Subscribe to Our Youtube Channel

Summary of Contents for Miller D-74DX

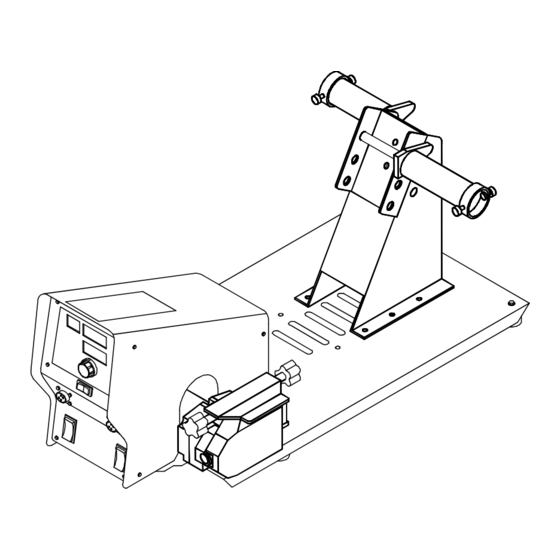

- Page 1 OM-1500-7 204129U 2015−04 Processes MIG (GMAW) Welding Flux Cored (FCAW) Welding (Gas- And Self-Shielded) Description Wire Feeder D-74DX File: MIG (GMAW) Visit our website at www.MillerWelds.com...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING ....... . . 1-1. -

Page 4: Declaration Of Conformity

DECLARATION OF CONFORMITY for European Community (CE marked) products. MILLER Electric Mfg. Co., 1635 Spencer Street, Appleton, WI 54914 U.S.A. declares that the product(s) identified in this declaration conform to the essential requirements and provisions of the stated Council Directive(s) and Standard(s). -

Page 5: Section 1 − Safety Precautions - Read Before Using

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING som 2013−09 Protect yourself and others from injury — read, follow, and save these important safety precautions and operating instructions. 1-1. Symbol Usage DANGER! − Indicates a hazardous situation which, if Indicates special instructions. - Page 6 D Remove stick electrode from holder or cut off welding wire at FUMES AND GASES can be hazardous. contact tip when not in use. D Wear body protection made from durable, flame−resistant material Welding produces fumes and gases. Breathing (leather, heavy cotton, wool). Body protection includes oil-free these fumes and gases can be hazardous to your clothing such as leather gloves, heavy shirt, cuffless trousers, high health.

-

Page 7: Additional Symbols For Installation, Operation, And Maintenance

1-3. Additional Symbols For Installation, Operation, And Maintenance FIRE OR EXPLOSION hazard. MOVING PARTS can injure. D Do not install or place unit on, over, or near D Keep away from moving parts such as fans. combustible surfaces. D Keep all doors, panels, covers, and guards D Do not install unit near flammables. -

Page 8: California Proposition 65 Warnings

1-4. California Proposition 65 Warnings Welding or cutting equipment produces fumes or gases This product contains chemicals, including lead, known to which contain chemicals known to the State of California to the state of California to cause cancer, birth defects, or other cause birth defects and, in some cases, cancer. -

Page 9: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION fre_som_2013−09 Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives aux précautions de sécurité et au mode opératoire. 2-1. - Page 10 D Ne pas raccorder plus d’une électrode ou plus d’un câble de D Avoir recours à des écrans protecteurs ou à des rideaux pour masse à une même borne de sortie de soudage. Débrancher le protéger les autres contre les rayonnements les éblouissements câble pour le procédé...

-

Page 11: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

DES PIECES DE METAL ou DES LES BOUTEILLES peuvent exploser si elles sont endommagées. SALETES peuvent provoquer des blessures dans les yeux. Les bouteilles de gaz comprimé contiennent du gaz sous haute pression. Si une bouteille est D Le soudage, l’écaillement, le passage de la endommagée, elle peut exploser. - Page 12 LES CHARGES ÉLECTROSTATI- RAYONNEMENT HAUTE QUES peuvent endommager les cir- FRÉQUENCE (H.F.) risque cuits imprimés. provoquer des interférences. D Établir la connexion avec la barrette de terre D Le rayonnement haute fréquence (H.F.) peut avant de manipuler des cartes ou des pièces. provoquer des interférences avec les équi- D Utiliser des pochettes et des boîtes antista- pements de radio−navigation et de com-...

