Summary of Contents for Practical Automation ITK 38 SERIES

- Page 1 ITK 38 Printer Series User’s Manual PRACTICAL AUTOMATION INC. ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 1 of 79...

-

Page 2: Table Of Contents

TABLE OF CONTENTS HOW TO CONTACT US..............................7 ............................7 IMITED RODUCT ARRANTY 1.1.1 Warranty Terms ................................7 1.1.2 Warranty Procedure ..............................7 FCC N ................................8 OTIFICATION .............................. 8 EGULATORY OMPLIANCE ITK 38 OVERVIEW ................................9 .................................. 9 NTRODUCTION .............................. - Page 3 4.14 ........................21 RINTHEAD LEANING IAGNOSTIC PAPER HANDLING OPTIONS & ACTIONS ......................22 ..........................22 APER ELIVERY UTPUT PTIONS 5.1.1 Disposing Transport-Presenter ..........................22 5.1.1.1 Perforated Paper Stock ............................. 22 5.1.1.2 Loop Storage Chamber............................. 22 5.1.1.3 Dispose Storage Chamber ..........................22 5.1.1.4 Host Monitoring of Dispose Documents ......................

- Page 4 6.3.3.1 Continuous Forms ............................34 6.3.3.2 Registration Marked Forms..........................34 6.3.3.2.1 Autosize Measurement of Form Length ...................... 34 6.3.3.2.2 Stored Form Length............................. 34 6.3.3.2.2.1 Default Form Size ..........................34 6.3.3.2.2.2 Entering a Fixed Form Size Into EEPROM Memory................34 6.3.3.2.2.3 Autosize Measurement and Save to EEPROM ..................

- Page 5 10.7.6 Autosize................................. 43 10.7.7 Minimum Form Length ............................43 10.7.8 Status Pointer................................ 43 10.7.9 Blocked Output Jam Error Control........................44 10.7.10 Document Not Taken Control ..........................44 10.8 EEPROM M #3 P ............................44 RINTOUT 10.9 EEPROM M #3 P ..........................

- Page 6 13.2.2 Command Entry ..............................57 13.3 ........................ 57 LASH EMORY RGANIZATION 13.4 ............................. 57 IRMWARE INARY ILES 13.5 ......................... 58 LASH EMORY EPROGRAMMING CTIONS 13.6 : ..............58 OMMAND RIVEN ROCESS FOR EPROGRAMMING THE LASH EMORY 13.6.1 Command Driven Process Details:........................60 14.0 APPLICATIONS PROGRAMMER INFORMATION ....................

-

Page 7: How To Contact Us

This warranty does not cover the repair or replacement of the printhead if it was damaged, or used in excess of its specified wear life. Also, only Practical Automation approved paper can be used to maintain the warranty. -

Page 8: Fcc Notification

FCC Notification FOR USERS IN THE UNITED STATES Warning: Changes or modifications to this unit not approved by the party responsible for compliance could void the user's authority to operate the equipment. Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules. -

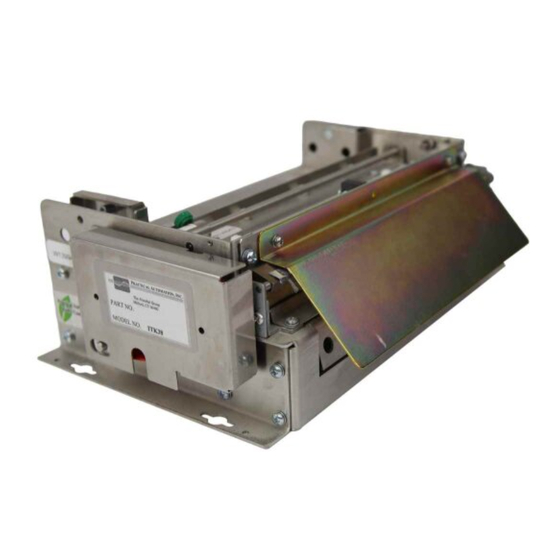

Page 9: Itk 38 Overview

If a user supplied alternate power supply is used it must meet these specifications. The ITK 38 operates under the Windows operating system utilizing a Practical Automation supplied WYSIWYG driver. Combined with a raster organized printer controller this flexible driver produces simple, direct, printed output, at 300 DPI resolution, from any Windows application or language. -

