menu

CONTROL PANEL OPERATING PROCEDURES 3.6 CONFIGURATION MENU NOTE The Configuration Menu shown in Table 3-4 The Configuration Menu settings shown in permits adjustment of the Internal Setpoint Table 3-4 are Factory-Set in accordance (Setpt) temperature regardless of whether the with the requirements specified for each valid password has been entered. -

Page 27: Tuning Menu

CONTROL PANEL OPERATING PROCEDURES Table 3-4. Configuration Menu - Continued Available Choices or Limits Menu Item Display Minimum Maximum Default Failsafe Mode Shutdown or Constant Setpt Shutdown *mA Output Setpoint, Outlet Temp, *Fire Rate (See CAUTION) Fire Rate Out, Off Low Fire Timer 2 sec. - Page 28 CONTROL PANEL OPERATING PROCEDURES DIAL SSOV INLET (DETAIL “A”) TO AIR/FUEL VALVE MANUAL SHUT-OFF VALVE Figure 3-3. STEPPER SSOV Location MOTOR With all required safety device switches closed, a purge cycle will be initiated and the following events will occur: (a) The Blower Relay energizes and turns on Blower.

-

Page 29: Start/Stop Levels

CONTROL PANEL OPERATING PROCEDURES DIAL 5. Upon completion of the purge cycle, the (DETAIL “A”) Control Box initiates an ignition cycle and the following events occur: (a) The Air/Fuel Valve rotates to the low- fire ignition position and closes the ignition switch. - Page 30 CONTROL PANEL OPERATING PROCEDURES Table 3-6. Relationship Between Air/Fuel Valve Position and Energy Input For Unit Running On Natural Gas Fire Rate, Air/Fuel Valve Energy Input Boiler Energy Input Position (BTU/Hr) (% of Full Capacity) (% Open) 5.0% (Stop Level) 100,000 134,000 349,000...

-

Page 31: Chapter 4 – Initial Start-Up

• Small and large flat blade screwdrivers. AERCO Gas Fired Startup Sheets, included with • Tube of silicone adhesive each Benchmark Boiler, must be completed for each unit for warranty validation and a copy must be returned promptly to AERCO at: 4.2.2 Installing Gas Supply Manometer... - Page 32 Factory Test Data sheets are (INSTALL MANOMETER shipped with each unit. These sheets must be HERE) filled out and returned to AERCO for proper Warranty Validation. LOW GAS TO AIR/ PRESSURE It is important to perform the following procedure...

- Page 33 INITIAL START-UP BRASS HEX HEAD CAP (REMOVE TO ACCESS INLET REGULATOR ADJUSTMENT) IRIS AIR TYPICAL SSOV ACTUATOR WITH REGULATOR DAMPER (SEE VIEW “A”) Figure 4-3 Regulator Adjustment Screw Location 11. Raise the firing rate to 100% and verify that the gas pressure downstream of the SSOV remains at 2.8”...

- Page 34 INITIAL START-UP 21. If the oxygen level is not within the specified range, adjust the level using the up (Λ) and down (V) arrow keys on the VFD. Using the up (Λ) arrow key will increase oxygen level and the down (V) arrow key will decrease the oxygen level.

-

Page 35: Unit Reassembly

INITIAL START-UP Combustion Oxygen Level at 18% Firing Rate Oxygen % Carbon ± 0.2 Monoxide 8.0 % <50 ppm <30 ppm DETAIL “A” 29. Adjust the oxygen level as necessary to obtain the required reading at the 18% firing rate. 30. -

Page 37: Chapter 5 - Mode Of Operation

MODE OF OPERATION CHAPTER 5 MODE OF OPERATION 5.1 INTRODUCTION 5.2.3 Outdoor Air Temperature Sensor Installation The Benchmark 2.0 Low NOx (LN) Boiler is capable of being operated in any one of six The outdoor air temperature sensor must be different modes. -

Page 38: Constant Setpoint Mode

PMC Board located in the Control Panel changing any temperature-related parameters, Assembly. Refer to GF-112, Appendix F other than the setpoint, it is suggested that an for instructions on changing Control Panel AERCO representative contacted. DIP switch settings. descriptions of temperature-related functions... -

Page 39: Direct Drive Modes

4-20 mA/1-5 Vdc applications. It is suggested that an AERCO representative be contacted, prior to changing 0-20 mA/0-5 Vdc any temperature related function settings. For... - Page 40 This mode of operation is factory preset and the System. The BMS mode is used when it is AERCO BMS controls the firing rate. There are desired to operate multiple units in the most no setup instructions for each individual unit.

