Yanmar 2YM15 Operation Manual

Ym series

Hide thumbs

Also See for 2YM15:

- Operation manual (116 pages) ,

- Service manual (231 pages) ,

- Operation manual (114 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Yanmar 2YM15

- Page 1 OPERATION MANUAL 2YM15 3YM20 3YM30 P/N: 0AYMM-G00100 MARINE ENGINES...

- Page 2 / or exemplify a product, service or maintenance improvement. We reserve the right to make any change at any time without notice. Yanmar and registered trademarks of Yanmar Co., Ltd. in Japan, the United States and / or other countries.

-

Page 3: Table Of Contents

......... Before You Operate ......... During Operation and Maintenance ..... Location of Safety Decals ........Product Overview ............9 Yanmar YM Features and Applications ....... New Engine Break-In ........Component Identification ........Service Side - 2YM15 ........Non-Service Side - 2YM15 ....... - Page 4 Checking the Engine After Operation ......Periodic Maintenance ..........43 Safety Precautions ..........Precautions ............The Importance of Periodic Maintenance ..... Performing Periodic Maintenance ...... The Importance of Daily Checks ......YM Series Operation Manual © 2007 Yanmar Marine International...

- Page 5 TABLE OF CONTENTS Keep a Log of Engine Hours and Daily Checks ..Yanmar Replacement Parts ......Tools Required ..........Ask Your Authorized Yanmar Marine Dealer or Distributor For Help ........Tightening Fasteners ........EPA Maintenance Requirements ......EPA Requirements for USA and Other Applicable Countries .............

- Page 6 TABLE OF CONTENTS Yanmar Co., Ltd. Limited Emission Control System Warranty - USA Only ......Maintenance Log ........... YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 7: Introduction

This manual should be considered a permanent part of the To help you enjoy your Yanmar YM series engine and remain with it. engine for many years to come, please follow these recommendations: •... -

Page 8: Record Of Ownership

INTRODUCTION RECORD OF OWNERSHIP Take a few moments to record the information you need when you contact Yanmar for service, parts or literature. Engine Model: Engine Serial No.: Date Purchased: Dealer: Dealer Phone: YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 9: Safety

SAFETY Yanmar considers safety of great DANGER importance and recommends that anyone Indicates a hazardous situation which, if who comes in close contact with its not avoided, will result in death or products, such as those who install, serious injury. -

Page 10: Safety Precautions

• Safety signs and decals are additional reminders for safe operating and maintenance techniques. • See your authorized Yanmar Marine dealer or distributor for additional training. YM Series Operation Manual © 2007 Yanmar Marine International... - Page 11 NEVER operate the engine while wearing a headset to listen to music or radio because it will be difficult to hear the warning signals. Stop the engine before you begin to service YM Series Operation Manual © 2007 Yanmar Marine International...

- Page 12 NEVER check for a fuel leak with your loosening or tightening engine parts. hands. ALWAYS use a piece of wood or cardboard. Have your authorized Yanmar Flying Object Hazard Marine dealer or distributor repair the damage.

- Page 13 Failure to do so If a Yanmar Marine Engine is installed at an may cause the running engine to overheat angle that exceeds the specifications stated...

-

Page 14: Location Of Safety Decals

SAFETY LOCATION OF SAFETY DECALS Figure 1 shows the location of safety decals on Yanmar YM series marine engines. YM Engines DANGER WARNING 196630-12980 0004780 Figure 1 1 – Part Number: 128377–07260 2 – Part Number: 128377–07350 3 – Part Number: 196630–12980 YM Series Operation Manual ©... -

Page 15: Product Overview

(including the propeller) and other onboard equipment, always observe the instructions The 2YM15 is a 2-cylinder engine and is and cautions given in the operation manuals naturally aspirated. supplied by the shipyard and equipment The 3YM20 is a 3-cylinder engine and is manufacturers. -

Page 16: New Engine Break-In

• Repeat this process five times. the engine will perform over its lifetime. Once past the initial 10 hours until 50 hours, A new Yanmar diesel engine must be the engine should be used over its full operated at suitable speeds and power... -