Page 10: Itk 38 Model Number System

ITK 38 Model Number System ITK 38 - ____ ____ __ __ ____ - ____ Note: The standard models are shown shaded. Prefix blank = Standard ITK 38 Printer (Note: this entry is normally blank) = Special Configuration Prefix (Refer to the CN information below) Base Number: ITK 38 Paper Output Options:... -

Page 11: Itk 38 Printer Model Number Example

- no special customization - (prefix blank) - ITK 38 Series 300 DPI, 8.5” (216mm) paper width printer ITK38 - a cutter with disposing/non-disposing transport-presenter is the paper output option - - the forms control jumper is set to except continuous form paper (blank) - the input paper option is an attached 6”/8”... -

Page 12: Preparation For Use

A compliant cable will be marked “IEEE 1284”, typically stamped on the cable’s outer cover or molded into one of the connector housings. This cable can be purchased “off-the-shelf” or from Practical Automation. Refer to section (2.3.3) for the cable’s ordering information. -

Page 13: Which Driver To Load

For customers who desire to implement this functionality Programming/Technical Support is available. These processes are, however, sufficiently complex so that this level of technical support is only available to qualified OEM customers. To access this level of technical support, please contact your Practical Automation Sales Representative and explain your project’s printer deployment plans. -

Page 14: Paper Supply

Paper Supply The paper supply for the ITK 38 can be from several sources depending on the selected options for the printer. These are: -1- an on mechanism mounted (detachable) paper roll holder -2- an externally mounted paper roll holder -3- a fan fold tray holder for registration marked paper. -

Page 15: Operator Controls And Indicators

3.0 OPERATOR CONTROLS AND INDICATORS Switch and Display The switch and display panel provides the operator with an interface to the printer. The display LEDs and Beeper are used to output relevant printer operational status and warnings. The switches provide a means to control the various printed output menus and test functions. -

Page 16: Rear I/O Panel

Rear I/O Panel Located on this rear printer panel are: the power switch, power input connector, auxiliary I/O cable connector and the parallel or USB data interface connector. The power switch in combination with holding one or more of the switch and display panel switches provides entry into special set-up menus or diagnostic programs. -

Page 17: Panel Switch Operations

4.0 PANEL SWITCH OPERATIONS Switch Modes The switch and display panel switches are used for two modes of operation. These are: offline and power-on operations. Offline Operations When the printer is operating normally, pressing the [SELECT/F0] switch manually takes the printer to an offline state. NOTE: As a reminder to the operator the A/E LED and beeper will produce a single flash/beep approximately every 14 seconds. -

Page 18: System Status Report

4.7.1 System Status Report This is a printed report, which contains much of the operational or stored parameter information for the system. It includes: firmware version number, diagnostic pass/fail results, interface configuration status, print intensity control levels, miscellaneous system control parameters and operational data. This report is printed by continuously holding the [F0] switch while turning on the power. -

Page 19: System Report - For Continuous Paper

System Report – for Continuous Paper ********************************************************************************** SYSTEM STATUS REPORT ********************************************************************************** *Model: ITK 38 *Firmware: V1.00 (mm/dd/yy) ALL SYSTEM TESTS PASSED *Interface: TYPE PARALLEL [INTERFACE MODE] [ PAR ACK CONTROL ] NO PARALLEL ACK *Configuration: FORM TYPE CONTINUOUS OUTPUT TYPE CUTTER &... -

Page 20: System Information Help Report

System Information Help Report The above report has a second part. If the [F0] switch is held after the first part has completed printing, the system information help report will also be printed. This report is a collection of menus (which are printed during the associated operating modes) and general help for other printer information such as error codes, etc. -

Page 21: Diagnostic Menu

Diagnostic Menu These functions are used by the factory during the manufacture or servicing of the printer. This menu is entered by continuously holding the [F1] switch while turning on the power. Refer to section 4.8 “Diagnostic Help”, for an example of this menu. Refer to section 16.4 for other diagnostic information 4.10 Change TOF Configurations The [F2] switch is used to force a change to the printer form type configuration, which is normally determined by the configuration... -

Page 22: Paper Handling Options & Actions

5.0 PAPER HANDLING OPTIONS & ACTIONS Paper Delivery Output Options The ITK 38 printer has paper delivery output options to address the needs of any application. These are: - Cutter with Disposing Transport-Presenter - Cutter with Jam Resistant Output Chamber - Cutter only Output - Tearbar with Jam Resistant Output Chamber Each option provides a unique set of characteristics to the deploying application. -

