Summary of Contents for Fujitsu AG * V09LAC Series

- Page 1 SPLIT TYPE ROOM AIR CONDITIONER FLOOR type INVERTER SERVICE INSTRUCTION Models Indoor unit Outdoor unit AO * V09LAC AG * V09LAC AG * V12LAC AO * V12LAC AG * V14LAC AO * V14LAC R410A...

-

Page 2: Table Of Contents

CONTENTS 1. SPECIFICATION AG*V09/ 12/ 14LAC, AO*V09/ 12/ 14LAC............... 01-01 2. DIMENSIONS AG*V09/ 12LAC, AO*V09/ 12LAC ................... 02-01 AG*V14LAC, AO*V14LAC....................02-02 3. REFRIGERANT SYSTEM DIAGRAM AG*V09/ 12/ 14LAC, AO*V09/ 12/ 14LAC ............... 03-01 4. CIRCUIT DIAGRAM AG*V09/ 12LAC, AO*V09/ 12LAC................... 04-01 AG*V14LAC, AO*V14LAC.................... - Page 3 6. REFRIGERANT CAUTION -R410A- 1. R410A TOOLS......................06-01 2. PRECAUTION FOR INSTALLATION................. 06-02 3. PRECAUTION FOR SERVICING................06-04 4. NEW REFRIGERANT R410A..................06-05 5. DEFFERENCE FROM CONVENTIONAL MODEL(R22) AND PRECAUTIONS..06-08 7. TROUBLE SHOOTING 1. WHEN THE UNIT DOES NOT OPERATE AT ALL............ 07-01 2.

-

Page 4: Specification

R410A FLOOR type INVERTER 1 . SPECIFICATIONS... -

Page 5: Ag*V09/ 12/ 14Lac, Ao*V09/ 12/ 14Lac

SPECIFICATIONS TYPE COOL & HEAT INVERTER INDOOR UNIT AG*V09LAC AG*V12LAC AG*V14LAC AO*V09LAC AO*V12LAC AO*V14LAC OUTDOOR UNIT COOLING CAPACITY (kW) 2.6 (0.9~3.5) 3.5 (0.9~4.0) 4.2 (0.9~5.0) (kW) 3.5 (0.9~5.5) 4.5 (0.9~6.6) 5.2 (0.9~8.0) HEATING CAPACITY ELECTRICAL DATA POWER SOURCE FREQUENCY (Hz) COOLING RUNNING CURRENT HEATING... -

Page 6: Dimensions

R410A FLOOR type INVERTER 2 . DIMENSIONS... -

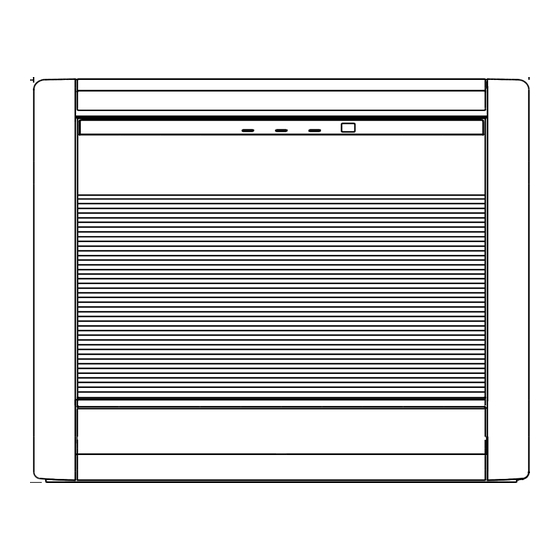

Page 7: Ag*V09/ 12Lac, Ao*V09/ 12Lac

DIMENSIONS Models : AG*V09LAC / AO*V09LAC AG*V12LAC / AO*V12LAC (unit : mm) 02-01... -

Page 8: Ag*V14Lac, Ao*V14Lac

DIMENSIONS Models : AG*V14LAC / AO*V14LAC (unit : mm) 02-02... -

Page 9: Refrigerant System Diagram

R410A FLOOR type INVERTER 3 . REFRIGERANT SYSTEM DIAGRAM... - Page 10 REFRIGERANT SYSTEM DIAGRAM Models : AG*V09LAC / AO*V09LAC AG*V12LAC / AO*V12LAC AG*V14LAC / AO*V14LAC Heat exchanger 3-Way ( INDOOR ) valve Muffler (2Pass) 2-Way valve 4-Way valve Strainer Expansion valve Heat exchanger Strainer ( OUTDOOR ) (4Pass) Cooling Heating 03-01...