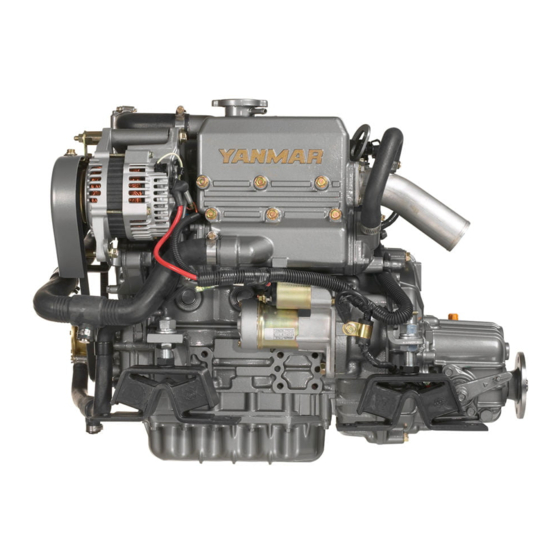

Page 17: Component Identification

PRODUCT OVERVIEW COMPONENT Non-Service Side - 2YM15 IDENTIFICATION Service Side - 2YM15 Figure 1 and Figure 2 illustrate a typical version of a 2YM15 engine. Your engine may have different equipment from that illustrated. 0004782 Figure 2 1 – Seawater Pump 2 –... -

Page 18: Service Side - 3Ym20

4 – Fuel Injection Pump 8 – Alternator 5 – Engine Oil Dipstick 6 – Engine Oil Filler Cap 7 – Fuel Feed Pump 8 – Engine Oil Filter 9 – Marine Gear YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 19: Service Side - 3Ym30

4 – Fuel Injection Pump 8 – Alternator 5 – Engine Oil Dipstick 6 – Engine Oil Filler Cap 7 – Fuel Feed Pump 8 – Engine Oil Filter 9 – Marine Gear YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 20: Location Of Nameplates

Check the marine gear's model, gear ratio, oil used, oil quantity and serial number The nameplate of the Yanmar YM series engine is shown in Figure 7. Check the MODE L engine's model, output, rpm and serial GEAR R ATIO number on the nameplate. -

Page 21: Function Of Major Components

Starter motor for the engine; powered by the battery. Alternator Driven by a belt and generates electricity and charges the battery. Engine Oil Dipstick Gauge stick for checking the engine oil level. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 22: Control Equipment

The hourmeter is located at the bottom of the tachometer. Instrument Panel Lights When turning the key switch to ON, the gauges will illuminate for easier viewing. YM Series Operation Manual © 2007 Yanmar Marine International... - Page 23 ON position and push the stop damage to the engine. Check the oil level button. After stopping the engine, turn the and troubleshoot the lubrication system. key to the OFF position. YM Series Operation Manual © 2007 Yanmar Marine International...

- Page 24 The key switch must be in the ON position for the stop button to operate. After the engine has come to a complete stop, you can turn the key to the OFF position. YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 25: Single-Lever Remote Control Handle

0004511 Figure 17 4 – Maximum Engine Speed - FWD or Note: Yanmar recommends the use of a 5 – Maximum Engine Speed - FWD or single-lever type for the remote control system. If only a two-lever type is available... - Page 26 PRODUCT OVERVIEW This Page Intentionally Left Blank YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 27: Before You Operate

Diesel Fuel Specifications replenish them. It also describes the daily NOTICE: Only use diesel fuels engine checks. recommended by Yanmar for the best Before performing any operations within this engine performance, to prevent engine section, review the Safety section on page damage and to comply with EPA warranty requirements. -

Page 28: Handling Of Diesel Fuel

• PAH (polycyclic aromatic hydrocarbons) and ignite fuel vapors. content should be below 10% by volume. • NEVER use Biocide. • NEVER use kerosene or residual fuels. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 29: Fuel System

20 to 30 mm (0.75 to 1.125 in.) above the center section of that line. bottom of the tank (Figure 2, (4)) so that only clean fuel is distributed to the engine. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 30: Filling The Fuel Tank

Stop fueling when the gauge shows the fuel tank is full. CAUTION! NEVER overfill the fuel tank. Replace the fuel cap and hand-tighten. Over-tightening the fuel cap will damage it. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 31: Bleeding The Fuel System

2 – Bracket 3 – O-Ring 4 – Fuel Filter Element 5 – Fuel Filter Housing 6 – Retaining Ring Check the fuel level in the fuel tank. Refill if necessary. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 32: Engine Oil