Page 23: Host Monitoring Of Dispose Documents

Host Monitoring of Dispose Documents The host system should supervise this dispose storage space. A printer status bit is toggled each time a document is disposed. The number of disposed documents can be counted, by monitoring this bit’s change of state (refer to section 11.2.3.2.4.1). -

Page 24: Printer Assisted - Document Not Taken Reactions

document, when it has confirmed that the printer is ready to deliver it. This provides the tightest closed loop control of the printing and document delivery process. This level of management is highly recommended for remote printer applications where system reliability is to be maintained at the highest level. The “EJECT AT NEXT DOC”... -

Page 25: Purge Options - Document Not Taken

5.1.1.6.1.3 Purge Options – Document Not Taken WARNING: If any of the purge options are selected (refer to section 10.7.10 ), the printer will purge (read and discard all interface data until a data timeout occurs) all data following the detection of an abandoned document. The host’s application program must understand this and manage the data sent to the spooler accordingly. -

Page 26: Printer & Host Reactions - Document Not Taken Or Blocked Output

5.1.1.7 Printer & Host Reactions – Document Not Taken or Blocked Output The following paragraphs discuss some of the printer and host system choices for the transport-presenter when it is deployed and operated as a disposing transport-presenter. 5.1.1.7.1 Document Not Taken In the event that document has not been removed it can be: -1- left for the next user to remove it (perhaps prompted by the host to take it before starting a new transaction) -2- expelled (at anytime or when a new user arrives and starts the next request for printed information) -

Page 27: Minimum Form Length Adjustment

5.1.5 Minimum Form Length Adjustment In certain installations where there is a throat extender, it may be necessary to force the minimum print length to be longer than 3 inches. Some of the diagnostic and menu tickets are only 3 inches long. If this condition exists, change the EEPROM setting to increase this minimum length (section 10.7.7). -

Page 28: Paper Input Delivery Options

Paper Input Delivery Options 5.2.1 Formula for Calculating Paper Roll Capacity The following formula is useful for calculating the length of supplied on rolls. L = (OD² - ID²) • π Calculated Roll Capacities Length 4 8 • T (in.) (in.) (in.) (ft.) -

Page 29: Externally Located Paper Design Considerations

5.2.3.2 Externally Located Paper Design Considerations Externally located paper supplies should be positioned and fastened to the host system chassis. The positioning should produce a simple, direct and repeatable paper path to the printer. The supply should be located in-line and centered to the printer. A skewed or off center path can result in poor paper tracking, binding and unreliable operation. -

Page 30: Printer Reactions To The Low Paper Conditions

5.2.4.2 Printer Reactions to the Low Paper Conditions There are several programmable printer responses to the low paper condition. If the “STATUS Only” (default mode) is selected, the printer will only display the condition on the switch and display panel, by a slow flashing of the P/P (Power/Paper) LED. If the “WARNING O NLY”... -

Page 31: Paper Information

6.0 PAPER INFORMATION Paper Specifications 6.1.1 Paper Width Standard: 8.5" +0/-0.04" Other widths Factory adjusted from 8.5" to 6.5" +0/-0.04" 6.1.2 Roll Size Internal roll: 8" maximum outside diameter x 1.5" inside diameter External roll: 10" maximum outside diameter x 2.0" inside diameter Active Surface: Located on inside of roll. -

Page 32: Paper Pre-Printing Information

6.1.8 Paper Pre-printing Information 6.1.8.1 Pre-printed Paper: Bottom Side Restrictions All versions of the ITK 38 utilize optical sensors to monitor the progress of paper through the system. Pre-printing of the paper in the area of these sensors should be avoided unless an infrared reflecting ink is used. High contrast ratio printing, in these areas, can interfere with this monitoring. -

Page 33: Registration Mark Location: Bottom Side

6.1.8.5 Registration Mark Location: Bottom Side Refer to the following diagram when specifying registration marked paper. Pay close attention to the inside/outside surfaces of the roll. The registration marks should be visible on the outside of the roll. Paper Form Type Recognition The printer and the host PC can determine if the paper in the printer is continuous or registration marked. -

