Table of Contents

Advertisement

SIMPLE-2

SERVICE MANUAL

COMPACT DISC

STEREO SYSTEM

SYSTEM

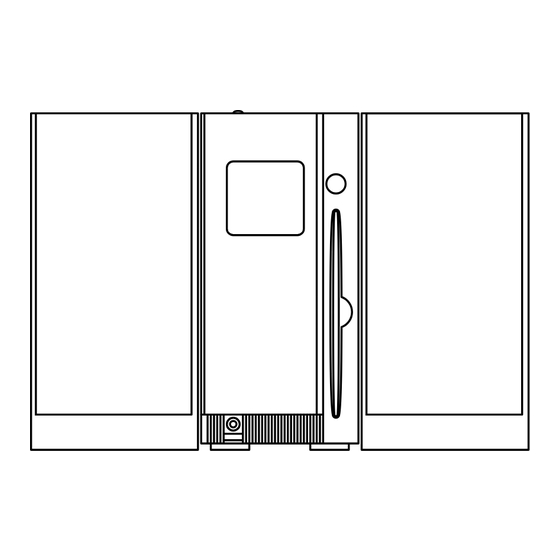

XR–MS5

XR–MS6

• This Service Manual is the “Revision Publishing” and replaces “Simple Manual”

(S/M Code No. 09-012-441-8T2).

XR-MS5

XR-MS6

A par t of contents is adequate.

Re-issuing is under r equest.

BASIC CD MECHANISM : AZG-X A1NM

CD

CASSEIVER

CX–LMS5

CX–LMS6

S/M Code No. 09-015-441-8R2

REMOTE

SPEAKER

CONTROLLER

SX–LMS5

RC–BAT01

K

EZ

Advertisement

Table of Contents

Summary of Contents for Aiwa XR-MS5

- Page 1 XR-MS5 XR-MS6 SIMPLE-2 A par t of contents is adequate. Re-issuing is under r equest. SERVICE MANUAL COMPACT DISC BASIC CD MECHANISM : AZG-X A1NM STEREO SYSTEM REMOTE SYSTEM SPEAKER CASSEIVER CONTROLLER XR–MS5 CX–LMS5 SX–LMS5 RC–BAT01 XR–MS6 CX–LMS6 • This Service Manual is the “Revision Publishing” and replaces “Simple Manual”...

-

Page 2: Table Of Contents

TABLE OF CONTENTS SPECIFICATIONS ................................3 PROTECTION OF EYES FROM LASER BEAM DURING SERVICING ................ 4 PRECAUTION TO REPLACE OPTICAL BLOCK ......................4 DISASSEMBLY INSTRUCTIONS – 1 ..........................5 ~ 7 DISASSEMBLY INSTRUCTIONS – 2 .......................... 8 ~ 13 ELECTRICAL MAIN PARTS LIST ........................... 14 ~ 17 CHIP RESISTOR PART CODE ............................ -

Page 3: Specifications

SPECIFICATIONS MAIN UNIT CX-LMS5/CX-LMS6 GENERAL TUNER Power requirements 230 V AC, 50 Hz Power consumption 45 W FM tuning range 87.5 MHz to 108 MHz Power consumption in standby mode FM usable sensitivity (IHF) 16.8 dBf With ECO mode on: 1.3 W FM antenna terminal 75 ohms (unbalanced) With ECO mode off: 12 W... -

Page 4: Protection Of Eyes From Laser Beam During Servicing

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING CAUTION This set employs laser. Therefore, be sure to follow carefully the instructions below when servicing. Use of controls or adjustments or performance of proce- dures other than those specified herin may result in WARNING!! hazardous radiation exposure. -

Page 5: Disassembly Instructions – 1

DISASSEMBLY INSTRUCTIONS – 1 1. DISASSEMBLY OF AZG-X AND SERVICE POSITION 1) Disassembling the AZG-X (1) Remove the two screws (1) and remove the PANEL, SIDE R (2). (2) Remove the two screws (1) and remove the PANEL, SIDE L (2). (3) Remove five screws (1), (2) and (3), and remove the PANEL, TOP ASSY (4). - Page 6 (5) Remove the FFC (1) and remove the two connectors (2) and (3). Remove the two screws (4) and remove the AZG-X (5). 2) CD Service Position (1) Install the CABI, FRONT ASSY. (2) Connect the FFC (1) to the connector (2). –...