- Page 41 When the boiler is switched to BMS mode, the switch over to space heating, their mode of AERCO BMS controls the firing rate. There are operation changes to the BMS mode. For more no setup requirements to the boiler(s) in this information concerning the operation of the mode.

-

Page 43: Chapter 6 - Safety Device Testing Procedures

SAFETY DEVICE TESTING CHAPTER 6 SAFETY DEVICE TESTING 6.1 TESTING OF SAFETY DEVICES 5. While the unit is firing, slowly close the external manual gas shut-off valve. Periodic safety device testing is required to 6. The unit should shut down and display a ensure that the control system and safety LOW GAS PRESSURE fault message at devices are operating properly. -

Page 44: Low Water Level Fault Test

SAFETY DEVICE TESTING 3. Slowly open the ball valve at the high gas 8. Open the water shut-off valve in the return pressure switch. piping to the unit. 9. Open the water supply shut-off valve to the 4. Start the unit in Manual mode at a firing rate unit to refill. - Page 45 SAFETY DEVICE TESTING 6.6.1 REMOTE INTERLOCK 1. Remove the cover from the I/O Box and locate the REMOTE INTL’K IN terminals. 2. Start the unit in the Manual Mode and set the firing rate between 25% and 30%. DETAIL “A” 3.

-

Page 46: Ssov Proof Of Closure Switch

SAFETY DEVICE TESTING 4. Set the ON/OFF switch to the ON position to Press the CLEAR button. The unit should start the unit. restart. 5. The unit should shut down after reaching the 6. Next, check the Blocked Inlet Switch by Ignition cycle and display FLAME LOSS closing the Iris Air Damper (Figure 4-4) to DURING IGN. -

Page 47: Purge Switch Open During

SAFETY DEVICE TESTING 3. Remove the Air/Fuel Valve cover (Figure 6-5) by rotating the cover counterclockwise to unlock and lift up to remove. 4. Remove one of the two wires (#169 or #170) from the Ignition Switch (Figure 6-6). 5. Initiate a unit start sequence. 6. -

Page 48: Safety Pressure Relief Valve

SAFETY DEVICE TESTING Figure 6-6 Air/Fuel Valve Purge and Ignition Switch Locations 6.12 SAFETY PRESSURE RELIEF VALVE TEST Test the safety Pressure Relief Valve in accordance with ASME Boiler and Pressure Vessel Code, Section VI. -

Page 49: Chapter 7 Maintenance

MAINTENANCE CHAPTER 7 MAINTENANCE 7.1 MAINTENANCE SCHEDULE 5. The igniter is gapped at 1/8-inch. If there is a substantial erosion of the spark gap or The unit requires regular routine maintenance to ground electrode, the igniter should be keep up efficiency and reliability. For best replaced. -

Page 50: Test

MAINTENANCE Table 7-1 - Maintenance Schedule Labor PARAGRAPH ITEM 6 Mos. 12 Mos. 24 Mos. Time Spark Igniter *Inspect Inspect Replace 15 mins. (GP-122435-S) Flame Detector *Inspect Inspect Replace 15 mins. (66006) Combustion *Check Check 1 hr. Calibration See CSD-1 Testing of Chart in 20 mins. - Page 51 MAINTENANCE 7.6 BURNER ASSEMBLY NOTE The burner assembly is located at the top of the unit. The burner assembly may be HOT. Allow The burner assembly is heavy, weighing the unit to cool sufficiently before removing the approximately 30 pounds. burner assembly.

-

Page 52: Condensate Drain Trap

7.8 SHUTTING THE BOILER DOWN FOR 7.7 CONDENSATE DRAIN TRAP AN EXTENDED PERIOD OF TIME Benchmark 2.0LN Boiler contains If the boiler is to be taken out of service for an condensate trap as shown in Figure 2-5. The extended period of time (one year or more), the trap is located external to the unit and attached following instructions must be followed. -

Page 53: Chapter 8 – Troubleshooting Guide

Troubleshooting Tables, contact your local AERCO Representative. 1. Observe the fault messages displayed in the Control Box display. 2. Refer to the Fault Indication column in Troubleshooting Table 8-1 which follows and locate the Fault that best describes the... -