-

Page 11: Circuit Diagram

R410A FLOOR type INVERTER 4 . CIRCUIT DIAGRAM... - Page 12 CIRCUIT DIAGRAM Models : AG*V09LAC / AO*V09LAC AG*V12LAC / AO*V12LAC INDOOR UNIT OUTDOOR UNIT 04-01...

-

Page 13: Ag*V14Lac, Ao*V14Lac

CIRCUIT DIAGRAM Models : AG*V14LAC / AO*V14LAC INDOOR UNIT OUTDOOR UNIT 04-02... -

Page 14: Description Of Each Control Operation

R410A FLOOR type INVERTER 5 . DESCRIPTION OF EACH CONTROL OPERATION... -

Page 15: Cooling Operation

1. COOLING OPERATION 1-1 COOLING CAPACITY CONTROL A sensor (room temperature thermistor) built in the indoor unit body will usually perceive difference or variation between a set temperature and present room temperature, and controls the operation frequency of the compressor. * If the room temperature is 2°C higher than a set temperature, the compressor operation frequency will attain to maximum performance. -

Page 16: Heating Operation

2. HEATING OPERATION 2-1 HEATING CAPACITY CONTROL A sensor (room temperature thermistor) built in the indoor unit body will usually perceive difference or variation between a set temperature and present room temperature, and controls the operation frequency of the compressor. * If the room temperature is lower by 3°C than a set temperature, the compressor operation frequency will attain to maximum performance. -

Page 17: Dry Operation

3. DRY OPERATION 3-1 INDOOR UNIT CONTROL The compressor rotation frequency shall change according to the temperature, set temperature, and room temperature variation which the room temperature sensor of the indoor unit body has detected as shown in the Fig 3. However, after the compressor is driven, the outdoor unit shall run at INITIAL frequency as shown in the Table 3 for a minute. -

Page 18: Auto Changeover Operation

4. AUTO CHANGEOVER OPERATION When the air conditioner is set to the AUTO mode by remote control, operation starts in the optimum mode from among the HEATING, COOLING, DRY and MONITORING modes. During operation, the optimum mode is automatically switched in accordance with temperature changes. The temperature can be set between 18°C and 30°C in 1°C steps. -

Page 19: Indoor Fan Control

5. INDOOR FAN CONTROL (1).Fan speed ( Table 5 : Indoor Fan Speed ) AG*V09/ 12LAC Speed (rpm) Air flow mode Operation mode Upper Upper& Lower air flow mode air flow mode Heating 1240/ 1040 1280/ --- (Upper/ Lower) 1040/ 880 1080/ --- (Upper/ Lower) 840/ 700... - Page 20 (3).COOLING OPERATION Switch the airflow [AUTO], and the (Fig.6) indoor fan motor will run according airflow change - over ( Cooling:AUTO ) to a room temperature, as shown in When the room Figure 6. temperature rises On the other hand, if switched in HIGH mode +2.5°C [HIGH]...

-

Page 21: Outdoor Fan Control

6. OUTDOOR FAN CONTROL (1). Fan Speed ( Table 6 : Outdoor fan speed ) (rpm) ZONE Cooling Heating AG*V09LAC A - C 800/ 760/ 470 760/ 470 AG*V12LAC 470/ 250 760/ 470 760/ 680/ 470 150 (by 1rpm or more) 150 (by 1rpm or more) A - C 860/ 820/ 670/ 500... -

Page 22: Louver Control

7. LOUVER CONTROL (1). VERTICAL LOUVER CONTROL (Function and Operation Range) Each time the button is pressed, the air direction range will change as follows: (Fig 9: Air Direction Range) Use the air direction adjustments within the ranges shown above. The vertical airflow direction is set automatically as shown, in accordance with the type of operation selected. -

