Table of Contents

Advertisement

It is of vital importance, before attempting to

operate your engine, to read the general

'SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-5 of this booklet and to strictly

adhere to the advice contained therein.

•

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself

with the controls and other features of the

engine.

•

Keep these instructions in a safe place so that

you may readily refer to them whenever

necessary.

•

It is suggested that any instructions supplied

with the model, radio control equipment, etc.,

are accessible for checking at the same time.

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for O.S. engine MAX-32SX-H Series

- Page 1 It is of vital importance, before attempting to operate your engine, to read the general 'SAFETY INSTRUCTIONS AND WARNINGS' section on pages 2-5 of this booklet and to strictly adhere to the advice contained therein. • Also, please study the entire contents of this instruction manual, so as to familiarize yourself with the controls and other features of the engine.

-

Page 2: Table Of Contents

CONTENTS SAFETY INSTRUCTIONS AND WARNINGS SUBSEQUENT READJUSTMENTS ABOUT YOUR O.S. ENGINE CARBURETOR CLEANLINESS INTRODUCTION ADJUSTING CHART BASIC ENGINE PARTS, INSTALLATION INSTALLATION OF THROTTLE SERVO NOTES CONCERNING THE RECOIL STARTER CARE AND MAINTENANCE BEFORE STARTING ENGINE EXPLODED VIEW & PARTS LIST... -

Page 3: Safety Instructions And Warnings About Your O.s. Engine

As owner, you, alone, are responsible for the safe operation of your engine, so act with discretion and care at all times. If at some future date, your O.S. engine is acquired by another person, we would respectfully request that these instructions are also passed on to its new owner. - Page 4 WARNINGS • Never touch, or allow any • Never operate your engine in an en- object to come into contact closed space. Model engines, like auto- mobile engines, exhaust deadly carbon- with, the rotating parts. monoxide. Run your engine only in an open area.

- Page 5 NOTES • • These engine were designed for model After starting the engine, carry out any needle- helicopters. Do not attempt to use it for any valve readjustments after stopping the rotor by other purpose. closing the throttle to the lowest r.p.m.. Stop the engine before attempting to make •...

- Page 6 NOTES • Take care that loose clothing (ties, shirt sleeves, • Do not attempt to disassemble the recoil scarves etc.) do not come into contact with the starter (if fitted). If you do so, the very strong rotor. Do not carry loose objects (such as pen- spring inside will be suddenly ejected.

-

Page 7: Introduction

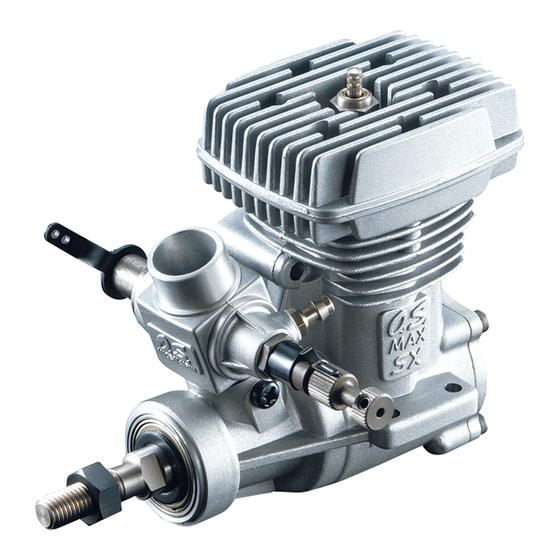

MAX-32SX-H Series is available in a adequately run-in. In this case, use a high- choice of three versions. The standard torque type starter. DO NOT,however, confuse... -

Page 8: Basic Engine Parts

INSTALLATION Typr 20C Recoil Starter Assembly No.O The under-surfaces of all O.S. engine beam mounting lugs are precision machined flat and Starter Handle exactyly parallel to the engine's horizontal axis. It is essential that the engine mounts in the model are also accurately made and aligned. -

Page 9: Notes Concerning The Recoil Starter

Note: CORRECT As the recoil starter is of unit construction, re- placement parts are not available. Replace- ment recoil starters are obtainable only as complete units. Side view Front view Do not pull the starter cord more than 50cm (20 Top surfaces are in the same plane. - Page 10 3 Glowplug battery 4 Plug wrench The power source for heating the glowplug may be Used for tightening glowplug. The either a large heavy-duty 1.5volt dry cell, or preferably, O.S. long plug wrench is available a 2-volt rechargeable lead-acid cell. as an optional accessory.