- Page 7 2. DISASSEMBLY OF HLDR, DOOR ASSY 1) Open the HLDR, DOOR ASSY and pull it in the direction of the arrow. 3. INSTALLATION OF HLDR, DOOR ASSY 1) Insert the HLDR, DOOR ASSY in the direction of the arrow. (Insert the boss of the CABI, FRONT ASSY into the holder of the HLDR, DOOR ASSY.) –...

-

Page 8: Disassembly Instructions – 2

DISASSEMBLY INSTRUCTIONS – 2 DISASSEMBLY AND REASSEMBLY OF AZG-X (30) AND AZG-A (10) 1) Removing the PWB, CD (1) Short the shorting-lands on the flexible card wire of the optical pickup by soldering. (2) Disconnect wires from the connectors CN706 and CN707. (3) Remove soldering of the loading motor. - Page 9 3) Removing the CD MECHA ASSY (1) Remove the SPR-E, MECHA. (2) Remove the hooks (at two positions) of the HOLDER MECHA and push down the CD mechanism and remove the CD mechanism. When reassembling it, align the positions of the rubber dampers and the damper hooks as shown. 2) HOOK CD MECHA 1) SPR-E, MECHA...

- Page 10 5) Removing the PLT, CD FR and LVR, ROLLER ASSY (1) Push down the LVR, ROLLER ASSY in the direction of the arrow. (2) Remove the four screws A. (3) Bend the mechanism and remove the boss. (4) Remove the PLT, CD FR. (5) Remove the LVR, ROLLER ASSY.

- Page 11 6) Removing the LVR, ROLLER ASSY (1) Insert the LVR, ROLLER ASSY L and R into the HLDR ASSY CLAMP. (2) Insert the SHAFT A into the BASE HOLE A’. (3) Insert the GEAR,SHAFT B into BASE HOLE B’. (4) Insert the SPRINGs C1 and C2 into the BASE SLITs C1' and C2'. (5) While pushing down the LVR, ROLLER ASSY, insert the SHAFT D into the BASE HOLE D’.

- Page 12 7) Disassembling the LVR, ROLLER ASSY (1) Push the HLDR ASSY CLAMP and release the lock at the (A) position. (2) Remove the SHAFT ROLLER from the CLR ROLLER and remove the LVR, ROLLER ASSY (B). (3) Remove the SHAFT ROLLER and remove the ROLLER RUBBER. HLDR ASSY CLAMP SHAFT ROLLER ROLLER RUBBER...

- Page 13 8) Removing the MOTOR ASSY (1) Remove the two screws A and remove the MOTOR. Reassembling MOTOR ASSY (1) Attach the MOTOR and PULLEY. MOT as shown below. (2) Align direction of the MOTOR ASSY label and fix it with the two screws A. LABEL LABEL PULLY...

-

Page 14: Electrical Main Parts List

ELECTRICAL MAIN PARTS LIST REF. NO. PART NO. KANRI DESCRIPTION REF. NO. PART NO. KANRI DESCRIPTION 87-010-831-080 C-CAP,U,0.1-16F 87-010-831-080 C-CAP,U,0.1-16F 8B-CL5-601-010 C-IC,LC876580W-5T99 87-010-831-080 C-CAP,U,0.1-16F 87-070-246-010 IC,GP1U271X 87-A10-520-000 CAP,E 3300-35 M SMG 87-A21-111-040 C-IC,M62495FP 87-010-831-080 C-CAP,U,0.1-16F 87-017-825-010 IC,GP1F32T 87-A21-695-010 IC,LA1845L 87-016-051-000 CAP,E 2200-35 M SMG 87-010-374-040 CAP,E 47-10... - Page 15 REF. NO. PART NO. KANRI DESCRIPTION REF. NO. PART NO. KANRI DESCRIPTION C669 87-012-199-080 C-CAP,U 220P-50 J CH S108 87-A90-095-080 SW,TACT EVQ11G04M C670 87-012-199-080 C-CAP,U 220P-50 J CH S109 87-A90-095-080 SW,TACT EVQ11G04M C703 87-010-831-080 C-CAP,U,0.1-16F S110 87-A90-095-080 SW,TACT EVQ11G04M C707 87-010-831-080 C-CAP,U,0.1-16F S111...

- Page 16 REF. NO. PART NO. KANRI DESCRIPTION REF. NO. PART NO. KANRI DESCRIPTION C825 87-A11-317-080 C-CAP,U 0.068U-16 K B CF832 82-785-747-010 CF,MS2 GHY,R C831 87-010-552-040 CAP,E 22-16 GAS CN991 87-A60-650-010 CONN,16P H GRY TUC-P16X-C1 C837 87-A12-022-080 C-CAP,U 0.22-16 Z F D901 87-A41-048-040 C-VARI-CAP,HVM16-03 TL C842...