Page 23: Compressor Control

8. COMPRESSOR CONTROL (1). OPEARTION FREQUENCY RANGE The operation frequency of the compressor is different based on the operation mode as shown in the table 8. (Table 8 : Compressor Operation Frequency Range) Cooling Heating AG*V09/ 12LAC 18Hz 96Hz 18Hz 130Hz 33Hz AG*V14LAC... -

Page 24: Timer Operation Control

9. TIMER OPEARTION CONTROL The table 9 shows the available timer setting based on the product model. (Table 9 : Timer Setting) ON TIMER / OFF TIMER PROGRAM TIMER SLEEP TIMER AG*V09/ 12/ 14LAC (1). OPEARTION FREQUENCY RANGE OFF timer : When the clock reaches the set time, the air conditioner will be turned off. Operation mode Stop mode Set time of timer... - Page 25 (3). SLEEP TIMER If the sleep is set, the room temperature is monitored and the operation is stopped automatically. If the operation mode or the set temperature is change after the sleep timer is set, the operation is continued according to the changed setting of the sleep timer from that time ON. In the cooling operation mode When the sleep timer is set, the setting temperature is increased 1°C.

-

Page 26: Electronic Expansion Valve Control

10. ELECTRONIC EXPANSION VALVE CONTROL The most proper opening of the electronic expansion valve is calculated and controlled under the present operating condition based on the following values. The compressor frequency, the temperatures detected by the discharge temperature sensor, the indoor heat exchanger sensor, the outdoor heat exchanger sensor, and the outdoor temperature sensor. -

Page 27: Manual Auto Operation ( Indoor Unit Body Operation )

15. MANUAL AUTO OPERATION (Indoor unit body operation) If MANUAL AUTO Button is set, the operation is controlled as shown in Table 10. If the remote control is lost or battery power dissipated, this function will work without the remote control. -

Page 28: Defrost Operation Control

19. DEFROST OPERATION CONTROL (1). CONDITION OF STARTING THE DEFROST OPERATION The defrost operation starts when the outdoor heat exchanger temperature sensor detects the temperature lower than the values shown in Table 13. (Table 13 : Condition of starting Defrost Operation) time defrosting Compressor operating time after starting... - Page 29 Defrost Flow Chart The defrosting shall proceed by the integrating operation time and outdoor heat exchanger temperature as follows. Heating operation start : Compressor ON (Not defrosted for 10 minutes) (In case of 1st defrost) (In case of 2nd and later defrost) Compressor integrating Compressor integrating Compressor integrating...

-

Page 30: Off Defrost Operation Control

20. OFF DEFROST OPEARTION CONTROL When operation stops in the [Heating operation] mode, if frost is adhered to the outdoor unit heat exchanger, the defrost operation will proceed automatically. In this time, if indoor unit operation lamp flashes slowly (7 sec ON / 2 sec OFF), the outdoor unit will allow the heat exchanger to defrost, and then stop. -

Page 31: Air Outlet Selection (Damper Control)

21. AIR OUTLET SELECTION ( DAMPER CONTROL ) With this function , air come out simultaneously from the upper and lower air outlets so that the room can be cooled or heated effectively. This function is set using the switch behind the front grille of the Indoor unit. (This function is available in cooling and heating operation.) (1). -

Page 32: C Heat Operation

(Fig.12) In Heating mode Indoor heat exchanger temperature Upper & Lower 44°C air flow 35°C Upper air flow (3). How to set to blow out air from the upper air outlet only Set the air outlet selection switch to 22. 10 °C HEAT OPERATION The 10°C HEAT operation functions by pressing 10°C HEAT button on the remote controller. -

Page 33: Various Protections

23. VARIOUS PROTECTIONS (1). DISCHARGE GAS TEMPERATURE OVERRISE PREVENSION CONTROL The discharge gas thermosensor (discharge thermistor : Outdoor side) will detect discharge gas temperature. When the discharge temperature becomes higher than Temperature ,the compressor frequency is decreased 20 Hz, and it continues to decrease the frequency for 20 Hz every 120 seconds until the temperature becomes lower than Temperature . - Page 34 (3). ANTIFREEZING CONTROL (Cooling and Dry mode) The compressor frequency is decrease on cooling & dry mode when the indoor heat exchanger temperature sensor detects the temperature lower than Temperature . Then, the anti-freezing control is released when it becomes higher than Temperature . (Table 19 : Anti-freezing Protection Operation / Release Temperature) Temperature Temperature...