-

Page 11: Facts About Glowplugs

7 Fuel container filter FACTS ABOUT GLOWPLUGS Fuel Can Filter Install a filter on the outlet tube Since the compatibility of glowplug and fuel may have of your refuelling container to a marked effect on performance and reliability, it may prevent entry of foreign matter be worthwhile to choose the R/C type plug found into the fuel tank... -

Page 12: Fuel 10

However, plug life can be extended and engine FUEL performance maintained by careful use, i.e.: Select, by practical tests, the most suitable fuel from • Install a plug suitable for the engine. among the best quality fuels available in your country •... -

Page 13: Carburetor Controls

REALIGNMENT OF MIXTURE CONTROL VALVE CARBURETOR CONTROLS In the course of making carburetor adjustments, it is With a fixed-wing model, power failure is rarely a just possible that the Mixture Control Valve may be serious threat to the safety of the aircraft since it can inadvertently screwed in or out too far and thereby usually glide down to a safe landing. -

Page 14: Starting

STARTING (32SX-H / SX-H STARTING (32SX-HX RING RING Be sure to use a muffler pressu- Be sure to use a muffler pressurized fuel feed. Use Needle-Valve the same fuel as you intend to employ for actual rized fuel feed. Use the same fuel Open operation of your model. -

Page 15: Running-In,Adjustment 14

Connect the battery to the glowplug and pull the short and simple running-in procedure is required and start knob smartly. can be carried out with the engine installed in the modle. For the first few flights with a new engine i.e. - Page 16 This enables the full r.p.m. range, from idling to full lf, at this time, the engine is slow to pick up and power, to be controlled by the throttle stick, and produces an excess of exhaust smoke, the mixture then allows the engine to be stopped, from the is too rich.

- Page 17 exhaust unduly smoky and the model fails to reach Hover the model and actuate the throttle to expected straight line speed, the mixture is too rich observe response over the medium speed range. and the Needle Valve setting will need to be lf the engine smokes excessiveIy and throttle reduced.

-

Page 18: Subsequent Readjustments

Readjustments should therefore be carried out as SUBSEQUENT READJUSTMENTS follows: Once the engine has been run-in and the carburetor lf the mid-range throttle response is not rapid and controls properly set up, it should be unnecessary to positive (indicating a rich mid-range mixture), turn alter the mixture settings, except to make minor the Needle Valve 2 or 3 clicks clockwise, or turn the adjustments to the Needle Valve occasionally, to take... -

Page 19: Carburetor Cleanliness

CARBURETOR CLEANLINESS Remove this with an 8mm spanner The correct functioning of the carburetor depends on its small fuel orifices remaining clear. The minute particles of foreign matter that are present in any fuel can easily partially obstruct these orifices upset mixture strength... -

Page 20: Adjusting Chart

ADJUSTING CHART Open the Needle Valve 1-1/2 turns from the fully closed position. Make sure that the Mixture Control Valve is at the factory setting. Start the engine Warm up the engine Observe the mixture condition while "floating" the model Rich mixture Lean mixture Turn the Mixture... -

Page 21: Installation Of Throttle Servo

INSTALLATION OF THROTTLE SERVO After the engine in the helicopter, please observe the following recommendations when linking the throttle servo to the carburettor. When the throttle is fully open or fully closed, the throttle lever angle should not be more than 45˚ either side of the mid-point of its travel (and where it is at a 90˚... -

Page 22: Care And Maintenance

CARE AND MAINTENANCE The minute particles of foreign matter, that are Finally, inject some after-run oil into the engine. present in any fuel may, by accumulating and Rotate the engine a few times by hand, to make partially obstructing fuel flow, cause engine sure that it is free, and then with an electric starter performance to become erratic and unreliable. -