Page 34: Registration Mark Document Size Measurement

6.3.2 Registration Mark Document Size Measurement The printer has a collection of functions which taken together provide several methods of measuring and storing the size fixed length document. This information is then available for reporting, to the host system application program, through IEEE-1284 nibble mode reverse channel communications. -

Page 35: Reporting Document Length

6.3.3.2.2.6 Reporting Document Length The length is measured, stored and reported in 1/100 inch increments. If a document has been measured (auto sized) then that dynamically acquired, volatile memory data, will be the length reported as status to the host. If the printer has the fixed size mode selected, the data which is stored in nonvolatile EEPROM memory will be the data reported. -

Page 36: Printer Programable Configuration Settings

7.0 PRINTER PROGRAMABLE CONFIGURATION SETTINGS Overview The ITK38 printer has programmable or configuration features permitting it to be customized to almost any printing task. This programmability resides in four areas: The I/O PCB’s configuration resistors or straps, a nonvolatile EEPROM parameter storage memory, the paper output’s automatic detection an attached option and special factory customizations. -

Page 37: Data And Auxiliary Interfaces

8.0 DATA AND AUXILIARY INTERFACES IEEE-1284 Parallel Data Interface The ITK 38 printer has a plug-in IEEE-1284 Parallel Interface module. This is the standard interface for the ITK 38 printer. 8.1.1 Parallel Interface Cable The Parallel Interface cable used to connect the printer to a standard PC is a standard, off-the-shelf, IEEE-1284 A-B style cable. Note the cable must be stamped “IEEE 1284”... -

Page 38: Error Codes

9.0 ERROR CODES Annunciations The ITK 38 printer uses the switch and display panel to output operational conditions or errors, to the user, by a series of sequential beeper tones (beeps) which coincide with the flash of the ATTN/ERR LED. The flash/beep signal is of a long (1) or short (0) duration. -

Page 39: Error Code Table

Error Code Table [#] Number flash/beeps signals in a repeated sequence Error Code Error Code Description Notes MPU/System Error RAM Fault Error EEPROM Checksum Error FLASH Memory Error Character Generator Memory Error IMAGE Memory Error Analog to Digital Converter Error FPGA/ASIC Error Voltage Error Printhead Thermistor Error... -

Page 40: Eeprom Printer Parameter Storage Memory

10.0 EEPROM PRINTER PARAMETER STORAGE MEMORY 10.1 EEPROM Overview The printer’s EEPROM memory is used to store a variety of parameter information. These stored parameters provide data that customizes the printer’s operation to a particular application. Examples of this are: - print intensity parameters are used to set the printer to match the response characteristic of the media being used;... -

Page 41: Eeprom Menu #1 Parameters

10.5 EEPROM Menu #1 Parameters 10.5.1 Print Intensity This parameter selects the amount of print energy applied to each printed dot. The lowest (lighter print) selection is “1” and the highest (darker print) is “16”. The default setting is 6. Setting above 6 decrease the print speed. 10.5.2 Print Energy Table This parameter selects between two defined energy operating modes for the printhead. -

Page 42: Purge Spooler On Error

As with all previous setting low status information is available. The DISABLED selection will cause the printer to completely ignore the low paper signal. The low paper status is not available for the DISABLED setting. 10.5.8 Purge Spooler on Error The selections for this are: “ENABLED”... -

Page 43: End Of Document Length

Please refer to the Printer Kiosk Deployment Guide, available on the Practical Automation WEB site, for additional information on this topic. 10.7.8 Status Pointer The selections for this parameter are: "SHORT", "NORMAL", "EXTENDED", “COMPLETE”. -

Page 44: Blocked Output Jam Error Control

10.7.9 Blocked Output Jam Error Control The following printer control parameters are used to select how the printer will react to a blocked output during the delivery of a document (document presentation). If either of the DISPOSE options are selected the disposing transport-presenter will operate in dispose mode. -

Page 45: Low Paper Cable Detection

10.9.2 Low Paper Cable Detection If your printer is equipped with the Low Paper Sensor that has Active Cable Detection (4 quarter 2004), then, by setting the LP CABLE DETECT to “ACTIVE” it will enable two actions: -1- the connected status (connected or disconnected), of the Low Paper cable, will be reported in the printer’s status information (refer to section 11.2.3.2.17). -