-

Page 35: Refrigerant Caution -R410A

R410A FLOOR type INVERTER 6 . REFRIGERANT CAUTION -R410A-... -

Page 36: R410A Tools

1. R410A TOOLS This air conditioner used R410A. TOOLS AND EQUIPMENT (R410A) For installation and servicing, it is necessary to prepare the tools and machines that are different from the previous Pressure control and Gas charging refrigerant. Circuit switching Safety charger Fig.4-13 Mark shows the exclusive use for R410A. -

Page 37: Precaution For Installation

2. PRECAUTION FOR INSTALLATION Precaution for installation Pipe diameter, recommended material and wall thickness Nominal diameter 1/4" 3/8" 1/2" 5/8" 3/4" 7/8" 1" 1 1/8" 1 1/4" 1 3/8" 1 1/2" (in) Outside diameter 6.35 9.52 12.70 15.88 19.05 22.22 25.40 28.58 31.75 34.92... -

Page 38: Refrigerant Charge

Be careful not to mix moisture and contamination into the pipe Moisture contamination in the pipe is a cause of trouble. Air purge Always use a vacuum pump to purge air. Refrigerant charge Don't charge from the phase side. Do it always from the liquid phase side. -

Page 39: Precaution For Servicing

3. PRECAUTION FOR SERVICING Feature 1 Refrigerant oil is different from before. Precaution on Tools Refrigerant oil for Different point from New Refrigerant previous one Use the gauge manifold and charge hose Synthetic oil Absorbent character for New Refrigerant(HFC), which shall is high. -

Page 40: New Refrigerant R410A

4. NEW REFRIGERANT R410A What is HFC ? Phase-out schedule of HCFC according to Montreal protocol (HCFC consumption of 1989) + 100% = (CFC consumption of 1989) x 2.8% total abolition only service use started control 0.5% 1996 2000 2004 2010 2015 2020... - Page 41 Ozone Layer depleting mechanism sunbeam Ozone CFCl What is CFC and HCFC? CFC : Chloro-Fluoro-Carbon High ODP( ozone depletion potential ) chemical compound, including chlorine. (ODP:0.6-1.0) For example : R12 (for refrigerator and car air-conditioner) HCFC : Hydro-Chloro-Fluoro-Carbon Low ODP chemical compound, including chlorine and hydrogen. (ODP:0.02-01) For example : R22 (for air-conditioner) : Hydro-Fluoro-Carbon...

- Page 42 Summary of R407C and R410A characteristics R410A R407C higher system similar pressure as R22 performance (possible to design Advantage Near-Azeotropic large equipment) refrigerant 1.6 times higher Zeotropic refrigerant pressure than R22 Disadvantage (handle with care) (difficult to design against pressure resistance) Large Air-Conditioners Suitable for Small Air-Conditioners...

-

Page 43: Defference From Conventional Model(R22) And Precautions

5. DEFFERENCE FROM CONVENTIONAL MODEL (R22) AND PRECAUTIONS • Use new synthetic oils such as ester because HFC series refrigerant has less solubility with mineral oils conventionally used for R22. • As these new synthetic oils are easily influenced by moisture and dusts, they must be treated more care- fully than the conventional lubricating oils. -

Page 44: Trouble Shooting

R410A FLOOR type INVERTER 7 . TROUBLE SHOOTING 1. When the unit does not operate at all (Operation lamp and Timer lamp do not light up) 2. Self Diagnosis Function (Either Operation lamp or Timer lamp is blinking) * How to operate the self-diagnosis function * Self- diagnosis table and Check points 3. - Page 45 When does not operate at all (Operation Lamp and Timer Lamp do not light up) [Check Point] (1) Is the input power voltage from the exclusive circuit AC outlet normal? (2) Is the AC plug inserted to the AC outlet securely and not loose? (3) Does not connected cable do wrong wiring? (4) Check if each connector is inserted securely.