Page 54: Troubleshooting

TROUBLESHOOTING TABLE 8-1. BOILER TROUBLESHOOTING FAULT INDICATION PROBABLE CAUSES TROUBLESHOOTING/CORRECTIVE ACTION AIRFLOW FAULT 1. Blower stopped running due to thermal 1. Check combustion blower for signs of excessive heat or high DURING IGNITION or current overload current drain that may trip thermal or current overload devices. 2. - Page 55 TROUBLESHOOTING TABLE 8-1. BOILER TROUBLESHOOTING – Continued FAULT INDICATION PROBABLE CAUSES TROUBLESHOOTING/CORRECTIVE ACTION (continued) 16. VFD is not starting or is faulting. 16. See Table 8-4 for VFD parameter settings and Table 8-5 for VFD faults. AIRFLOW FAULT 1. Blower not running or running too slow 1.

- Page 56 TROUBLESHOOTING TABLE 8-1. BOILER TROUBLESHOOTING – Continued FAULT INDICATION PROBABLE CAUSES TROUBLESHOOTING/CORRECTIVE ACTION DELAYED 1. Delayed Interlock Jumper not 1. Check for a jumper properly installed across the delayed INTERLOCK OPEN installed or removed. interlock terminals in the I/O box. 2.

- Page 57 TROUBLESHOOTING TABLE 8-1. BOILER TROUBLESHOOTING – Continued FAULT INDICATION PROBABLE CAUSES TROUBLESHOOTING/CORRECTIVE ACTION (continued) 8. Defective staged ignition solenoid 8. When boiler goes to ignition, listen to solenoid valve to ensure it valve. is opening. 9. Clogged staged ignition piece. 9.

- Page 58 TROUBLESHOOTING TABLE 8-1. BOILER TROUBLESHOOTING – Continued FAULT INDICATION PROBABLE CAUSES TROUBLESHOOTING/CORRECTIVE ACTION HIGH WATER TEMP 1. Faulty Water temperature switch. 1. Test the temperature switch to insure it trips at its actual water SWITCH OPEN temperature setting. 2. Incorrect PID settings. 2.

- Page 59 TROUBLESHOOTING TABLE 8-1. BOILER TROUBLESHOOTING – Continued FAULT INDICATION PROBABLE CAUSES TROUBLESHOOTING/CORRECTIVE ACTION IGN SWTCH CLOSED 1. Air/Fuel Valve not rotating 1. Start the unit. The Air/Fuel Valve should rotate to the purge DURING PURGE (open) position. If the valve does not rotate at all or does not rotate fully open, check the Air/Fuel Valve calibration.

- Page 60 TROUBLESHOOTING TABLE 8-1. BOILER TROUBLESHOOTING – Continued FAULT INDICATION PROBABLE CAUSES TROUBLESHOOTING/CORRECTIVE ACTION continued 3. Device proving switch hooked to 3. Check that proving switch for any device hooked to the interlock interlocks is not closed. circuit is closing and that the device is operational. LINE VOLTAGE 1.

- Page 61 TROUBLESHOOTING TABLE 8-1. BOILER TROUBLESHOOTING – Continued FAULT INDICATION PROBABLE CAUSES TROUBLESHOOTING/CORRECTIVE ACTION PRG SWTCH OPEN 1. Defective purge switch. 1. If the air-fuel valve does rotate, check the purge switch for DURING PURGE continuity when closing. Replace switch if continuity does not exist.

- Page 62 TROUBLESHOOTING TABLE 8-1. BOILER TROUBLESHOOTING – Continued FAULT INDICATION PROBABLE CAUSES TROUBLESHOOTING/CORRECTIVE ACTION (continued) 2. Defective Flame Detector 2. Replace Flame Detector. SSOV FAULT See SSOV SWITCH OPEN DURING PURGE SSOV FAULT 1. SSOV switch closed for 15 seconds 1. Replace or adjust microswitch in SSOV actuator. If fault during run.

- Page 63 TROUBLESHOOTING ADDITIONAL FAULTS WITHOUT SPECIFIC FAULT MESSAGES Refer to Table 8-2 to troubleshoot faults which may occur without a specific fault message being displayed. TABLE 8-2. BOILER TROUBLESHOOTING WITH NO FAULT MESSAGE DISPLAYED OBSERVED INCIDENT PROBABLE CAUSES TROUBLESHOOTING/CORRECTIVE ACTION Hard Light-Off 1.