150 hours thereafter. See limits shown, you must consult your Changing the Engine Oil on page authorized Yanmar Marine dealer or distributor for special lubricants or starting aids. Select the oil viscosity based on the ambient temperature where the engine is being operated. -

Page 33: Checking The Engine Oil

(Figure 6, (4)) and lower (Figure 6, (5)) lines on the dipstick. Add oil if necessary. See Adding Engine Oil on page 27. Fully reinsert the dipstick. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 34: Marine Gear Or Sail Drive Oil

Remove the dipstick. The oil level should be between the upper (Figure 7, (3)) and lower (Figure 7, (4)) lines on the dipstick. Fully reinsert the dipstick. QuickSilver is a registered trademark of Brunswick Corporation. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 35: Adding Marine Gear Oil

NEVER mix different types or brands of LLC, as a harmful sludge may form. Mixing different brands of antifreeze may cause chemical reactions, and may make the antifreeze useless or cause engine problems. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 36: Checking And Adding Coolant

3 – Seawater Drain Plug 4 – Coolant Pump 5 – Seawater Pump 0005576 Figure 9 1 – Coolant Tank / Heat Exchanger 2 – Coolant Drain Plug 3 – Seawater Drain Cock YM Series Operation Manual © 2007 Yanmar Marine International... - Page 37 WARNING! ALWAYS tighten the coolant tank cap securely after checking the coolant tank. Steam can spray out during engine operation if the cap is loose. Coolant Recovery Tank Capacity 0.8 L (0.95 qt) YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 38: Cranking The Engine

After a long period of non-use, distribute coolant or air leaks in the cooling engine oil to each part by cranking the system. See your authorized Yanmar engine. Perform the following procedure Marine dealer or distributor. before beginning operation: Open the seacock. -

Page 39: Daily Checks

Check for damaged or missing parts. Check for loose, missing or damaged fasteners. Check the electrical harnesses for cracks, abrasions, and damaged or corroded connectors. Check hoses for cracks, abrasions and damaged, loose or corroded clamps. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 40: Checking Diesel Fuel, Engine Oil And Engine Coolant Levels

If the lever is too loose, adjust the remote control cable. See Checking and Adjusting the Remote Control Cables on page 54. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 41: Engine Operation

All internal combustion engines create carbon monoxide gas during operation and special precautions are required to avoid carbon monoxide poisoning. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 42: Starting The Engine

• If the ambient temperature is below -16˚C (+5˚F), rubber components such as gaskets and seals will harden causing premature engine wear and damage. • Contact your authorized Yanmar Marine engine dealer or distributor if the engine will be operated outside of this standard 0003622 temperature range. -

Page 43: Restarting After Starting Failure

ON speed and under moderate load until the position, see your authorized engine reaches normal operating Yanmar Marine dealer or distributor temperature. A light load on a cold engine for service before operating the provides better combustion and faster engine. -

Page 44: After The Engine Has Started

65 or Troubleshooting Chart on page Check that the exhaust color, engine vibration and sound are normal. If necessary, see your authorized Yanmar When there are no problems, keep the Marine dealer or distributor. engine at low speed with the boat still stopped to distribute engine oil to all parts of the engine. -

Page 45: Remote Control Handle Operation

Do not shift abruptly from on installation location. FORWARD to REVERSE or vice versa. Use the throttle handle (Figure 2, (4)) to control acceleration and deceleration. Move the handle slowly. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 46: Shutting Down The Engine

Emergency Shutdown NOTICE: NEVER use the emergency stop switch for a normal engine shutdown. Use this switch only when stopping the engine suddenly in an emergency. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 47: Checking The Engine After Operation

0˚C [32˚F]), drain the seawater system. See Draining the Cooling System on page 72 and connect the engine heater (if equipped). 0004787 Figure 4 1 – STOP Button 2 – Stop Solenoid YM Series Operation Manual © 2007 Yanmar Marine International... - Page 48 ENGINE OPERATION This Page Intentionally Left Blank YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 49: Periodic Maintenance

ALWAYS use the engine lifting eyes when lifting the engine. Additional equipment is necessary to lift the marine engine and marine gear together. ALWAYS use lifting equipment with sufficient capacity to lift the marine engine. YM Series Operation Manual © 2007 Yanmar Marine International... - Page 50 Always possible to the welding point. use Yanmar genuine replacement parts. • NEVER connect the weld clamp to the engine or in a manner which would allow current to pass through a mounting bracket.