-

Page 46: Self Diagnosis Function

SELF-DIAGNOSIS FUNCTION This function memorizes the self-diagnosis function (lamp display) in the in door control P.C.Board when trouble occurs. (The memory contents are not destroyed even when the power cord is unplugged from the AC outlet.) The self-diagnosis function (lamp display) can also be switched between major classification display and minor classification display and precise diagnosis can be made. -

Page 47: Self-Diagnosis Function And Checking Points

Self - diagnosis function and Checking points Error Indication Error Diagnosis Method Wired remote Operation Timer 10°C HEAT (Protection) controller (RED) (GREEN) (ORANGE) 0.5 sec Serial reverse transfer At the start up, the indoor unit does not receive the signal for 10 consecutive seconds from the time when the power relay was ON. >Permanent stop after 30 seconds. - Page 48 Self - diagnosis function and Checking points Error Indication Error Diagnosis Method Wired remote Operation Timer 10°C HEAT (Protection) controller (RED) (GREEN) (ORANGE) 0.5 sec 0.5 sec Discharge thermistor The detection value of the discharge thermistor is either open or shorted. 3 times 2 times error...

- Page 49 Self - diagnosis function and Checking points Error Indication Error Diagnosis Method Wired remote Operation Timer 10°C HEAT (Protection) controller (RED) (GREEN) (ORANGE) 0.5 sec 0.5 sec IPM protection Abnormal current value of IPM is detected. > Permanent stop. 5 times 2 times [Diagnosis Point] Heat radiation is blocked (inlet/outlet).

- Page 50 Self - diagnosis function and Checking points Error Indication Error Diagnosis Method Wired remote Operation Timer 10°C HEAT (Protection) controller (RED) (GREEN) (ORANGE) 0.5 sec 0.5 sec Indoor UPPER fan The indoor fan speed is 1/3 of the target frequency after 56 seconds from starting operation or from the time the fan mode was 6 times 3 times speed error...

- Page 51 Self - diagnosis function and Checking points Error Indication Error Diagnosis Method Wired remote Operation Timer 10°C HEAT (Protection) controller (RED) (GREEN) (ORANGE) 0.5 sec 0.5 sec Discharge temperature The discharge temperature error is activated. > Permanent stop. 7 times 2 times error [Diagnosis Point]...

-

Page 52: Serial Signal Diagnosis

Serial Signal Diagnosis [Check Point] Check which has a cause of error, either Indoor unit or Outdoor unit. * Remove indoor unit front panel and cable xlampers and keep the terminal block clear so that it can be measured with a meter. * Remove AC power and reset the power, and press Test Operation switch on remote control. -

Page 53: Ipm Protection

IPM Protection [Checking Points] Check the following points and locate the cause in the outdoor unit. [Cause] (1) Compressor failure (2) Refrigeration cycle failure (3) PC Board defective (4) IPM defective (5) Incorrect wiring [First step] Measure the DC voltage at terminals (between Electrolytic Capacitor and discharge resistance) in the Inverter Controller Assy, and make sure it is lower than DC5V. -

Page 54: Trouble Shooting Of Refrigerant Cycle

Trouble Shooting of Refrigerant Cycle [Diagnosis Table for Defective Component] : Item of most possible cause Cooling High Compressor Discharge IPM Protection Pressure Location error Temperature Error Protection Refrigerant leak Compressor failure(*) EEV failure (*) Thermistor failure (*) (*) Trouble Shooting Method (1) Checking method of the compressor failure Insert the AC plug and start up the cooling operation. -

Page 55: Appending Data

R410A FLOOR type INVERTER 8 . APPENDING DATA 1. Jumper setting of Indoor unit and Outdoor unit 2. Outdoor unit Pressure Value and Total Electric Current Curve 3. Thermistor Resistance Values... - Page 56 JP (Jumper) Setting [Indoor Unit] AG*V09/ 12/ 14LAC - Remote control custom code When multiple number of indoor units are installed in the same room, erroneous receipt of the signal can be avoided by setting up the remote control custom code separately. To set up the remote control custom code, always set up the same code on both indoor unit PCB and remote control PCB.

- Page 57 Outdoor Unit Low Pressure Value and Outdoor Total Electric Current Curve (Cooling) Model Name : AG*V09/ 12LAC [Condition] Ambient temperature : Indoor / Outdoor - Same temperature Amount of refrigerant : Regulation amount Piping length : 5m (Difference of elevation 1m) Power voltage : 50Hz - 230V Operating condition...