- Page 64 TROUBLESHOOTING HIGH GAS PRESSURE SWITCH TO AIR/FUEL VALVE SSOV SNUBBER LOW GAS PRESSURE SWITCH MANUAL SHUT-OFF VALVE STAGED IGNITION LINE INLET Figure 8-3 BALL VALVE Damping Orifice Location Figure 8-1 High Pressure Gas Switch & Snubber Locations Figure 8-4 Figure 8-2 VFD Terminal Locations Staged Ignition Solenoid Location...

- Page 65 TROUBLESHOOTING Table 8-3 BMK 2.0 LN (3.3 KΩ) Temperature Sensor and Temperature Transmitter Outputs TEMP Volts TEMP Volts TEMP Resistance TEMP Resistance ºF outputs ºF outputs ºC ºC UA33 UA33 UA33 UA33 111177 0.289 82.4 2915 6.16 58443 0.523 84.2 2787 6.31 32814...

- Page 66 TROUBLESHOOTING Table 8-4. VFD Parameter Settings VFD Parameter Parameter Value 100.0 AI.AV Between -70.0 & 100.0 Between -150 & 250 Between 200 & 500 Between 250 & 600 Between 250 & 700 Between 400 & 850 18.20 18.21 18.22 18.23 18.24 •...

- Page 67 TROUBLESHOOTING 16. Shut down VFD power. 17. Turn On VFD power. 18. Set Pr. 59 to 1 19. Recalibrate the boiler using the combustion calibration procedures in Chapter 4. Table 8-5. VFD Faults NOTE Check parameters 55, 56, 57, & 58 for the last 4 Trips. VFD Fault Possible Cause Low AC supply voltage...

- Page 69 APPENDIX A APPENDIX A - BOILER MENU ITEM DESCRIPTIONS MENU LEVEL & OPTION DESCRIPTION OPERATING MENU Active Setpoint This is the setpoint temperature to which the control is set when operating in the Constant Setpoint, Remote Setpoint or Outdoor Reset Mode.

- Page 70 APPENDIX A APPENDIX A - BOILER MENU ITEM DESCRIPTIONS - Continued MENU LEVEL & OPTION DESCRIPTION SETUP MENU Password Allows password to be entered. Once the valid password (159) is entered, options in the Setup, Configuration and Tuning Menus can be modified.

- Page 71 APPENDIX A APPENDIX A - BOILER MENU ITEM DESCRIPTIONS - Continued MENU LEVEL & OPTION DESCRIPTION Reset Ratio Permits setting of Reset Ratio when operating boiler in the Outdoor Reset Mode. Reset Ratio is adjustable from 0.1 to 9.9. Default is 1.2. Outdoor Sensor Allows outdoor sensor function to be enabled or disabled.

- Page 72 APPENDIX A APPENDIX A - BOILER MENU ITEM DESCRIPTIONS - Continued MENU LEVEL & OPTION DESCRIPTION TUNING MENU Prop Band Generates a fire rate based on the error that exists between the setpoint temperature and the actual outlet temperature. If the actual error is less than the proportional band setting (1 to 120°F), the fire rate will be less than 100%.

- Page 73 APPENDIX B APPENDIX B - STARTUP, STATUS AND FAULT MESSAGES TABLE B-1. STARTUP AND STATUS MESSAGES MESSAGE DESCRIPTION DISABLED Displayed if ON/OFF switch is set to OFF. The display also HH:MM pm MM/DD/YY shows the time and date that the unit was disabled. STANDBY Displayed when ON/OFF switch is in the ON position, but there is no demand for heat.

- Page 74 APPENDIX B TABLE B-2. FAULT MESSAGES FAULT MESSAGE FAULT DESCRIPTION HIGH WATER TEMP The High Water Temperature Limit Switch is open. SWITCH OPEN LOW WATER The Water Level Control board is indicating low water level. LEVEL LOW GAS The Low Gas Pressure Limit Switch is open. PRESSURE HIGH GAS The High Gas Pressure Limit Switch is open.

- Page 75 APPENDIX B TABLE B-2. FAULT MESSAGES - Continued FAULT MESSAGE FAULT DESCRIPTION RESIDUAL The Flame signal was seen for more than 60 seconds during FLAME standby. HEAT DEMAND The Heat Demand Relays on the Ignition board failed to FAILURE activate when commanded. IGN BOARD A communication fault has occurred between the CPU board COMM FAULT...