Page 46: Printer Status Information

11.0 PRINTER STATUS INFORMATION 11.1 ITK 38 Printer Status Overview The ITK 38 printer has a wide range of status information available to suit any application environment. There are three types of status: - Operator Status. - Parallel Interface - Compatibility Mode Status. - Parallel Interface Reverse Channel IEEE 1284 Status. -

Page 47: Reverse Channel - Detailed Status - Application Program Reading Protocol

-2- is a request to have “normal” status data returned. This status information is the printer’s Detailed Status information. This status information, available via this reverse data channel, includes the information contained in the Compatibility Mode signals as well as additional detailed printer status information. The application software can use this detailed status information for printer supervision, in unattended, remote site deployments. -

Page 48: Status Group Selection Commands

The data organization for the two types of reverse channel data (11.1.4.2) are detailed below. 11.2.3.1 IEEE 1284 ID String Format (Plug & Play ID String Reverse Channel Status) String Length MSB; String Length LSB; String Byte #1...; String Byte #n For example: MFG: Practical Automation, Inc; CMD: PARL V1.0; CLS: Printer;... -

Page 49: Status Field Format

11.2.3.2.1 Status Field Format There are 16 data fields. The first five (00-04) are fixed length and the remaining are variable length fields. The Status data is arranged into numbered fields. These fields can be requested individually or they can be requested in pre-defined groups, as described section (11.2.2). -

Page 50: Short Status Group

11.2.3.2.4 Short Status Group The ESC I S Status Group Selection command is used to select this status group. The Short Status Group only returns data field 00. Field 00 is a 16-bit binary data word (2-bytes), which contain the Bit Flag Status defined below. The status data string format, for the Short Status Group, is: “S00bb”... -

Page 51: Complete Status Group

11.2.3.2.7 Complete Status Group The ESC I C Status Group Selection command is used to select this status group. The Complete Status Group returns data fields 00 through 05. These are the Bits Status, Error, Document Count, PH Temperature, Form Length and the Firmware Version. -

Page 52: Form Length - Status Field 04

11.2.3.2.13 Form Length – Status Field 04 This is a fixed length status data field that contains a two digit Binary number (MSB first) representing the reported document length. This data will always be a non-zero number when the printer is operating with registration marked paper stock. -

Page 53: Field 01 Error Code List

11.2.4 Field 01 Error Code List Description Error Code /* System temporary conditions */ MANUALLY DESELECT CONDITION TICKET NOT TAKEN CONDITION THERMISTOR TOO COLD WAIT THERMISTOR TOO HOT WAIT CONDITION AVERAGE POWER WAIT CONDITION DATA_RECOVERY_INCIDENT /*Miscellaneous print time errors */ PRINTHEAD LEVER OPENED PRINTHEAD LEVER OPENED WHILE PRINTING PAPER OUT WHILE PRINTING... - Page 54 SYSTEM POWER ERROR PH SUPPLY INCORRECT SYSTEM POWER ERROR CALLER ERROR Description Error Code /* Parameter EEPROM Errors */ EEPROM ERROR PROGRAMMING DID NOT START EEPROM ERROR PROGRAMMING TIMEOUT VOLTAGE TOO LOW TO START A STORE OPERATION EEPROM PARAMETER DATA CHECKSUM ERROR EEPROM ALTERNATE DATA SECTOR 0 CHECKSUM ERROR EEPROM ALTERNATE DATA SECTOR 1 CHECKSUM ERROR /* Flash Errors */...

-

Page 55: Operator Re-Programming Of Flash Memory Procedure

12.0 OPERATOR RE-PROGRAMMING OF FLASH MEMORY PROCEDURE 12.1 General Using this procedure the printer’s operating system can be re-programmed with new firmware from a data file. This should only be done by technical personnel who are familiar with this concept. Although the process is very simple, under some version update conditions, if the printer lost power before the operation was completed successfully, there is a possibility that it could leave the printer inoperable requiring it to be to the returned to the factory for programming (via the BDM interface). -

Page 56: Flash Loading Time

unit. If the loading was unsuccessful the ATTN/ERR LED will remain on, the long 5-second load beep will reoccur. This indicates that a re-load of the data is necessary. The power must not be removed. The copy command should be re-invoked to re-start the loading process. -