- Page 58 Outdoor Unit Low Pressure Value and Outdoor Total Electric Current Curve (Cooling) Model Name : AG*V14LAC [Condition] Ambient temperature : Indoor / Outdoor - Same temperature Amount of refrigerant : Regulation amount Piping length : 5m (Difference of elevation 1m) Power voltage : 50Hz - 230V Operating condition...

- Page 59 Outdoor Unit High Pressure Value and Outdoor Total Electric Current Curve (Heating) Model Name : AG*V09/ 12LAC [Condition] Ambient temperature : Indoor 15 - 23degC, Outdoor 2 - 12degC Amount of refrigerant : Regulation amount Piping length : 5m (Difference of elevation 1m) Power voltage : 50Hz - 230V Operating condition...

- Page 60 Outdoor Unit High Pressure Value and Outdoor Total Electric Current Curve (Heating) Model Name : AG*V14LAC [Condition] Ambient temperature : Indoor 15 - 23degC, Outdoor 2 - 12degC Amount of refrigerant : Regulation amount Piping length : 5m (Difference of elevation 1m) Power voltage : 50Hz - 230V Operating condition...

-

Page 61: Thermistor Resistance Values

Thermistor resistance values Room temperature thermistor Indoor heat exchanger thermistor Characteristics of room temperature thermistor 40.00 Resistance(k ) Voltage(V) Resistance(k ) Voltage(V) Temp ( C) Temp ( C) 35.00 0.00 33.62 1.15 0.00 176.03 1.10 30.00 5.00 25.93 1.39 5.00 134.23 1.36 25.00... -

Page 62: Replacement Parts

R410A FLOOR type INVERTER 9 . REPLACEMENT PARTS... -

Page 63: Disassembly Illustration & Parts List

1. DISASSEMBLY ILLUSTRATION & PARTS LIST MODELS : AG*V09LAC AG*V12LAC AG*V14LAC Parts No. Description Q'ty AG*V09LAC AG*V12LAC AG*V14LAC INTAKE GRILLE ASSY (FUJITSU BRAND) 9316418011 9316418011 9316418011 INTAKE GRILLE ASSY (GENERAL BRAND) 9316418028 9316418028 9316418028 INTAKE GRILLE ASSY (FUJI BRAND) 9316418035... - Page 64 MODELS : AG*V09LAC AG*V12LAC AG*V14LAC Parts No. Description Q'ty AG*V09LAC AG*V12LAC AG*V14LAC MOTOR CUSHION NR 9313168018 9313168018 9313168018 MOTOR DC BRUSHILESS MFD-34ROM 9602109012 9602109012 9602109012 MOTOR CUSHION N 9312979011 9312979011 9312979011 CROSS FLOW FAN ASSY 9312004034 9312004034 9312004034 BEARING C ASSY 9306628017 9306628017 9306628017...

- Page 65 MODELS : AG*V09LAC AG*V12LAC AG*V14LAC Parts No. Description Q'ty AG*V09LAC AG*V12LAC AG*V14LAC EVAPORATOR HOLDER 9316199019 9316199019 9316199019 EVAPORATOR TOTAL ASSY 9316091016 9316091016 9316091023 EVAPORATOR ASSY 9316092013 9316092013 9316092013 JOINT PIPE OUTLET 9316440012 9316440012 9316440029 JOINT PIPE INLET 9316439016 9316439016 9316439016 WATER SEAL 9316271012 9316271012...

- Page 66 MODELS : AG*V09LAC AG*V12LAC AG*V14LAC Parts No. Description Q'ty AG*V09LAC AG*V12LAC AG*V14LAC TOP COVER 9316207011 9316207011 9316207011 SPACER C 9315281012 9315281012 9315281012 SPACER D 9315282019 9315282019 9315282019 R AND L LOUVER U 9316208018 9316208018 9316208018 JOINT U 9316209015 9316209015 9316209015 HOLDER (GUARD) 9316210011 9316210011...