-

Page 13: Proposition Californienne 65 Avertissements

2-4. Proposition californienne 65 Avertissements Les équipements de soudage et de coupage produisent des Ce produit contient des produits chimiques, notamment du fumées et des gaz qui contiennent des produits chimiques plomb, dont l’État de Californie reconnaît qu’ils provoquent dont l’État de Californie reconnaît qu’ils provoquent des mal- des cancers, des malformations congénitales ou d’autres formations congénitales et, dans certains cas, des cancers. - Page 14 OM-1500-7 Page 10...

-

Page 15: Section 3 − Definitions

A complete Parts List is available at www.MillerWelds.com SECTION 3 − DEFINITIONS 3-1. Additional Safety Symbols And Definitions Some symbols are found only on CE products. Warning! Watch Out! There are possible hazards as shown by the symbols. Safe1 2012−05 Do not discard product (where applicable) with general waste. - Page 16 A complete Parts List is available at www.MillerWelds.com Do not weld on drums or any closed containers. Safe64 2012−06 Do not remove or paint over (cover) the label. Safe20 2012−05 Drive rolls can injure fingers. Safe32 2012−05 Welding wire and drive parts are at welding voltage during operation − keep hands and metal objects away. Safe33 2012−05 Wear hat and safety glasses.

-

Page 17: Miscellaneous Symbols And Definitions

A complete Parts List is available at www.MillerWelds.com 3-2. Miscellaneous Symbols And Definitions Some symbols are found only on CE products. Rated Welding Amperes Three Phase Current Direct Current Primary Voltage (DC) Program Degree Of Protection Variable Output Inductance Hertz Duty Cycle Preflow Time Set Up... -

Page 18: Section 4 − Specifications

A complete Parts List is available at www.MillerWelds.com SECTION 4 − SPECIFICATIONS 4-1. Serial Number And Rating Label Location The serial number and rating information for this product is located on the rear panel. Use rating label to determine input power requirements and/or rated output. -

Page 19: Section 5 − Installation

A complete Parts List is available at www.MillerWelds.com SECTION 5 − INSTALLATION 5-1. Site Selection Do not put feeder where welding wire hits cylinder. Do not move or operate equipment when it could tip. Wire Feeder Rubber Feet Choose slot that allows all rubber feet to sit securely on top of welding power source. -

Page 20: Equipment Connection Diagrams

A complete Parts List is available at www.MillerWelds.com 5-2. Equipment Connection Diagrams Welding Power Source Contactor Control/Power Cord Positive (+) Weld Cable Negative (−) Weld Cable Workpiece Welding Gun Wire Feeder Gas Hose Gas Cylinder and Regulator (Customer Supplied) Shielding gas pressure not to exceed 100 PSI (689 kPa). -

Page 21: Rear Panel Connections And Rotating Drive Assembly

A complete Parts List is available at www.MillerWelds.com 5-3. Rear Panel Connections And Rotating Drive Assembly 14-Pin Control Cable - 10 Ft (3.0 m) Shielding Gas Valve Fittings Requires fitting with 5/8-18 right- hand threads. Connect customer- supplied gas hose. Weld Cable Terminal Jumper Weld Cable Weld Cable... -

Page 22: 14-Pin Plug Information

A complete Parts List is available at www.MillerWelds.com 5-4. 14-Pin Plug Information Pin* Pin Information 24 volts AC with respect to socket G. Contact closure to A completes 24 volts AC contactor control circuit. Circuit common for 24 volts AC circuit. +10 volts DC input from power source to wire feeder with respect to socket D. -

Page 23: Installing And Threading Welding Wire

A complete Parts List is available at www.MillerWelds.com 5-6. Installing And Threading Welding Wire Install wire guides and Install wire spool. Adjust tension nut so anti-wear guide. wire is taut when wire feed stops. Install drive rolls. Pressure Indicator Pressure Scale Adjust Rear... -

Page 24: Power Source Selection Menu

A complete Parts List is available at www.MillerWelds.com 5-7. Power Source Selection Menu Upper Display Lower Display Non-CE Model Shown When the feeder is turned on, the Power Source Selection Menu allows the operator to se- lect a default power source. Selecting a default power source, automatically sets the correct Vmin and Vmax set-... -

Page 25: Section 6 − Operation

A complete Parts List is available at www.MillerWelds.com SECTION 6 − OPERATION 6-1. Operational Terms The following is a list of terms and their definitions as they apply to this wire feeder: General Terms: Cold Wire Jog Feeding wire without contactor or gas valve being energized. Sequence A portion of the weld program, such as preflow, run-in, start, weld, crater, burnback, and postflow. -