Page 57: Host Re-Programming Of Flash Memory Procedure

13.0 HOST RE-PROGRAMMING OF FLASH MEMORY PROCEDURE 13.1 Overview The printer’s operating program, called “firmware,” is stored in Flash memory. Occasionally, it is necessary to reprogram this Flash memory to add a new printer feature or correct an error. The printer has a Flash Memory Reprogramming Mode that permits this update process to take place. The Flash Memory Reprogramming Mode uses that printer’s data interface to receive a binary data file, from the host computer, to update the Flash memory. -

Page 58: Flash Memory Reprogramming Actions

13.5 Flash Memory Reprogramming Actions Protected Boot-Sector Flash Memory Reprogramming is the most common form of Flash memory reprogramming. This programming action only causes the Program Data Sector to be erased and then reprogrammed. The advantage to this technique is that the printer always retains its ability to be reprogrammed even if something caused the reprogramming process to fail (for example, due to a power interruption). - Page 59 (11): Printer: uploads all the Firmware Binary Data and checks for errors. If no errors are found the printer will execute a reset operation and be ready for normal printer operation. If an error was detected the printer will re-enter the start of the Flash Reprogramming Mode and wait for the Firmware Data File to be re-sent.

-

Page 60: Command Driven Process Details

13.6.1 Command Driven Process Details: The following are details, related to the re-programming process, and are a supplement to the information above: Command Driven Process Steps: (1): The status command to request complete status is detailed in the Programmer’s Manual. The ASCII character command format is: <ESC IC>... - Page 61 (12): The host computer can determine if the printer has returned back to normal operating mode (has successfully exited from the Flash Memory Reprogramming Mode) by reading, or receiving, the printer’s “default” status information. For the Parallel Data Interface (or USB) this is accomplished by reading the Parallel Interface Port. This read operation triggers a hardware interface level request, to the printer, to send its default status information (over the reverse data channel).

-

Page 62: Applications Programmer Information

14.0 APPLICATIONS PROGRAMMER INFORMATION 14.1 Printer Utility DLL To assist the programmer with these and other printer related programming tasks, a Printer Utility DLL is available. Refer to section 2.8.1.6 for additional details. 14.2 Document Page Lengths The printer driver has a selection of pre-defined page sizes ranging from 3.25" to 17.0" in length, in 0.25" increments, and a User Defined size. -

Page 63: Maintenance

15.0 MAINTENANCE 15.1 Printer Assembly- Maintenance Points 15.2 Paper Registration Mark Sensor Periodic cleaning of this sensor is required to insure that the accumulation of paper dust, over time, does not impair its operation. This is accomplished by using a soft cotton swab dampened with isopropyl alcohol. Access to the sensor is via a slide cover on the printhead mounting assembly. -

Page 64: Printhead Cleaning Diagnostic Mode

[F3] – Move backward rapidly. 15.4.2 Printhead Cleaning Sheets Printhead cleaning sheets are available from Practical Automation our part number is A15-70071. Note: the cleaning instructions on the card are generic. The instructions listed in section 15.4.1 are designed for the ITK38 printer and should be used. -

Page 65: Document Jam - Requiring Removal Of The Head

15.7 Document Jam – Requiring Removal of the Head To remove a jam between the roller and cutter refer to the drawing below. 1. Turn off the power and disconnect the power supply cable. 2. Lift Printhead Lever to eliminate pressure against the Paper Advance Roller. 3. -

Page 66: Diagnostic

16.0 DIAGNOSTIC 16.1 General A wide range of diagnostics have been built into the printer to assist: factory production, installation and field service. 16.2 Off-line Switch Operations These basic printer functions outlined in section 4.3 provide for a fast and efficient method for verifying basic printer operation. 16.3 Power On Switch These functions provide access to many functions needed to change and maintain correct operation of the printer. -

Page 67: Power Information

17.1 D.C. Power Input The ITK 38 Series Printer uses an external 24V, 60 or 130 watt power supply. A 60 watt power supply is completely adequate for most applications. However, for printing applications that require large dark areas that need to be printed at the highest print speed (2 IPS), a 130 watt supply can be used as an optional choice. -