- Page 67 MODELS : AG*V09LAC AG*V12LAC AG*V14LAC Parts No. Description Q'ty AG*V09LAC AG*V12LAC AG*V14LAC MOTOR STEP (DAMPER) 9900384050 9900384050 9900384050 LIMIT SWITCH COVER 9316217010 9316217010 9316217010 SWITCH MICRO 9900424015 9900424015 9900424015 MOTOR STEP (DAMPER LOCK LEFT) 9900384067 9900384067 9900384067 KEY TOP 9316218017 9316218017 9316218017 CAP (DRAIN)

- Page 68 MODELS : AO*V09LAC AO*V12LAC Parts No. Description Q'ty AO*V09LAC AO*V12LAC 1 PANEL (TOP) ASSY 9313988029 9313988029 PROTECTIVE NET 9313941024 9313941024 3 THERMISTOR (OUTDOOR TEMP) 9900210038 9900210038 4 TERMINAL COVER 9315234018 9315234018 5 COVER (SWITCH) 9310979013 9310979013 6 CABINET RIGHT ASSY 9313994051 9313994051 7 REM PLATE...

- Page 69 MODELS : AO*V09LAC AO*V12LAC Parts No. Description Q'ty AO*V09LAC AO*V12LAC 15 CONDENSER TOTAL ASSY 9314107047 9314107047 SEPARATER B 9313815011 9313815011 17 REACTOR ASSY 9900343019 9900343019 18 COMPRESSOR ASY 9315206015 9315206015 19 2-WAY VALVE ASSY 9314554018 9314554018 20 3-WAY VALVE ASSY 9314022012 9314022012 21 BRACKET (VALVE)

- Page 70 MODELS : AO*V09LAC AO*V12LAC Parts No. Description Q'ty AO*V09LAC AO*V12LAC 28 COVER (CASE) 9309913011 9309913011 INVERTER PCB ASSY 9707039221 9707039238 30 HOLDER (PCB) 9313074029 9313074029 31 INVERTER CASE ASSY 9315690012 9315690012 32 TERMINAL 9703874031 9703874031 33 CORD CLAMP 9307271014 9307271014 34 TERMINAL BRACKET 9315233028 9315233028...

- Page 71 MODELS : AO*V14LAC Parts No. Description Q'ty AO*V14LAC 1 PANEL (TOP) ASSY 9309230057 THERMISTOR (OUTDOOR TEMP) 9900210045 3 PROTECTIVE NET 9315319012 4 CABINET RIGHT ASSY 9309236011 5 COVER (SWITCH) ASSY 9309237025 6 BRACKET (MOTOR) ASSY 9313432010 7 MOTOR DC BRUSHLESS MFE-63NOM 9601725015 8 PROPELLER FAN 9309909014...

- Page 72 MODELS : AO*V14LAC Parts No. Description Q'ty AO*V14LAC 13 CONDENSER ASSY 9311382065 JOINT E 9309495005 15 ENTRANCE PIPE ASSY 9310812013 16 JOINT PIPE ASSY A 9309488007 17 JOINT PIPE ASSY B 9311287018 18 CORD CLAMP 9307271014 19 2-WAY VALVE ASSY 9313064013 20 3-WAY VALVE ASSY 9315159014...

- Page 73 MODELS : AO*V14LAC Parts No. Description Q'ty AO*V14LAC 31 COVER (CASE) 9309913011 INVERTER PCB ASSY 9707039245 33 HOLDER (PCB) 9313074029 34 INVERTER CASE ASSY 9315690012 35 TERMINAL 9703874031 36 TERMINAL BRACKET 9315037039 37 FUSE HOLDER 0501454012 38 FUSE 250V-20A 0600382018 39 FUSE HOLDER 0501456016 40 FUSE 250V- 5A...

- Page 74 STANDARD ACCESSORIES INDOOR UNIT Name and Shape Q'ty Part No. Bracket panel For indoor unit installation 9316272019 Remote control unit AR-RAC1E Use for air conditioner 9316397019 operation Battery (penlight) For remote control unit 0600185527 Cloth tape For indoor unit installation 9310519004 Remote control unit holder...

-

Page 75: Disassembly Process

2. DISASSEMBLY PROCESS 1. INTAKE GRILLE ASSY removal Open the INTAKE GRILLE ASSY. Remove the rope and hook. Lay down the INTAKE GRILLE ASSY, until the axle at the bottom of the INTAKE GRILLE ASSY is removed. Mounting shaft Rope Hook Intake Grille Assy 2. - Page 76 3. CONTROLLER PCB removal Remove the CONTROL COVER. Remove the connectors and cords. Remove the CONTROLLER PCB. Hook Control Cover Controller PCB 4. PANEL (FRONT) removal Remove 4 screws. Remove the PANEL (FRONT) by sliding upward. Hook Screw Panel (Front) 09-14...