Page 23: Engine Exploded View & Parts List 22

EXPLODED VIEW ( 32SX-H / 32SX-H RING MAX- C.M2.6X12 N.+M3.5X5 C.M2.6X7 Type of screw … … Cap Screw M Oval Fillister-Head Screw … … … Flat Head Screw N Round Head Screw S Set Screw... -

Page 24: Parts List

ENGINE PARTS LIST ( 32SX-H / 32SX-H RING MAX- Description Code No. Heatsink Head 23404000 Cylinder & Piston Assembly(For 32SX-H) 23403000 Piston Pin 23406000 Connecting Rod 23405000 Carburetor Complete(Type 20C) 23481000 Carburetor Rubber Gasket 22615000 Carburetor Retaining Screw(2pcs.) 23081706 Propeller Nut 23210007 Thrust Washer 22620003... - Page 25 EXPLODED VIEW ( 32SX-HX RING MAX- C.M2.6X12 N.+M3X8 N.+M3.5X5 F.M2.6X10 Type of screw … … Cap Screw M Oval Fillister-Head Screw … … … Flat Head Screw N Round Head Screw S Set Screw...

-

Page 26: Carburetor Exploded

ENGINE PARTS LIST ( 32SX-HX RING MAX- Code No. Description 23404000 Heatsink Head 23403100 Cylinder Liner 22903400 Piston Ring Piston 23403200 23406000 Piston Pin Connecting Rod 23405000 Carburetor Complete(20C) 23481000 Carburetor Rubber Gasket 22615000 Carburetor Retaining Screw(2pcs.) 23081706 Propeller Nut 23210007 Thrust Washer 22620003... - Page 27 CARBURETTOER PARTS LIST & EXPLODED VIEW 1 -2 1 -1 5 -1 9 -4 9 -1 9 -5 N.+M3.5X5 9 -2 9 -3 S.M3X3 Type of screw C … Cap Screw M … Oval Fillister-Head Screw F … Flat Head Screw N … Round Head Screw S … Set Screw Description Code No.

-

Page 28: Three View Drawing 27

MAX-32SX-H/32SX-H THREE VIEW DRAWING Dimensions(mm) RING SPECIFICATIONS 5.23 cc ( 0.319 cu.in. ) Displacement 19.5mm ( 0.768 in. ) Bore 17.5mm ( 0.689 in. ) Stroke Practical R.P.M. 2,000 22,000 r.p.m. Power output 1.2 bhp / 18,000 r.p.m. Weight 290g(10.23oz.) SX-H 285g(10.06oz.) SX-H RING... -

Page 29: Three View Drawing

MAX-32SX-HX THREE VIEW DRAWING Dimensions(mm) RING SPECIFICATIONS 5.23 cc ( 0.319 cu.in. ) Displacement 19.5mm ( 0.768 in. ) Bore 17.5mm ( 0.689 in. ) Stroke Practical R.P.M. 2,000 21,000 r.p.m. Power output 1.15 bhp / 17,000 r.p.m. Weight 387g(13.66oz.) -

Page 30: O.s. Genuine Parts & Accessories

O.S. GENUINE PARTS & ACCESSORIES 843 SILENCER EXHAUST O.S. GLOW PLUGS DRIVE HUB EXTENSION ADAPTOR ADAPTORS 90 degree (23408000) No.8 (23325100) (22625508) (71608001) (71605100) E-3030 SILENCER (23325020) BOOSTER TERMINAL KIT FOR 'SHUTTLE' (72200160) LONG SOCKET WRENCH CRANKSHAFT CLAMP SUPER FILTER 3261 WITH PLUG GRIP (For 32F-H, SX-H, 61SX-H,RX-H ) - Page 31 MEMO...

- Page 32 6-15 3-Chome Imagawa Higashisumiyoshi-ku Osaka 546-0003, Japan TEL. (06) 6702-0225 FAX. (06) 6704-2722 URL : http://www.os-engines.co.jp Copyright 2000 by O.S.Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan. 100102...

Need help?

Do you have a question about the MAX-32SX-H Series and is the answer not in the manual?

Questions and answers