-

Page 51: Precautions

Yanmar Replacement Parts Maintenance Yanmar recommends that using genuine WARNING! NEVER block windows, Yanmar parts when replacement parts are vents, or other means of ventilation if needed. Genuine replacement parts help the engine is operating in an enclosed ensure long engine life. -

Page 52: Tightening Fasteners

5.1 ± 0.5 9.2 ± 1.0 14.3 ± 1.0 23.5 ± 1.0 Torque lb-ft 8.0 ± 0.7 19.0 ± 2.1 37 ± 3.6 66.0 ± 7.2 103 ± 7.2 170 ± 7.2 YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 53: Epa Maintenance Requirements

Compliance with EPA Emission within the standard values during the Standards warranty period. The warranty period is The 2YM15, 3YM20 and 3YM30 are EPA- determined by the age of the engine or the certified engines. number of hours of operation. -

Page 54: Periodic Maintenance Schedule

Failure to follow these guidelines will impair the engine’s safety and performance characteristics, shorten the engine’s life and may affect the warranty coverage on your engine. See your authorized Yanmar Marine dealer or distributor for assistance when checking items marked with a ●. - Page 55 PERIODIC MAINTENANCE ◯: Check or Clean ◊: Replace ●: Contact your authorized Yanmar Marine dealer or distributor Periodic Maintenance Interval Every Every Every Every Every 50 1000 Before hours or hours or hours or hours or hours or Starting monthly...

- Page 56 PERIODIC MAINTENANCE ◯: Check or Clean ◊: Replace ●: Contact your authorized Yanmar Marine dealer or distributor Periodic Maintenance Interval Every Every Every Every Every 50 1000 Before hours or hours or hours or hours or hours or Starting monthly...

-

Page 57: Inspection And Maintenance Of Epa Emission-Related Parts

Check the electronic engine control unit and its associated sensors and actuators (if equipped) Note: The inspection and maintenance items shown above should be performed at your Yanmar Marine dealer or distributor. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 58: Periodic Maintenance Procedures

Vapors from the rag are flammable and explosive. Wipe up any spills immediately. Wear eye protection. The fuel system is under pressure and fuel could spray out when you remove any fuel system component. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 59: Changing The Engine Oil

Perform a trial run and check for oil leaks. Approximately 10 minutes after stopping the engine, remove the oil dipstick and check the oil level. Add oil if the level is too low. YM Series Operation Manual © 2007 Yanmar Marine International... - Page 60 Improper adjustment will cause the engine to run noisily, resulting in poor engine performance and engine damage. See your authorized Yanmar Marine dealer or distributor to adjust the intake / exhaust valve clearance. Checking and Adjusting the Remote...

- Page 61 Adjust the high-speed stop position first and then adjust the low speed idling by the adjustment bolt on the remote control lever. YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 62: Every 50 Hours Of Operation

Draining Fuel Filter / Water techniques. Consult your authorized Separator Yanmar Marine dealer or distributor. WARNING! When removing any fuel system component to perform maintenance (such as changing the fuel filter), put an approved container under the opening to catch the fuel. - Page 63 After draining, tighten the air bleed screw (Figure 6, (1)). Be sure to bleed air from the fuel system. See Bleeding the Fuel System on page 25. YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 64: Every 100 Hours Of Operation

Figure 7 1 – Lower Level 2 – Distilled Water 3 – Upper Level Note: The maximum fill level is approximately 10 to 15 mm (3/8 to 9/16 in.) above the plates. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 65: Every 150 Hours Of Operation

Exhaust / Water Mixing Elbow • Adjusting the Tension of the Alternator V-Belt • Cleaning the Breather Pipe • Checking the Wiring Connectors Draining the Fuel Tank See Draining the Fuel Tank on page 52. YM Series Operation Manual © 2007 Yanmar Marine International... - Page 66 If any of the following are found, service the seawater pump: • Impeller blades are cracked or nicked. Edges or surfaces of the blades are marred or scratched. • Wear plate is damaged. YM Series Operation Manual © 2007 Yanmar Marine International...

- Page 67 Replace coolant every year. See your authorized Yanmar Marine dealer or distributor. Note: If Long Life Coolant (LLC) is used, replace coolant every two years. When disassembly and maintenance of the...