- Page 77 5. CASING ASSY removal Remove Remove 4 screws. Remove the CASING ASSY by sliding front side. Cross Flow Fan assy Screw Casing assy 6. FAN MOTOR removal Remove Remove 1 screw. Remove the MOTOR HOLDER by sliding upward. Remove the FAN MOTOR. Motor Holder Fan Motor Screw...

- Page 78 7. HOSE (DRAIN) ASSY removal Remove Remove 1 screw. Remove the HOLDER (DRAIN HOSE) and HOSE (DRAIN) ASSY. Screw 8. DRAIN PAN ASSY removal Remove Remove 2 screws. Remove the DRAIN PAN ASSY by sliding front side. Screw Drain Pan assy 09-16...

- Page 79 9. FAN MOTOR removal Remove Remove 1 screw. Remove the MOTOR HOLDER by sliding downward. Remove the FAN MOTOR. Screw Fan Motor Motor Holder 09-17...

- Page 80 R410A FLOOR type INVERTER 10 . INSTALLATION MANUAL...

- Page 81 SPLIT TYPE ROOM AIR CONDITIONER For authorized service personnel only. INSTALLATION MANUAL WARNING (1) For the room air conditioner to operate satisfactory, install it as outlined in this installation manual. (2) Connect the indoor unit and outdoor unit with the air conditioner piping and cords available standards parts. This (PART No.

- Page 82 CUTTING THE HOLE IN THE WALL FOR THE CONNECTING PIPING NOTE ON DRAIN HOSE (1) Cut a 65 mm diameter hole in the wall at the position shown in (Fig. The drain hose can be connected at either side of Fig.

- Page 83 SPLIT TYPE ROOM AIR CONDITIONER For authorized service personnel only. INSTALLATION MANUAL WARNING (V09LA) (1) For the room air conditioner to operate satisfactory, install it as outlined in this installation manual. (2) Connect the indoor unit and outdoor unit with the air conditioner piping and cords available standards parts. This (V12LA) (PART No.

- Page 84 POWER CONNECTING THE PIPING Fig. 5 Tighten with two wrenches. WARNING CONNECTION The rated voltage of this product is 230 V AC 50 Hz. Do not extend the power supply cord and connection cord. (1) Install the outdoor unit wall cap (supplied with the optional installation set Wrench (fixed) or procured at the site) to the wall pipe.

- Page 85 SPLIT TYPE ROOM AIR CONDITIONER For authorized service personnel only. INSTALLATION MANUAL WARNING (1) For the room air conditioner to operate satisfactory, install it as outlined in this installation manual. (2) Connect the indoor unit and outdoor unit with the air conditioner piping and cords available standards parts. This (V14LA) (PART No.

- Page 86 POWER CONNECTING THE PIPING Fig. 5 Tighten with two wrenches. WARNING CONNECTION The rated voltage of this product is 230 V AC 50 Hz. Do not extend the power supply cord and connection cord. (1) Install the outdoor unit wall cap (supplied with the optional installation set Wrench (fixed) or procured at the site) to the wall pipe.

-

Page 87: Installation Manual

FLOOR TYPE HALF CONCEALED KIT: UTR-STA INSTALLATION MANUAL (PART No. 9316532014) G Be careful not to scratch the air conditioner when handling it. G After installation, explain correct operation to the customer, using the operating manual. G Let the customer keep this installation manual because it is used when the air conditioner is serviced or moved. STANDARD ACCESSORIES The following installation accessories are supplied. -

Page 88: Installing The Indoor Unit

3. ATTACHMENT OF INSURATION SEAL Cut the insulation seal in length in the Fig.3 and seal the insulation seal to the indoor unit on the top and back side in Fig.4. Fig. 3 Fig. 4 Attachment datum: Base edge line Top view Front side INSULATION SEAL... - Page 89 1116, Suenaga, Takatsu-ku, Kawasaki 213-8502, Japan May. 2007 Printed in Japan...

Need help?

Do you have a question about the AG * V09LAC Series and is the answer not in the manual?

Questions and answers