-

Page 17: Chip Resistor Part Code

REF. NO. PART NO. KANRI DESCRIPTION REF. NO. PART NO. KANRI DESCRIPTION C720 87-016-421-080 C-CAP,E 10-16 M WX C770 87-010-831-080 C-CAP,U 0.1-16 Z F C721 87-A10-589-080 C-CAP,E 100-10 M WX C771 87-012-272-080 C-CAP,U 680P-50 K B GRM C722 87-A10-260-080 C-CAP,U 0.1-16 K B C772 87-012-272-080 C-CAP,U 680P-50 K B GRM... -

Page 18: Transistor Illustration

TRANSISTOR ILLUSTRATION E C B E C B B C E B C E 2SA1296 CSD655 2SB1370 2SB1677 CC5551 2SD2619 CSC4115 KTA1266 KTC3198 E C B DTC114ES 2SA1235 DTC114YKA 2SK2158 2SK360 KTC3199 2SA1369 KRA102S 2SC2714 KRA107S 2SC3326 KRC102S CMBT5401 KTA1504 CMBT5551 KTC3875 CSD1306... -

Page 19: Wiring – 1 (Main / Hp – J)

WIRING – 1 (MAIN / HP – J) – 19 –... -

Page 20: Schematic Diagram – 1 (Main : 1 / 2 / Hp – J)

SCHEMATIC DIAGRAM – 1 (MAIN : 1 / 2 / HP – J) – 20 –... -

Page 21: Schematic Diagram – 2 (Main : 2 / 2

SCHEMATIC DIAGRAM – 2 (MAIN : 2 / 2 <MICON SECTION>) – 21 –...) -

Page 22: Wiring – 2 (Front / Amp)

WIRING – 2 (FRONT / AMP) – 22 –... -

Page 23: Schematic Diagram – 3 (Front)

SCHEMATIC DIAGRAM – 3 (FRONT) – 23 –... -

Page 24: Schematic Diagram – 4 (Amp)

SCHEMATIC DIAGRAM – 4 (AMP) – 24 –... -

Page 25: Wiring – 3 (Tuner)

WIRING – 3 (TUNER) – 25 –... -

Page 26: Schematic Diagram – 5 (Tuner)

SCHEMATIC DIAGRAM – 5 (TUNER) – 26 –... -

Page 27: Wiring – 4 (Ac 2M / Pt Main)

WIRING – 4 (AC 2M / PT MAIN) – 27 –... -

Page 28: Schematic Diagram – 6 (Ac 2M / Pt Main)

SCHEMATIC DIAGRAM – 6 (AC 2M / PT MAIN) – 28 –... -

Page 29: Wiring – 5 (Cd) <1 / 2

WIRING – 5 (CD) <1 / 2> <WHT> – 29 –... -

Page 30: Wiring – 5 (Cd) <2 / 2

WIRING – 5 (CD) <2 / 2> – 30 –... -

Page 31: Schematic Diagram – 7 (Cd)

SCHEMATIC DIAGRAM – 7 (CD) – 31 –... -

Page 32: Fl (9 – St – 24Gonk) Grid Assignment / Anode Connection / Pin Connection

FL (9 – ST – 24GONK) GRID ASSIGNMENT / ANODE CONNECTION / PIN CONNECTION GRID ASSIGNMENT – 32 –... - Page 33 ANODE CONNECTION – 33 –...

- Page 34 – 34 –...

- Page 35 PIN CONNECTION – 35 –...

-

Page 36: Ic Block Diagram

IC BLOCK DIAGRAM – 36 –... - Page 37 – 37 –...

- Page 38 – 38 –...

-

Page 39: Ic Description

IC DESCRIPTION IC, LC876580W-5T99 Pin No. Pin Name Description – 39 –... - Page 40 Pin No. Pin Name Description – 40 –...

- Page 41 IC, CXA1992AR Pin No. Pin Name Description – 41 –...

- Page 42 Pin No. Pin Name Description IC, CXD2589Q Pin No. Pin Name Description – 42 –...

- Page 43 Pin No. Pin Name Description – 43 –...

- Page 44 Pin No. Pin Name Description – 44 –...

- Page 45 IC, LC72131D-N Pin No. Pin Name Description – 45 –...