Page 68: Appendix

18.0 APPENDIX 18.1 Printer Specifications CHARACTERISTIC SPECIFICATIONS Print: Method: Raster, direct thermal. The printed image is created using Windows WYSIWYG Printer Driver (PA Supplied Printer Driver Required) Speed: 2.00 IPS Max. Width: 8 in. (203mm) Max. Printhead: Dot Density: 300 DPI (11.81 dots/mm) Dot Size: 3.33x10 in. - Page 69 CHARACTERISTIC SPECIFICATIONS System Windows Compatible PC w/Pentium CPU @ 300MHZ, Requirements: (or faster) and ECP Port with DMA. (Recommended) Printer Drivers: WIN: 98/ME, NT4.0, 2K, XP Regulatory Compliance: CE Mark: Compliant Safety: UL-60950, 3 Edition CAN/CSA C22.2 No. 60950-00 EMI / EMC: CENELEC EN 60950: (2000) FCC Part 15 Class A EN 55024: 1998...

-

Page 70: Itk 38 Printer Dimensional Drawings - Cutter With Disposing Transport-Presenter

18.3 ITK 38 Printer Dimensional Drawings – Cutter with Disposing Transport-Presenter 18.4 ITK 38 Printer Dimensional Drawings – Optional Output Extension ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 70 of 79... -

Page 71: Itk 38 Printer Dimensional Drawings - Cutter With Output Protection Chamber

18.5 ITK 38 Printer Dimensional Drawings – Cutter with Output Protection Chamber 18.6 ITK 38 Printer Dimensional Drawings – Cutter Only Output ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 71 of 79... -

Page 72: Itk 38 Printer Dimensional Drawings - Tearbar With Output Protection Chamber

18.7 ITK 38 Printer Dimensional Drawings – Tearbar with Output Protection Chamber 18.8 ITK 38 Printer Dimensional Drawings – Fanfold Paper Tray Model # ATX-FFPHLP ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 72 of 79... -

Page 73: Itk 38 Printer Dimensional Drawings - Large (10" Diameter) Paper Roll Holder

18.9 ITK 38 Printer Dimensional Drawings – Large (10" diameter) Paper Roll Holder MODEL # ATX-10RHLP (shown) MODEL # ATX-10RH 18.10 ITK 38 Printer Dimensional Drawings – Standard (6"/8" diameter) Paper Roll Holder ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 73 of 79... -

Page 74: Itk 38 Printer Dimensional Drawings - 60 Watt Power Supply

18.11 ITK 38 Printer Dimensional Drawings – 60 Watt Power Supply ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 74 of 79... -

Page 75: Itk 38 Printer Dimensional Drawings - 130 Watt Power Supply

18.12 ITK 38 Printer Dimensional Drawings – 130 Watt Power Supply 18.13 Connector Pin-out – 8 Pin Power Connector PIN # SIGNAL TITLE SIGNAL DESCRIPTION NOTES POWER GROUND POWER RETURN POWER GROUND POWER RETURN +24 VDC POWER INPUT +24 VDC @ 2.3A Avg. POWER GROUND POWER RETURN +24 VDC... -

Page 76: Connector Pin-Out 26 Pin Parallel Connector

18.15 Connector Pin-out 26 Pin Parallel Connector PIN # SIGNAL TITLE SIGNAL DESCRIPTION SOURCE nStrobe/HostClk Compatibility Mode: Set active low to transfer data into the input latch of the peripheral. Data is valid while nStrobe is low. Nibble Mode: Set high during transfers to avoid latching data into the peripheral. -

Page 77: Ieee-1284 Parallel A-B Cable Schematic

18.16 IEEE-1284 Parallel A-B Cable Schematic ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 77 of 79... -

Page 78: Test Document (Small)

18.17 Test Document (Small) PRACTICAL AUTOMATION 45 WOODMONT RD MILFORD CT 06460 (203) 882-5640 www.practicalautomation.com ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 78 of 79... -

Page 79: Test Document (Large)

18.18 Test Document (Large) PRACTICAL AUTOMATION 45 WOODMONT RD MILFORD CT 06460 (203) 882-5640 www.practicalautomation.com ITK 38 User’s Manual Version V1.03 Date: (7/2/09) File: UMITK103.pdf 79 of 79...

Need help?

Do you have a question about the ITK 38 SERIES and is the answer not in the manual?

Questions and answers

hello dear, i need firmware for PA ITK 38 and manual book how update for this printer firmware. if you have (pa_itk38_f2itk1_v337s_202) or more i need this. i using for kiosk in airport