-

Page 68: Every 1000 Hours Of Operation

• Checking and Adjusting the Remote comes first, even if no damage is found. Control Cables • Adjusting the Propeller Shaft See your authorized Yanmar Marine dealer Alignment or distributor. • Tightening All Major Nuts and Bolts Adjusting the Alternator V-Belt... - Page 69 This can cause poor engine cooling. Inspect these items: • Heat Exchanger • Pressure Cap See your authorized Yanmar Marine dealer or distributor. 0004807 Checking the Diaphragm Assembly Figure 11 NOTICE: If the diaphragm is damaged, 1 –...

- Page 70 PERIODIC MAINTENANCE Adjusting the Propeller Shaft Alignment See your authorized Yanmar Marine dealer or distributor. Tightening All Major Nuts and Bolts See Tightening Fasteners on page 46 or see your authorized Yanmar Marine dealer or distributor. YM Series Operation Manual...

-

Page 71: Troubleshooting

Periodically operate the engine near maximum speed while underway. This will generate higher exhaust temperatures, which will help clean out hard carbon deposits, maintain engine performance and prolong the life of the engine. YM Series Operation Manual © 2007 Yanmar Marine International... -

Page 72: Troubleshooting Information

System on page 25. Troubleshooting Information If the engine does not operate properly, refer to the Troubleshooting Chart on page 67 or see your authorized Yanmar Marine dealer or distributor. Supply your authorized Yanmar Marine dealer or distributor with the following... -

Page 73: Troubleshooting Chart

Stop the engine and inspect. If no abnormality is identified and there is no problem alarm sounds during with operation, return to port at lowest speed and see your authorized Yanmar operation Marine dealer or distributor. • Engine oil low Engine oil level is low. - Page 74 Power lacking due to accessory See your authorized drive being engaged. Yanmar Marine dealer or distributor. • Engine cannot be Internal parts seized. See your authorized turned manually Yanmar Marine dealer or distributor. YM Series Operation Manual © 2007 Yanmar Marine International...

- Page 75 See your authorized Yanmar Marine dealer or distributor. Fuel injection timing off. See your authorized Yanmar Marine dealer or distributor. Excessive diesel fuel See your authorized consumption. Yanmar Marine dealer or distributor. YM Series Operation Manual © 2007 Yanmar Marine International...

- Page 76 TROUBLESHOOTING This Page Intentionally Left Blank YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 77: Long-Term Storage

6 months. If it remains unused for longer maintenance interval, perform those than this, please contact your authorized maintenance procedures before putting the Yanmar Marine dealer or distributor. engine into long-term storage. Wipe off any dust or oil from the outside of engine. -

Page 78: Draining The Cooling System

Close all drain cocks. Figure 2 1 – Coolant Tank / Heat Exchanger 2 – Seawater Drain Cock 3 – Coolant Drain Cock 4 – Coolant Pump 5 – Seawater Pump YM Series Operation Manual © 2007 Yanmar Marine International... - Page 79 If the coolant without LLC is not removed, it may freeze and damage parts of the cooling system or engine when ambient temperature is below 0°C (32°F). YM Series Operation Manual © 2007 Yanmar Marine International...

- Page 80 LONG-TERM STORAGE This Page Intentionally Left Blank YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 81: Specifications

Clockwise viewed from stern (Ahead) Cooling System Closed coolant system with heat exchanger Lubrication System Complete enclosed forced lubrication system Coolant Capacity Engine 3.0 L (3.17 qt), Coolant recovery tank: 0.8 L (0.95 qt) YM Series Operation Manual © 2007 Yanmar Marine International... - Page 82 The effective amount of oil shows the difference in maximum scale of the dipstick and minimum scale. Note: Density of fuel: 0.842g/cm at 15˚C. Fuel temperature at the inlet of the fuel injection pump. 1 hp metric = 0.7355 kW YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 83: 3Ym20 Engine Specifications

1.4 L (1.48 qt) 1.5 L (1.59 qt) Starting Type Electric System Starting Motor DC 12 V - 1.4 kW AC Alternator 12 V - 60 A (12 V - 80 A optional) YM Series Operation Manual © 2007 Yanmar Marine International... - Page 84 The effective amount of oil shows the difference in maximum scale of the dipstick and minimum scale. Note: Density of fuel: 0.842g/cm at 15˚C. Fuel temperature at the inlet of the fuel injection pump. 1 hp metric = 0.7355 kW YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 85: 3Ym30 Engine Specifications