-

Page 77: Temperature Sensor Resistance Chart

APPENDIX C TEMPERATURE SENSOR RESISTANCE CHART (BALCO) TEMPERATURE SENSOR AERCO PART NO. 123449 R = RESISTANCE (OHMS) T = TEMPERATURE (°F) R=.00161T^2+1.961T+854.841 TEMP (°F) RES. (OHMS) 779.0 797.5 816.3 835.4 854.8 874.6 894.7 915.1 935.9 956.9 978.3 1000.0 1022.0 1044.4 1067.0... - Page 79 APPENDIX D APPENDIX D. - INDOOR/OUTDOOR RESET RATIO CHARTS Table D-1. Header Temperature for a Building Reference Temperature of 50F RESET RATIO Temp -10F -15F -20F Table D-2. Header Temperature for a Building Reference Temperatrure of 60F RESET RATIO Temp -10F -15F -20F...

- Page 80 APPENDIX D Table D-3. Header Temperature for a Building Reference Temperature of 65F RESET RATIO Temp Table D-4. Header Temperature for a Building Reference Temperature of 70F RESET RATIO Temp -10F -15F -20F...

- Page 81 APPENDIX D Table D-5. Header Temperature for a Building Reference Temperature of 75F RESET RATIO Temp -10F -15F Table D-6. Header Temperature for a Building Reference Temperature of 80F RESET RATIO Temp -10F...

- Page 82 APPENDIX D Table D-7. Header Temperature for a Building Reference Temperature of 90F RESET RATIO Temp...

- Page 83 APPENDIX E BOILER DEFAULT SETTINGS MENU & OPTION FACTORY DEFAULT Setup Menu Password Language English Unit of Temp Fahrenheit Comm Address Baud Rate 9600 Configuration Menu Internal Setpt 130°F Unit Type Boiler Unit Size 1.5 MBTU Boiler Mode Constant Setpoint Remote Signal 4 –...

- Page 85 APPENDIX F...

- Page 86 APPENDIX F...

- Page 87 APPENDIX F...

- Page 88 APPENDIX F...

- Page 89 APPENDIX F...

- Page 90 97004-18 HOSE, FLEXIBLE 6" I.D. - A/F 123583 CLAMP HOSE SAE #96 81057 BLOWER GASKET (A/F) BLOWER TO A/F VALVE 42065 ADAPTOR AERCO INTERNATIONAL, INC. BLOWER GASKET (TO NORTHVALE, NJ 07647 81100 ADAPTOR) BENCHMARK 2.0 LOW NOx BOILER PARTS LIST...

- Page 91 1 1/2" NPT BALL VALVE TWO (2) REQUIRED FOR DUAL FUEL BMK2.0 LN 24060 COND. TRAP ASSEMBLY (7) SEE DRAWING AP-A- FOR DUAL FUEL DETAILS AERCO INTERNATIONAL, INC. NORTHVALE, NJ 07647 BENCHMARK 2.0 LOW NOx BOILER PARTS LIST PL - A - 158...

- Page 92 APPENDIX F...

- Page 93 APPENDIX F AERCO INTERNATIONAL, INC. NORTHVALE, NJ 07647 BENCHMARK 2.0 LOW NOx DETAIL B BOILER PARTS LIST DRWN BY:SJD PL - A - 158 DATE:08/06/09 (SHEET 4 OF 7) *NOT TO SCALE*...

- Page 94 APPENDIX F F-10...

- Page 95 APPENDIX F AERCO INTERNATIONAL, INC. NORTHVALE, NJ 07647 BENCHMARK 2.0 LOW NOx BOILER PARTS LIST DRWN BY:SJD PL - A - 158 DATE:08/06/09 (SHEET 6 OF 7) *NOT TO SCALE* F-11...

- Page 96 APPENDIX F F-12...

- Page 97 APPENDIX G...

- Page 98 APPENDIX G...

- Page 99 APPENDIX G...

- Page 100 APPENDIX G...

- Page 101 APPENDIX H...

- Page 102 APPENDIX H...

- Page 103 APPENDIX H...

- Page 104 APPENDIX H...

-

Page 105: Recommended Periodic Testing

APPENDIX I RECOMMENDED PERIODIC TESTING CHECK LIST WARNING NOTE: Periodic testing of all boiler controls and safety devices is required to determine that they are operating as designed. Precautions shall be taken while tests are being performed to protect against bodily injury and property damage. - Page 107 APPENDIX J BENCHMARK CONTROL PANEL EXPLODED VIEW...

- Page 108 APPENDIX J BENCHMARK CONTROL PANEL REAR VIEW...

Need help?

Do you have a question about the GF-123 and is the answer not in the manual?

Questions and answers