Page 26: Jog/Purge Switch

A complete Parts List is available at www.MillerWelds.com 6-4. Jog/Purge Switch Jog/Purge Switch Adjust Control Gun Trigger Receptacle Ref. 803 053 Pressing the Jog/Purge switch allows the op- trigger is still activated after two minutes, the unit displays jog speed when the unit is be- erator to jog wire without energizing the weld jog operation is terminated to prevent com- ing jogged. -

Page 27: Program Push Button

A complete Parts List is available at www.MillerWelds.com 6-6. Program Push Button Program Display The number of the active program is displayed. Program Push Button Press button to activate program select feature. To change the pro- gram number, press the Program push button and rotate the Adjust control. -

Page 28: Lower Display

A complete Parts List is available at www.MillerWelds.com 6-8. Lower Display Lower Display to indicate that information displayed can be just control is activated while welding, the changed by the Adjust control. unit displays and permits adjustment of the The lower display shows wire speed or weld sequence wire feed speed regardless Wire Speed LED amperage. -

Page 29: Adjust Control

A complete Parts List is available at www.MillerWelds.com 6-10. Adjust Control Adjust Control The Adjust control is used to change various sequence parame- ters, and to select various se- quences. Refer to the section for the function in question for informa- tion related to using the Adjust con- trol. -

Page 30: Auxiliary Menus

A complete Parts List is available at www.MillerWelds.com 6-12. Auxiliary Menus Program Display Program Push Button Sequence Push Button Upper Display Upper Display Push Button Lower Display Lower Display Push Button Adjust Control Setup Push Button 6-12 Auxiliary Menus (Continued) Reset To Factory Settings cates “VMIN”. - Page 31 A complete Parts List is available at www.MillerWelds.com 6-12 Auxiliary Menus (Continued) Trigger Hold Setup operator to select programs during preflow by the upper display and “OPT1” in the lower dis- clicking the trigger (pulling and releasing the play. • If the Setup push button is pressed, the unit trigger in a maximum of 0.2 seconds).

-

Page 32: Section 7 − Setting Sequence Parameters

A complete Parts List is available at www.MillerWelds.com SECTION 7 − SETTING SEQUENCE PARAMETERS 7-1. Sequence Parameters In A Program For more information on Sequence Push Button see Section 6-12. If time is set to zero in Weld sequence, welding continues until Sequence Parameters gun trigger is released. -

Page 33: Diagnostics

A complete Parts List is available at www.MillerWelds.com 8-2. Diagnostics LED3 On Right Side Motor Control Board PC1 LED3 On Left Side Motor Control Board PC101 LED4 On Dual Board PC70 There is a two-position DIP switch S1 located on motor con- trol boards PC1 and PC101. -

Page 34: Diagnostics For User Defined Options

A complete Parts List is available at www.MillerWelds.com 8-3. Diagnostics For User Defined Options Front Panel Front Panel Board PC20 User Defined Shutdown Error Messages (Additional hardware required for these to be functional) If OPT1 and/or OPT2 are enabled without additional hardware setup, the following error messages will be displayed on the front panel meters. -

Page 35: Troubleshooting

A complete Parts List is available at www.MillerWelds.com 9-2. Troubleshooting Disconnect power before troubleshooting. Trouble Remedy Wire feeds, shielding gas flows, but elec- Check interconnecting cord connections. If secure, check cord for continuity and repair or replace (see trode wire is not energized. Sections 5-2 and 5-3). -

Page 36: Section 10 − Electrical Diagram

SECTION 10 − ELECTRICAL DIAGRAM Figure 10-1. Circuit Diagram OM-1500-7 Page 32... - Page 37 236 292-B OM-1500-7 Page 33...

- Page 38 Notes...

- Page 39 Effective January 1, 2015 (Equipment with a serial number preface of MF or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other guarantees or warranties expressed or implied. Warranty Questions? LIMITED WARRANTY − Subject to the terms and conditions below, 6 Months —...

- Page 40 Contact the Delivering Carrier to: File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © ORIGINAL INSTRUCTIONS − PRINTED IN USA 2015 Miller Electric Mfg. Co. 2015−01...

Need help?

Do you have a question about the D-74DX and is the answer not in the manual?

Questions and answers