1.4 L (1.48 qt) 1.5 L (1.59 qt) Starting Type Electric System Starting Motor DC 12 V - 1.4 kW AC Alternator 12 V - 60 A (12 V - 80 A optional) YM Series Operation Manual © 2007 Yanmar Marine International... - Page 86 The effective amount of oil shows the difference in maximum scale of the dipstick and minimum scale. Note: Density of fuel: 0.842g/cm at 15˚C. Fuel temperature at the inlet of the fuel injection pump. 1 hp metric = 0.7355 kW YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 87: Marine Gear And Sail Drive Specifications

0.05 L (0.05 qt) 0.15 L (Effective) (0.16 qt) Cooling System Air cooling by fan on flywheel Weight 10.3 kg (27.7 lb) 30 kg (66.1 lb) At continuous power engine speed 2907 rpm YM Series Operation Manual © 2007 Yanmar Marine International... - Page 88 SPECIFICATIONS This Page Intentionally Left Blank YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 89: System Diagrams

SYSTEM DIAGRAMS PIPING DIAGRAMS Piping diagrams and wiring diagrams are provided for reference only. Contact your authorized Yanmar Marine dealer or distributor for the most current diagrams. YM Series Operation Manual © 2007 Yanmar Marine International... - Page 90 SYSTEM DIAGRAMS 2YM15 with KM2P-1 Marine Gear ( 7 ) ( 4 ) ( 3 ) ( 10 ) ( 8 ) ( 9 ) ( 11 ) ( 5 ) ( 6 ) ( 1 ) ( 2 )

- Page 91 7.8 x t4.5 Rubber Hose rubber hose shows ID x wall thickness. 5 x t4.5 Rubber Hose Rubber fuel lines meet EN/ISO7840. 7.8 x t4.5 Rubber Hose Unit: mm Fuel Feel Pump YM Series Operation Manual © 2007 Yanmar Marine International...

- Page 92 ( A3 ) ( 17 ) ( A2 ) ( 16 ) ( 10 ) ( 15 ) ( 13 ) ( 12 ) ( 11 ) ( 14 ) 0002760A Figure 2 YM Series Operation Manual © 2007 Yanmar Marine International...

- Page 93 Engine Oil Pump Insertion joint Pressure Control Valve Drill hole Fuel Oil Filter Coolant piping Seawater piping To oil pan Engine oil pipe To cam shaft Diesel fuel pipe From cylinder head YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 94: Wiring Diagrams

SYSTEM DIAGRAMS WIRING DIAGRAMS 2YM15, 3YM20, 3YM30 - B-Type Instrument Panel Figure 3 YM Series Operation Manual © 2007 Yanmar Marine International... - Page 95 White / Green Buzzer Oil Pressure Green / Red Cooling Temperature Orange Alarm Lamps White / Brown Sail Drive Seal Charge 3A Fuse Stop Switch Relay Engine Stop Solenoid Battery Switch YM Series Operation Manual © 2007 Yanmar Marine International...

- Page 96 SYSTEM DIAGRAMS This Page Intentionally Left Blank YM Series Operation Manual © 2007 Yanmar Marine International...

-

Page 97: Emission System Warranty

California The California Air Resources Board (CARB), the Environmental Protection Agency (EPA) and Yanmar Co., Ltd. hereafter referred to as Yanmar, are pleased to explain the emission control system warranty on your compression-ignition engine. In California, model year 2000 or... - Page 98 < 37 kW whichever occurs first. In the absence of a of the engine as delivered by Yanmar to the (25.5 hp ≤ and less device to measure the original retail purchaser. Such components than <...

-

Page 99: Customer Assistance

You are responsible for initiating the warranty process. You must present your engine to a Yanmar dealer as soon as a problem exists. The warranty repairs should be completed by the dealer as expeditiously as possible. -

Page 100: Ym Series Operation Manual

Maintenance Log Date Operating Maintenance Performed Dealer Name Stamp or Hours Signature YM Series Operation Manual © 2007 Yanmar Marine International... - Page 101 Date Operating Maintenance Performed Dealer Name Stamp or Hours Signature YM Series Operation Manual © 2007 Yanmar Marine International...

- Page 102 YM Series Operation Manual © 2007 Yanmar Marine International...

Need help?

Do you have a question about the 2YM15 and is the answer not in the manual?

Questions and answers