-

Page 46: Adjustment (Tuner / Micon)

ADJUSTMENT (TUNER / MICON) < TUNER SECTION > 1. Clock Frequency Check 8. FM Tracking Adjustment Settings : • Test point : TP2 (CLK) Settings : • Test point : TP8 (Rch), TP9 (Lch) Method : Set to MW 1602kHz and check that the test point is •... -

Page 47: Cd Test Mode

CD TEST MODE 1. How to Start the CD Test Mode While pressing the ENTER key, connect the AC power plug to the wall outlet. When the test mode starts up, all indicators light. 2. How to Exit the CD Test Mode Either press the POWER button or press any button other than CD or disconnect the AC power plug. -

Page 48: Cd Test Mode

4. TRAY (Loading Mechanism) Test Mode When the TUNER/BAND key is pressed while all indicators light in the CD test mode, the display as shown appears. Pressing the TUNER/BAND key again returns to the CD test mode. 4-1. TRAY Test Mode Operations and Displays Pressing the FF key rotates the motor (F display) in the loading direction. -

Page 49: Mechanical Parts Arrangement 1 / 5

MECHANICAL PARTS ARRANGEMENT 1 / 5 – 49 –... - Page 50 MECHANICAL PARTS ARRANGEMENT 2 / 5 – 50 –...

- Page 51 MECHANICAL PARTS ARRANGEMENT 3 / 5 – 51 –...

- Page 52 MECHANICAL PARTS ARRANGEMENT 4 / 5 – 52 –...

-

Page 53: Mechanical Parts Arrangement

MECHANICAL PARTS ARRANGEMENT 5 / 5 – 53 –... -

Page 54: Mechanical Parts List 1 / 1

MECHANICAL PARTS LIST 1 / 1 REF. NO. PART NO. KANRI DESCRIPTION REF. NO. PART NO. KANRI DESCRIPTION 1 8B-CL5-048-010 PANEL,SIDE R(B) 31 8B-CL5-049-010 DUST COVER, CD LMS 2 8B-CL5-047-010 PANEL,SIDE L(B) 32 8B-CL5-044-010 CABI,FR(B) EZ<EZ> 3 8B-CL5-046-010 CABI,TOP(B) 32 8B-CL5-045-010 CABI,FR(B) K<K>... -

Page 55: Cd Mechanism Exploded View 1 / 1

CD MECHANISM EXPLODED VIEW 1 / 1 SHAFT, ROLLER SH, 4.5-2.1-0.25 W/O ADH SH, 6-2.55-0.5 W/ADH KSM-900AMA BASE – 55 –... -

Page 56: Cd Mechanism Parts List 1 / 1

CD MECHANISM PARTS LIST 1 / 1 REF. NO. PART NO. KANRI DESCRIPTION REF. NO. PART NO. KANRI DESCRIPTION 1 8A-ZGA-243-110 HLDR,MECHA 26 8A-ZGA-254-010 SPR-E,LVR TRIG 2 8A-ZGA-267-010 CUSH,MECHA 27 8A-ZGA-209-010 LEVER,TRIG 3 8A-ZGA-204-110 GUIDE,CD FR 28 8A-ZGA-203-010 PLATE,CD RE 4 8A-ZGA-202-110 PLATE,CD FR 29 8A-ZGA-236-010... -

Page 57: General Speaker Disassembly Instructions (For Reference)

GENERAL SPEAKER DISASSEMBLY INSTRUCTIONS (FOR REFERENCE) Type.1 Type.4 Insert a flat-bladed screwdriver into the position indicated by the TOOLS arrows and remove the panel. Remove the screws of each speaker 1 Plastic head hammer unit and then remove the speaker units. 2 (() flat head screwdriver 3 Cut chisel How to Remove the PANEL, FR... -

Page 58: Speaker Parts List (Sx – Lms5)

SPEAKER PARTS LIST (SX – LMS5) <YJ1BN> REF. NO. PART NO. KANRI DESCRIPTION 1 8B-CP5-001-010 PANEL,FR 2 8B-CP5-005-010 PANEL,TW 3 8B-CP5-003-010 GRILLE,FRAME ASSY 4 8A-CJ5-411-010 SPKR,W 87S 5 8A-CJ5-417-010 SPKR,TW 25 6 8B-CP5-610-010 CORD,SPKR 7 8A-CJ5-415-010 TERMINAL ACCESSORIES / PACKAGE LIST REF. - Page 59 2–11, IKENOHATA 1–CHOME, TAITO-KU, TOKYO 110, JAPAN TEL:03 (3827) 3111 9420025 2000045 921338 931261 Printed in Singapore...

Need help?

Do you have a question about the XR-MS5 and is the answer not in the manual?

Questions and answers